Patents

Literature

30results about How to "Constant liquid level" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Standpipe direct float valve

InactiveUS20090120511A1Constant liquid levelOperating means/releasing devices for valvesPipeline systemsEngineeringFluid level

The standpipe direct float valve of the present invention is configured such that the valve plug is directly connected to the float element and both the valve plug and the float element are deployed within the standpipe housing. The standpipe housing has an inlet port and at least one outlet port. The valve plug is configured to regulate the fluid level, commonly referred to in the art as head, in the standpipe housing by controlling the flow of fluid through the inlet port and into the standpipe housing. The valve plug is deployed within the standpipe housing and is directly connected to, and actuated by, a float element that is deployed within the standpipe housing and reactive to the fluid level in the standpipe housing. Preferably, the valve plug and the float element are integrally formed. So configure, the standpipe float valve of the present invention provides a method for maintaining a substantially constant flow pressure through an outlet port of a standpipe float valve having a standpipe housing configured with an inlet port and an outlet port. This is accomplished by maintaining a substantially constant fluid level into the standpipe housing by displacement of the float element in response to the fluid level in the standpipe housing so as to actuate the valve plug between an open position, in which fluid flows through the inlet port into the standpipe housing and a closed position in which fluid flow through the inlet port is blocked. A full range of fluid flow through the inlet port and into the standpipe housing is possible due to the fill range of movement of the valve plug between filly closed and fully open is possible.

