Fine broken rice screening system and application method thereof

A fine crushing and broken rice technology, which is applied in the field of fine crushed rice screening system, can solve the problems affecting the quality of whole rice and the amount of broken rice in whole rice exceeds the standard, so as to realize the technical effect, ensure effective utilization and improve economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

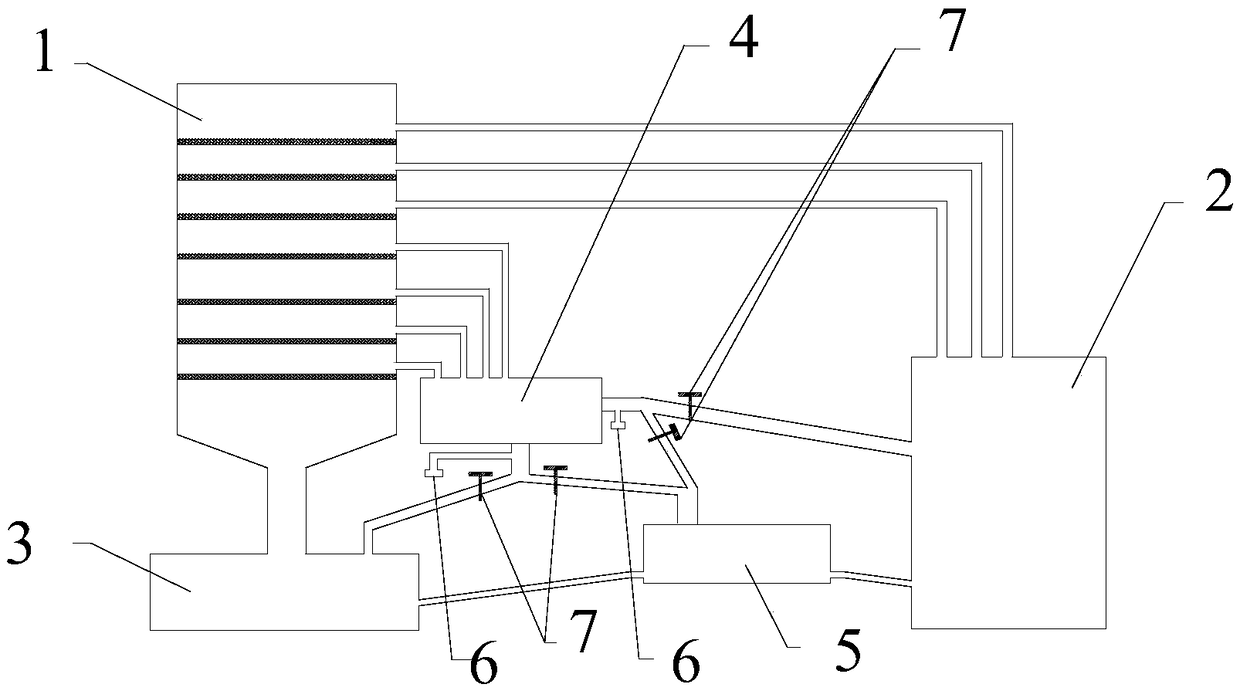

[0026] A screening system for finely ground rice, comprising a multi-layer sieve 1, the multi-layer sieve 1 includes an uppermost sieve set, a middle sieve set, and a lowermost sieve, and the uppermost layer includes two sieves, each with a mesh size of 7 mesh, the middle sieve set includes three sieves with a mesh size of 9 mesh, and the bottom sieve with a mesh size of 10 mesh. The multi-layer sieve 1 is equipped with a vibrating device for vibrating the sieve. The oversize outlet of the uppermost sieve group is connected to the feed port of the whole rice storage device 2, and the discharge of the undersize of the bottom sieve is The port is connected to the feed port of the broken rice storage device 3, the oversize discharge port of the middle sieve group and the discharge port of the bottom sieve are connected to the feed port of the color sorter 4, and the color sorter 4 The discharge ports are respectively connected to the feed ports of the whole rice storage device 2 ...

Embodiment 2

[0032] A screening system for finely ground rice, comprising a multi-layer sieve 1, the multi-layer sieve 1 includes the uppermost sieve set, the middle sieve set, and the lowermost sieve, the uppermost layer includes two layers of sieves, the mesh size of the first layer is The mesh size of the second layer is 7 mesh, and the mesh size of the third layer is 8 mesh. The mesh size is 10 mesh, and the mesh size of the bottom sieve is 11 mesh. The multi-layer sieve 1 is equipped with a vibrating device for vibrating the sieve. The oversize outlet of the uppermost sieve group is connected to the feed port of the whole rice storage device 2, and the discharge of the undersize of the bottom sieve is The port is connected to the feed port of the broken rice storage device 3, the oversize discharge port of the middle sieve group and the discharge port of the bottom sieve are connected to the feed port of the color sorter 4, and the color sorter 4 The discharge ports are respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com