Tail gas collecting equipment for automotive fault overhauling

A technology for exhaust gas collection and car failure, applied in gas treatment, cleaning methods and appliances, sound-generating devices, etc., can solve problems such as complicated operation process and poor exhaust gas collection effect, and achieve the effect of reducing damage and eliminating noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

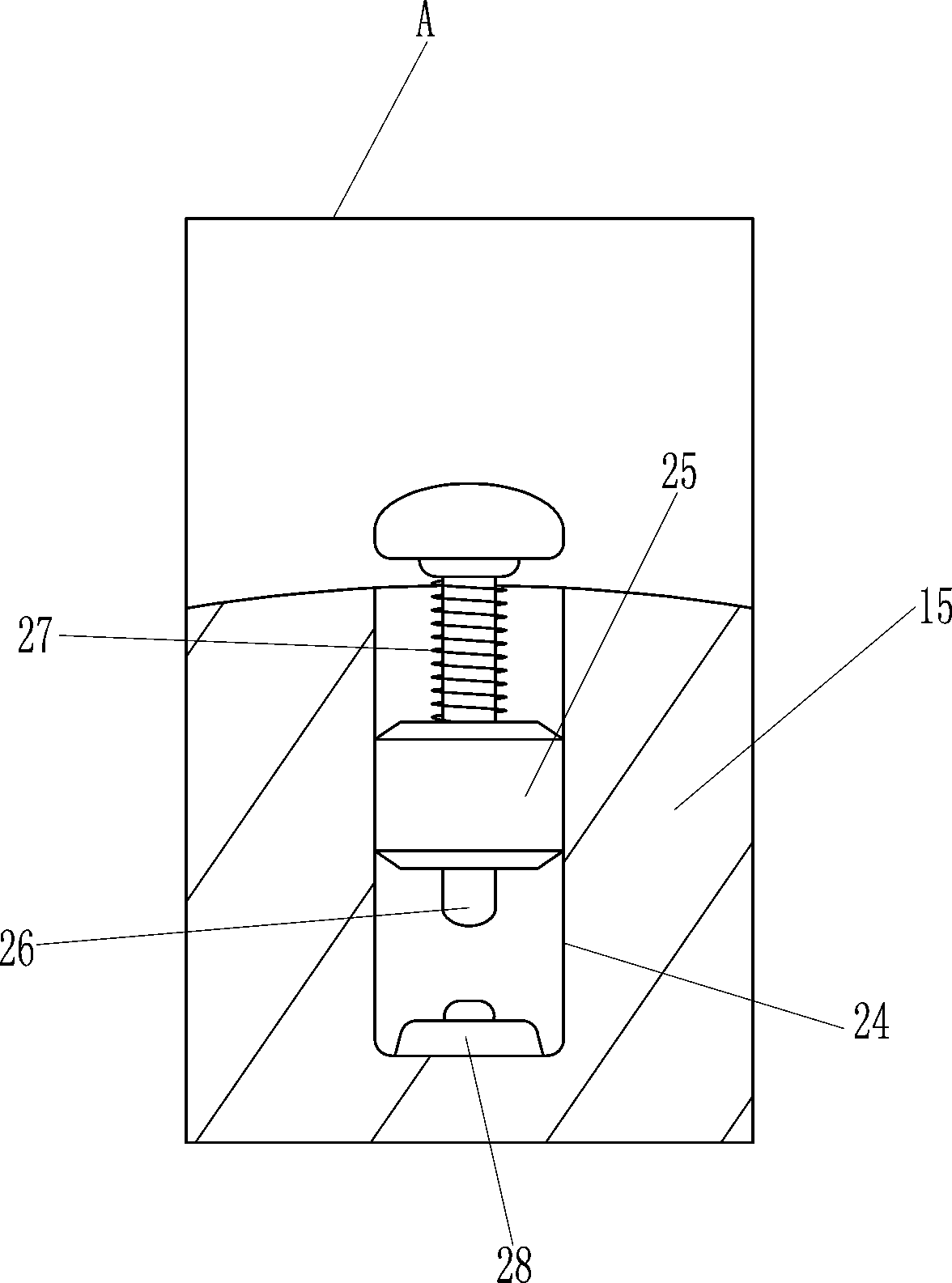

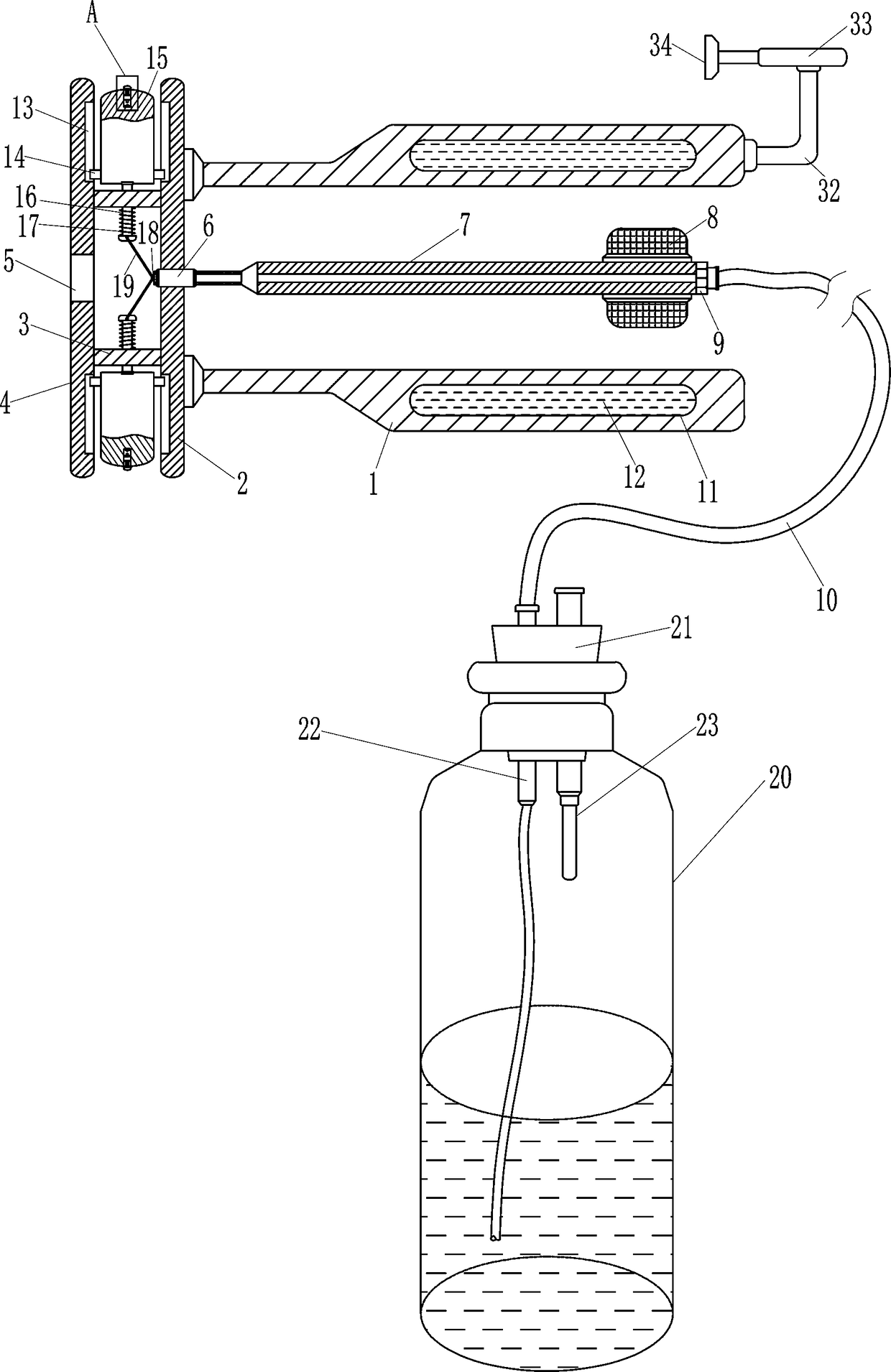

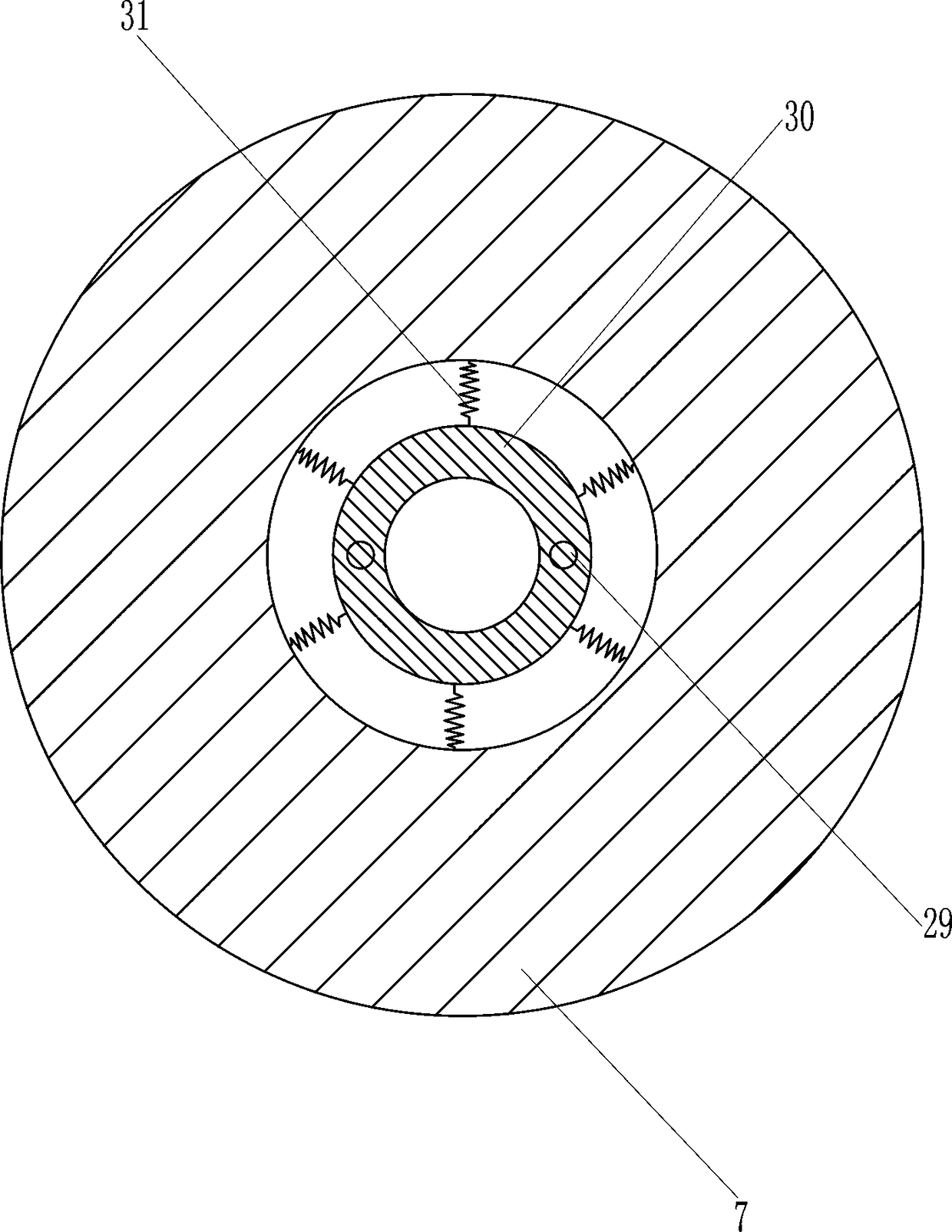

[0019] A kind of exhaust gas collection equipment for automobile troubleshooting, such as Figure 1-3 As shown, it includes a cross bar 1, a first connecting plate 2, a connecting rod 3, a second connecting plate 4, a first nut 6, a long hollow bolt 7, a handle 8, a second nut 9, a bolt hose 10, Heat-absorbing liquid 12, slide rail 13, slider 14, baffle plate 15, connecting rod 16, first compression spring 17, mounting block 18, rotating rod 19, exhaust gas treatment bottle 20, rubber plug 21, intake pipe 22 and exhaust Pipe 23, the first connecting plate 2 is connected to the left end of the horizontal bar 1 on the upper and lower sides, the upper