Owner:BERMAD CS LTD

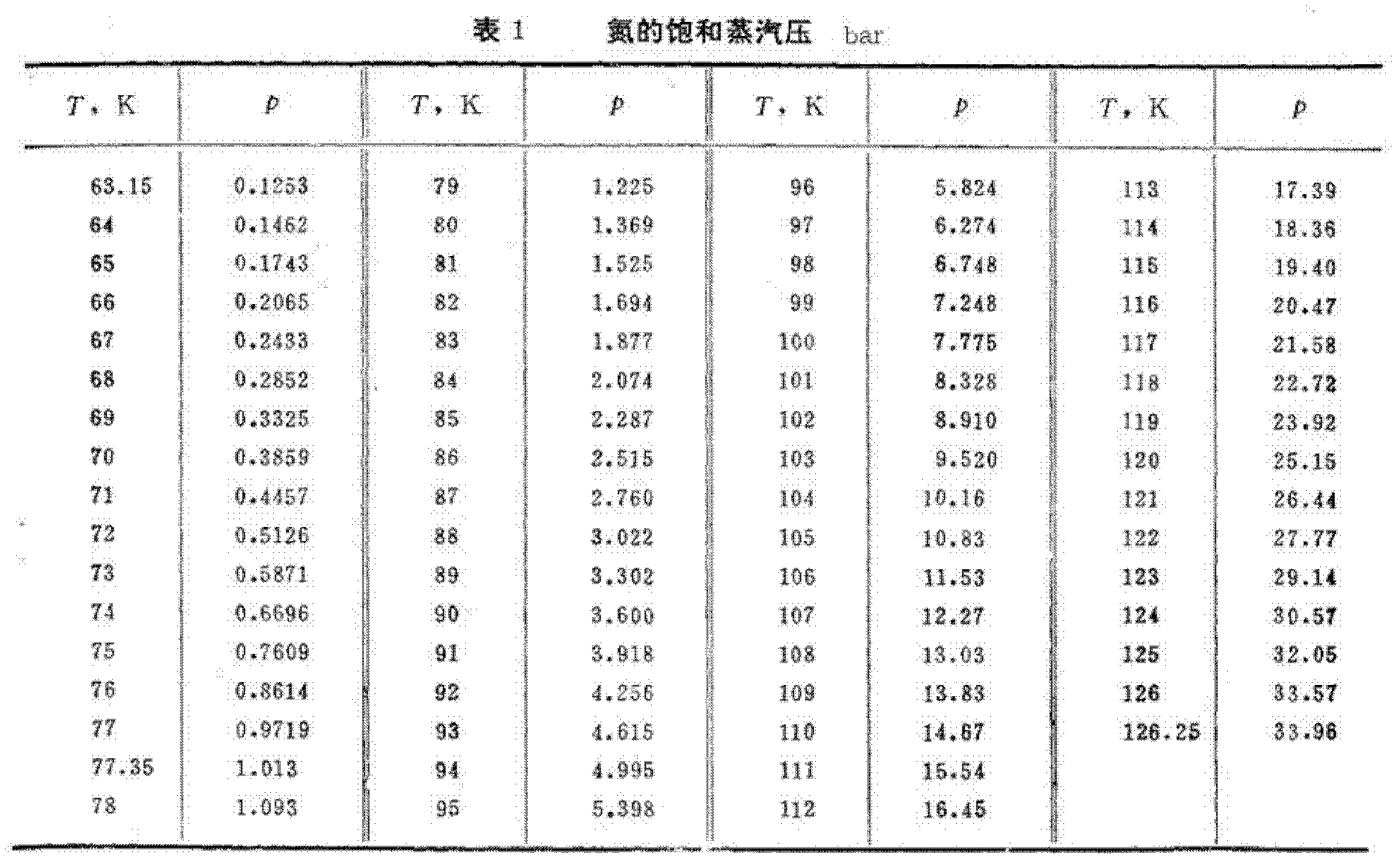

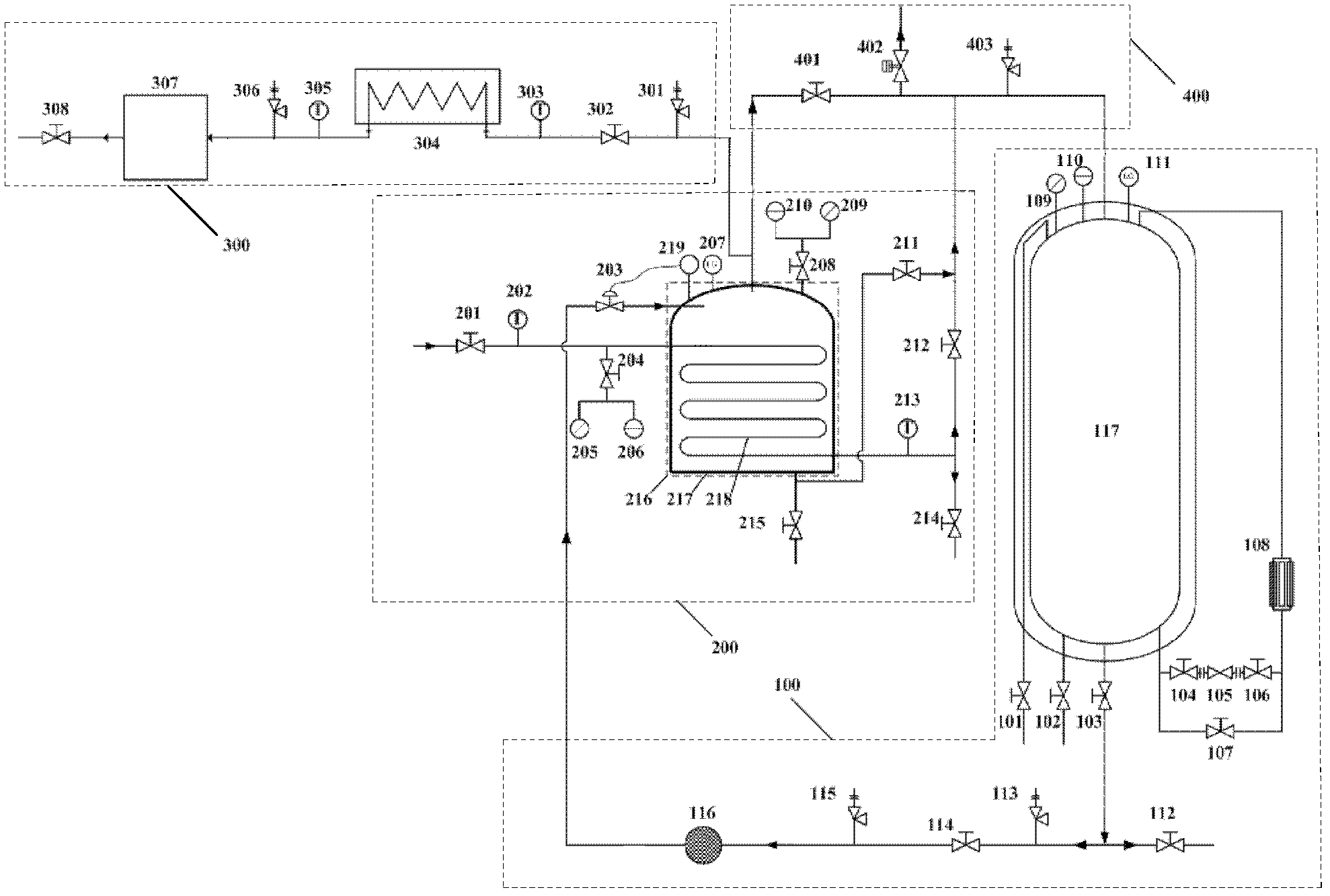

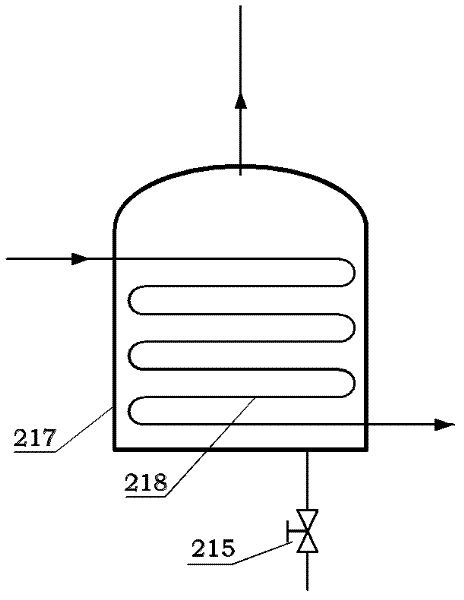

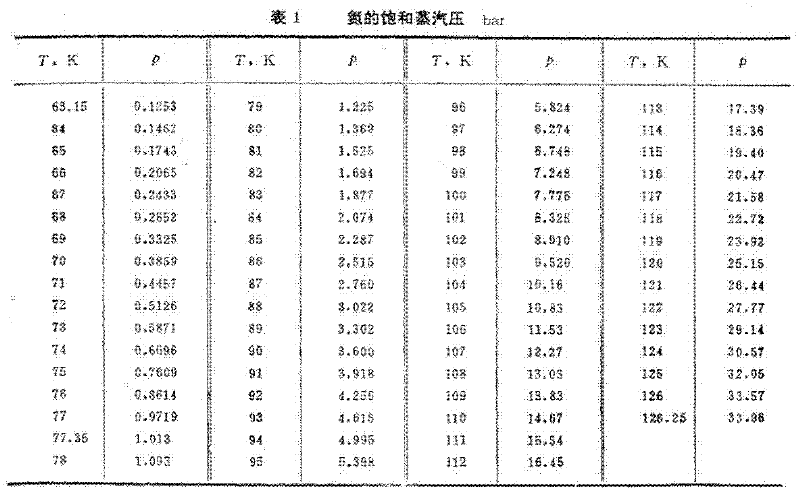

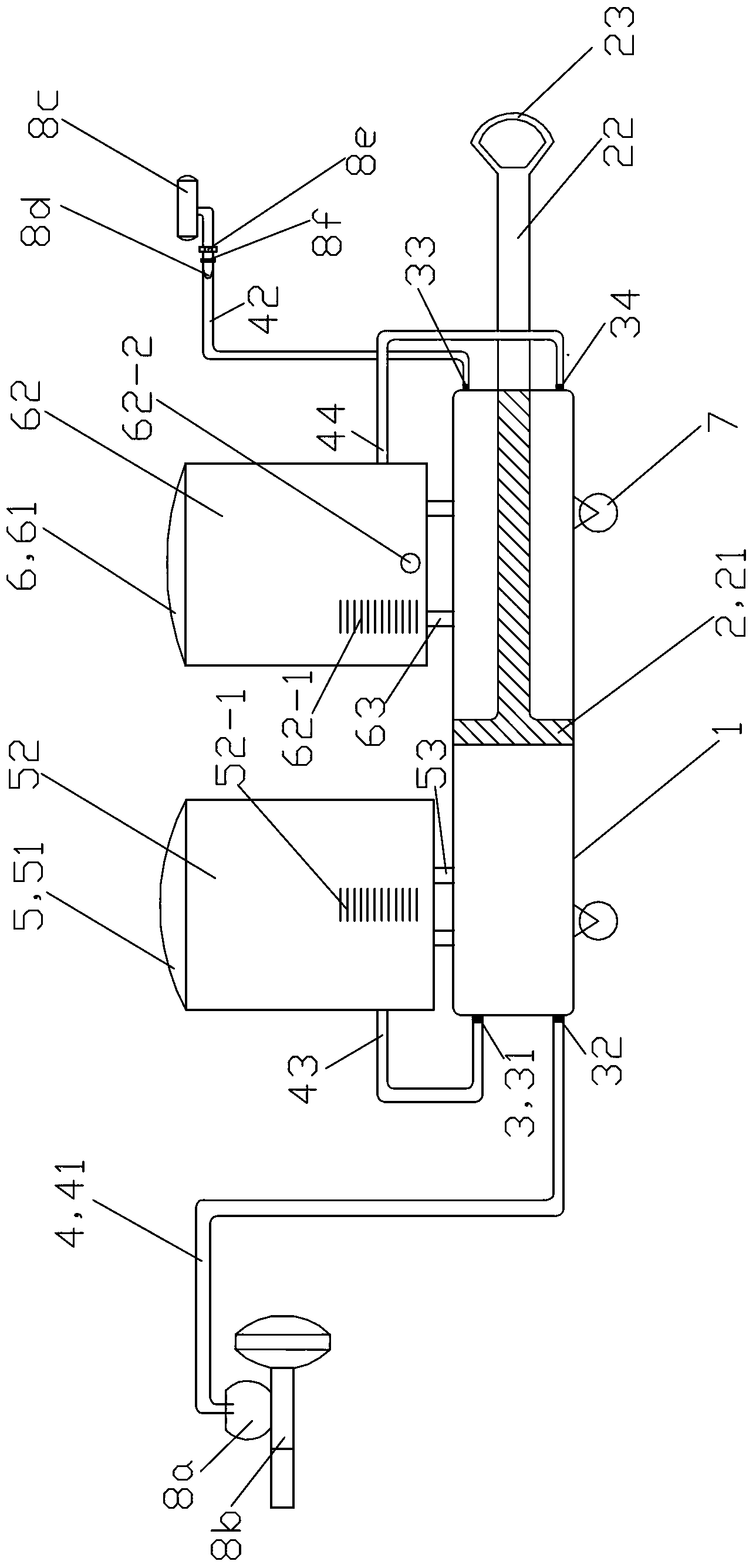

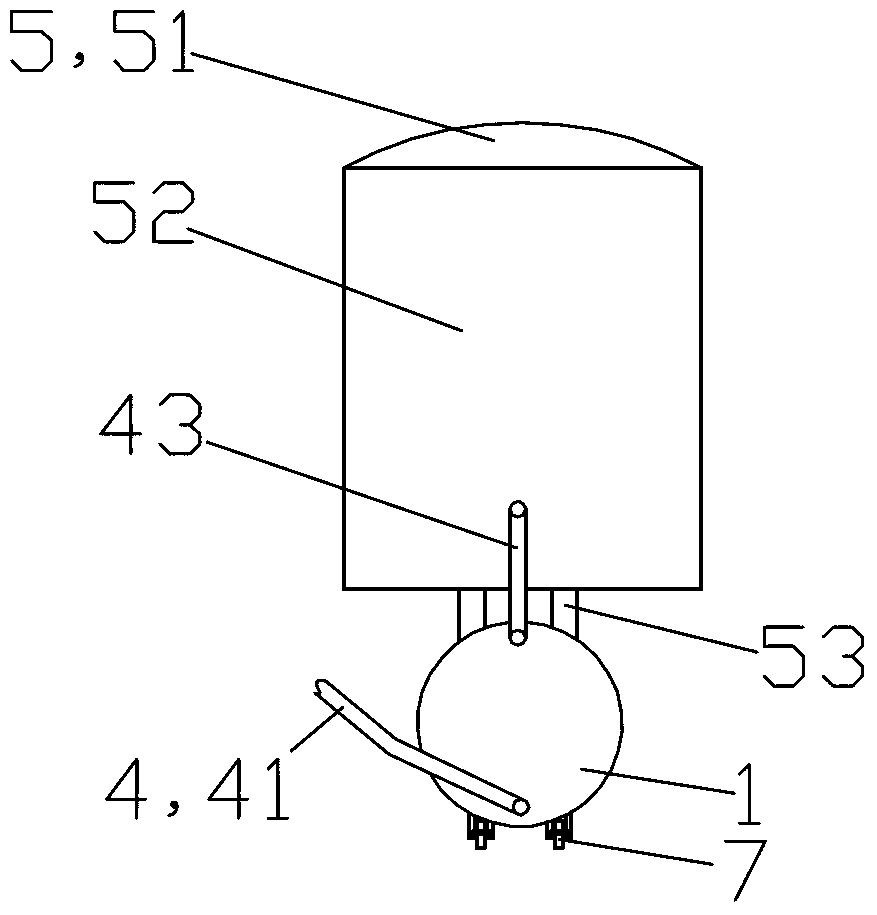

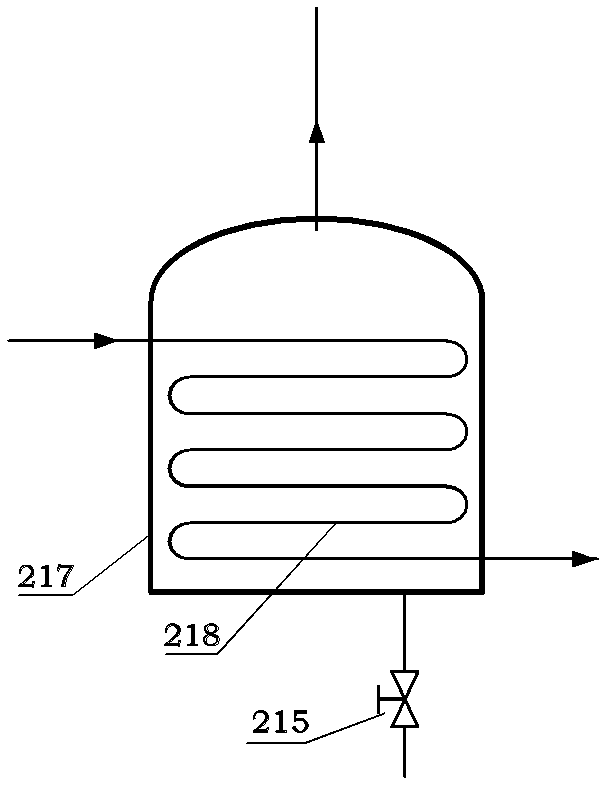

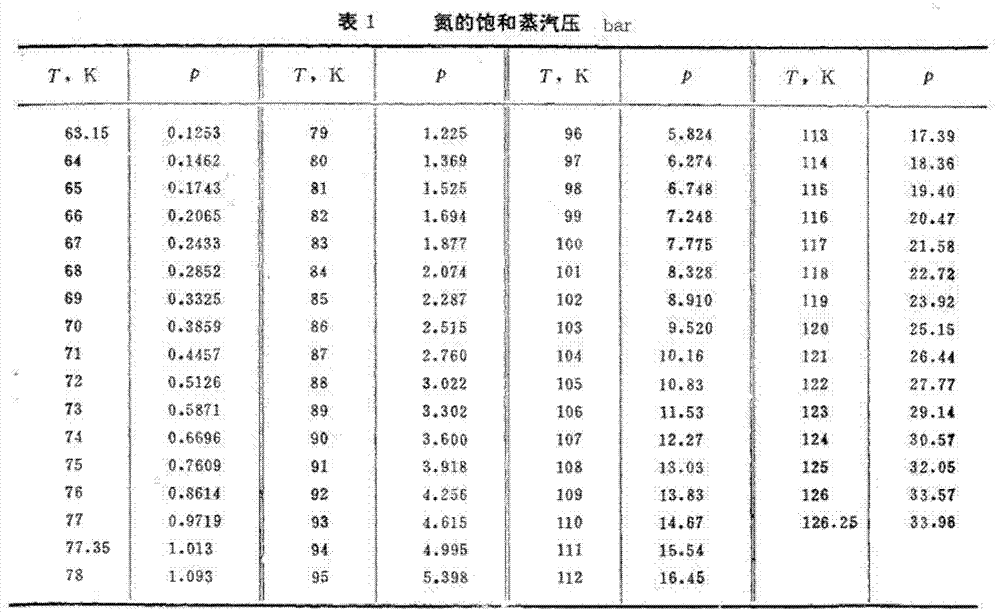

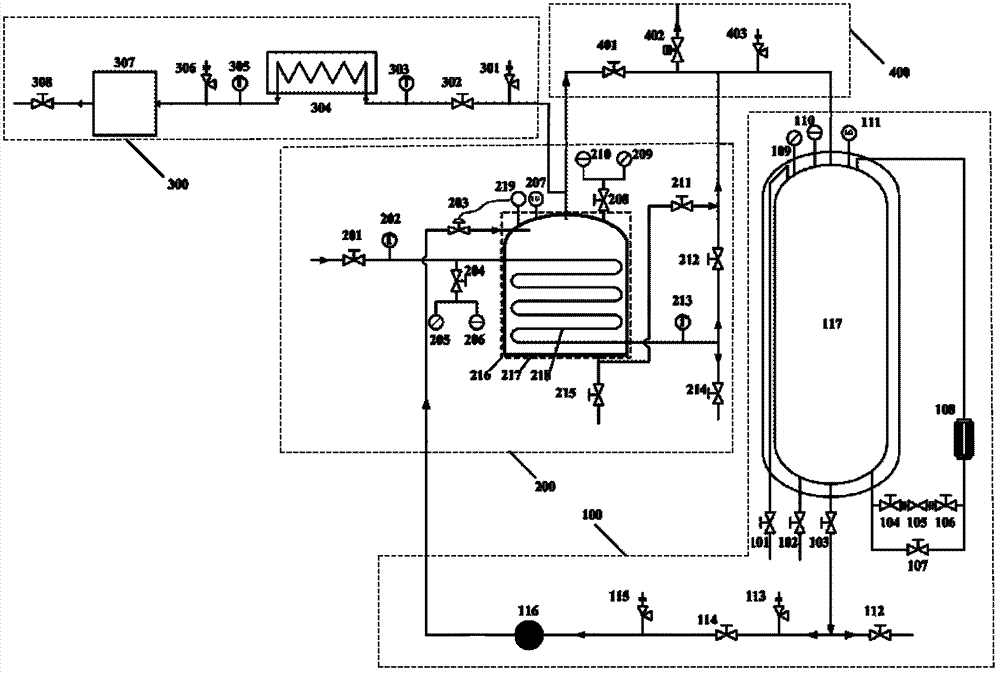

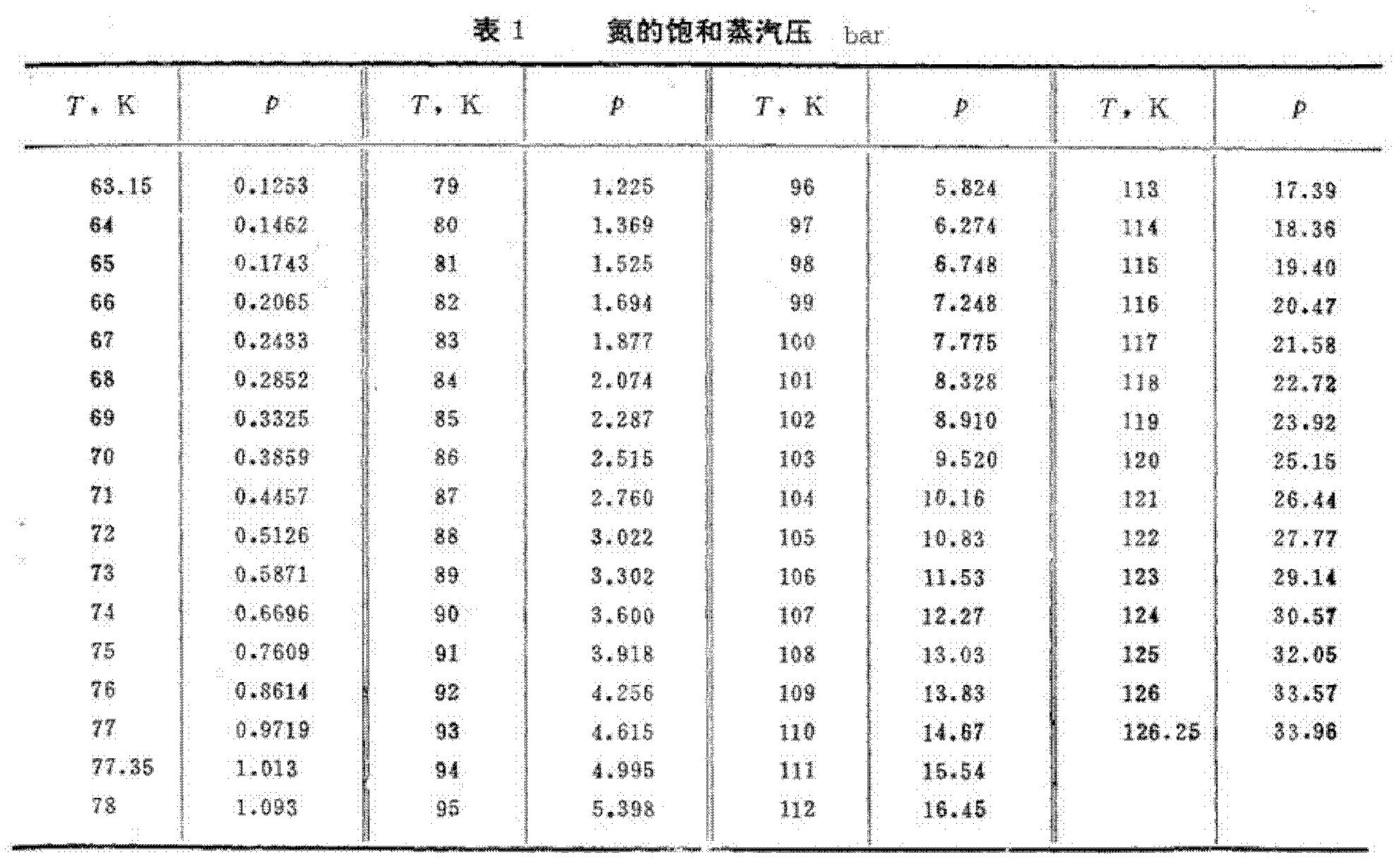

Negative-pressure liquid nitrogen subcooler and method therefore for reducing liquid nitrogen temperature

InactiveCN102374708ALower heat sink temperatureIncreased pumping capacity and efficiencySubcoolersChemistryHeat sink

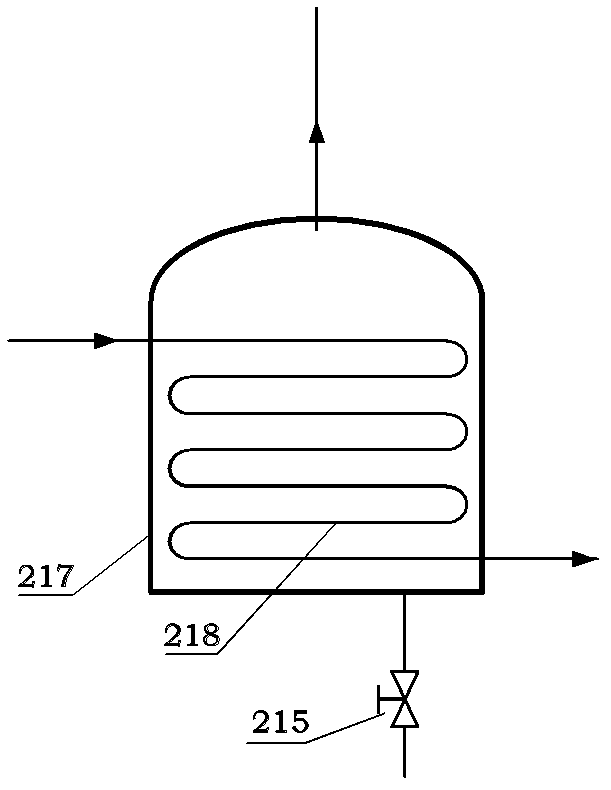

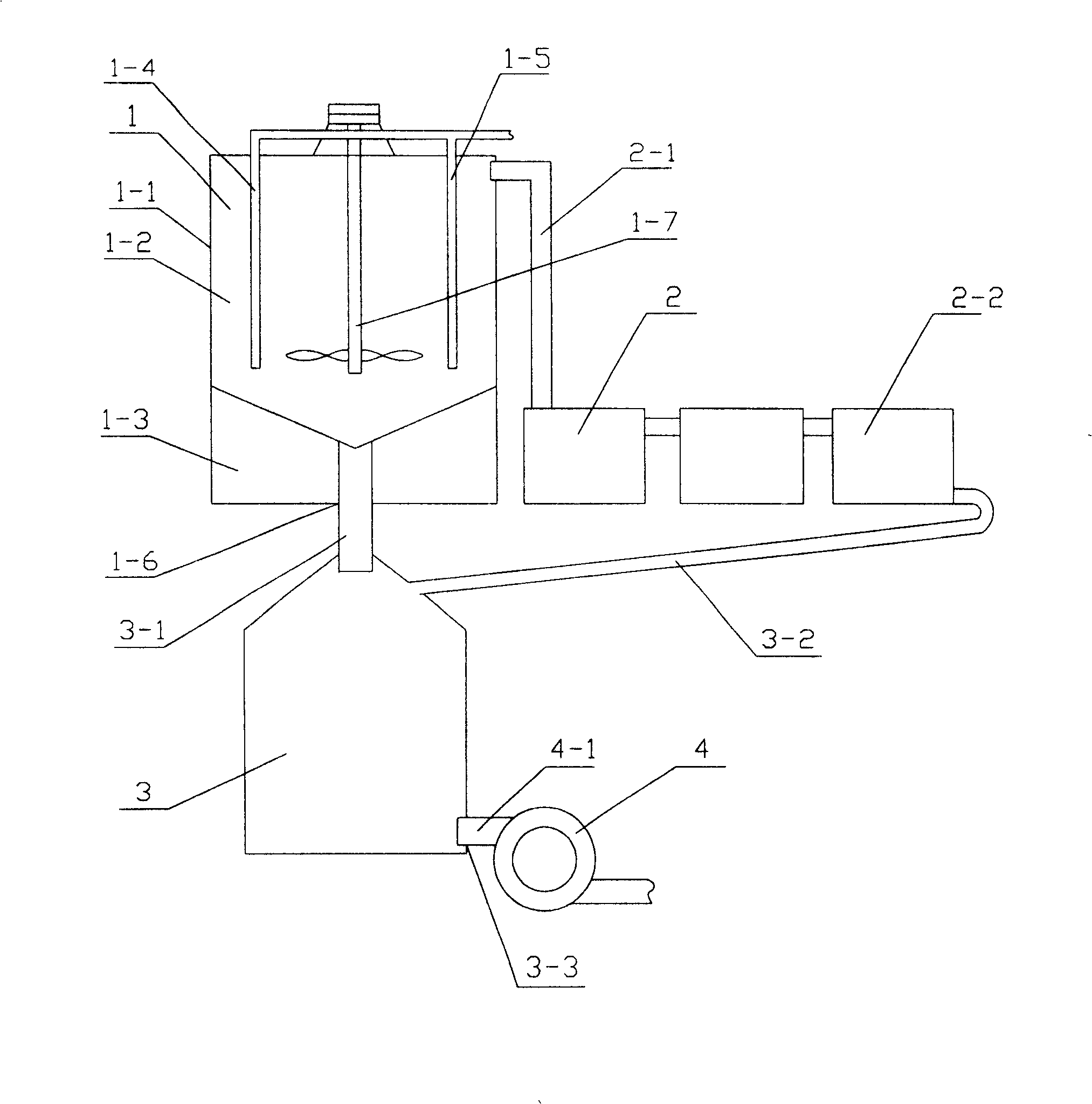

The invention provides a negative-pressure liquid nitrogen subcooler and a method therefore for reducing liquid nitrogen temperature. The negative-pressure liquid nitrogen subcooler comprises a liquid nitrogen conveying system, a subcooler system, a negative-pressure air exhausting system and a discharging system, wherein the liquid nitrogen conveying system is used for supplying liquid nitrogen to the subcooler system; the negative-pressure air exhausting system is used for reducing pressure for the subcooler; and the discharging system is used for discharging gasified nitrogen. In the negative-pressure liquid nitrogen subcooler, an electric heater is adopted to raise the temperature of gaseous nitrogen to 20-30 DEG C, so that the subcooler is not limited to the weathers; a liquid level sensor is adopted to automatically regulating the opening of a pneumatic regulating valve, so that the height of the liquid level is maintained. The method comprises the steps of: firstly, injecting the liquid nitrogen for a liquid nitrogen container and regulating pressure; then injecting the liquid nitrogen for the subcooler, wherein the height of the liquid level of the liquid nitrogen in the subcooler is kept constant; then starting the negative-pressure air exhausting system, and cooling the liquid nitrogen through a heat exchanger; and finally, recovering the liquid nitrogen and discharging the liquid nitrogen. According to the invention, the temperature of a heat sink can be further reduced, the temperature of the heat sink is regulatable within a range of 70-77k, and the advantagesof simple equipment, good effect and low operating cost are achieved.

Owner:BEIHANG UNIV

Negative-pressure liquid nitrogen subcooler and method for liquid nitrogen temperature reduction

InactiveCN102393107AImprove the pumping effectImprove efficiencySubcoolersLiquid nitrogen containerNitrogen

The invention relates to a negative-pressure liquid nitrogen subcooler and a method for liquid nitrogen temperature reduction. The negative-pressure liquid nitrogen subcooler is applied to the field of motor vacuum science and technology and comprises a liquid nitrogen conveying system, a subcooler system, a negative-pressure air exhaust system and a discharge system. Wherein the liquid nitrogen conveying system is used for providing liquid nitrogen for the subcooler system, the negative-pressure air exhaust system is provided with an air temperature type vaporizer which is used for reducing the pressure of the subcooler, gas and nitrogen are discharged by the discharge system, in the subcooler system, a pneumatic control valve is adjusted manually in a long-distance manner, so that liquid level of the liquid nitrogen in the subcooler is kept constant. The method comprises the following steps that: firstly, the liquid nitrogen is filled into a liquid nitrogen container, pressure is adjusted, the liquid nitrogen is filled into the subcooler, and the liquid level of the liquid nitrogen in the subcooler is kept constant; then, the negative-pressure air exhaust system is started, and the liquid nitrogen is cooled through a heat exchanger; at last, the liquid nitrogen is recycled and residual liquid is discharged. In the negative-pressure liquid nitrogen subcooler, defect that a constant-pressure liquid nitrogen subcooler only can provide the liquid nitrogen with the minimum temperature of 77 DEG C can be overcome, heat sink temperature can be further reduced, adjustable heat sink temperature between 70 DEG C and 77 DEG C can be achieved, equipment is simple, effect is good and cost is low.

