Automatic detecting and discharging device and method for metal nuts in plastic water pipe

An automatic detection and nut technology, applied in the direction of conveyor control devices, transportation and packaging, conveyor objects, etc., can solve the problems of unguaranteed insertion direction of metal nuts, easy fatigue of operators, increased error rate, etc., to achieve The structure design is reasonable and ingenious, the direction is guaranteed, and the effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

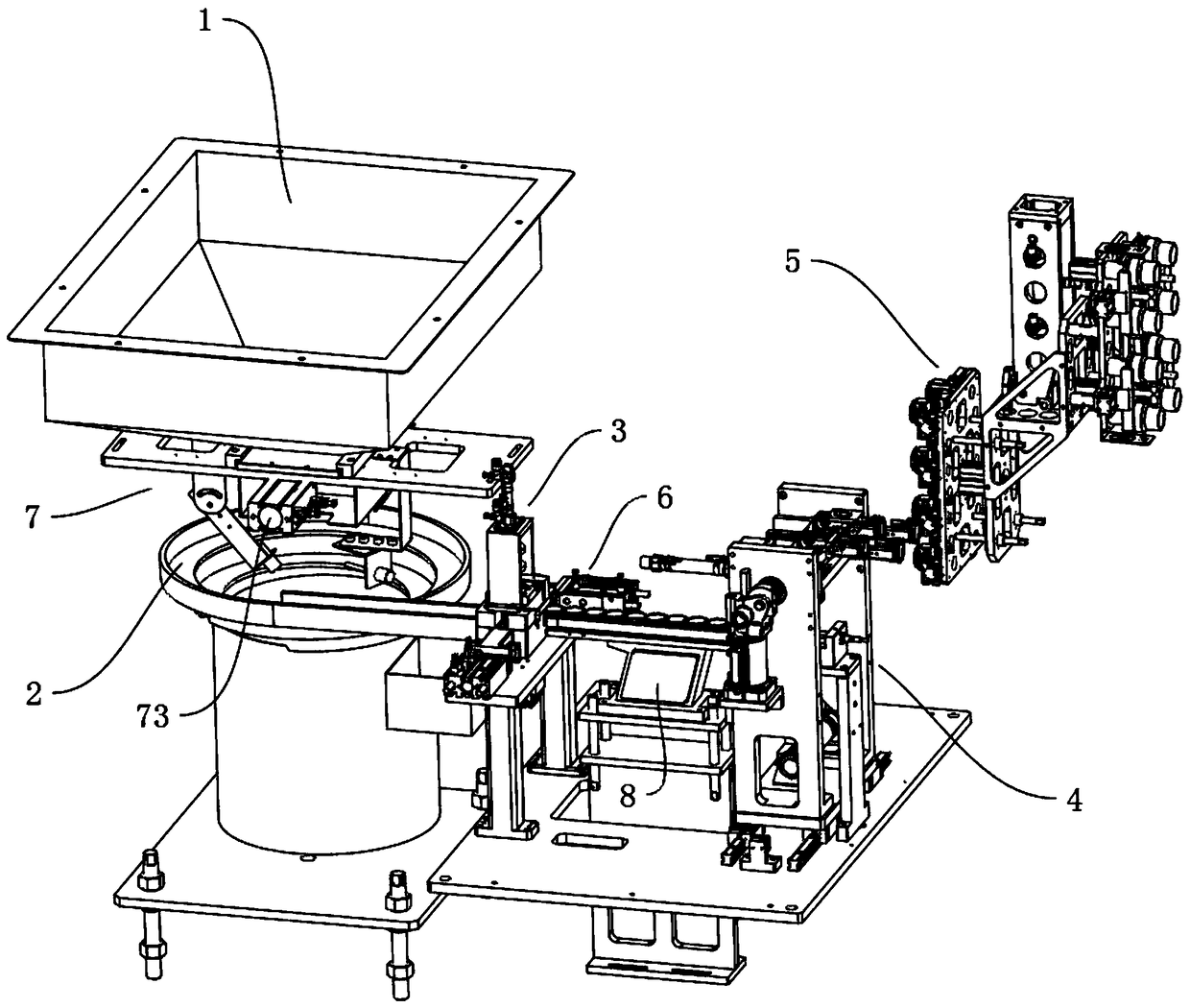

