A wall-mounted ultrasonic cleaning device

A cleaning device, ultrasonic technology, applied in the washing device, washing machine control device, other washing machines, etc., can solve the problems of clothing pollution, large loss, oil stain shedding, etc., and achieve the effect of cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

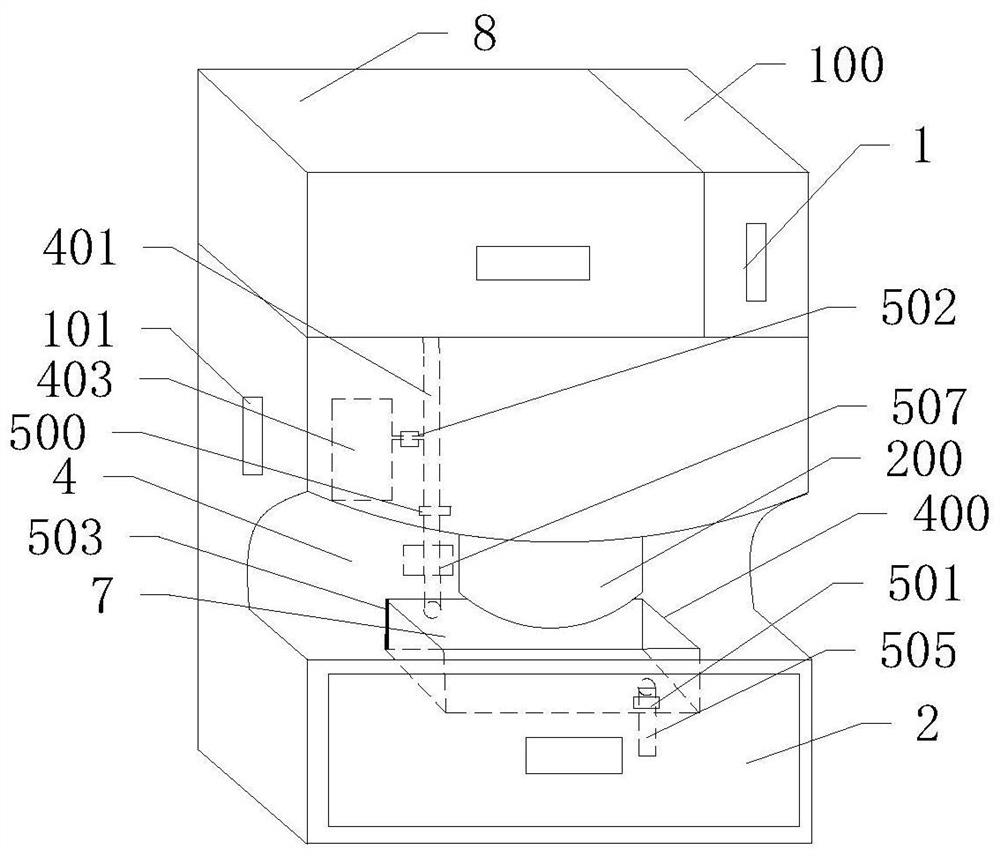

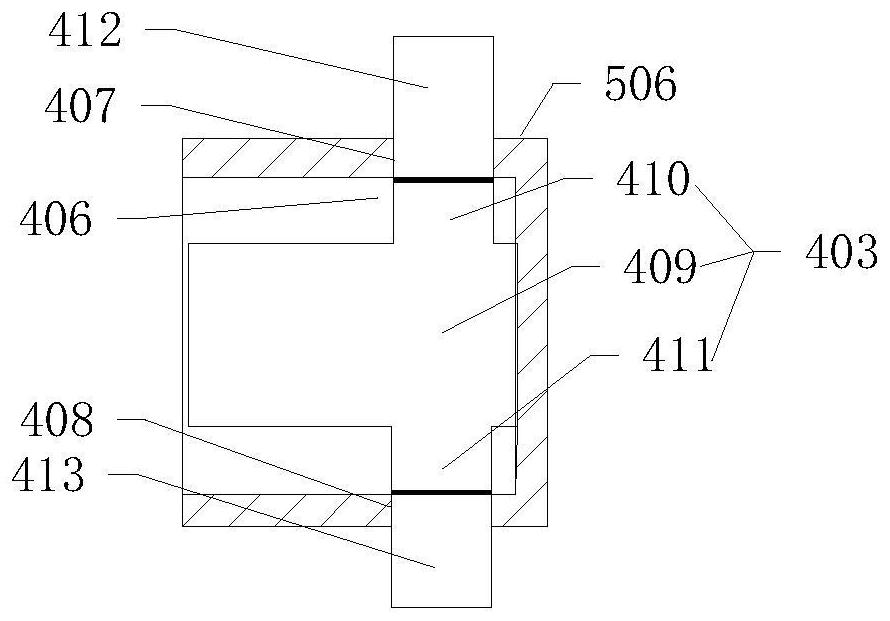

[0037] Such as figure 1 As shown, a wall-mounted ultrasonic cleaning device includes a body 100 installed on the wall, an ultrasonic generating device 200 arranged on the main body 100, and a cleaning tank 400 for holding the washing liquid 7. The ultrasonic generating device 200 has the ability to generate ultrasonic waves. The vibration end, the vibration end is arranged on the top of the cleaning tank 400, and also includes a liquid supply pipeline and a liquid discharge pipeline communicated with the cleaning tank 400. During washing, the liquid supply pipeline supplies liquid to the cleaning tank 400 and drains the liquid at the same time The pipeline discharges the liquid in the cleaning tank 400, so that the washing liquid 7 in the cleaning tank 400 keeps flowing and the liquid level remains constant.

