A device and method for improving solidification quality of electroslag steel and reducing element segregation

A technology of quality reduction and electroslag steel, which is applied in the field of metallurgy and casting, can solve problems such as prolonging the cooling time of ingots, intensified segregation of steel ingot components, and poor thermal conductivity, so as to improve the solidification quality of electroslag steel, reduce element segregation, and improve The effect of the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

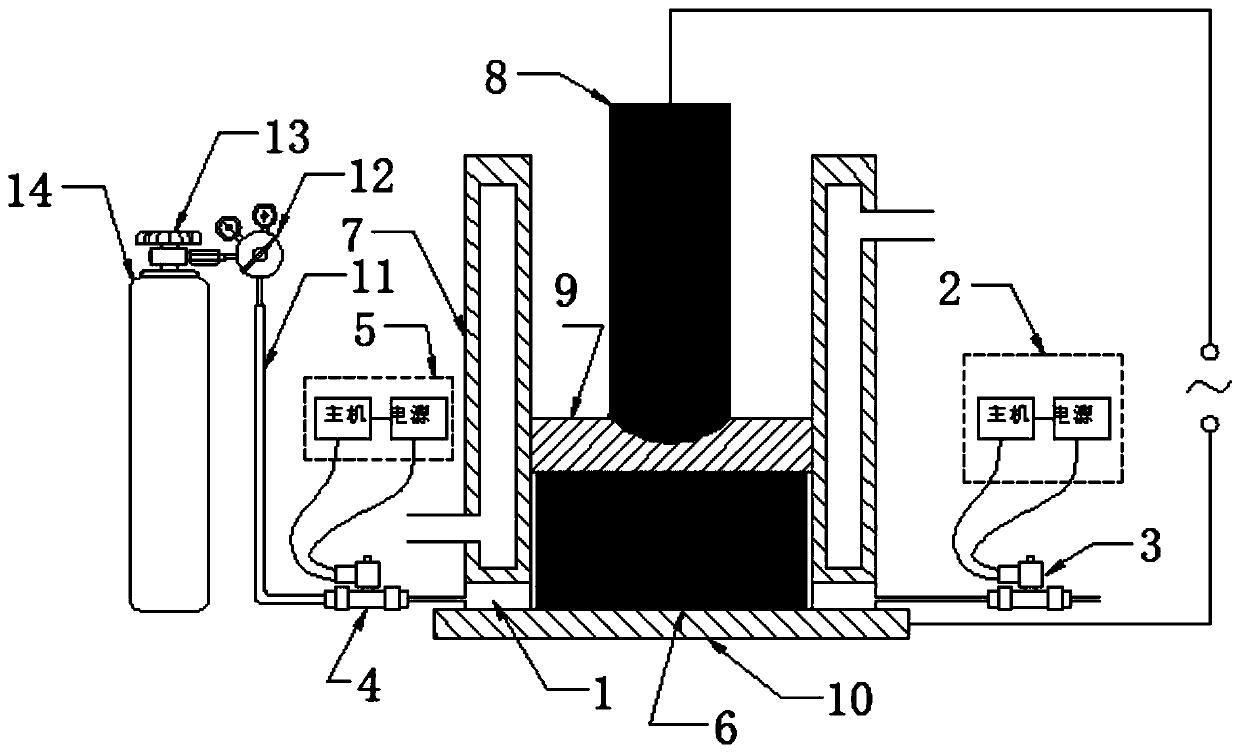

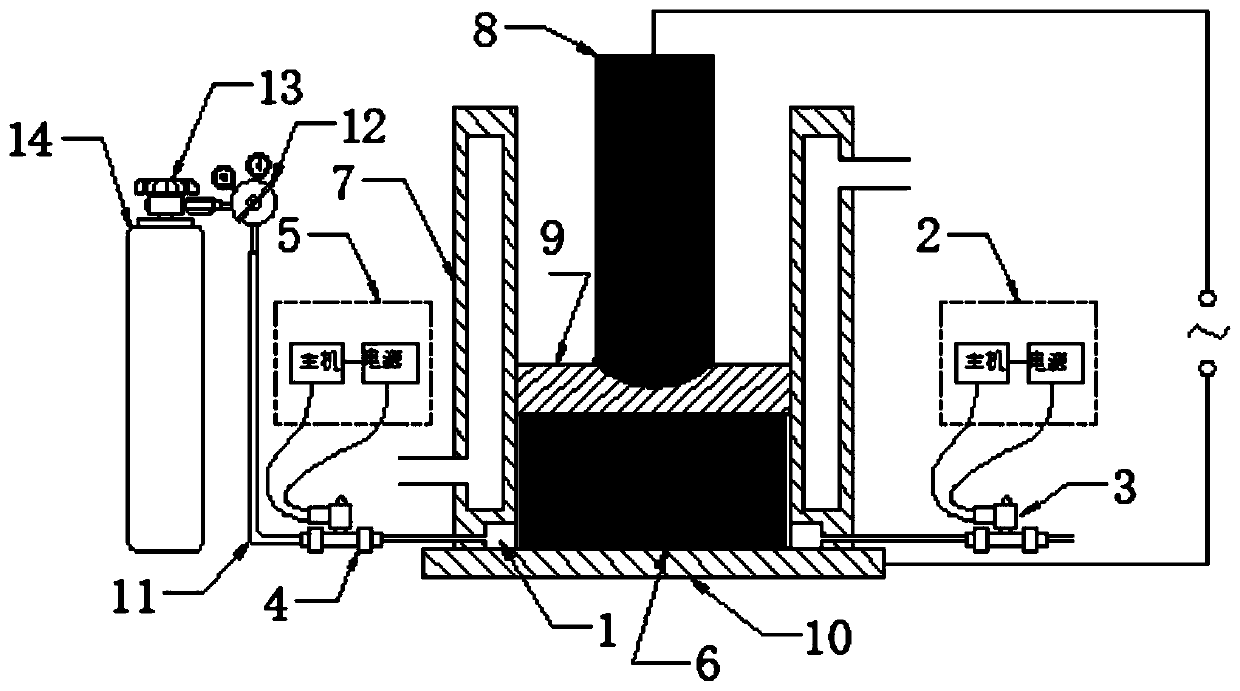

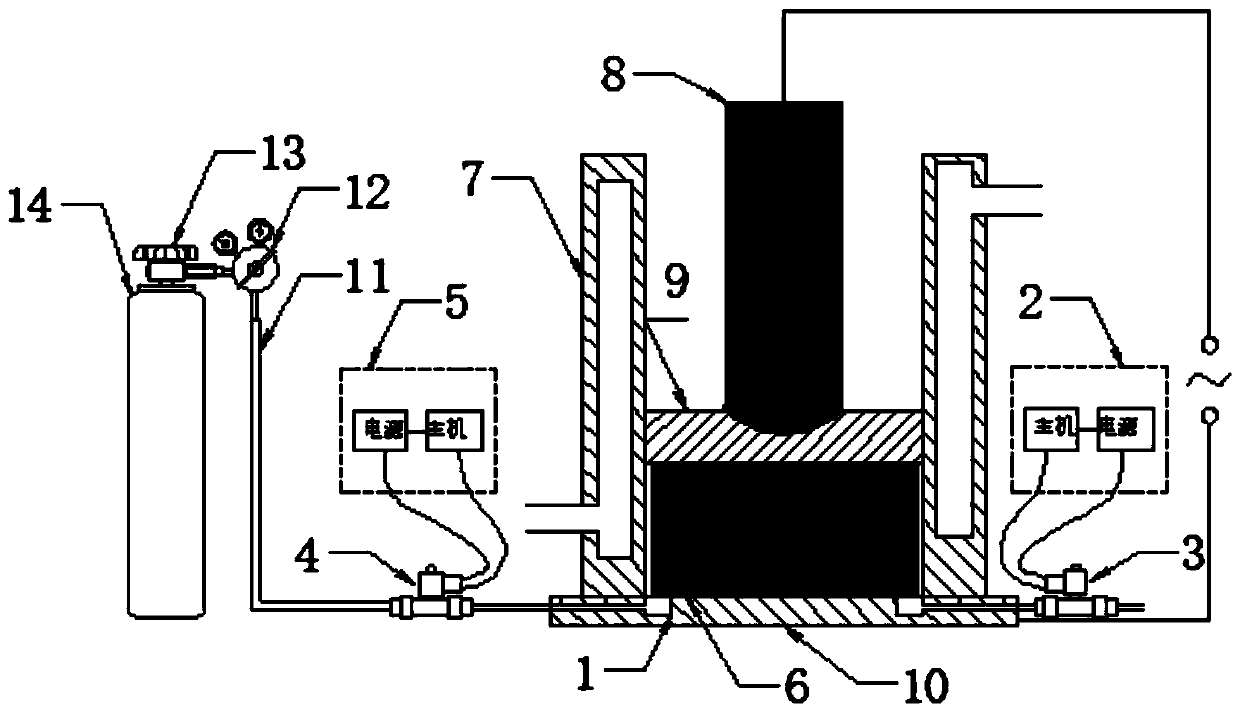

[0041] A device for improving the solidification quality of electroslag steel and reducing element segregation, its front view is as follows figure 2 As shown, including gas supply system, ring piping system and smelting system, where:

[0042] Described gas supply system is made up of gas storage bottle 14, decompression valve 13, steady pressure gauge 12 and air guide pipe 11, and described gas storage bottle 14 is connected with air guide pipe 11, and described gas storage bottle 14 bottleneck places Pressure reducing valve 13 and pressure stabilizing gauge 12 are set;

[0043]The annular piping system is composed of an air inlet electromagnetic valve 4, an air inlet electromagnetic valve controller 5, an annular pipeline 1, an air outlet electromagnetic valve 3 and an air outlet electromagnetic valve controller 2. The annular pipeline 1. An air inlet and an air outlet are arranged symmetrically along the horizontal center line; the air inlet of the annular pipeline is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com