A kind of surface coating method of spherical aluminum powder

A technology of spherical aluminum powder and surface coating, which is applied in transportation and packaging, metal processing equipment, etc., can solve problems such as discomfort, large consumption of methanol and ether, and pollution in the operating environment, and achieve simple process flow and fluidity Good, excellent water resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

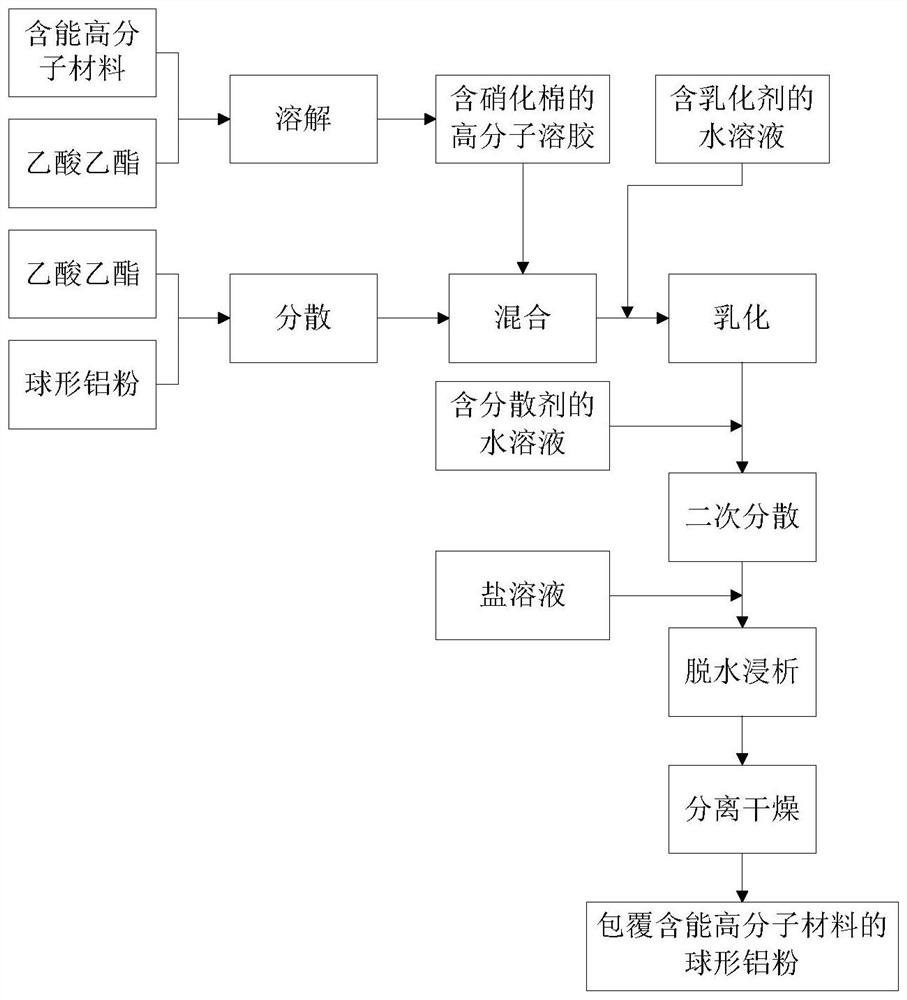

Method used

Image

Examples

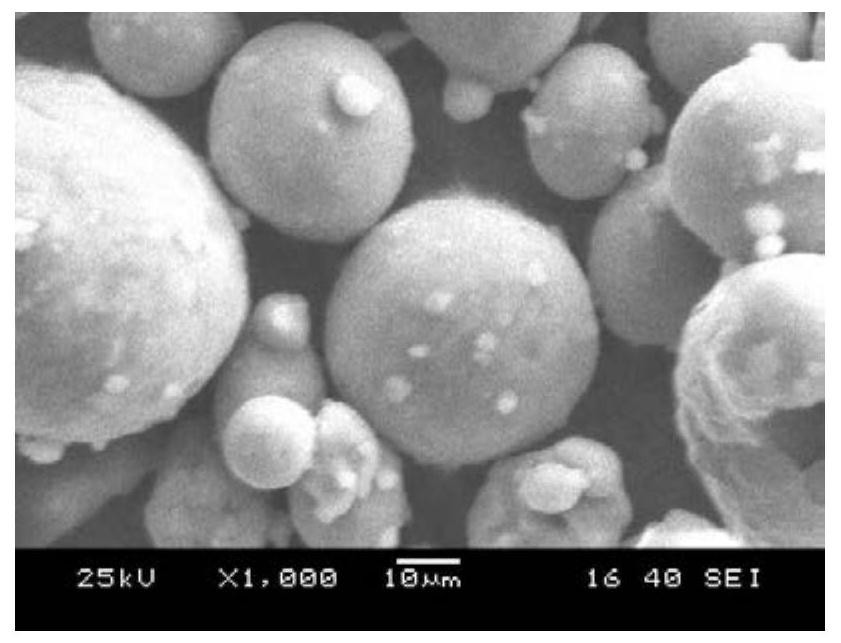

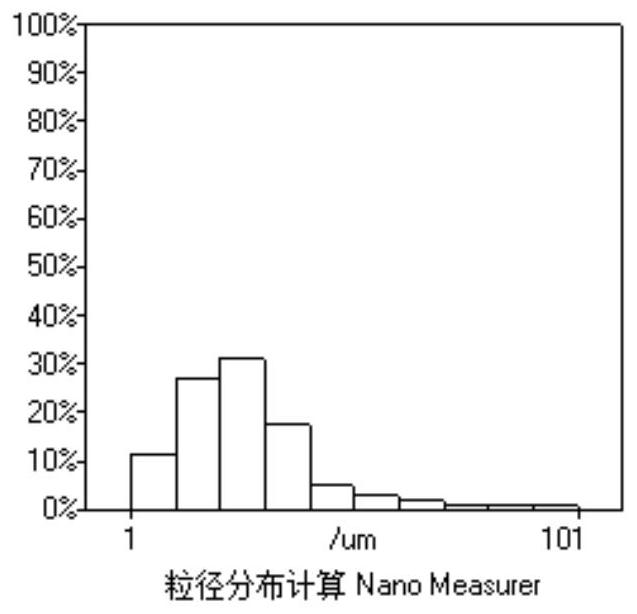

Embodiment 1

[0037] At room temperature, use the energetic polymer material with 100% nitrocellulose content as the coating material of spherical aluminum powder, first use the above energetic polymer material and ethyl acetate solvent to prepare an energetic polymer sol with a mass concentration of 5% . Weigh 36g of ethyl acetate and pour it into the reaction device, start stirring, and adjust the speed to 550rpm, then weigh 6g of spherical aluminum powder (with a particle size range of 1 μm to 100 μm, and an average particle size of 26.57 μm) and pour it into the reaction device, and disperse for 10 minutes According to the fact that the energetic polymer material accounted for 1% of the mass of the aluminum powder, 1.2 g of the above-mentioned energetic polymer sol was added, and mixed and stirred for 20 minutes. Gradually add 29.7g (0.8 times the mass of ethyl acetate used above) to the above-mentioned energy-containing polymer sol material dispersed with aluminum powder. The OP-10 emu...

Embodiment 2