Owner:BEIHANG UNIV

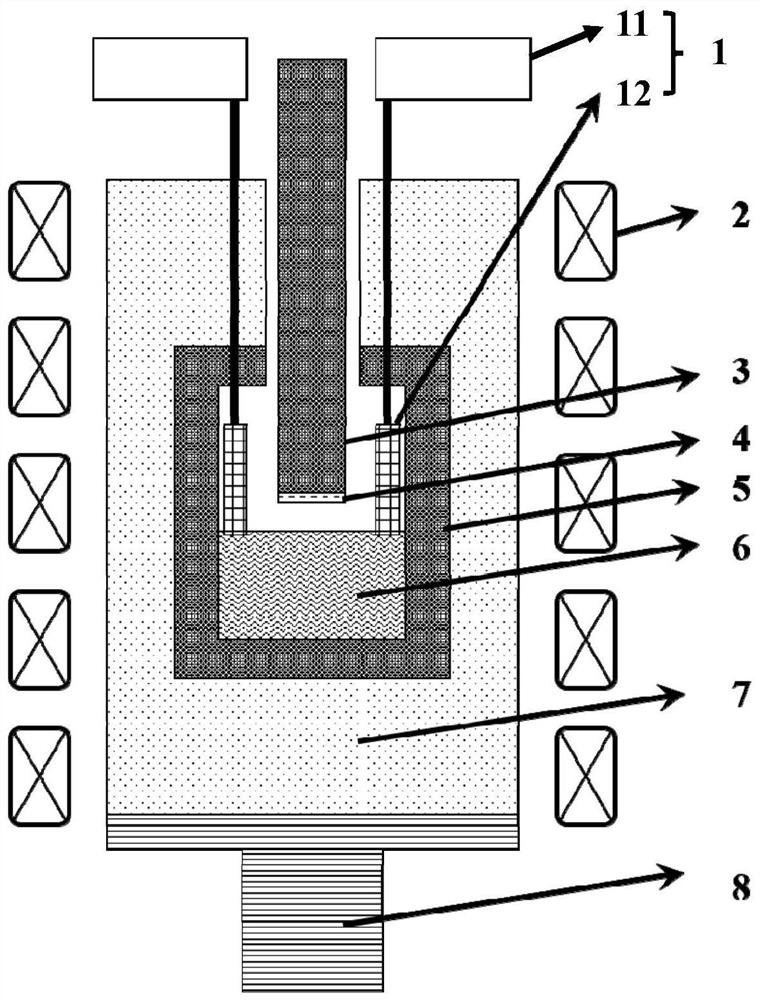

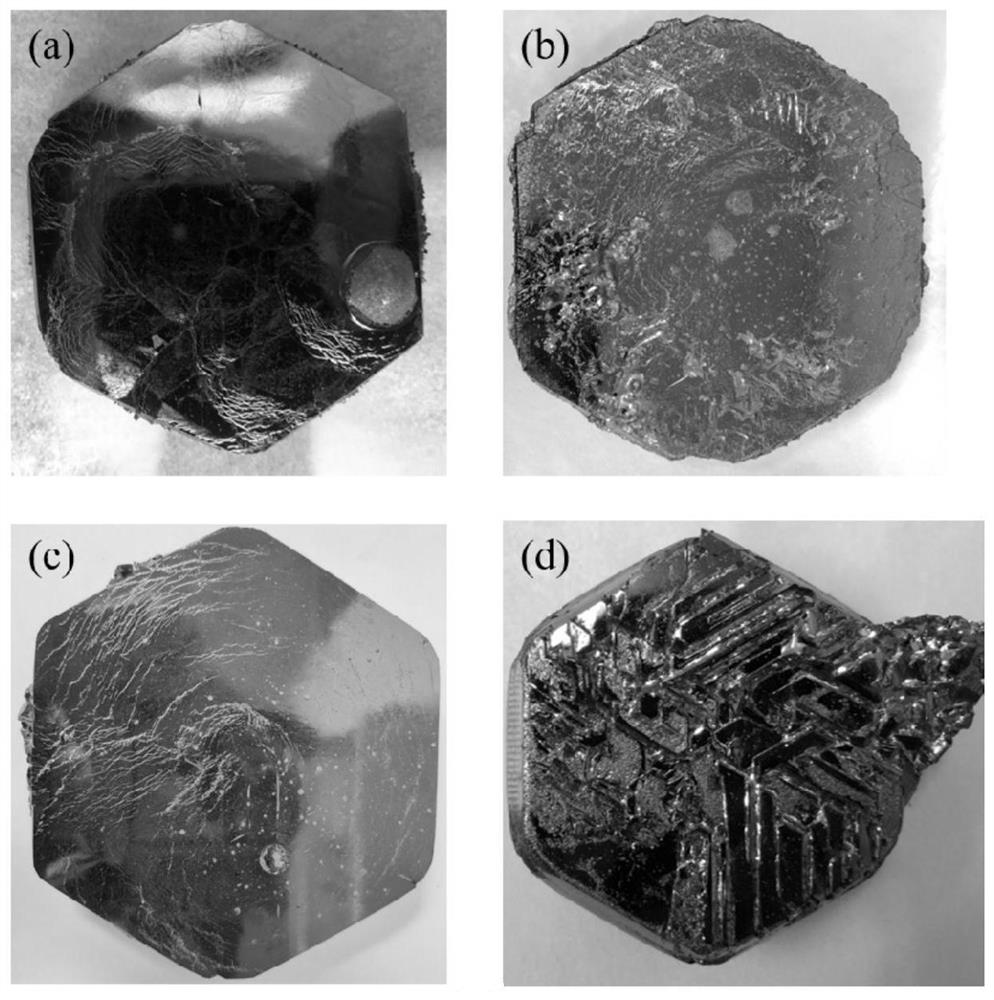

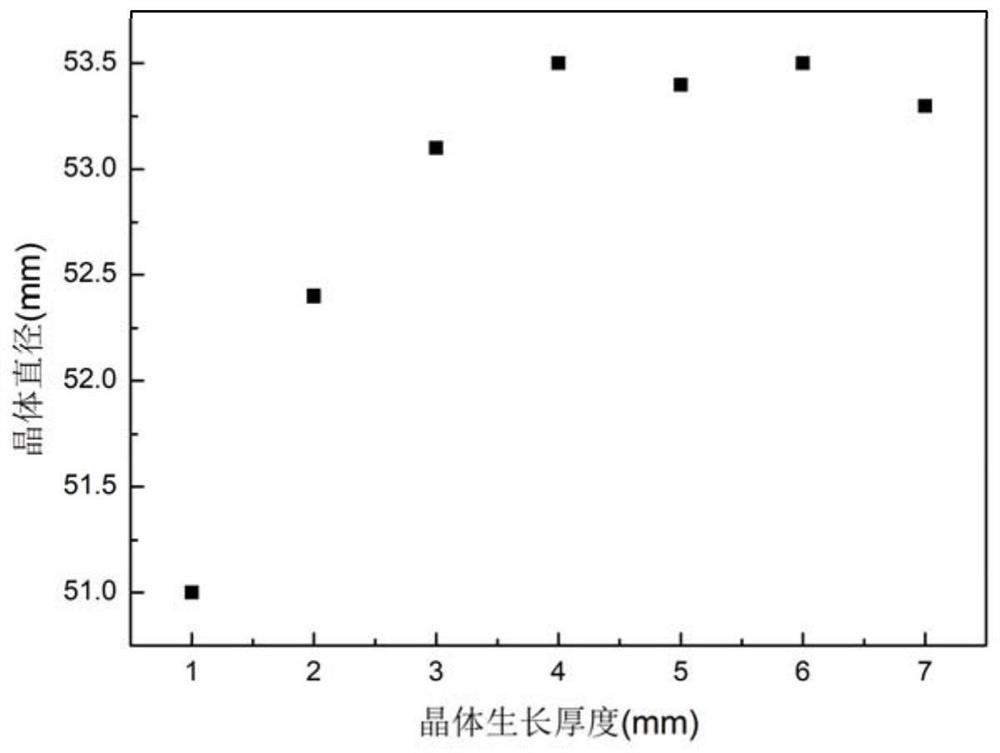

Device and method for growing silicon carbide crystals via liquid phase method

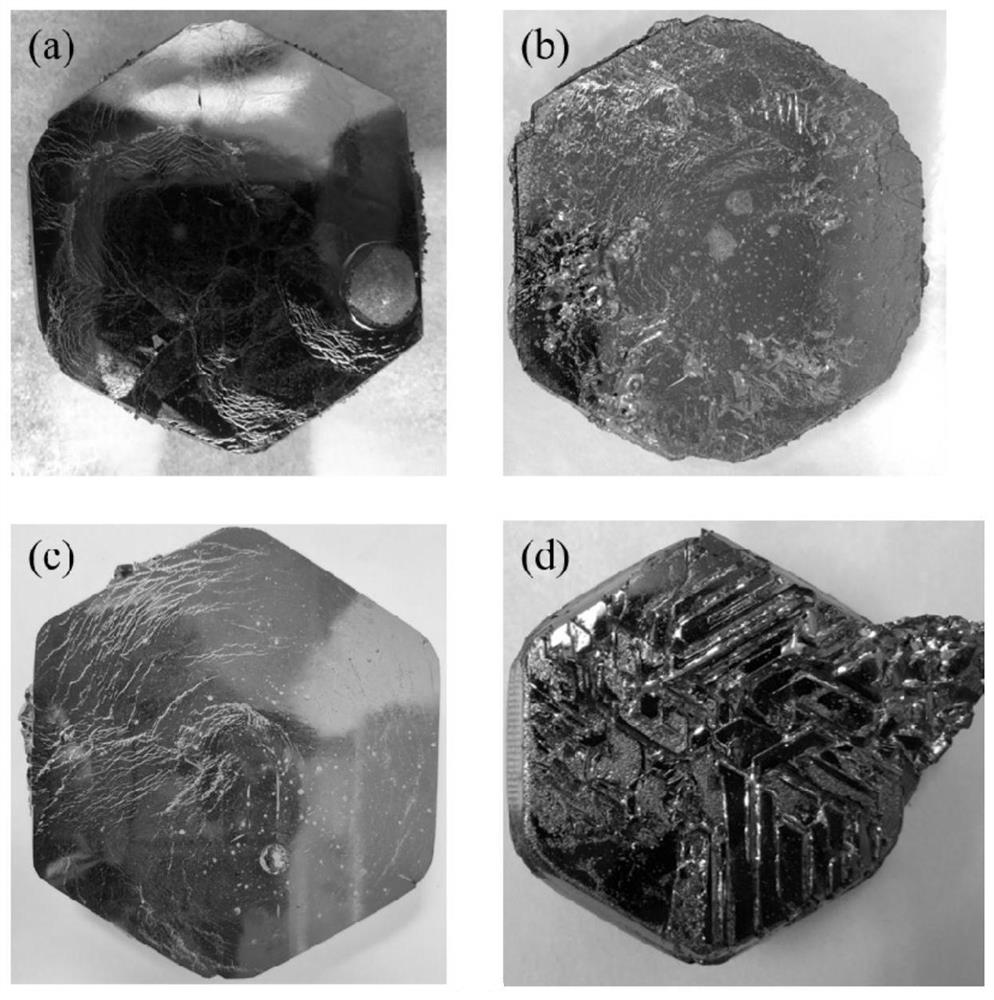

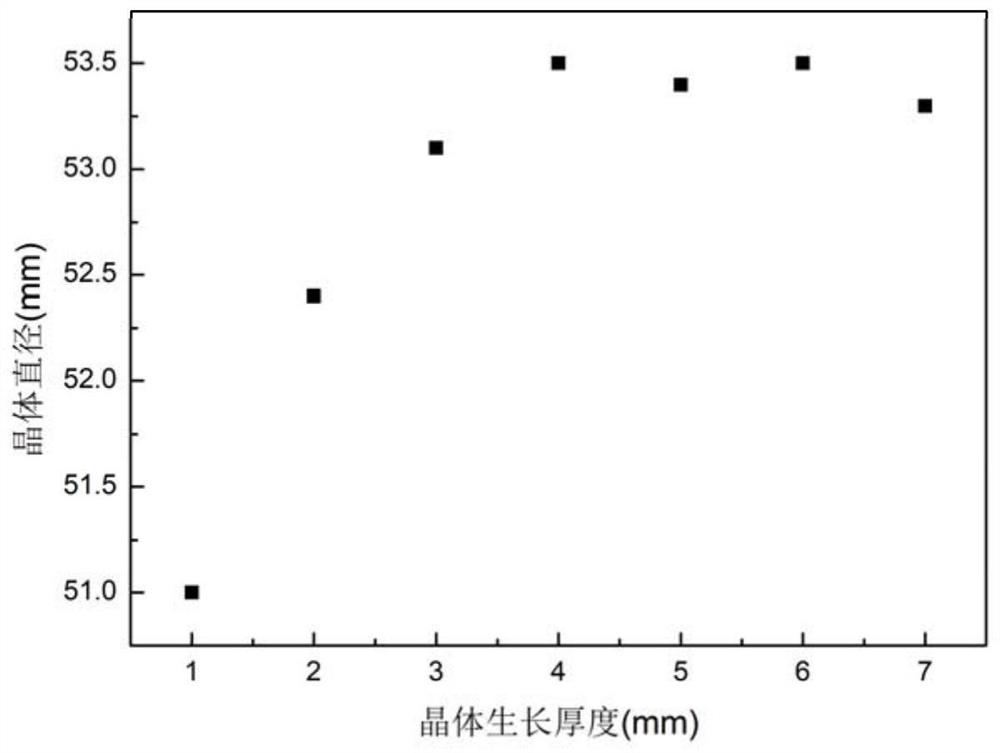

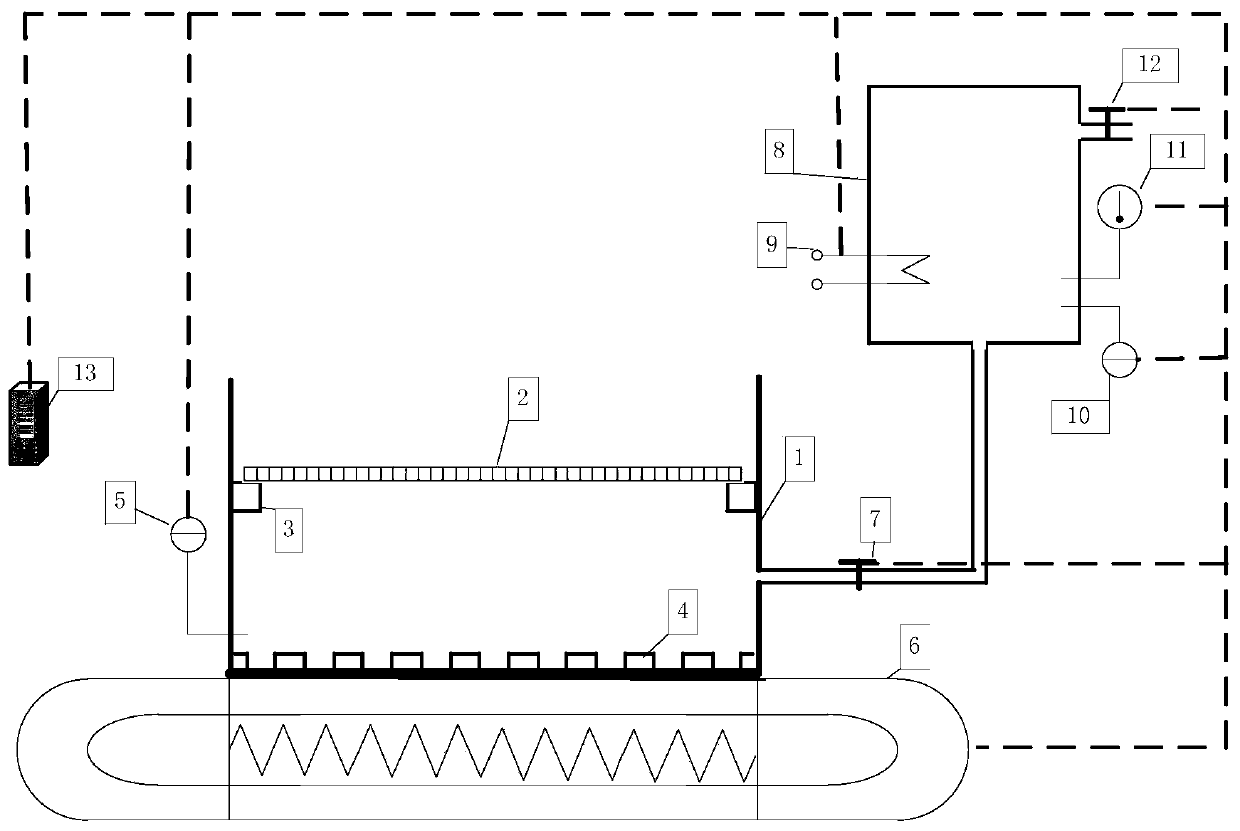

ActiveCN113718337AStable growthQuality improvementPolycrystalline material growthFrom melt solutionsCarbide siliconCrucible

The invention relates to a device and a method for growing silicon carbide crystals via a liquid phase method. The device comprises a crucible for accommodating a Si alloy assistant solution and a seed crystal rod for fixing a silicon carbide seed crystal; and the device further comprises a liquid level height keeping device, wherein the liquid level height keeping device comprises a circular liquid level keeping ring and a pushing device used for pushing the circular liquid level keeping ring to descend into the Si alloy assistant solution. The method comprises the following steps: melting a growth raw material containing Si and a metal simple substance into the Si alloy assistant solution; and lowering the silicon carbide seed crystal for contacting with the assistant solution to grow the silicon carbide crystals, wherein in the growth process of the silicon carbide crystals, the circular liquid level maintaining ring is pushed by the pushing device to descend into the Si alloy assistant solution so as to keep the liquid level height of the Si alloy assistant solution unchanged. According to the invention, the liquid level in the growth process of the silicon carbide crystals is not changed, a temperature field is kept constant, the stability of the assistant solution components can be kept, and the thickness of the generated silicon carbide crystals is improved.

Owner:北京晶格领域半导体有限公司

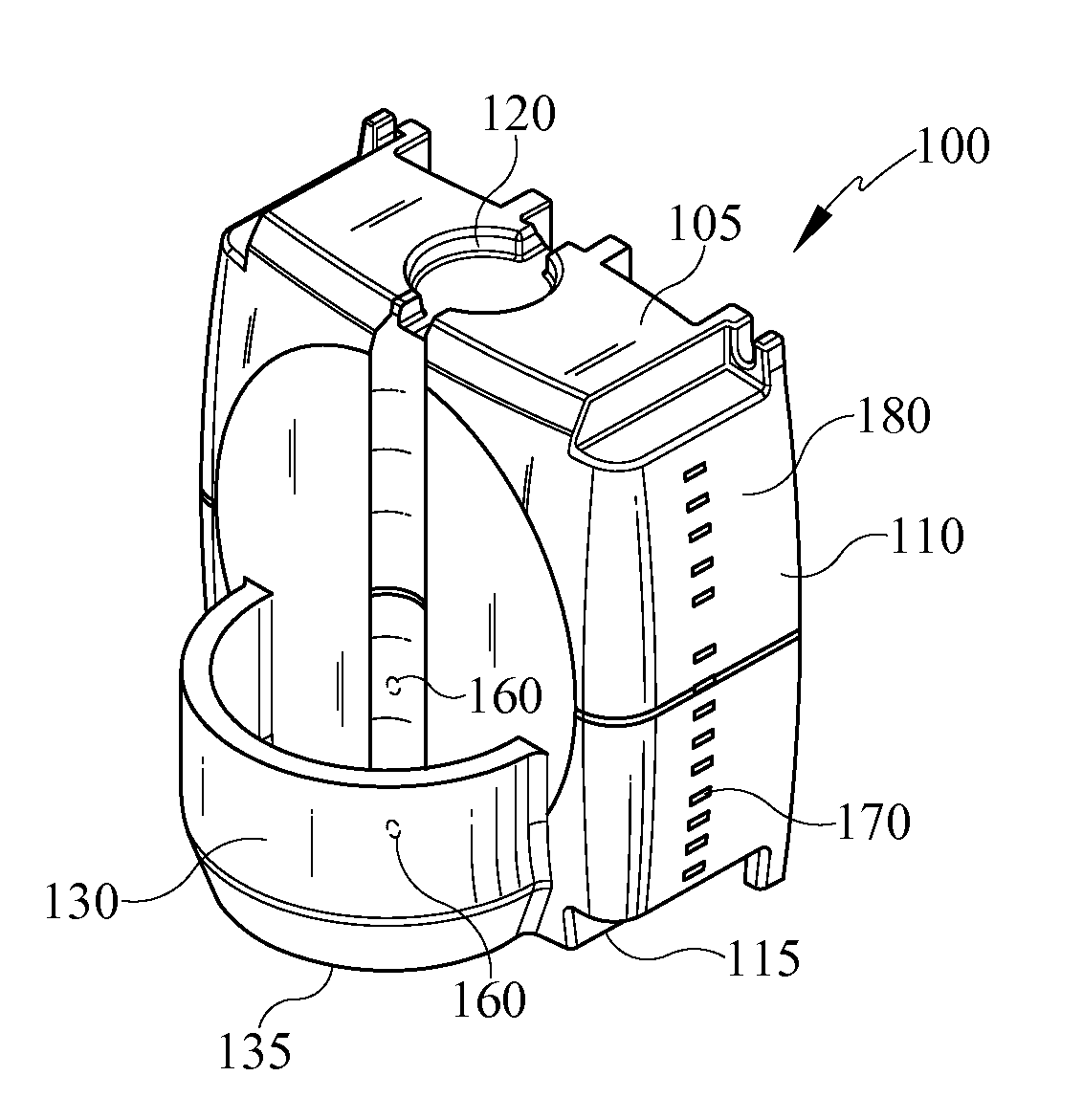

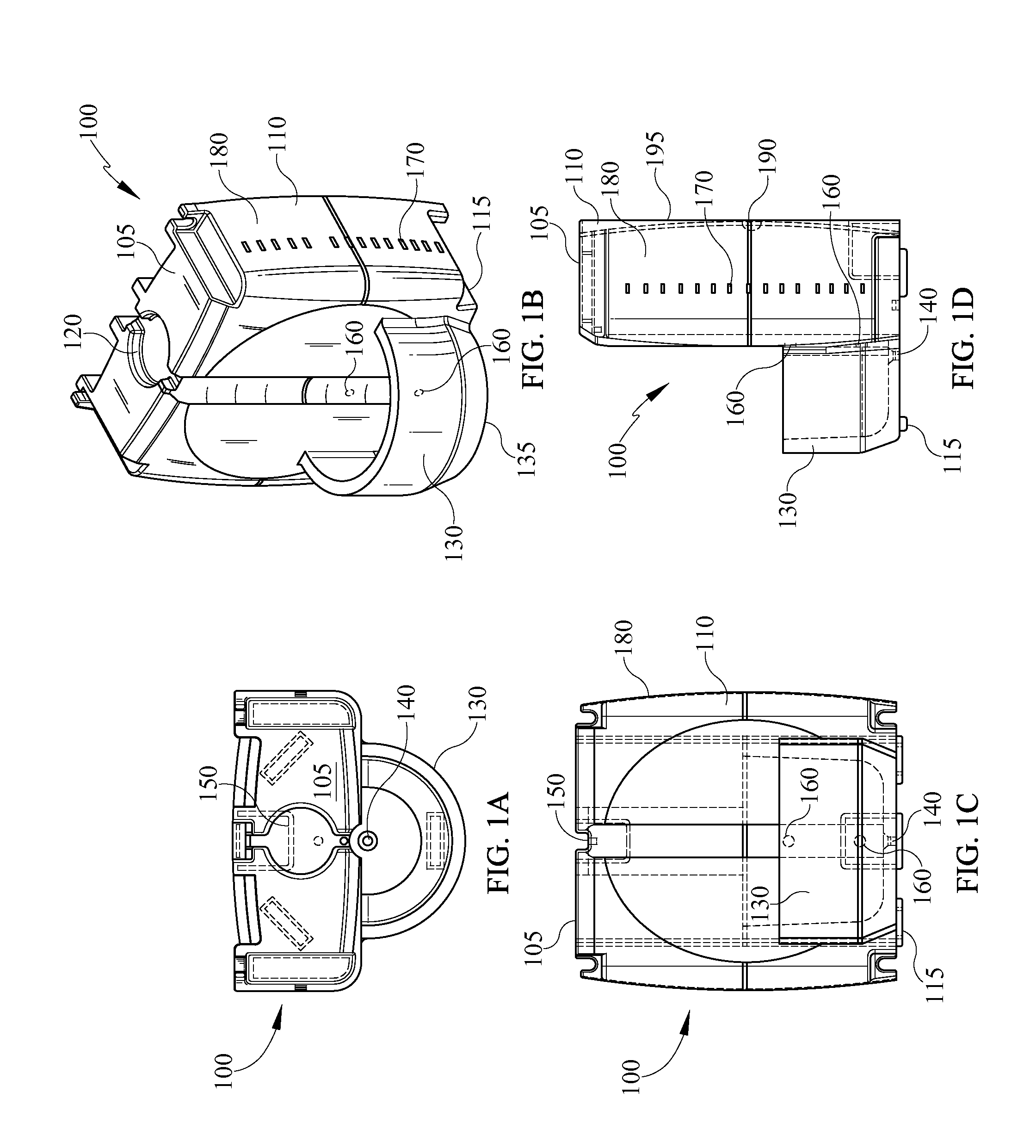

Livestock waterer

InactiveUS8161907B2Preventing the liquid from overflowingConstant liquid levelAnimal watering devicesEngineeringLivestock

A device and method designed to provide a continuous supply of liquid to livestock is presented. The one-piece device comprises a storage tank and a drinking bowl. The storage tank can have a filling access hole for filling the tank. The tank can have at least one drinking bowl access hole which allows access from the tank to the bowl. Both the filling access hole and the drinking bowl access holes can be opened and closed. While filling, the drinking bowl access hole can be closed. After filling, the filling access hole can be closed and the drinking bowl access hole can be opened allowing liquid to flow from the tank into the bowl. Gravity and air pressure within the tank maintain a constant liquid level in the bowl while simultaneously preventing liquid from overflowing the bowl. A heating element can be placed into the tank to prevent freezing.

