Bubble dust falling and haze removing device

A technology for dust reduction and air bubbles, which is applied in the separation of dispersed particles, chemical instruments and methods, and the use of liquid separators. , the effect of long range and large amount of bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

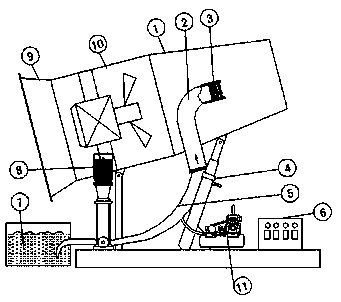

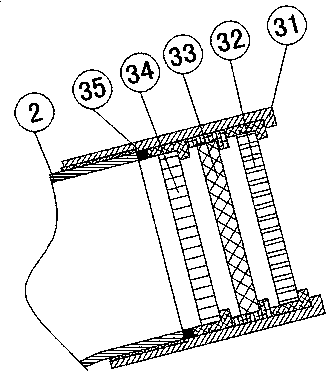

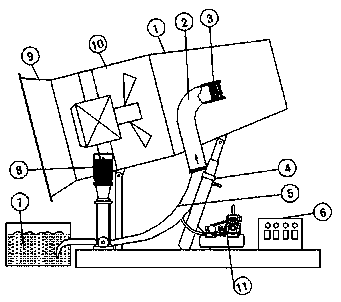

[0020] figure 1 As shown, a kind of air bubble dedusting and haze removal device is composed of fan 10, front cylinder 1, tail cylinder 9, foaming pipe 2, bubbler 3, water inlet pipe 5, bracket 4, water pump 8, air compressor 11, water tank and The foaming agent solution 7 and the electric control cabinet 6 are composed.

[0021] The fan 10 is connected with the front cylinder 1 and the tail cylinder 9 and is installed between the front cylinder 1 and the tail cylinder 9. The fan 10 and the front cylinder 1 are all installed on the bracket 4; the foaming pipe 2 passes through the front cylinder 1 so that the outlet is arranged on At the center of the front cylinder, the bubbler 3 is installed at the outlet of the foaming pipe 2; one end of the water inlet pipe 5 is connected to the foaming pipe 2, and the other end of the water inlet pipe 5 is connected to the water pump 8 and the air compressor 11; The foaming agent solution is supplied to the foaming pipe 2 through the wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com