[0040]Adopt the process similar to embodiment 1, only change the proportion and type of some materials, do not change the order of addition and processing time. At room temperature, a double-base absorbent containing 70% nitrocellulose was used as an energetic polymer material to coat the surface of aluminum powder, and an energetic polymer sol with a mass concentration of 5% was prepared. Weigh 36g of ethyl acetate and pour it into the reaction device, start stirring, and adjust the speed to 550rpm, then weigh 6g of spherical aluminum powder (with a particle size range of 1 μm to 100 μm, and an average particle size of 26.57 μm) and pour it into the reaction device, and disperse for 10 minutes According to the fact that the energetic polymer material accounted for 5% of the mass of the aluminum powder, 6g of the above-mentioned energetic polymer sol was added, and mixed and stirred for 20 minutes. Gradually add 29.7g (0.8 times the mass of ethyl acetate used above) to the abo...

Embodiment 3

[0042] Adopt the process similar to embodiment 1, only change the proportion and type of some materials, do not change the order of addition and processing time. At room temperature, the double-base absorbent with a mass concentration of nitrocellulose of 40% was used as an energetic polymer material for aluminum powder coating, and an energetic polymer sol with a mass concentration of 5% was prepared. Weigh 36g of ethyl acetate and pour it into the reaction device, start stirring, adjust the speed to 550rpm, then weigh 6g of spherical aluminum powder (with a particle size range of 1 μm to 100 μm, and an average particle size of 26.57 μm) and pour it into the reaction device, and disperse for 10 minutes. According to the fact that the energetic polymer material accounted for 10% of the mass of the aluminum powder, 12 g of the above-mentioned energetic polymer sol was added, and mixed and stirred for 20 minutes. Gradually add 29.2g (0.8 times the mass of ethyl acetate used abov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com