Owner:DOUBLE C RANCH SUPPLY

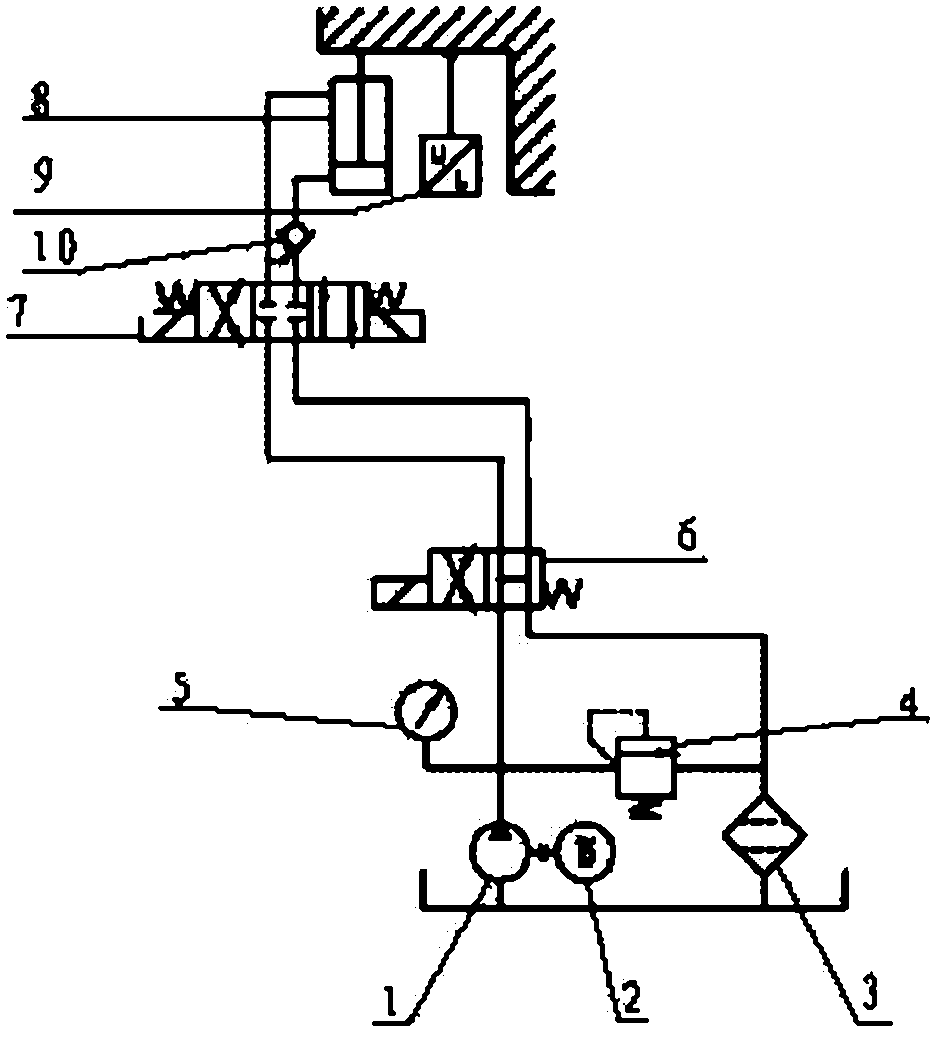

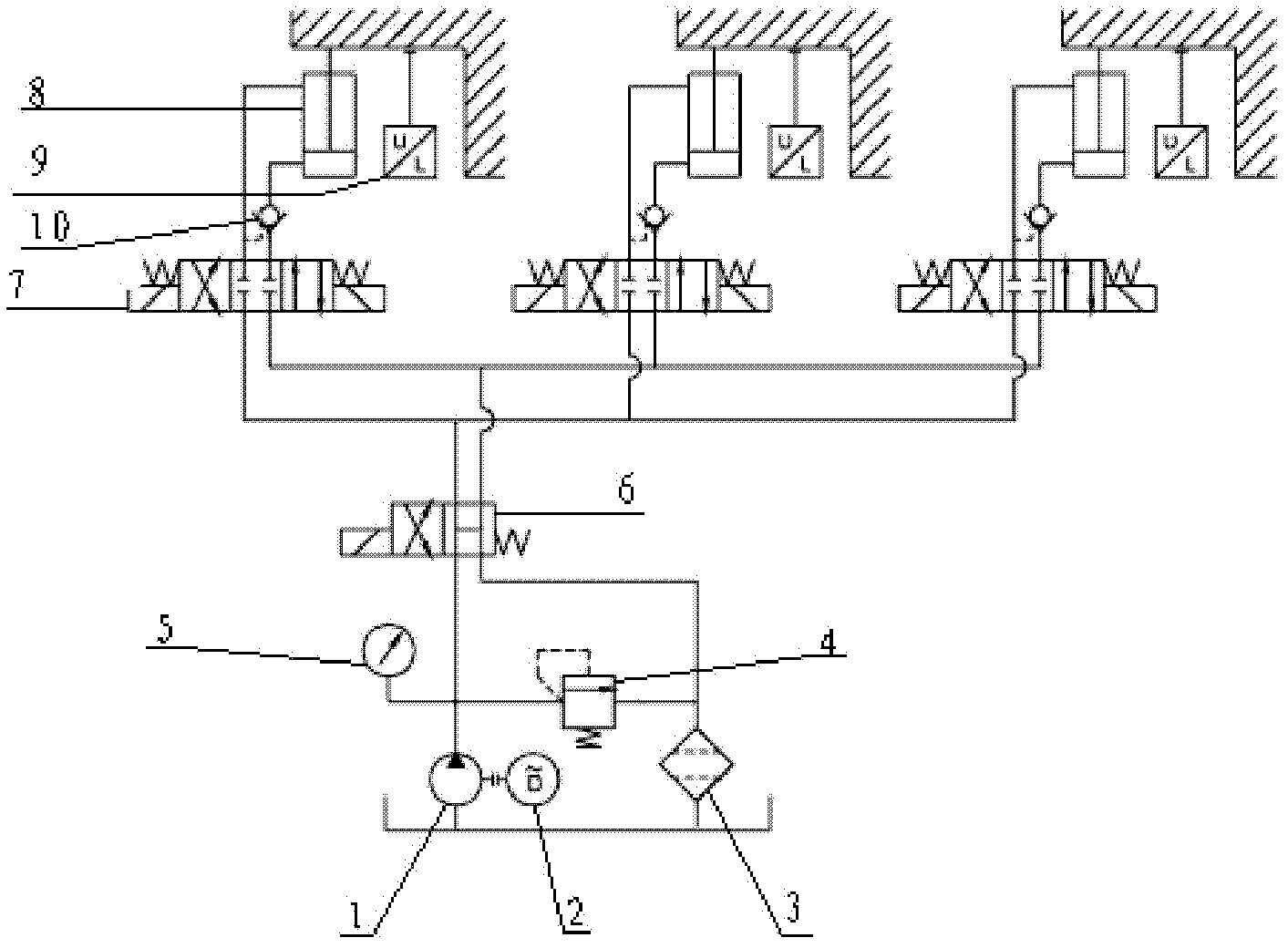

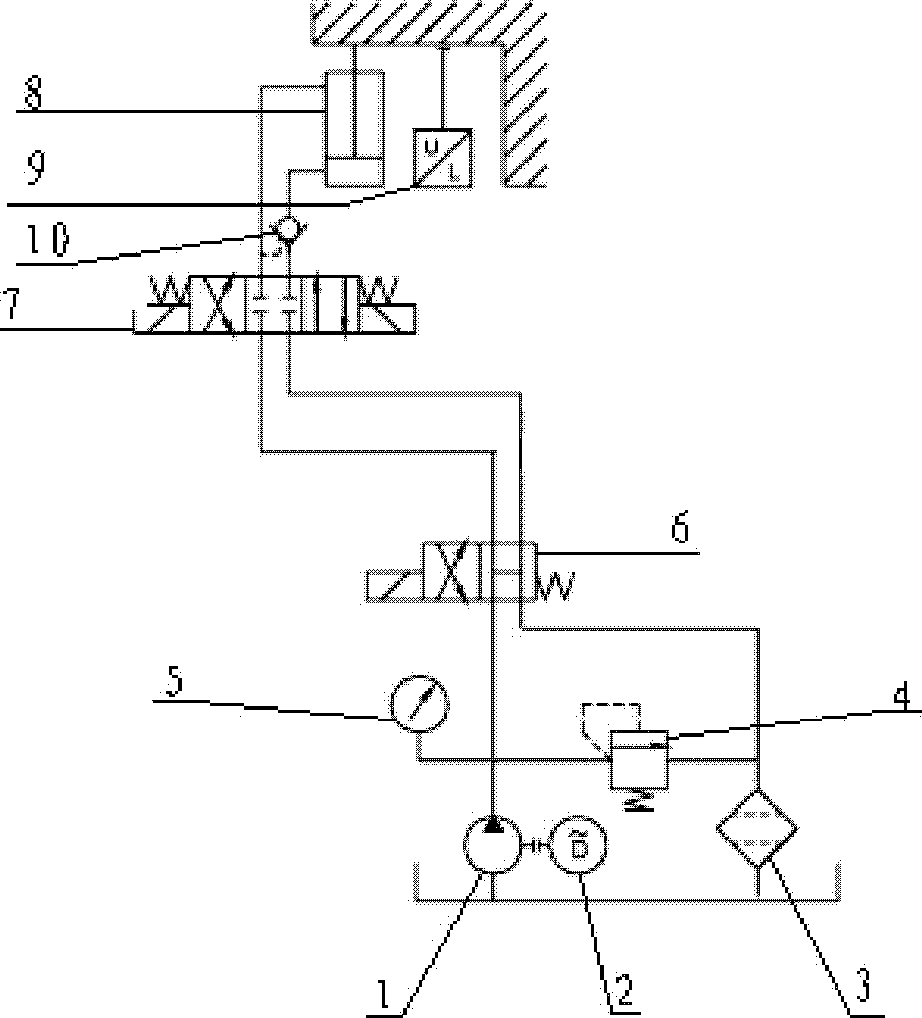

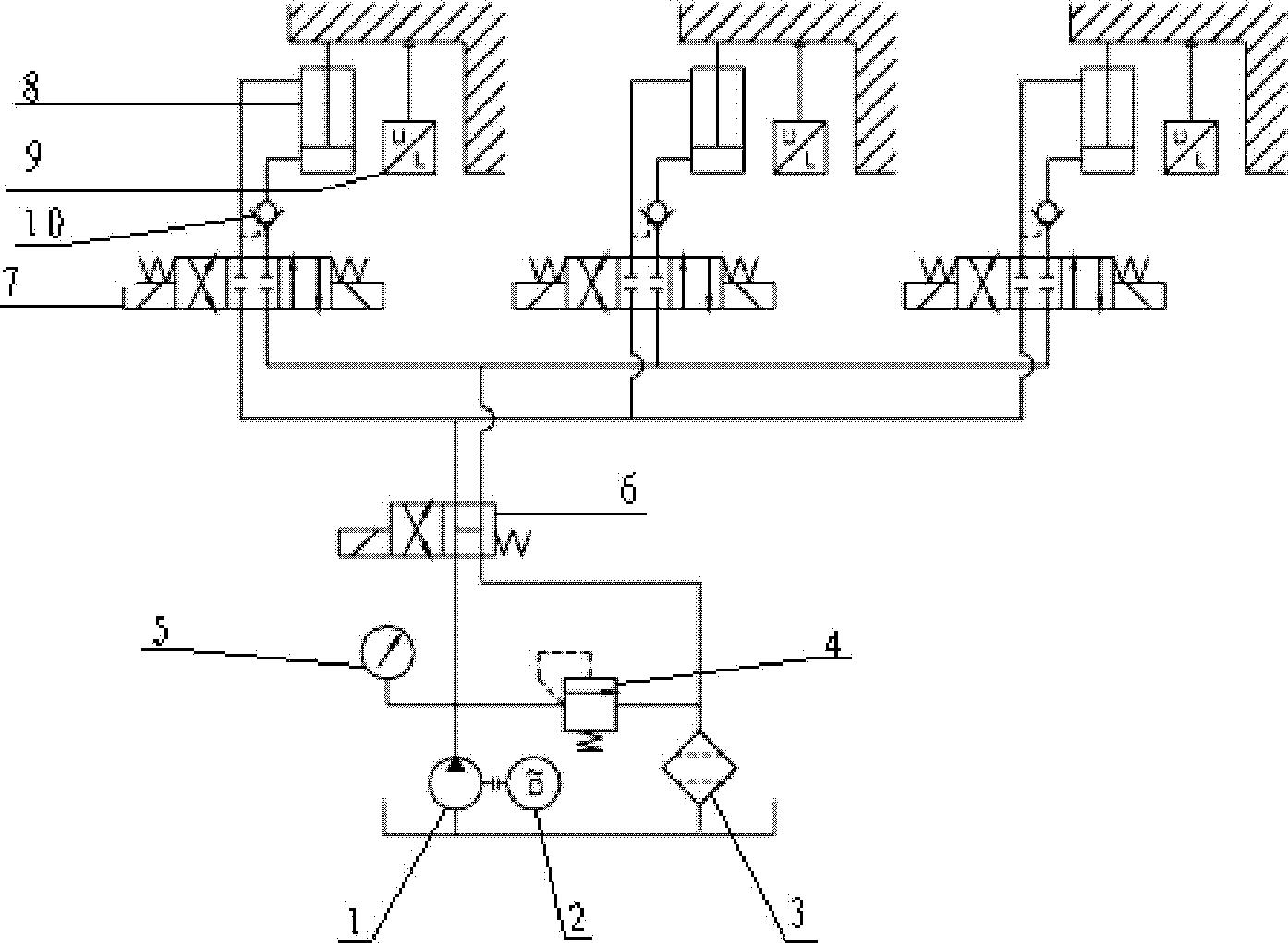

Brake fluid replacing device and working method thereof

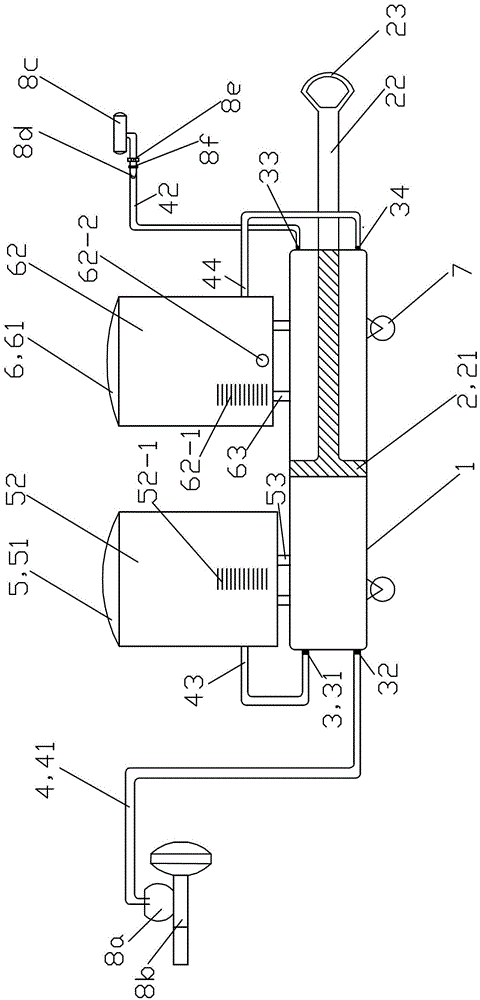

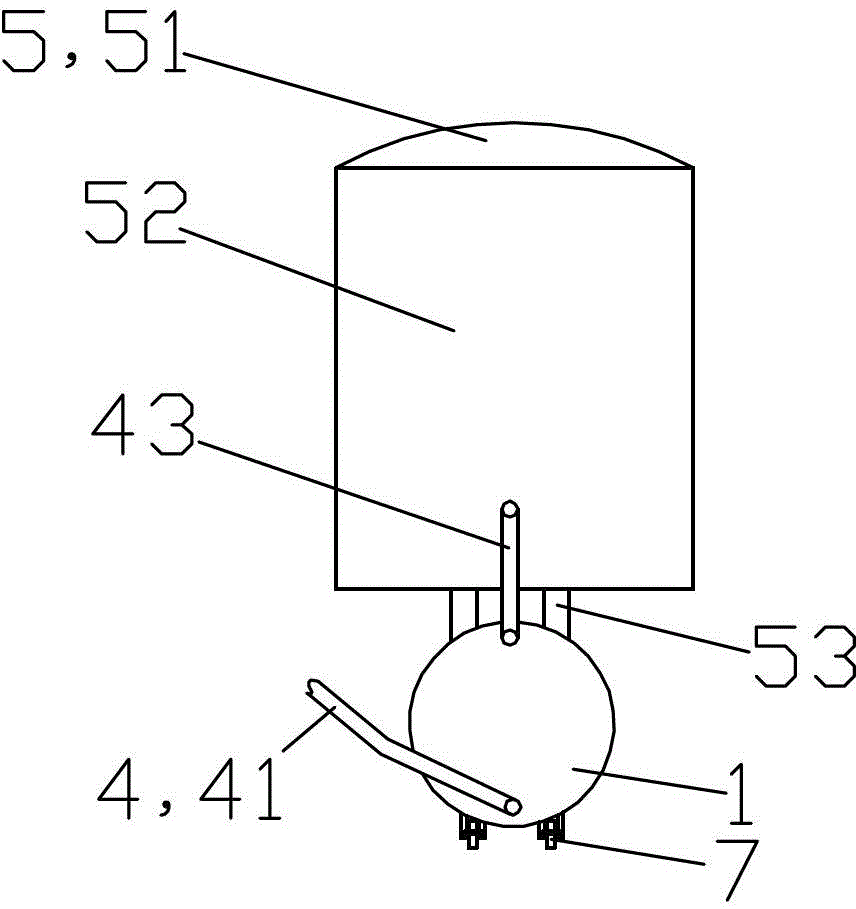

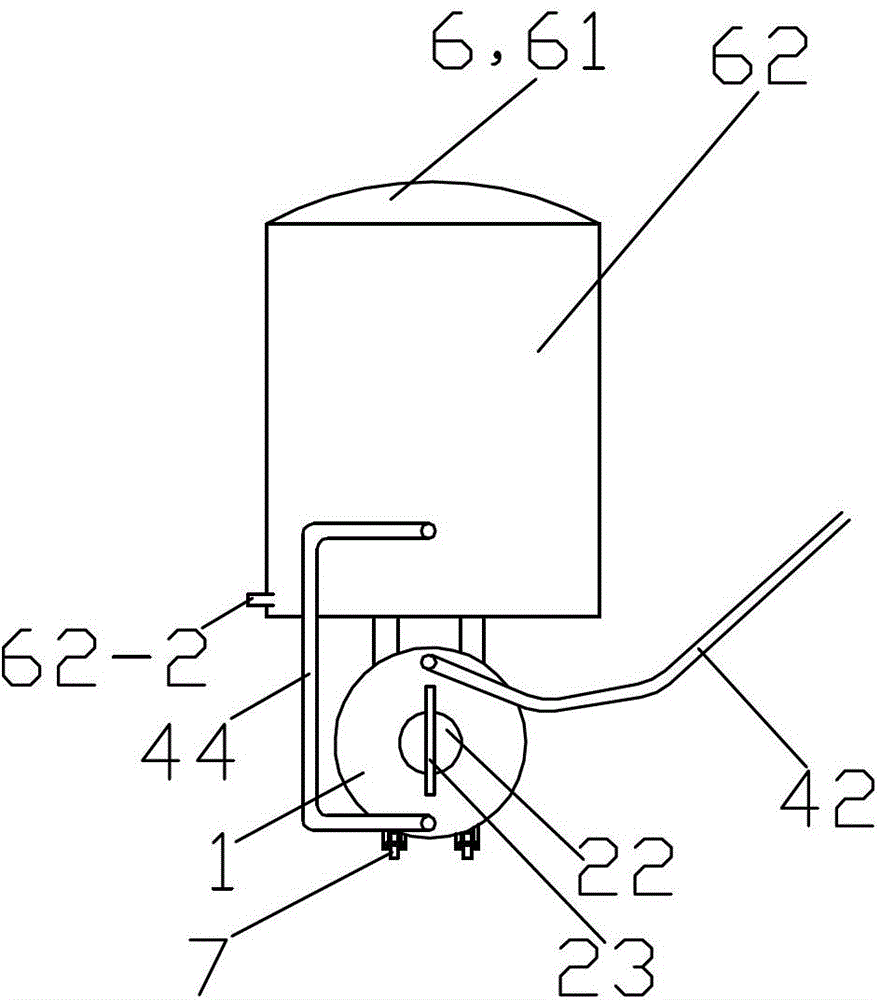

InactiveCN103241222ASimple structureLow costVehicle servicing/repairingAutomotive engineeringPiston cylinder

The invention provides a brake fluid replacing device. The brake fluid replacing device comprises a piston cylinder body, a piston assembly, a one-way valve assembly, a communicating pipe assembly, a brake fluid barrel, a waste liquid barrel and an idler wheel, wherein the piston cylinder body uses the one-way valve assembly and the communicating pipe assembly through a piston, sucks new hydraulic drive fluid in the brake fluid barrel, and pushes the new hydraulic drive fluid into a brake fluid storage pot of a car, and simultaneously, the piston cylinder body achieves replacement of waste brake fluid by sucking the waste brake fluid in a car brake wheel cylinder through the piston and pushing the waste brake fluid into the waste liquid barrel. The brake fluid barrel and the waste liquid barrel are fixedly installed at the upper end of the piston cylinder body through supports, and the idler wheel is fixedly installed below the piston cylinder body. A working method of the brake fluid replacing device is a negative pressure suction method. The brake fluid replacing device is simple in structure and low in cost, effectively guarantees that no air enters into a brake pipeline system during the brake fluid replacing process, and therefore can not reduce brake performance of the car, facilitates judging whether a brake pipeline leaks or not, is convenient to replace and operate, and saves manpower and material resources.

