Tool fixture device for electronic component machining and maintaining

A technology of electronic components and tooling fixtures, which is applied in the direction of auxiliary devices, manufacturing tools, metal processing equipment, etc., can solve the problems of inconvenient operation of electronic components, inability to adjust the angle of tooling, troublesome tooling and clamping operations, etc., to achieve clamping Simple and convenient, convenient clamping and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

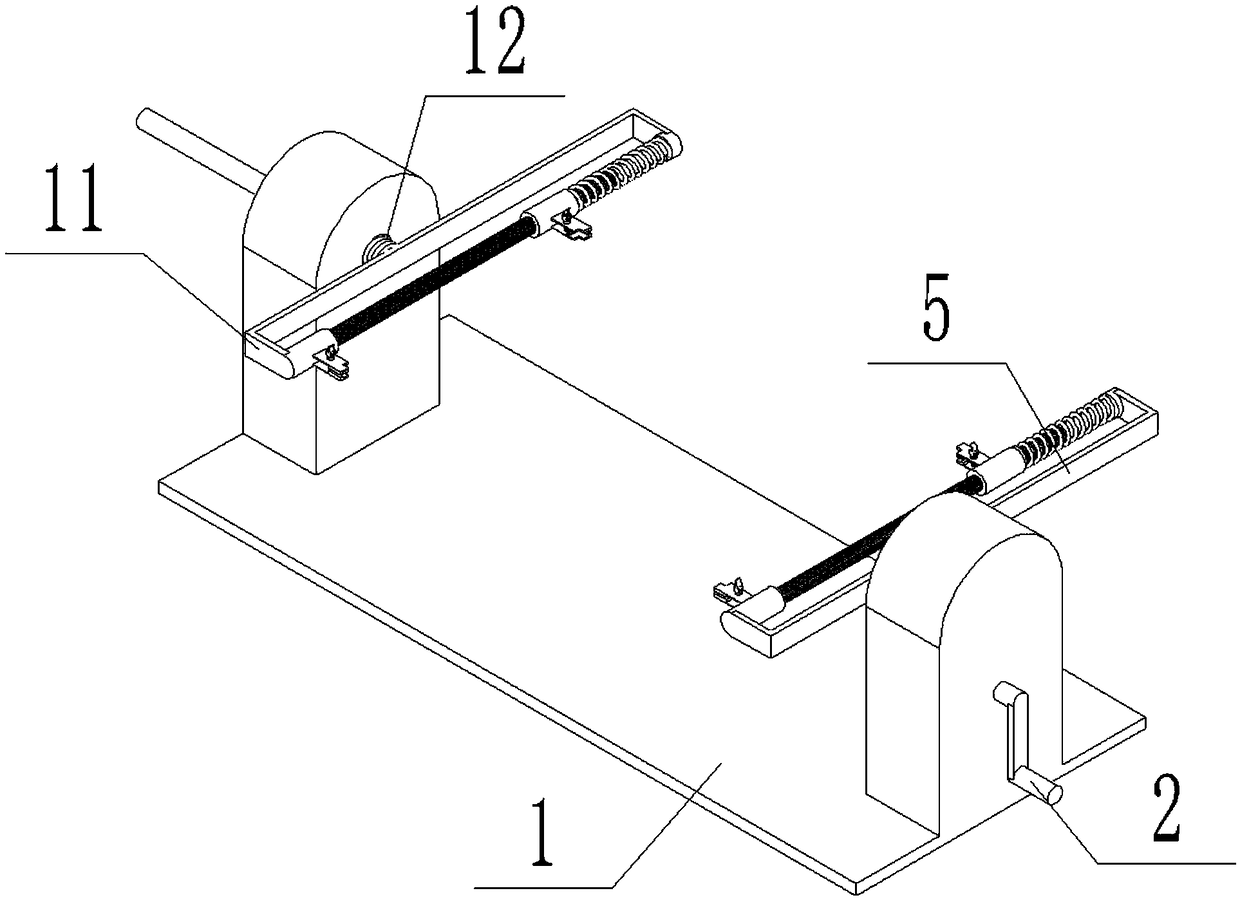

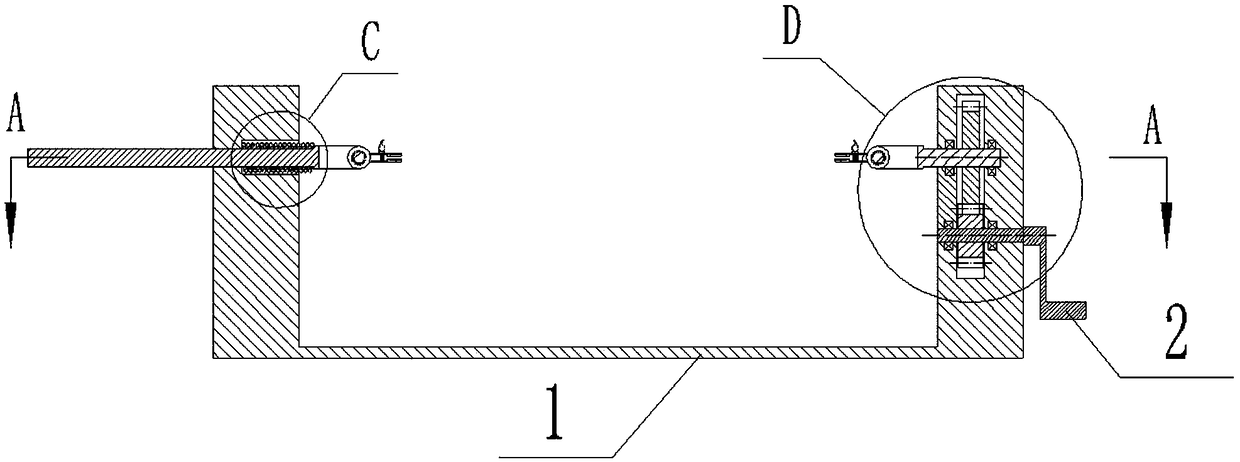

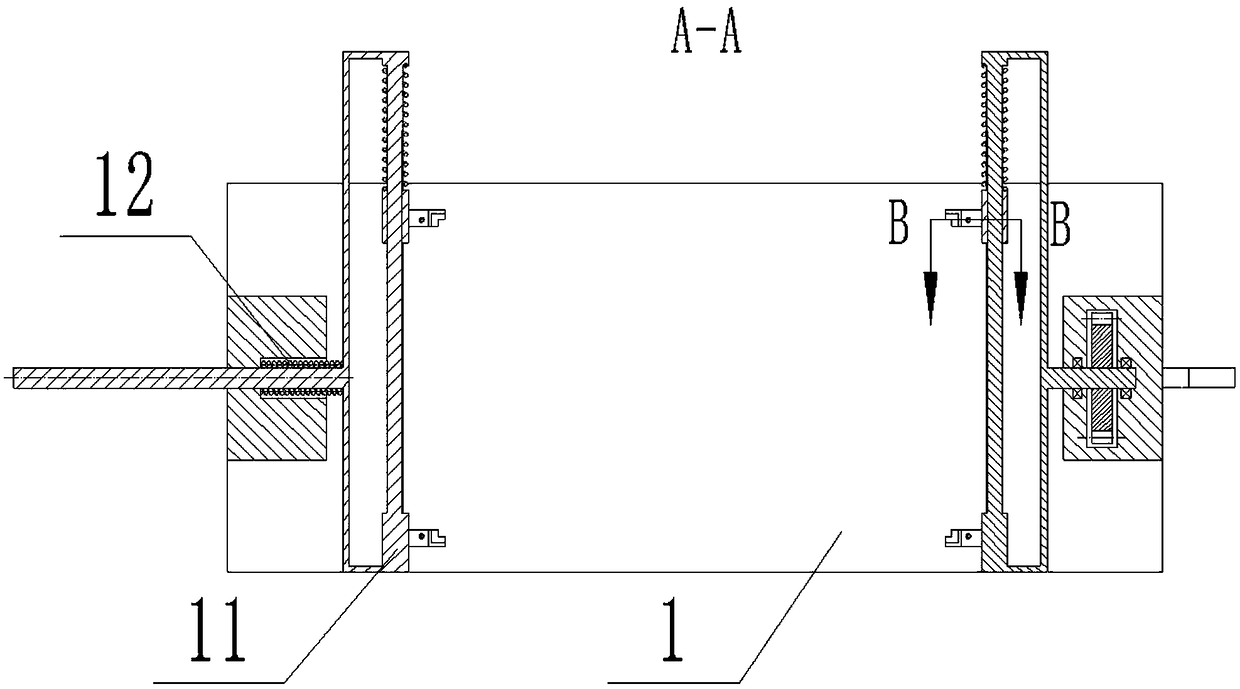

[0032] as attached figure 1 to attach Figure 8 Shown:

[0033] The invention provides a fixture device for processing and maintaining electronic components, including: a base 1, a handle 2, a driving gear 3, a driven gear 4, a right connecting rod 5, a spline groove 0501, a width adjustment spring 6, and a fixing clip Clamping block 7, positioning table 0701, clamping block 8, clamping pad 9, quick clamping handle 10, left connecting rod 11, length adjustment spring 12 and clamping reset spring 13; the right end of base 1 is axially connected with a group Handle 2; the left side of the handle 2 is coaxially fixedly connected with a group of driving gears 3; the right side of the base 1 is axially connected with a group of right connecting rods 5; the right end face of the right connecting rod 5 is coaxially fixedly connected with a group of driven gears Gear 4; the left side of the base 1 is axially slidingly connected with a group of left connecting rods 11; the left conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com