Lifting roll bending machine for hanging basket machining

A technology of a roll brake and a casing, which is applied to the field of lifting and lowering roll brakes for hanging basket processing, can solve problems such as inconvenience of use, reduced work efficiency, and interference of applicable personnel, and achieves convenient use and operation, improved work efficiency, and increased productivity. The effect of great practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

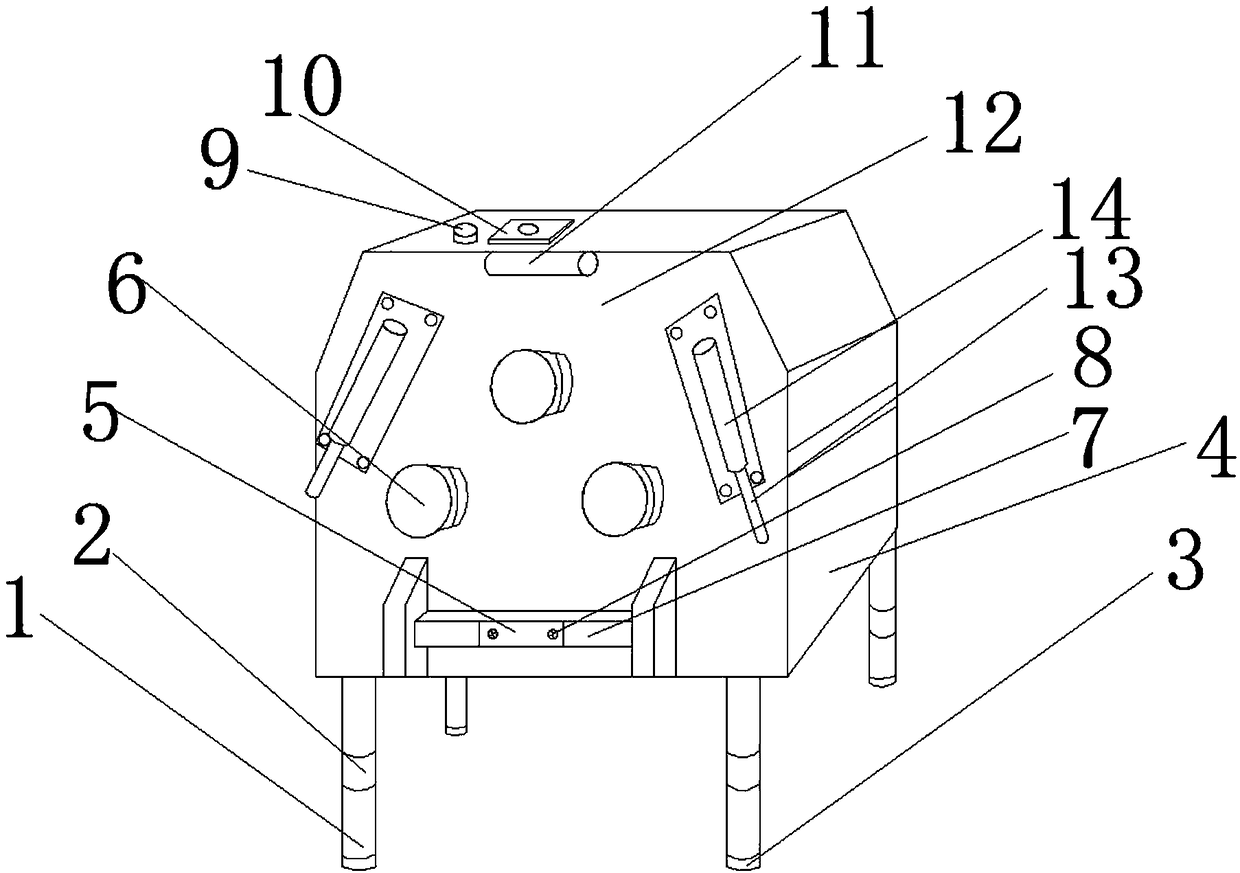

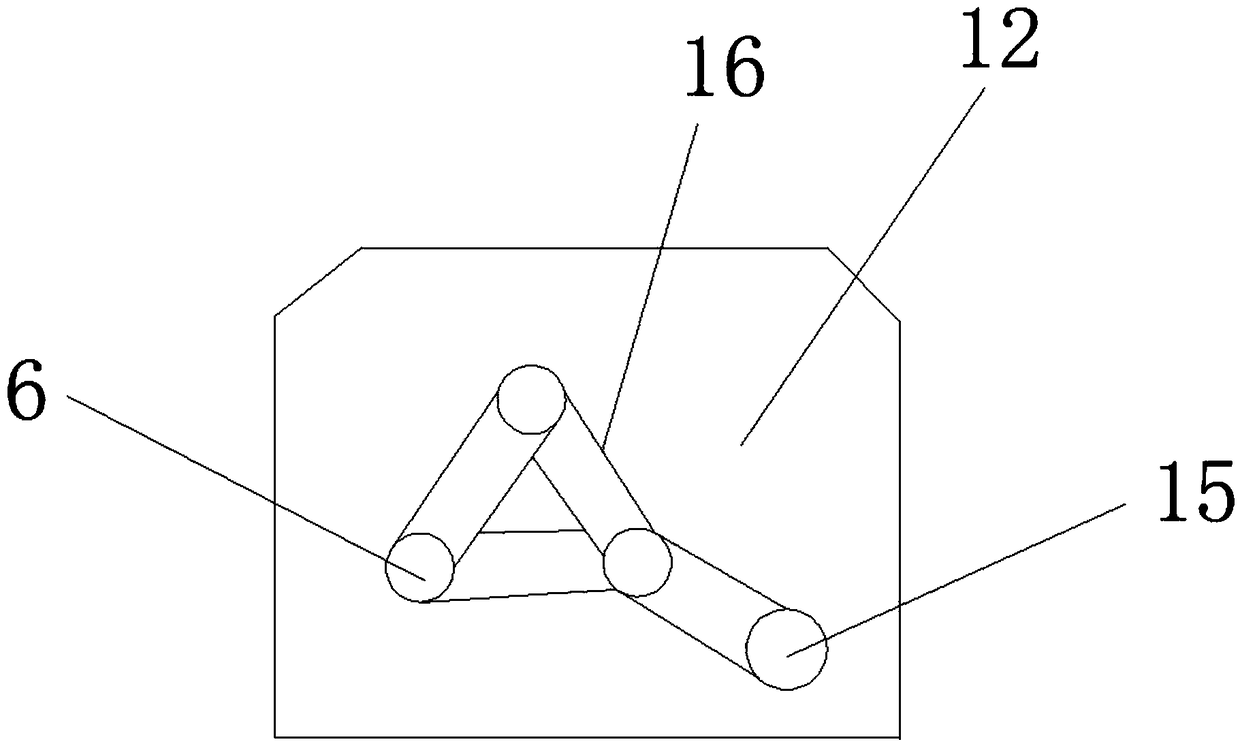

[0016] Such as Figure 1-2 As shown, a hanging basket processing liftable roll bending machine includes a machine foot 1, a casing 12 and a stop rod 14. The inner surface of the machine foot 1 is provided with a telescopic shaft 2, and the lower end of the machine foot 1 is provided with a Shock plate 3, the inner surface of the casing 12 is movably installed with a rolling device 6 and the motor box 4, the outer surface of the casing 12 is fixedly installed with a fixed rod 7 and a lighting lamp 11, and the outer surface of the fixed rod 7 A trademark plate 5 is provided, and a screw 8 is provided on the inner surface of the fixed rod 7, and the trademark plate 5 is fixedly connected with the fixed rod 7 through the screw 8, and a switch 9 and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com