and lower parts on the left side of the first connecting plate 2 are connected to the connecting rod 3, and the left end of the connecting rod 3 on the upper and lower sides is connected to the second connecting plate 4. There is a first opening 5 in the middle of the second connecting plate 4, a first nut 6 is embedded in the middl...

Embodiment 2

[0021] A kind of exhaust gas collection equipment for automobile troubleshooting, such as Figure 1-3As shown, it includes a cross bar 1, a first connecting plate 2, a connecting rod 3, a second connecting plate 4, a first nut 6, a long hollow bolt 7, a handle 8, a second nut 9, a bolt hose 10, Heat-absorbing liquid 12, slide rail 13, slider 14, baffle plate 15, connecting rod 16, first compression spring 17, mounting block 18, rotating rod 19, exhaust gas treatment bottle 20, rubber plug 21, intake pipe 22 and exhaust Pipe 23, the first connecting plate 2 is connected to the left end of the horizontal bar 1 on the upper and lower sides, the upper and lower parts on the left side of the first connecting plate 2 are connected to the connecting rod 3, and the left end of the connecting rod 3 on the upper and lower sides is connected to the second connecting plate 4. There is a first opening 5 in the middle of the second connecting plate 4, a first nut 6 is embedded in the middle...

Embodiment 3

[0024] A kind of exhaust gas collection equipment for automobile troubleshooting, such as Figure 1-3 As shown, it includes a cross bar 1, a first connecting plate 2, a connecting rod 3, a second connecting plate 4, a first nut 6, a long hollow bolt 7, a handle 8, a second nut 9, a bolt hose 10, Heat-absorbing liquid 12, slide rail 13, slider 14, baffle plate 15, connecting rod 16, first compression spring 17, mounting block 18, rotating rod 19, exhaust gas treatment bottle 20, rubber plug 21, intake pipe 22 and exhaust Pipe 23, the first connecting plate 2 is connected to the left end of the horizontal bar 1 on the upper and lower sides, the upper and lower parts on the left side of the first connecting plate 2 are connected to the connecting rod 3, and the left end of the connecting rod 3 on the upper and lower sides is connected to the second connecting plate 4. There is a first opening 5 in the middle of the second connecting plate 4, a first nut 6 is embedded in the middl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com