Owner:JIANGSU UNIVERSITY OF TECHNOLOGY

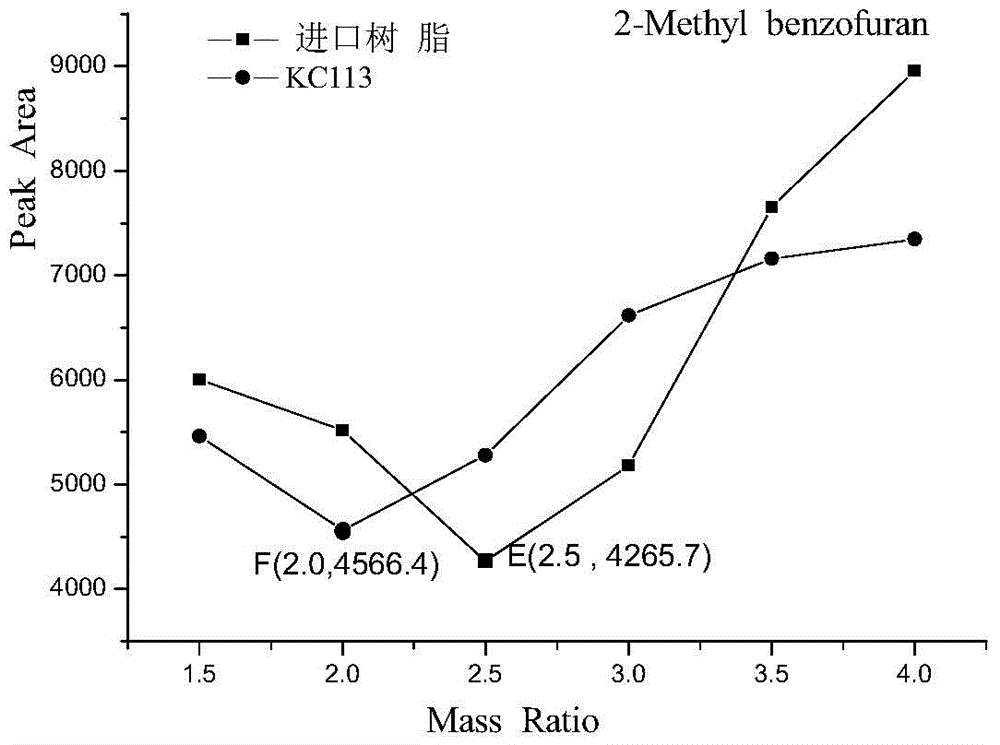

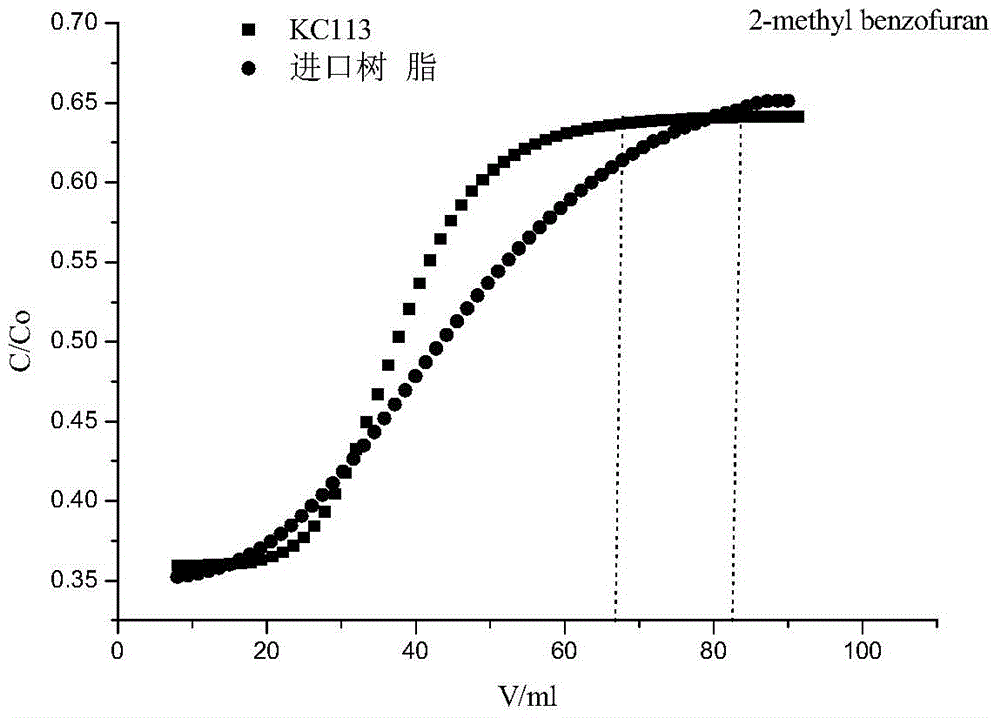

An evaluating method for resin adsorption performance in a phenol refining process

InactiveCN104483397ANormal adsorptionWon't freezeComponent separationSolid-phase microextractionGas phase

The invention belongs to the technical field of resin evaluation, and mainly relates to an evaluating method for resins in a phenol refining process. The evaluating method mainly relates to evaluation of adsorption performance of two resins. Firstly, the total ion-exchange capacity of each resin is measured, and then the adsorption performance of each of the resins is evaluated by utilization of static adsorption and dynamic adsorption methods. A method combining headspace solid-phase microextraction and gas chromatography is utilized for measuring impurity contents in phenol in the whole evaluating process. The evaluating method is simple in operation and comprehensive in applications, can be used for evaluation of all resins in industrial applications, and has a good using prospect in the field of fine chemicals.