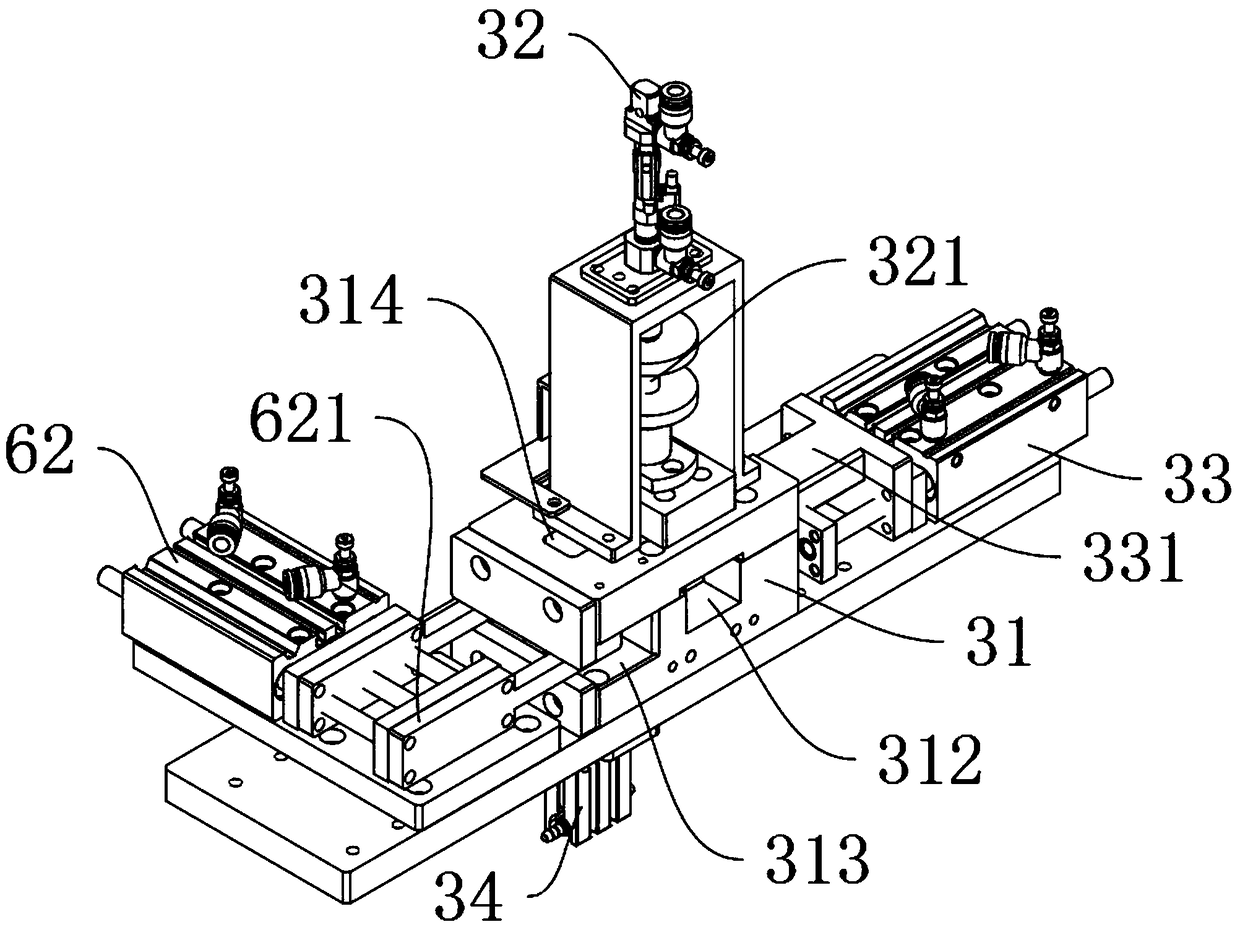

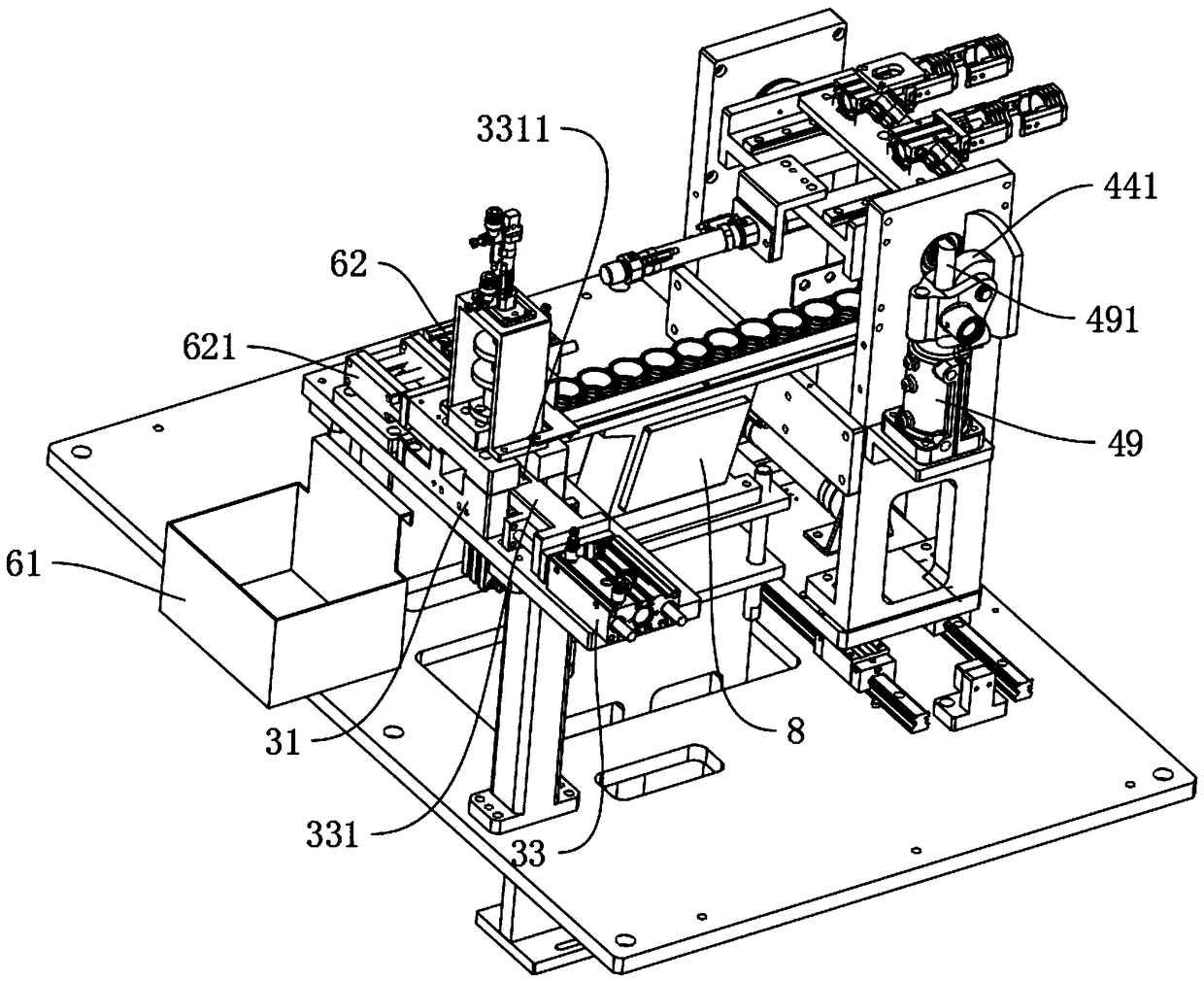

[0028] Examples, see Figure 1 to Figure 6 , a device for automatic detection and discharge of metal nuts in plastic water pipes provided in this embodiment, which includes a hopper 1, a vibrating plate 2, a reversing detection mechanism 3, a nut discharge steering mechanism 4 and a take-off mechanism set according to the material conveying direction. The material mechanism 5 is provided with a material distribution mechanism 6 corresponding to the reversing detection mechanism 3, and the reversing detection mechanism 3 includes a mechanism base 31, a detection rod 321 and a direction detection cylinder 32 arranged above the mechanism base 31. The detection rod 321 is fixedly connected with the piston rod of the direction detection cylinder 32, and the mechanism base 31 is horizontally provided with a reversing channel 311 and a feed channel 312 and a discharge channel 313 perpendicular to the reversing channel 311. , a nut reversing cylinder 33 is provided corresponding to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com