Vehicle brake disc conveying drilling device

A technology for automobile brakes and drilling devices, which is applied in the directions of boring/drilling, drilling/drilling equipment, maintenance and safety accessories, etc. It can solve the problems of wasting working time and the inability of a single drilling to adapt to mass production and processing. , to achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

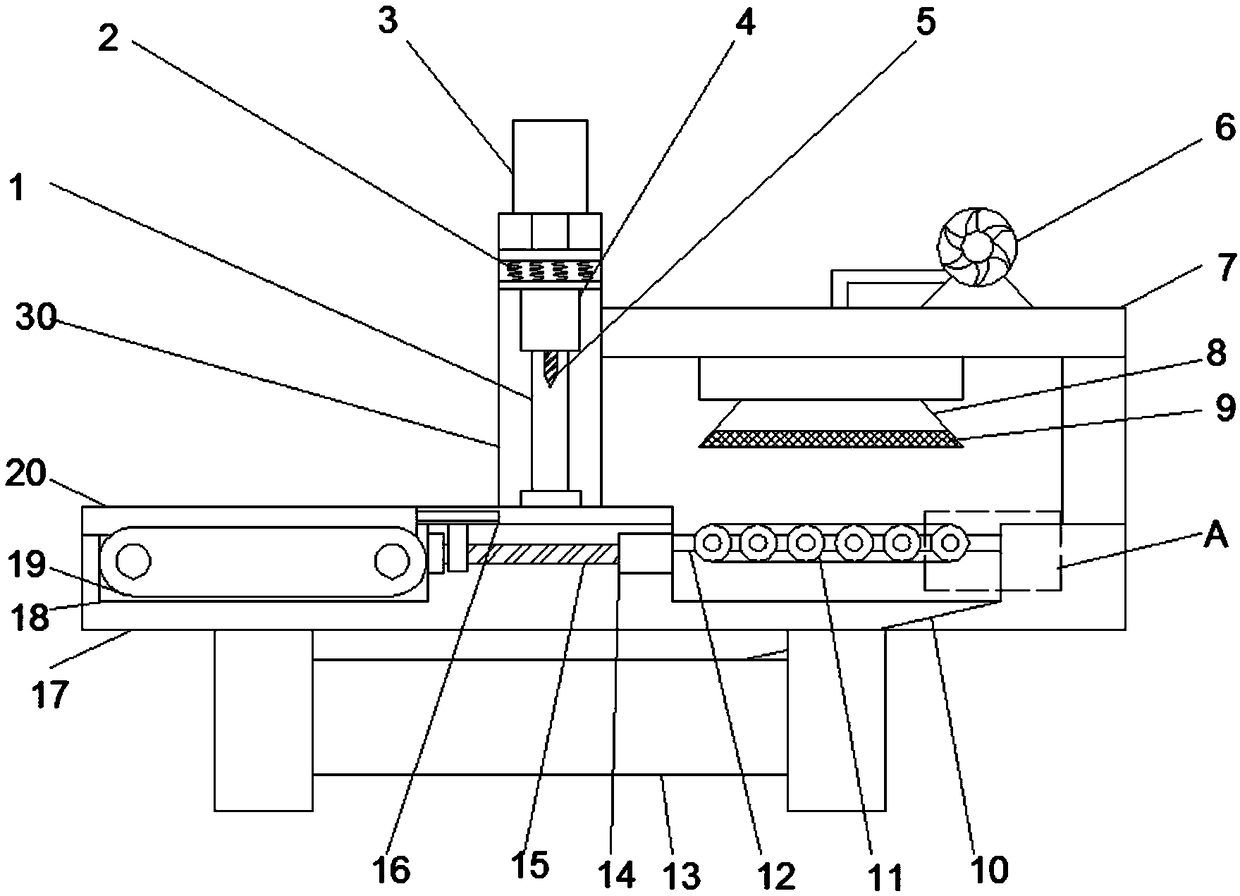

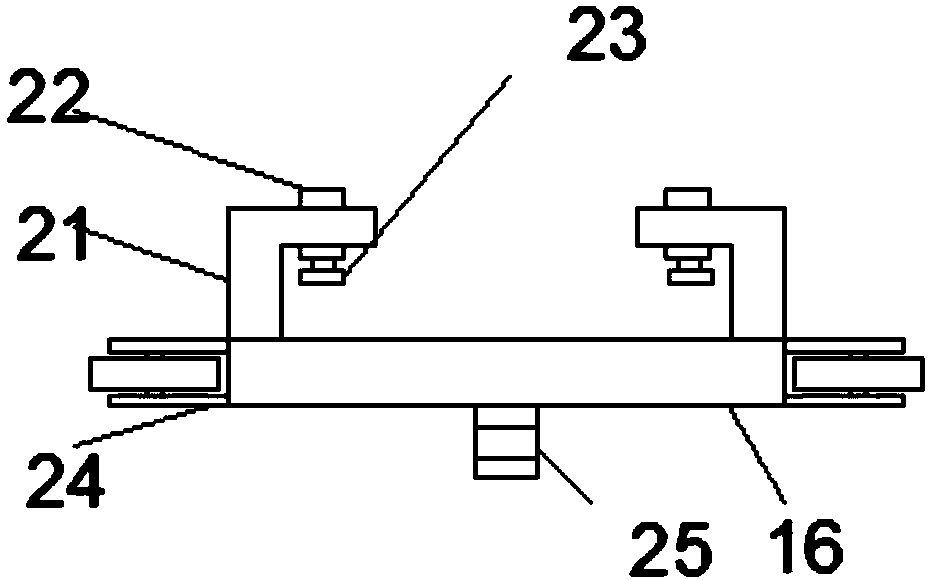

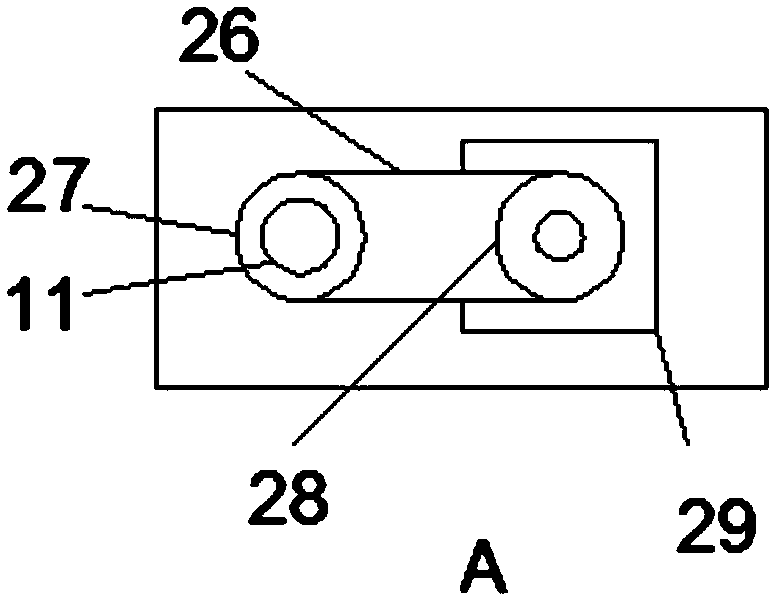

[0019] Such as Figure 1-Figure 3 As shown, a kind of automobile brake disc conveying drilling device proposed by the present invention includes a base 17 and a support 7, grooves 18 are arranged on the left and right sides of the base 17, and a conveyor belt 19 is arranged inside the left groove 18. The upper surface of 17 is provided with a chute 20, the middle position of the upper surface of the base 17 is provided with a motor frame 30, the upper end of the motor frame 30 is provided with a first motor 3, the shaft of the first motor 3 is connected with a threaded rod 1, and the surface of the threaded rod 1 is sleeved There is a fixed plate, the lower surface of the fixed plate is provided with a number of springs 2, the other end of the spring 2 is connected to the placement plate, the second motor 4 is fixedly connected to the lower surface of the placement plate, the shaft of the second motor 4 is connected to the drill bit 5, and the right groove 18 The outer surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com