Owner:JILIN INST OF CHEM TECH

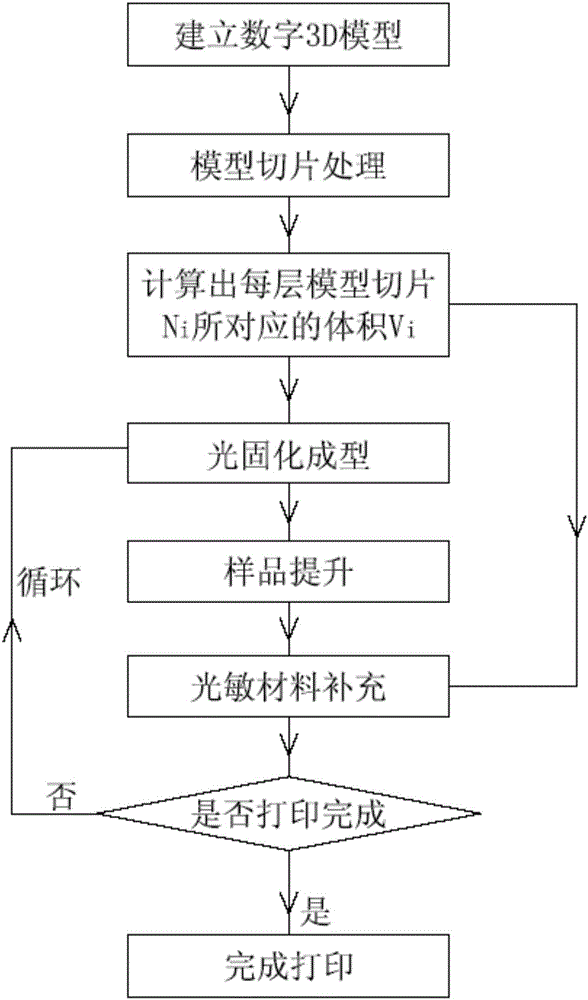

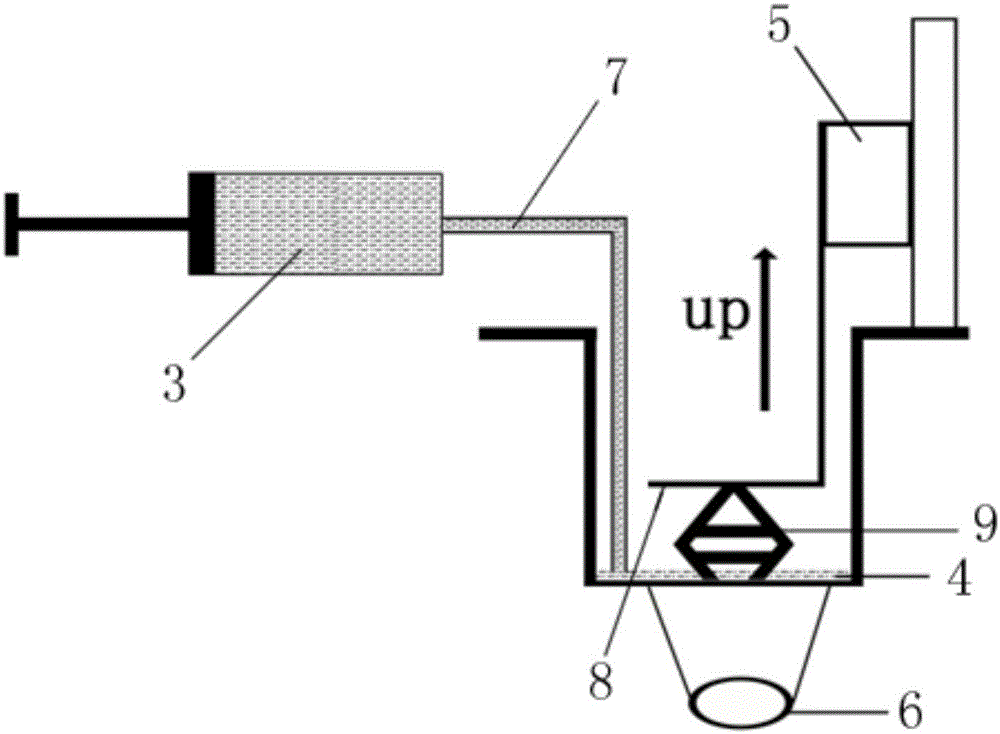

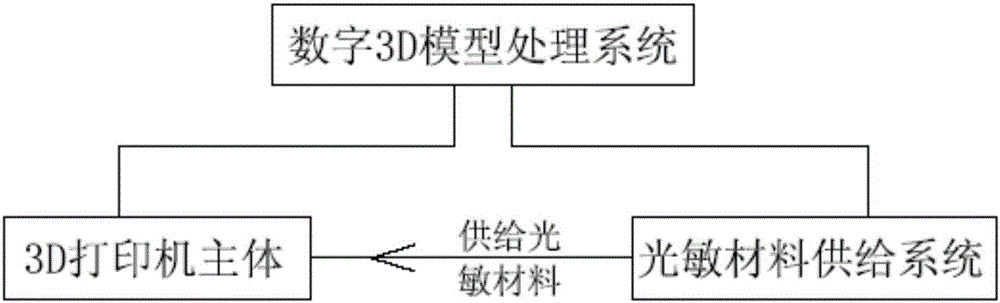

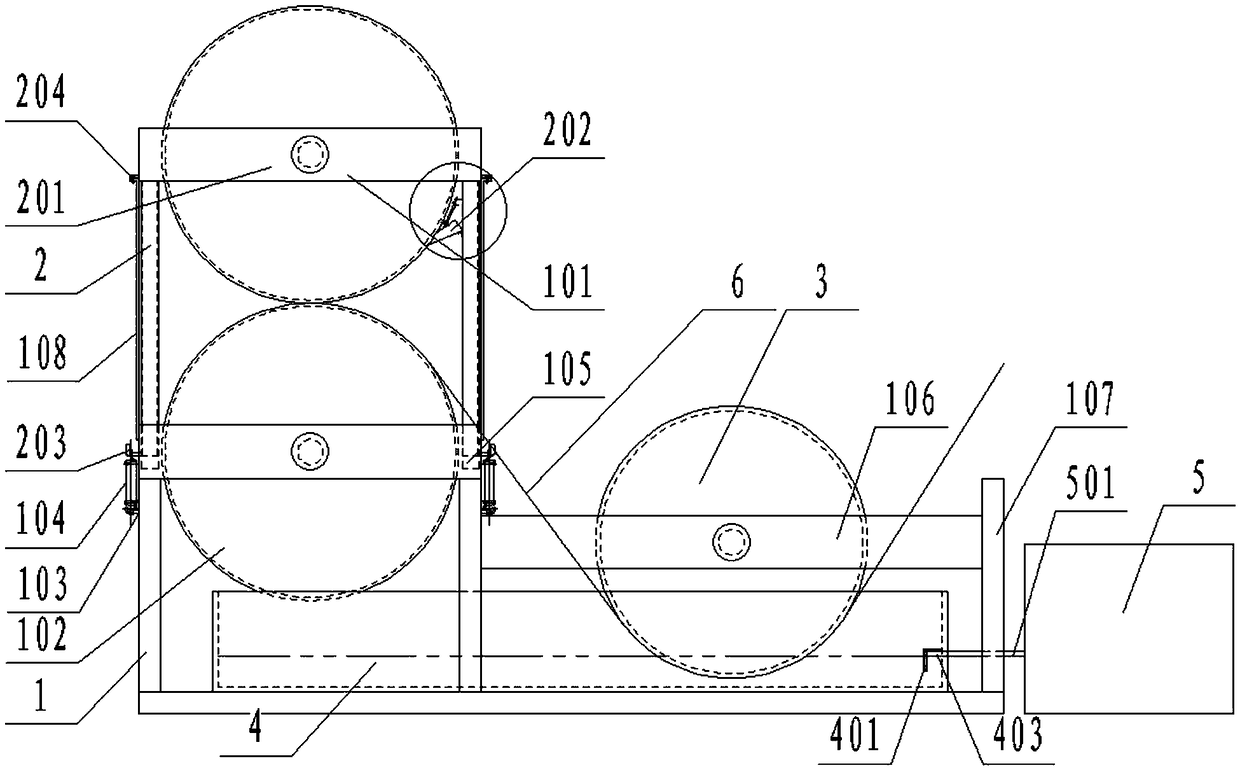

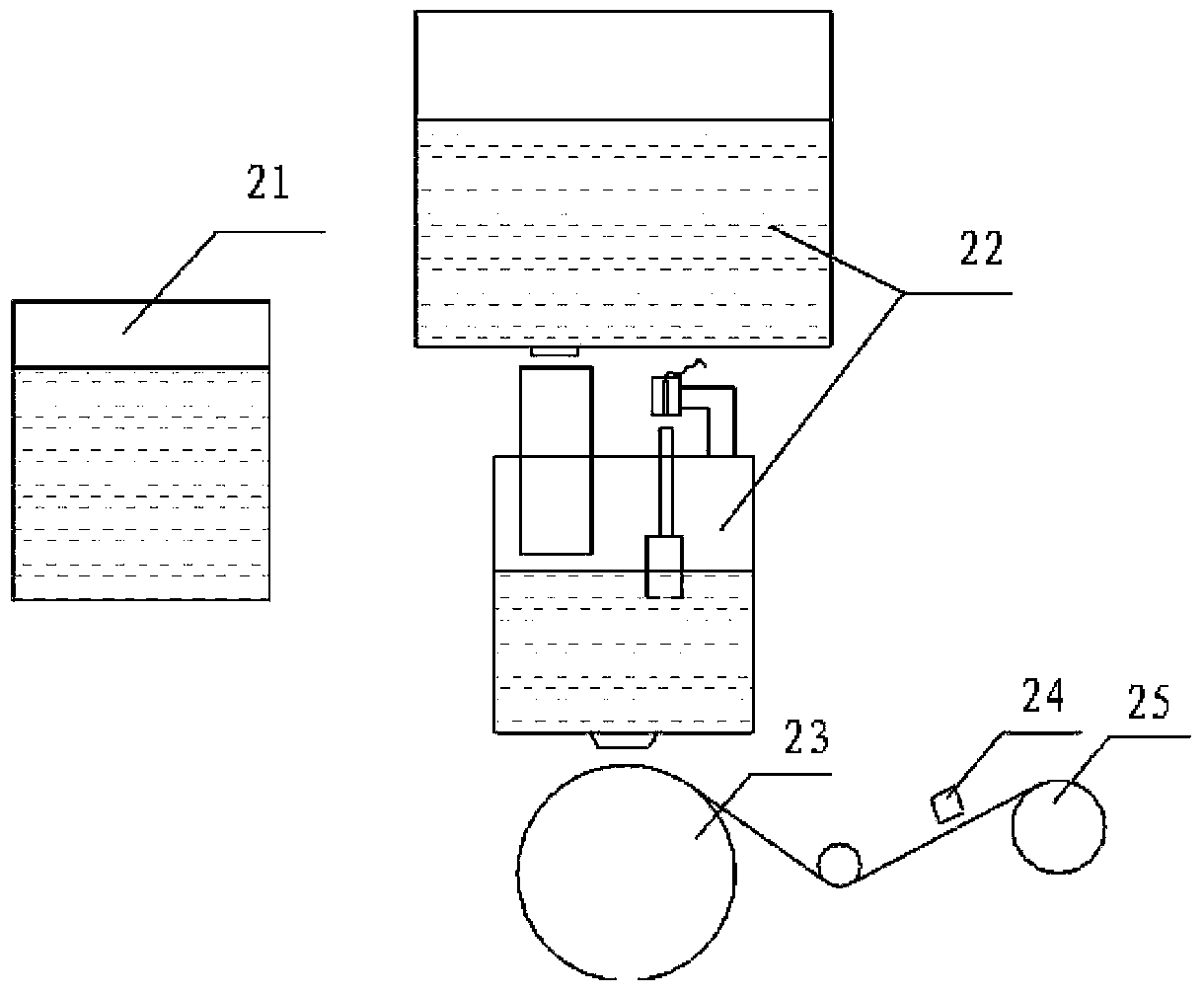

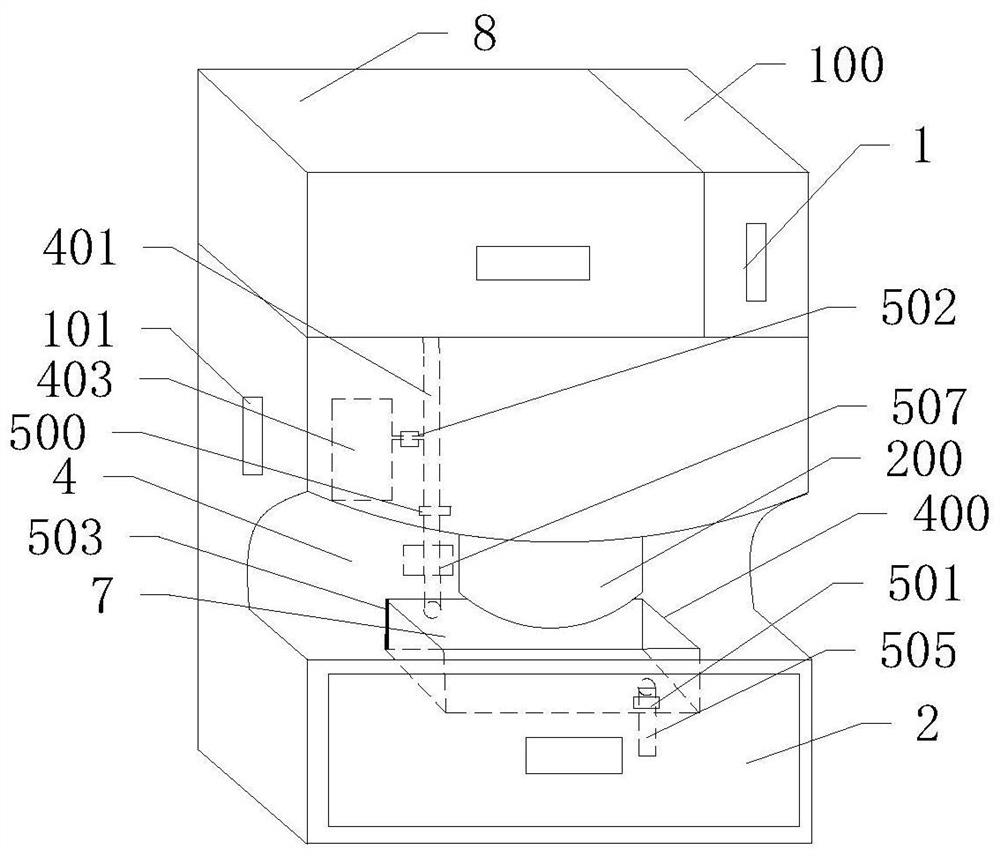

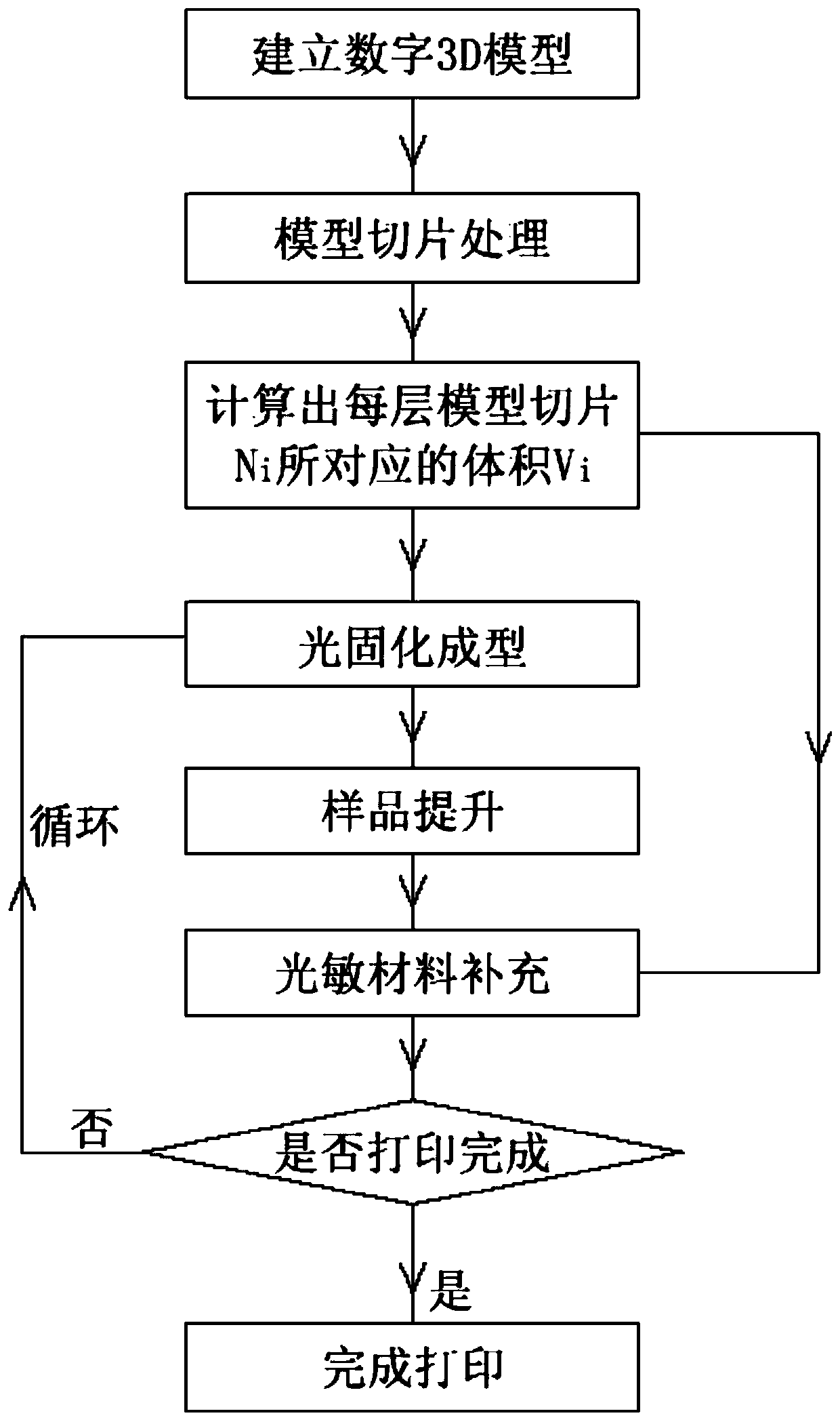

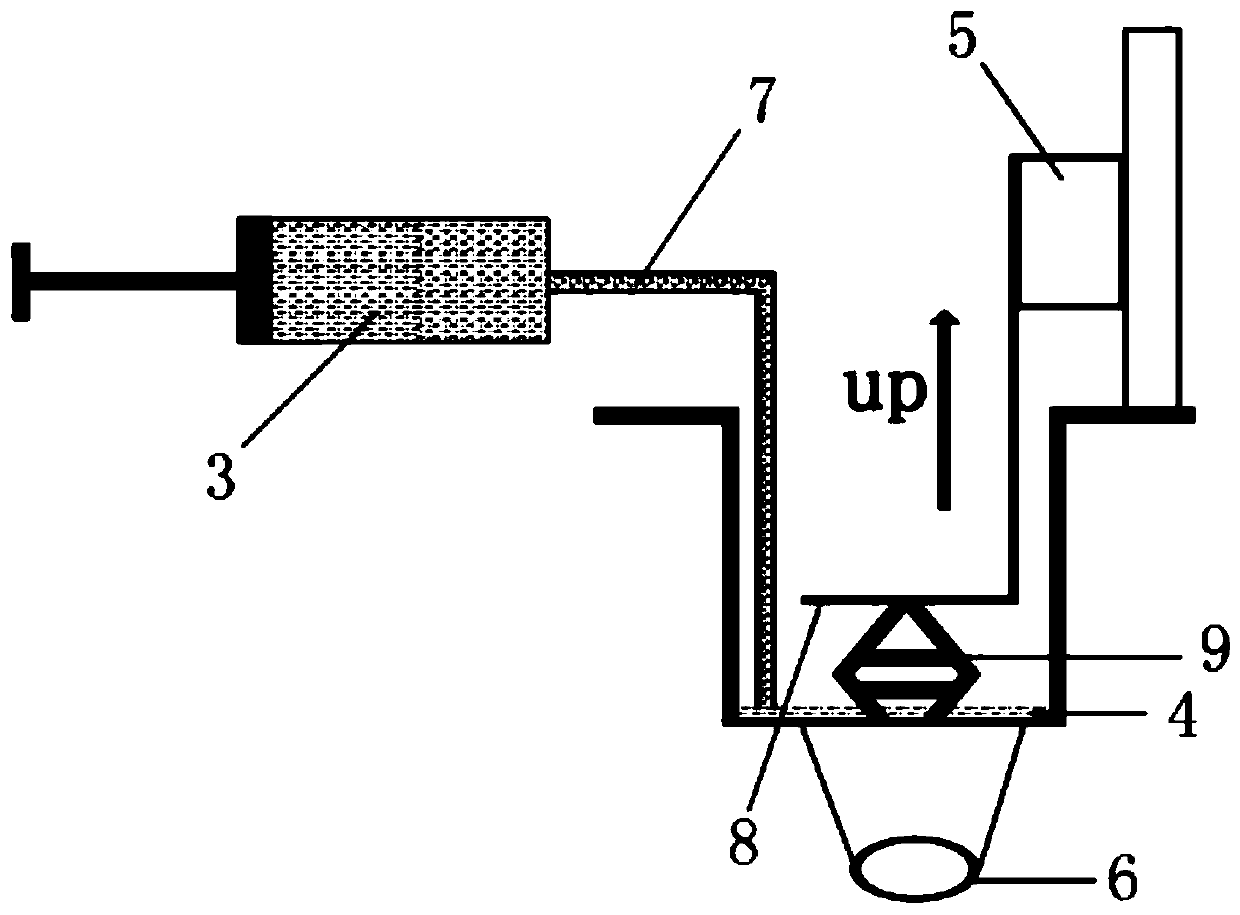

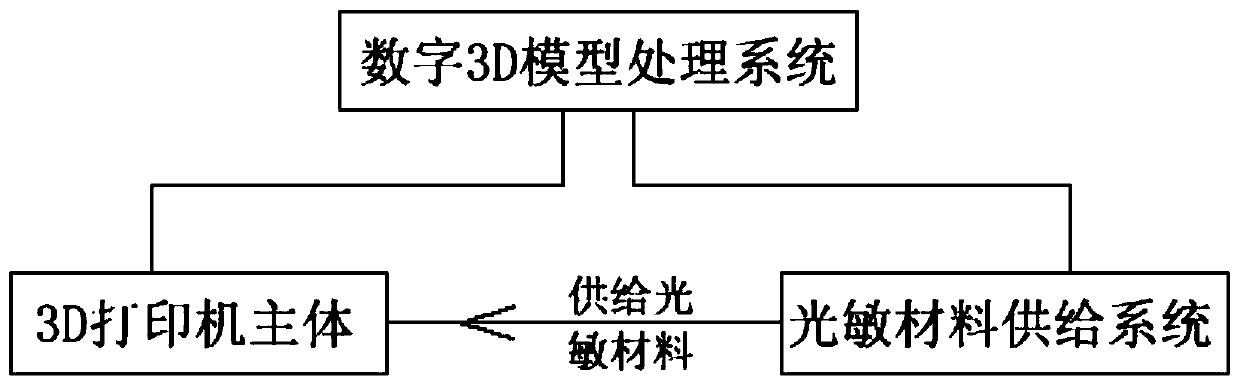

Light-sensitive material supplying method and DLP (Data Loss Prevention) principle-based 3D (three-dimensional) printer system

ActiveCN106827510AHigh precisionConstant liquid levelAdditive manufacturing apparatus3D object support structuresEngineering3d printer

The invention discloses a light-sensitive material supplying method and a DLP (Data Loss Prevention) principle-based 3D (three-dimensional) printer system, and belongs to the technical field of 3D printing. The liquid level height of a light-sensitive material in a controllable sample pool is constant. The volume Vi corresponding to each layer of model slice Ni is calculated and serves as the parameter for controlling the light-sensitive material added into the sample pool after finishing printing each layer of model slice Ni and before printing the next layer of model slice Ni+1, so that constant liquid level height of the light-sensitive material in the sample pool can be guaranteed when each layer of model slice is printed. The liquid depth of the light-sensitive material in the sample pool can also be guaranteed to be equal to the thickness h of the single layer of model slice during the process of printing each layer of model slice by further setting the liquid depth of the light-sensitive material in the sample pool to be consistent to the thickness h of the single layer of model slice, so that model printing precision can be greatly improved.

Owner:SICHUAN UNIV

Warp sizing device

InactiveCN109056223AAvoid runoutUniform sizeTextile treatment machine arrangementsLiquid/gas/vapor yarns/filaments treatmentEngineeringSizing

The invention provides a warp sizing device which comprises a sizing pipe and a warp. Four hanging rings are arranged and are respectively welded to the front end and the rear end of the left side andthe right side of a lower support, and a spring is hooked at each hanging ring; an immersion roller is connected between two right-side plates through hinge pins and can radially rotate. A sizing tank is used for immersive sizing and is placed at the bottom of a lower support. A sizing injection cylinder is placed on the right side of a right column, the sizing pipe communicated with the sizing injection cylinder is fixed to the left side of the sizing injection cylinder, the other end of the sizing pipe is connected to a through hole, and the inside of the sizing injection cylinder is communicated with the inside of the sizing tank; the warp moves through guiding of each guide roller at each position. By adding elastic devices and upgoing limiting devices for two extruding rollers, the rollers can produce extruding forces under the effect of elastic forces to overcome relative radial run-out when being meshed to produce radial run-out, and meanwhile a lifting stop block lifts with lifting of liquid level so that the liquid level height of sizing in the sizing tank is kept constant, manual control is not needed, and uniform sizing is kept.

Owner:石三平

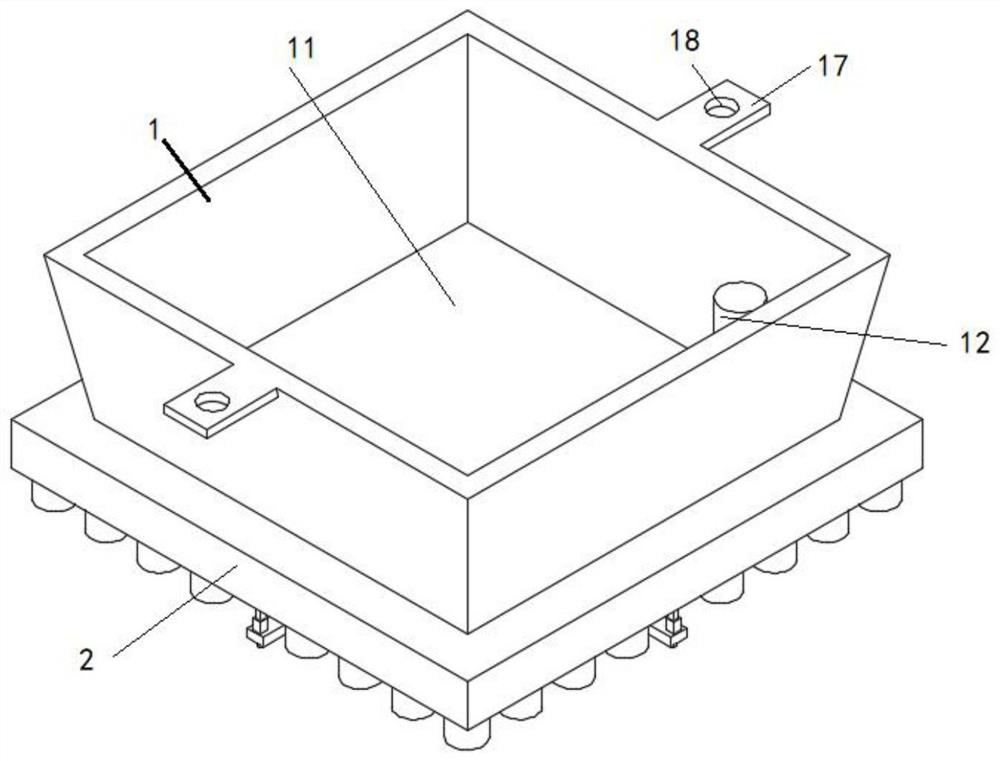

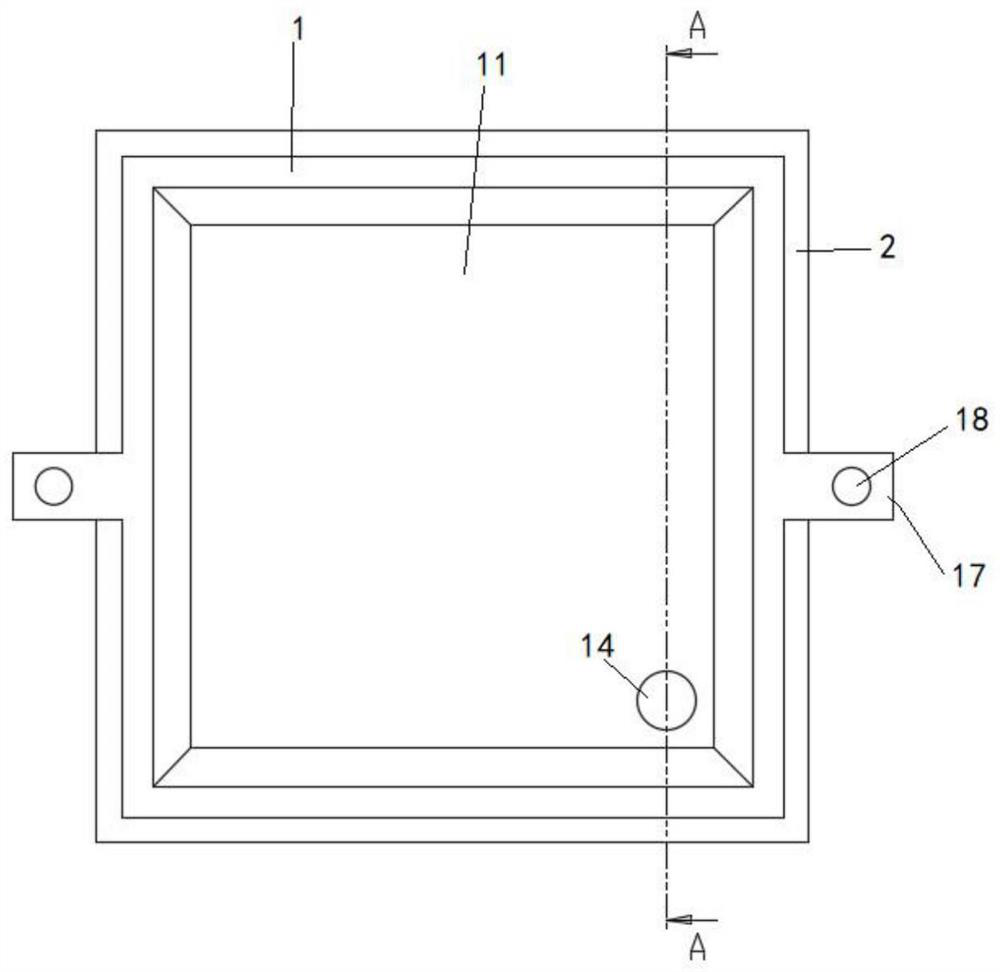

Self-floating rural ecological landscape plant planting device

PendingCN114128518ARich water surface greeningConstant liquid levelReceptacle cultivationLandscape engineeringGreening

The invention discloses a self-floating rural ecological landscape plant planting device, and relates to the technical field of landscape engineering ecological landscapes. The self-floating planting device comprises a self-floating planting container, the planting container comprises a shell with an isosceles trapezoid section, and the self-floating planting device further comprises a floating block assembly arranged at the bottom of the shell; the wide-opening end of the shell faces upwards; a partition plate with water permeability is arranged at the bottom of the shell, and a cavity is formed between the partition plate and the bottom side face of the shell; an opening is formed in the upper surface of the partition plate, an inverted pipe body is arranged at the opening, and a top plate is arranged at the top of the pipe body; a water inlet which is concentric with the opening hole is formed in the bottom side surface of the shell under the opening hole; a floating block is arranged in the pipe body, and the bottom side face of the floating block is connected with a plugging cover through a connecting rod. By arranging the self-floating planting container and planting plants in the planting container, soil plants can be planted on the water surface, and water surface greening is enriched.

