Medicinal material slicing machine

A slicer and medicinal material technology, applied in metal processing, etc., can solve problems such as time-consuming, inconsistent cutting thickness, and affecting sales prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

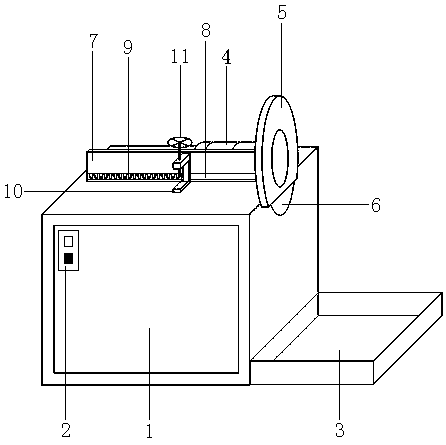

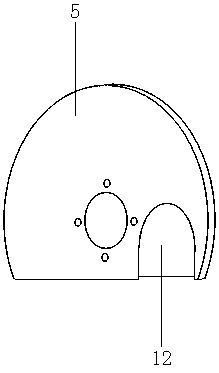

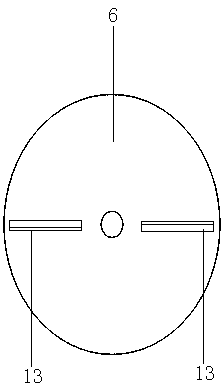

[0014] A medicine slicer: including a cuboid bracket 1, a power switch 2, a tray 3, a gear motor 4, a safety shield 5, a thickness-limiting cutting disc 6, a baffle 7, a chute 8, a thrust spring 9, a clip 10, a locking Handle 11, velvet feeding hole 12, cutting blade 13, cuboid support is connected with power switch, tray, geared motor, baffle plate, power switch is connected with geared motor through power cord, geared motor is connected with safety shield, thickness-limiting cutting disk, The safety protection cover is connected with the antler feeding hole, the thickness-limiting cutting disc is connected with the cutting blade, the baffle is connected with the chute, the thrust spring, and the clip, and the clip is connected with the locking handle;

[0015] The geared motor is arranged above the cuboid support, the front end of the motor casing is provided with a safety shield, and the interior of the shield is provided with a thickness-limiting cutting disc connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com