Redundancy mechanical arm repetitive motion planning method for suppressing periodic noise

A technology of repetitive motion and cycle suppression, applied in the direction of program control of manipulators, manipulators, manufacturing tools, etc., can solve the problems of redundant manipulator periodic noise interference, redundant manipulator arm repetitive motion planning failure, etc., to prevent periodic noise interference Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below.

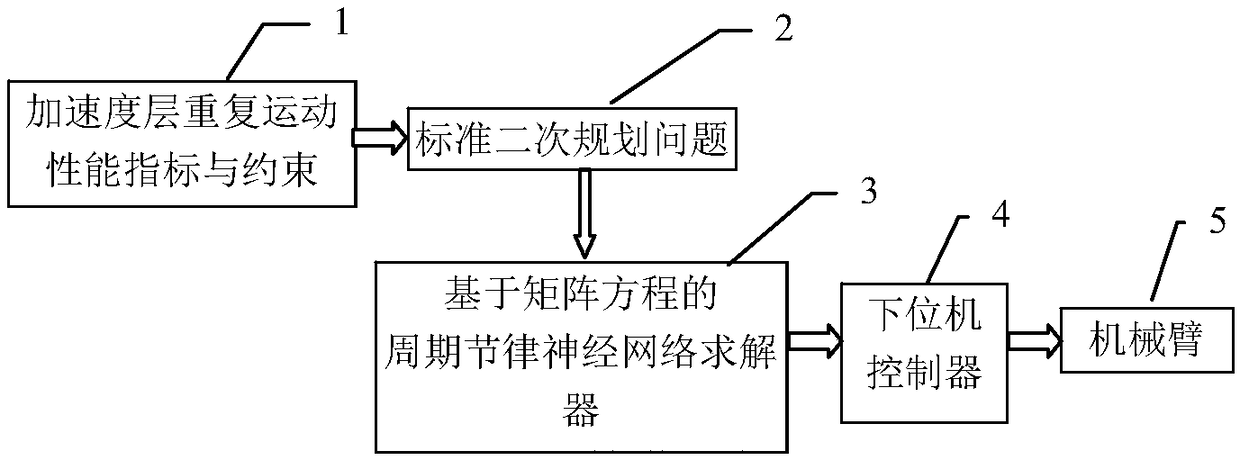

[0024] figure 1 The shown repetitive motion planning method of redundant manipulator mainly consists of acceleration layer repetitive motion performance index and constraint 1, standard quadratic programming 2, periodic rhythmic neural network solver based on matrix equation 3, lower computer controller 4 and manipulator 5 composition. Specifically, the method includes the following steps:

[0025] 1) The quadratic optimization is used to analyze the inverse kinematics of the manipulator on the angular acceleration layer. The minimum performance indicators designed can be the angular velocity norm and the torque norm, which are constrained by the angular acceleration Jacobian with angular velocity and position feedback, etc. Mode;

[0026] 2) carry out the equivalent conversion of angular velocity index and angular acceleration index, described quadratic optimization is converted into standard quadrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com