Owner:合肥草木皆兵环境科技有限公司

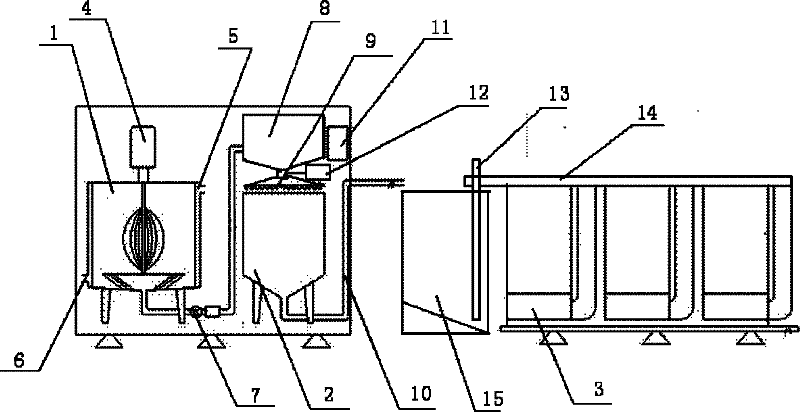

Movable overflow type hydraulic brake saline water tank

InactiveCN102360033APlay a cooling roleAvoid load fluctuationsElectrical measurement instrument detailsDynamo-electric machine testingSaline waterWater storage tank

The invention provides a movable overflow type hydraulic brake saline water tank, which belongs to the field of generator experiment equipment and comprises a work tank, a water storage tank, an electrode plate and a busbar, wherein the electrode plate is positioned in the work tank, the busbar is connected with the electrode plate, the work tank is positioned above the water storage tank, the movable overflow type hydraulic brake saline water tank also comprises a water pump station and an overflow door, the overflow door consists of a door frame and a hydraulic door, the door frame is fixedat an opening part of the side surface of the work tank, the hydraulic door can move upwards and downwards along the door frame and can be fixed in any position of the door frame through a fixing element, the top end of the hydraulic door is provided with an overflow groove, the bottom of the overflow groove is provided with a pipeline communicated to the water storage tank, and the water pump station is respectively connected with the work tank and the water storage tank through pipelines. The overflow door and the water pump are adopted, water can be continuously circulated, the load can not be changed, a cooling effect is realized, the problem of load fluctuation caused by serious violent boiling is also solved, and the movable overflow type hydraulic brake saline water tank also has the advantages that the load does not need to be frequently regulated, and the carrying capability is great. The movable overflow type hydraulic brake saline water tank can be widely applied to large-scale generator tests.

Owner:GUANGZHOU WENCHONG SHIPYARD CO LTD

Siphon drainage device, irrigation system and irrigation planting method

ActiveCN114208649AAvoid the problem of siphon actionControl liquid levelLiquid fertiliser distributionAgriculture gas emission reductionSiphonStructural engineering

The invention relates to a siphon sewer device, an irrigation system and an irrigation planting method.The siphon sewer device comprises a pipeline, a plurality of siphons are arranged in the pipeline, the outer wall of the pipeline is sleeved with a fixing disc, and the fixing disc is in relative sliding connection with the outer wall of the pipeline; the fixing part is arranged above the pipeline, open holes with the number being double of the number of the siphons are formed in the fixing part, the siphons comprise the inner siphons and the outer siphons, the length of the inner siphons in the vertical direction is larger than that of the outer siphons in the vertical direction, and the inner siphons are communicated with the outer siphons in the vertical direction. The top of the inner siphon is communicated with the open hole located in the range corresponding to the section of the inner wall of the pipeline, and the top of the outer siphon is communicated with the open hole located in the range exceeding the range corresponding to the section of the outer wall of the pipeline. A plurality of siphons generate a siphoning effect to automatically guide and discharge the nutrient solution in the tray from the pipeline; the problem that in the prior art, due to the fact that the tide immersion time is uncontrollable, the cultivation process is unstable is solved.

Owner:4D BIOS INC

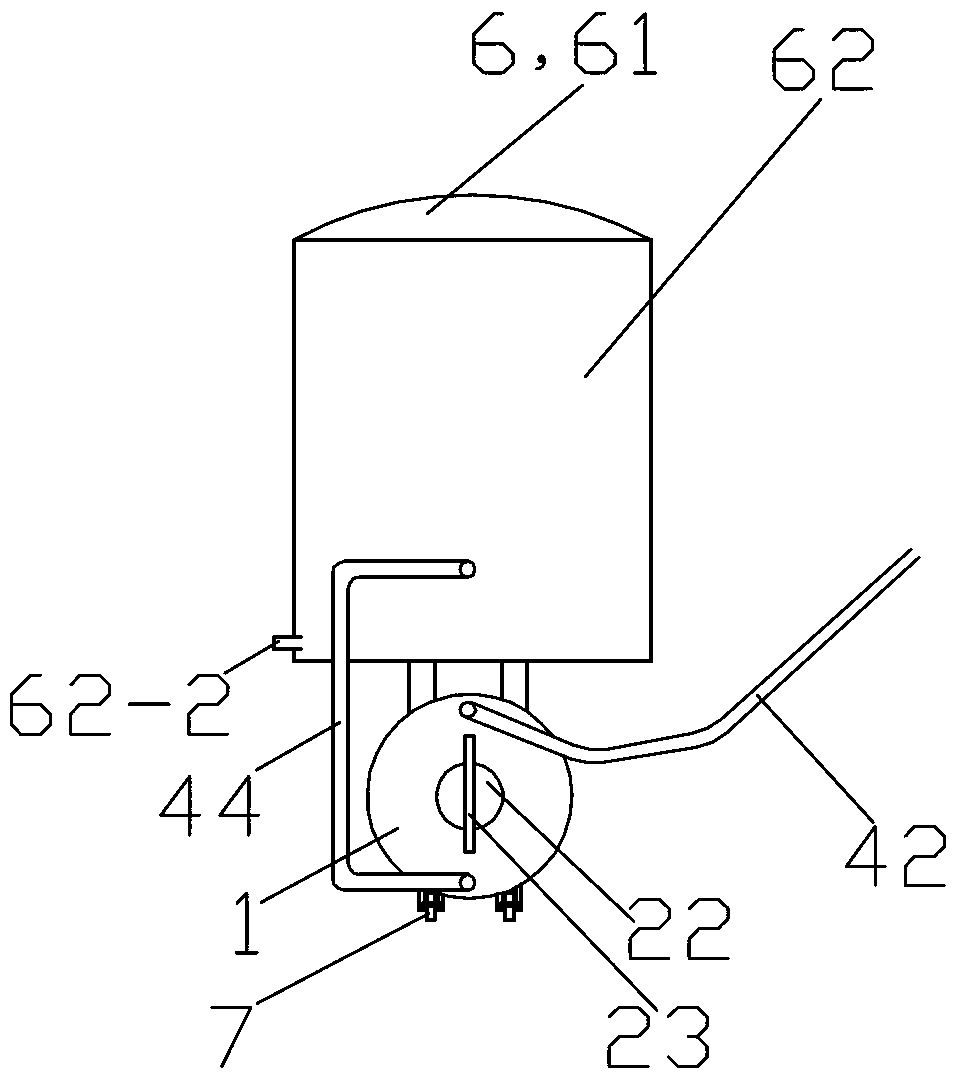

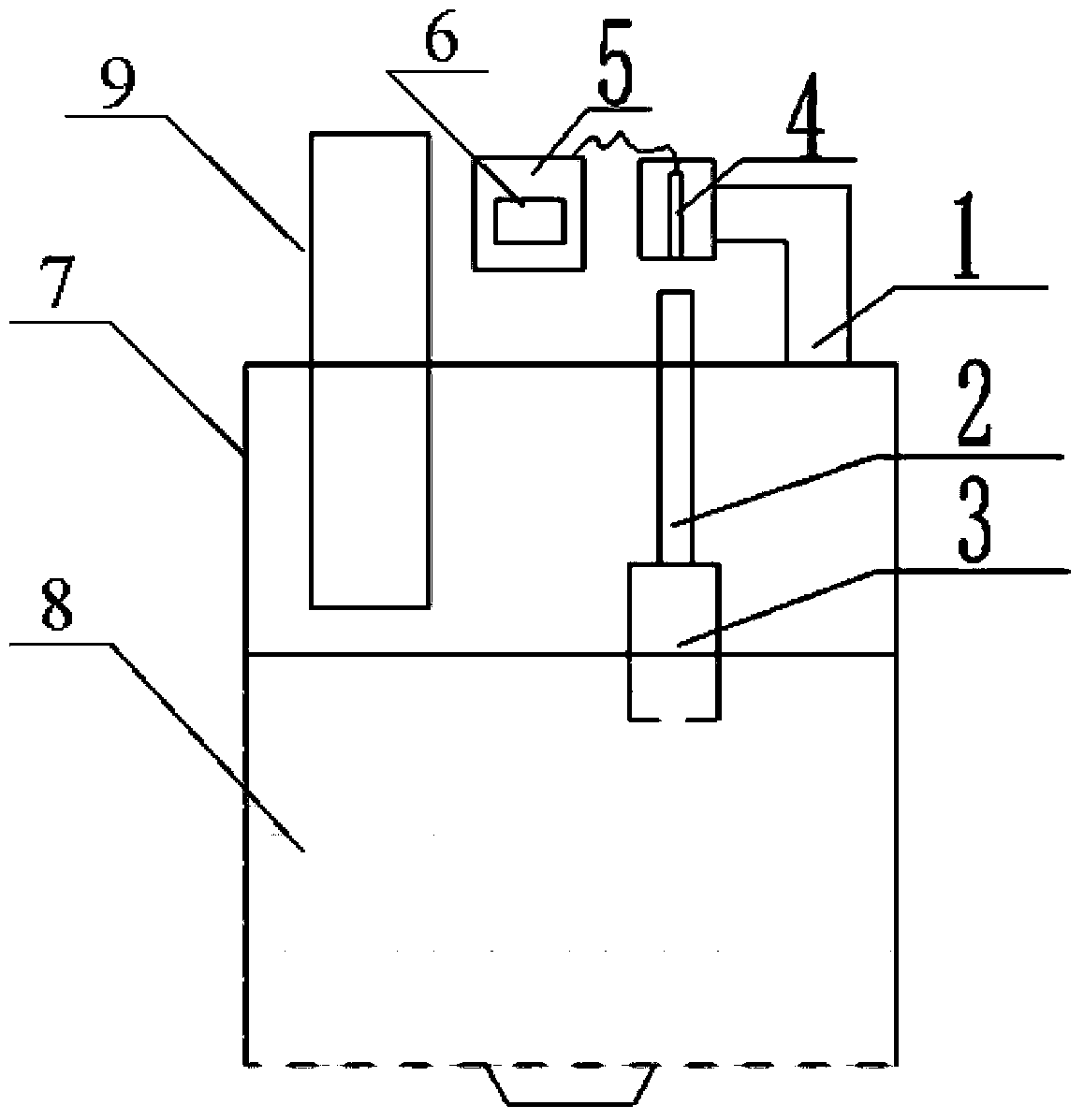

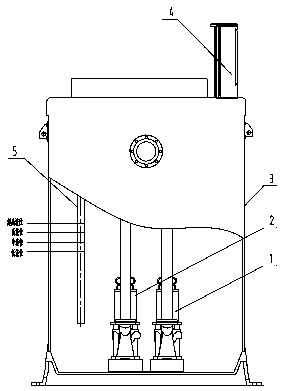

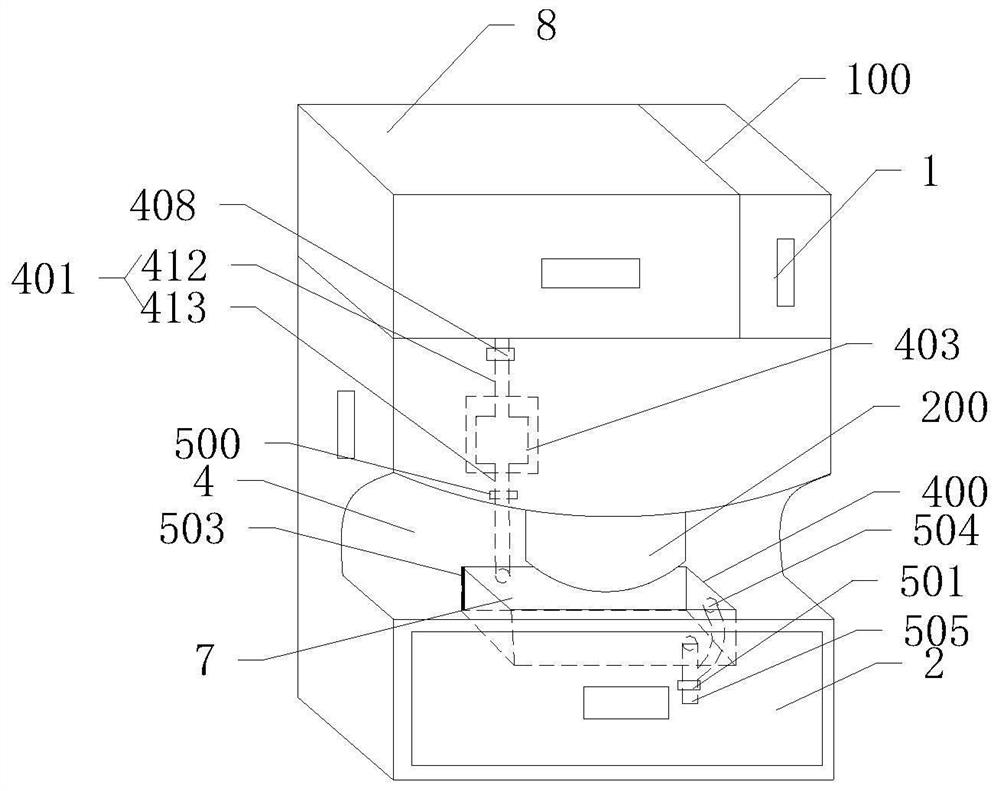

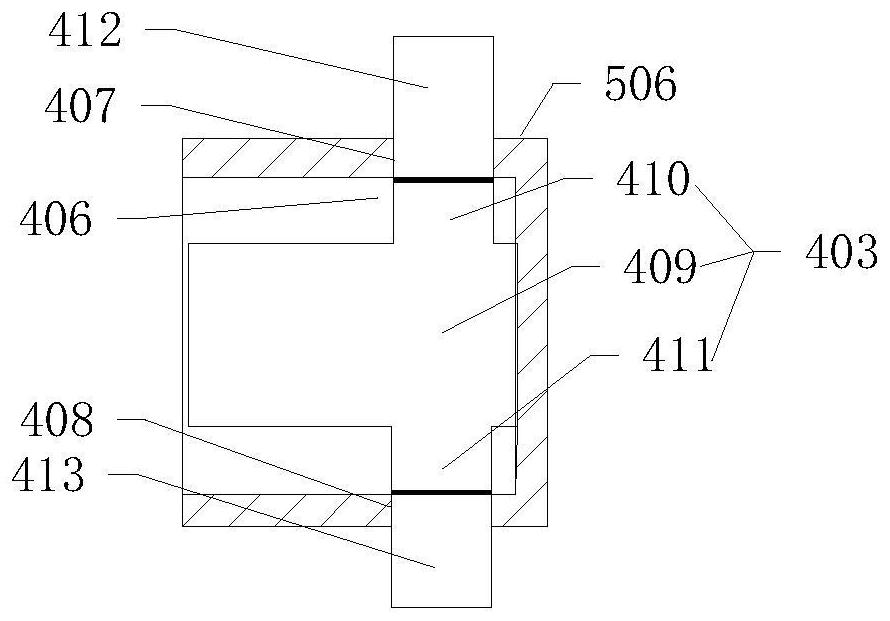

Detection device of molten steel liquid level in belt spraying packet

InactiveCN103398757AConstant liquid levelAvoid product qualityLevel indicators by floatsEngineeringMolten steel

The invention relates to a detection device of the molten steel liquid level in a belt spraying packet. The detection device comprises a floater 3, a floater rod 2, a liquid level detection mechanism 1 and a PLC system 5. The bottom of the floater rod 2 is installed on the floater 3, and the top of the floater rod 2 penetrates though a guide sleeve on the belt spraying packet 7; the floater 3 directly makes contact with molten steel 8 in the belt spraying packet 7 to drive the floater rod 2 to reflect the liquid level of the molten steel 8; the liquid level detection mechanism 1 is provided with an optical fiber sensor 4; the optical fiber sensor 4 is used for detecting displacement changes of the top of the floater rod 2 and feeds detection results back to the PLC system 5; the current liquid level of the molten steel 8 is worked out by the PLC system 5 according to the detection results. According to the detection device of the molten steel liquid level in the belt spraying packet, the height of the liquid level of the molten steel in the belt spraying packet can be accurately mastered, and accordingly steel can be continuously supplemented into the belt spraying packet in real time, the liquid level of the molten steel in the belt spraying packet can be kept constant and the quality of products can be further controlled.