[0038] The ultrasonic generator 200 includes an ultrasonic generator and an ultrasonic vibrator electrically connected to the ultrasonic generator.

[0039] By setting ...

Embodiment 2

[0053] Such as Figure 1-3 As shown, this embodiment is a further limitation of Embodiment 1, the adjustment device is arranged on the liquid supply pipeline and / or the liquid discharge pipeline, and is used to adjust the liquid supply pipeline and / or the liquid discharge pipeline. The liquid flow rate keeps the washing liquid 7 in the washing tank 400 flowing and the liquid level remains constant.

[0054] Solution 1, the regulating device includes a first regulating valve 500 arranged on the liquid supply pipeline, when the opening of the first regulating valve 500 is the largest, the liquid flow in the liquid supply pipeline is greater than the liquid flow in the liquid discharge pipeline, so that The liquid in the cleaning tank 400 flows. When the ultrasonic cleaning device is opened, the first regulating valve 500 is opened, and the liquid level of the cleaning liquid in the cleaning tank 400 gradually increases. When the liquid level in the cleaning tank 400 reaches the ...

Embodiment 3

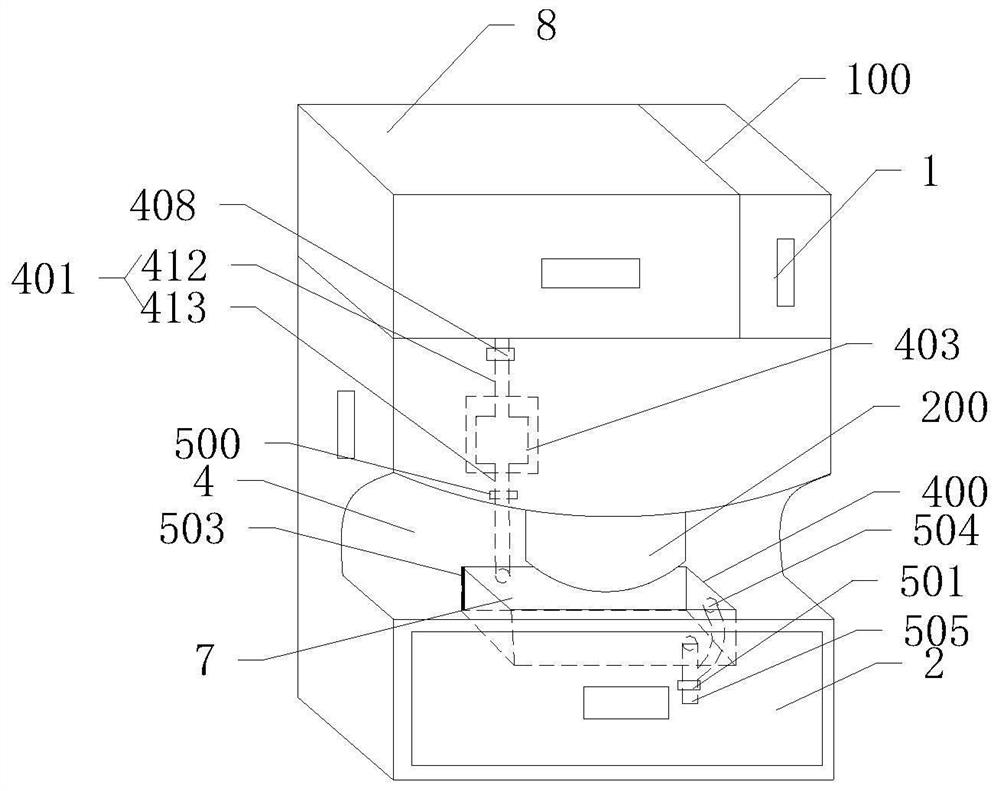

[0073] Such as figure 2 As shown, this embodiment is a further limitation of Embodiment 1. An overflow port 504 is provided on the cleaning tank 400, and the overflow port 504 communicates with the drain pipeline. When the washing liquid 7 is higher than the overflow When the flow port 504 overflows from the overflow port 504, the liquid level remains constant during the washing process.

[0074] By setting the overflow port 504, the liquid level height of the liquid in the cleaning tank 400 is controlled according to the height of the overflow port 504. When the position of the overflow port 504 is set higher, the target height in the cleaning tank 400 is higher, which can be used to For washing thinner laundry 5 , if the overflow port 504 is set at a lower position, the target height in the washing tank 400 is lower, which can be used to wash thicker laundry 5 .

[0075] A plurality of overflow ports 504 can be provided, and can be arranged at different liquid heights. Aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com