Owner:QINGDAO YUNLU ADVANCED MATERIALS TECH CO LTD

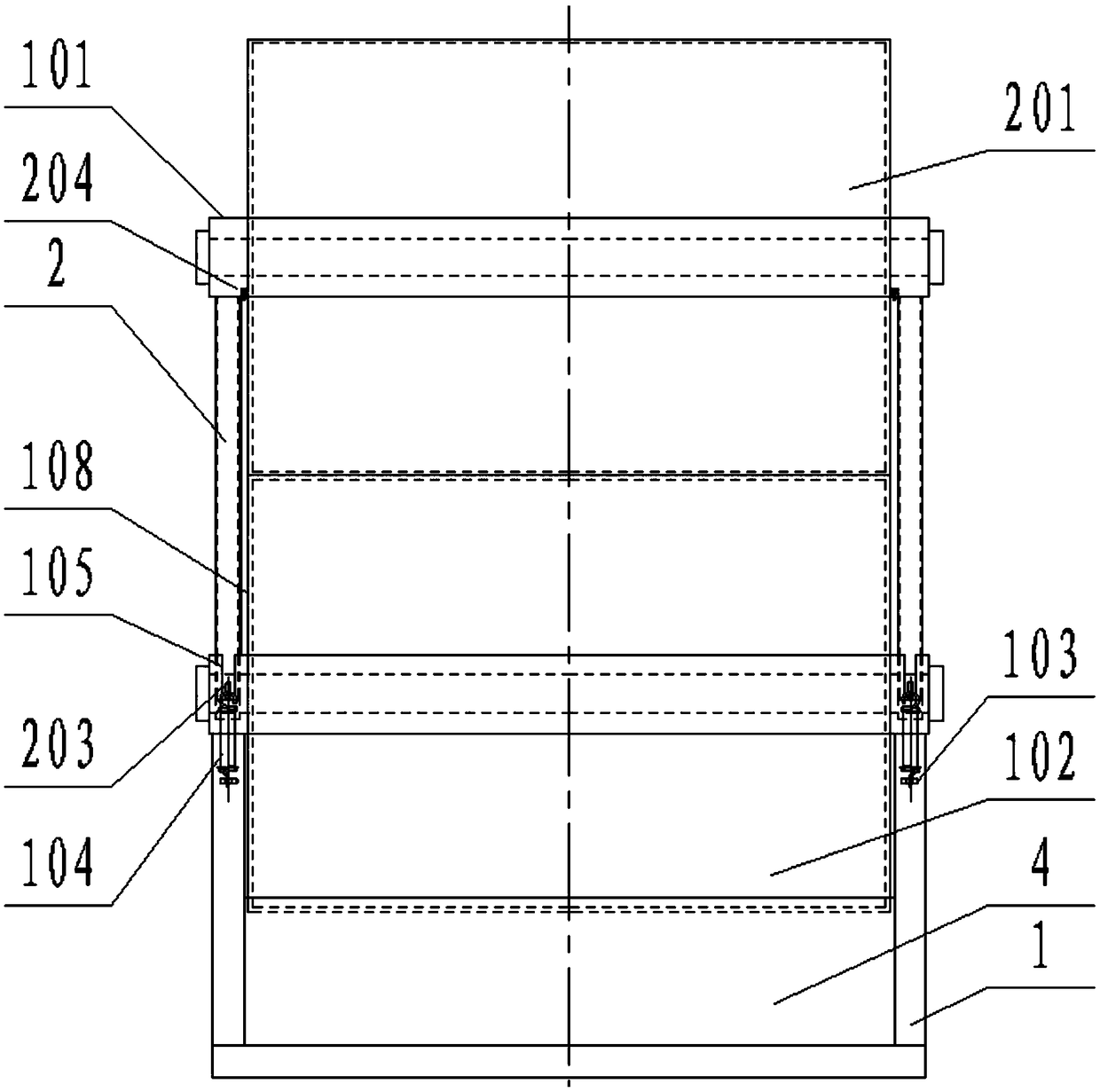

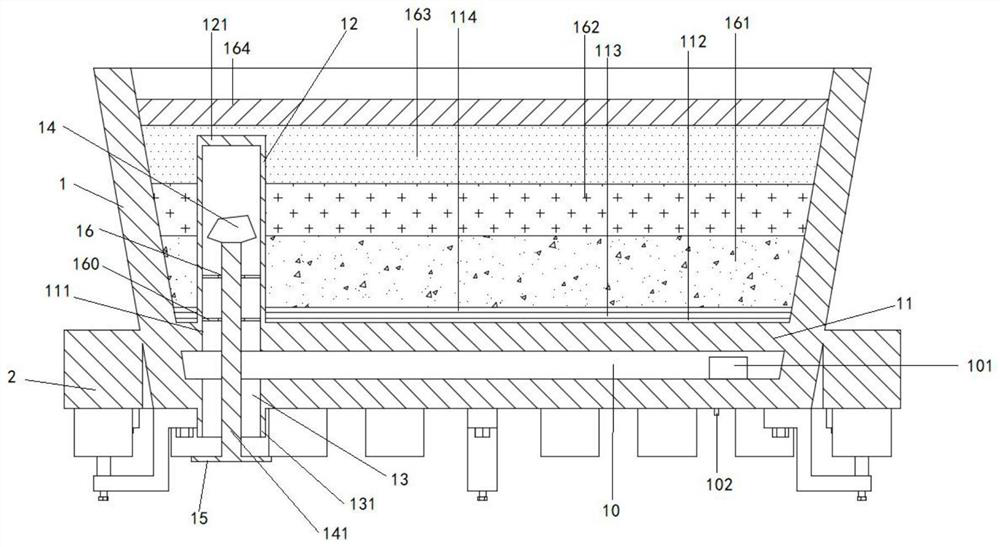

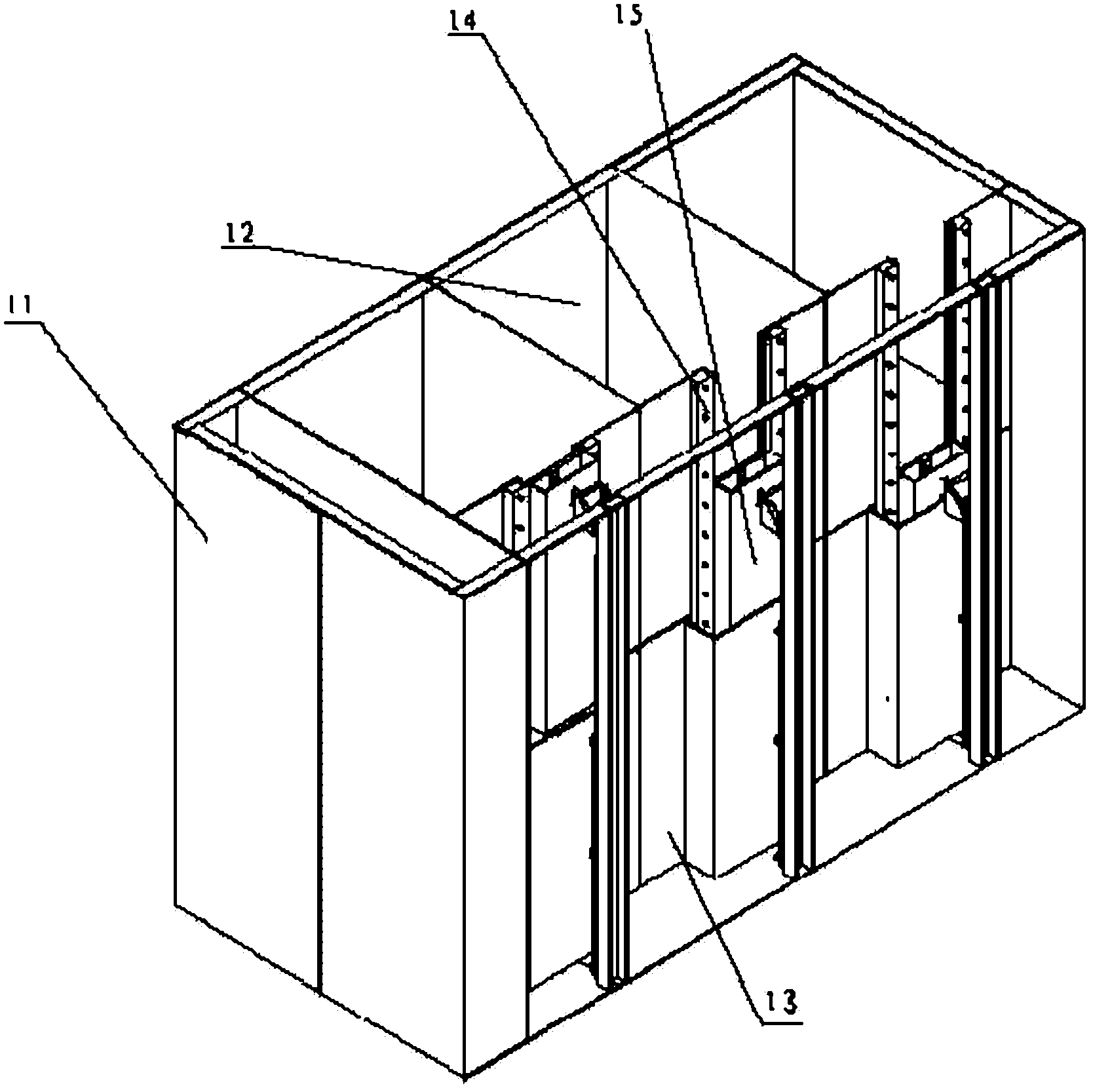

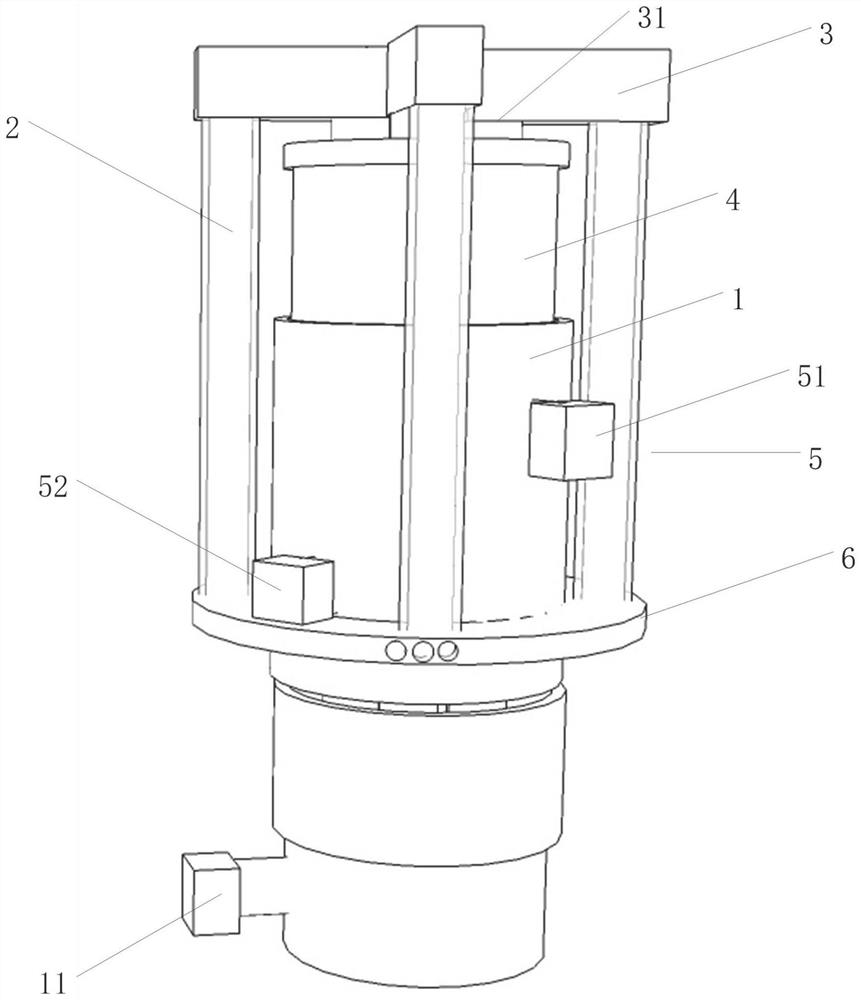

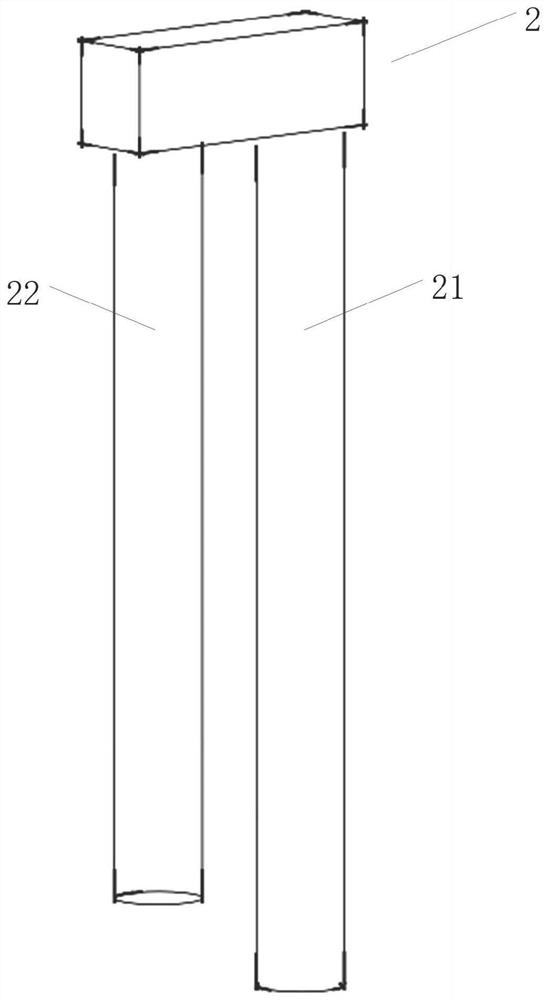

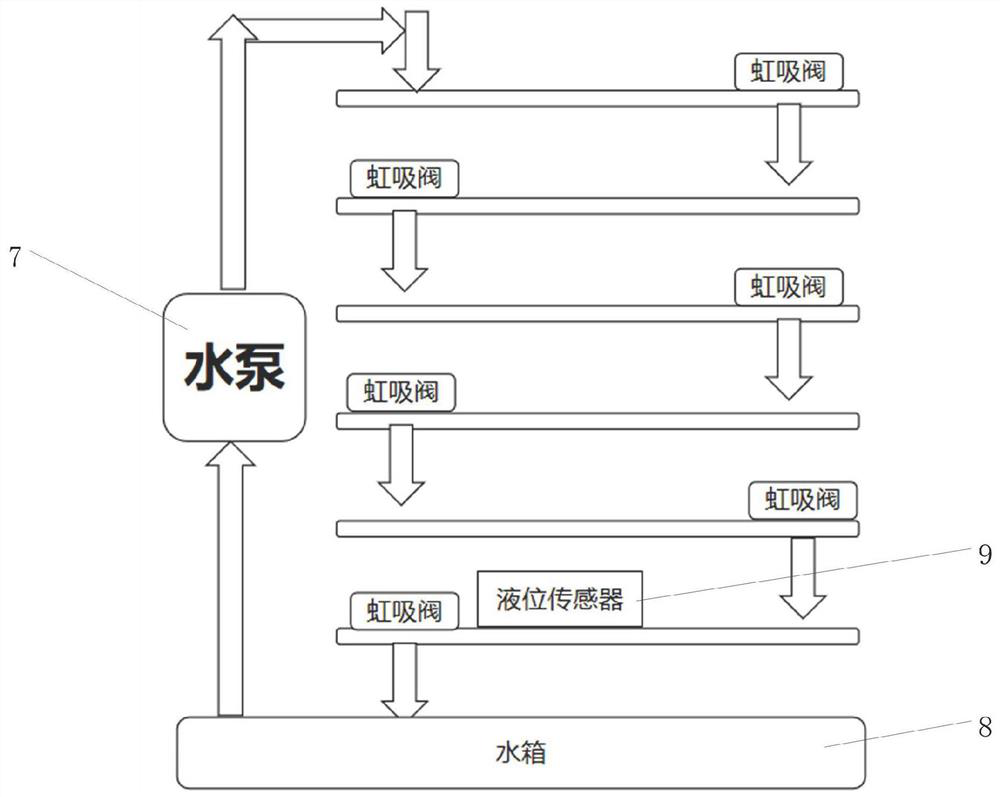

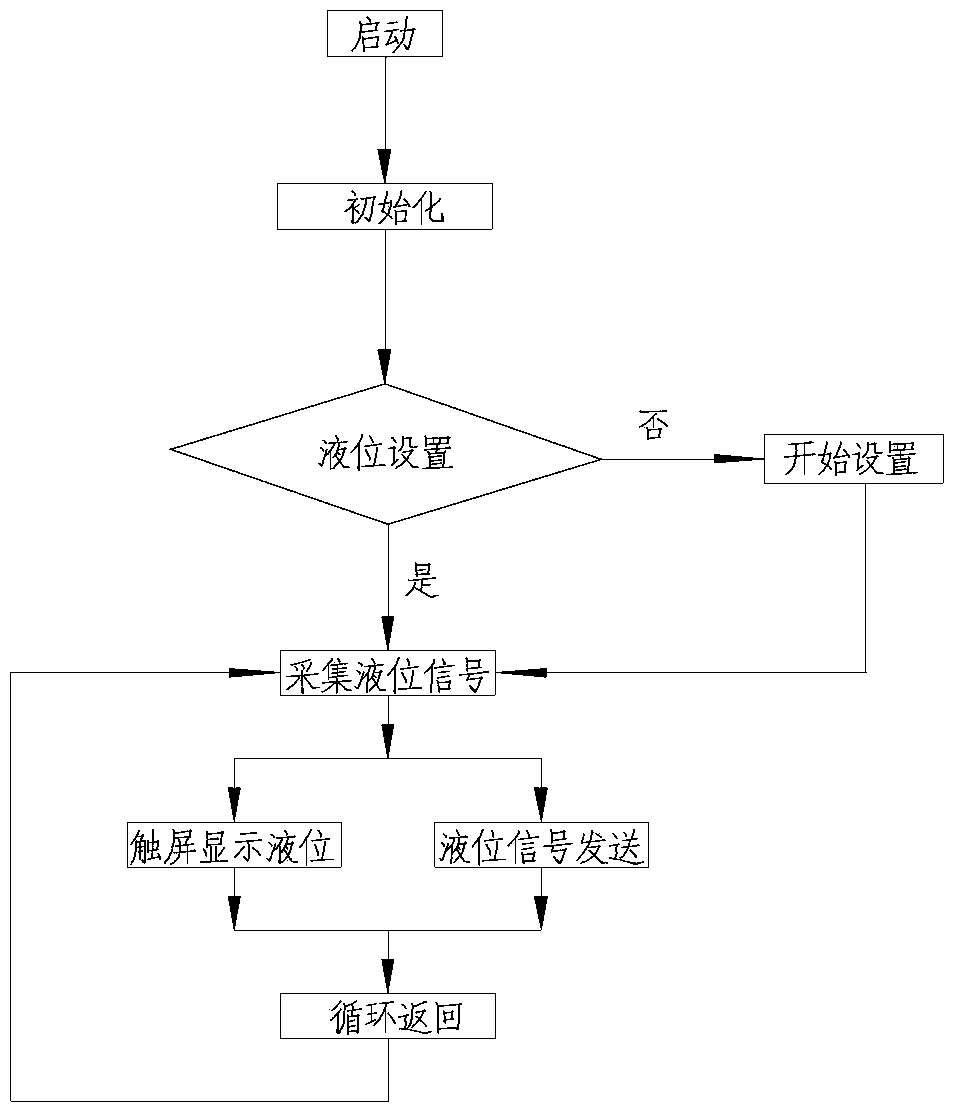

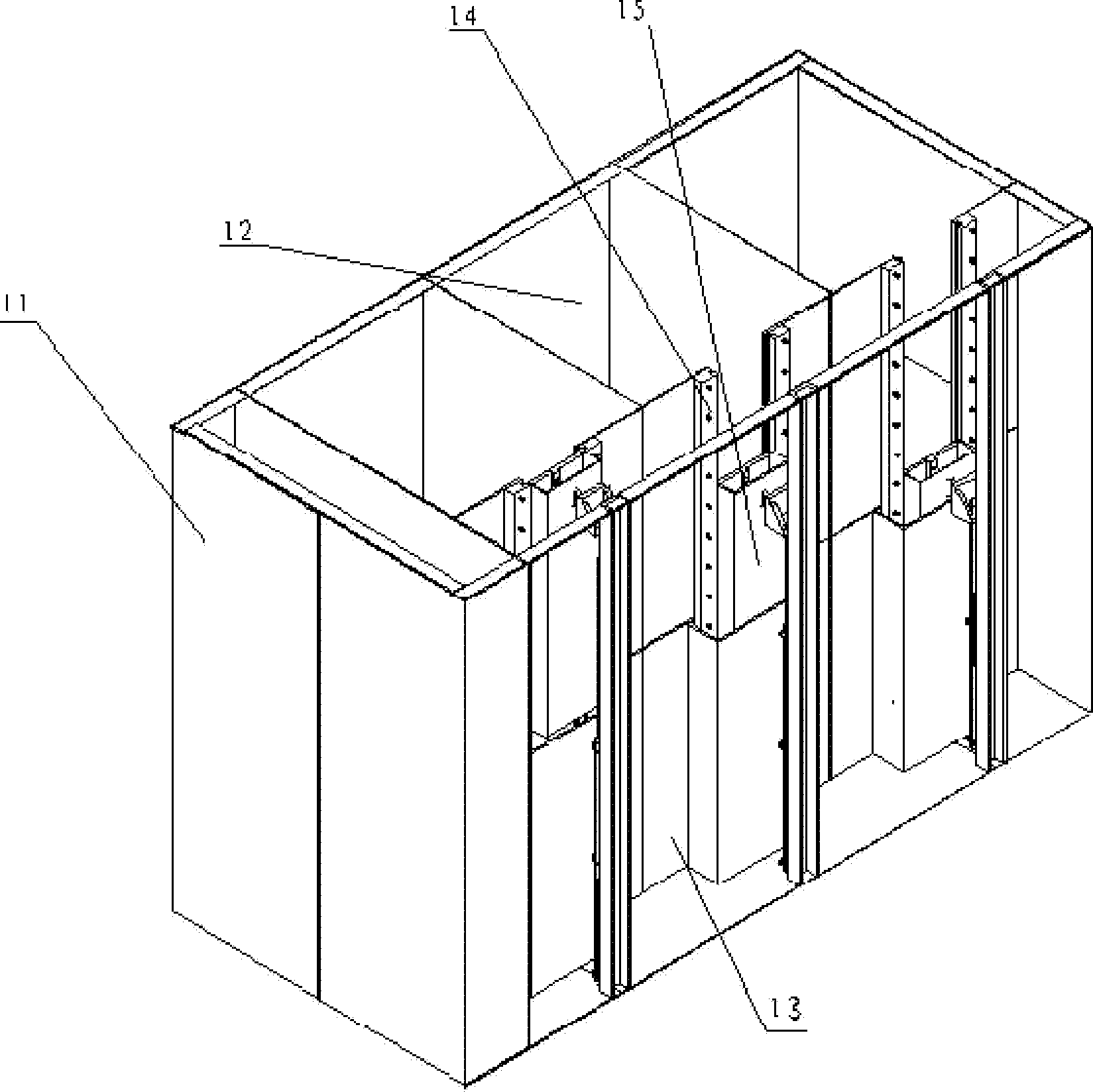

Energy-saving intelligent prefabricated pump station

InactiveCN110863559AGuaranteed uptimeConstant liquid levelSewerage structuresVariable frequency controlFrequency conversion

The invention relates to an energy-saving intelligent prefabricated pump station. The energy-saving intelligent prefabricated pump station comprises a barrel body, a liquid level meter, a first waterpump, a second water pump and a frequency conversion control cabinet, wherein the first water pump and the second water pump are mounted at the bottom of the barrel body, the liquid level meter is installed inside the barrel body, and the frequency conversion control cabinet is mounted at the top of the barrel body. The energy-saving intelligent prefabricated pump station has the beneficial effects that by additionally arranging the frequency conversion control cabinet, the frequency conversion operation of the water pumps is realized; and by arranging multi-gear liquid levels of the liquid level meter, water pump frequency increasing can be controlled, the liquid level in the barrel body is guaranteed to be constant, and the stable operation of the water pumps in the efficient area all the time is realized. The economic cost is greatly saved, and the energy-saving intelligent prefabricated pump station is stable, reliable, simple in structure, convenient to operate, economical and practical.

Owner:SHANGHAI PANDA MACHINEGRP CO LTD

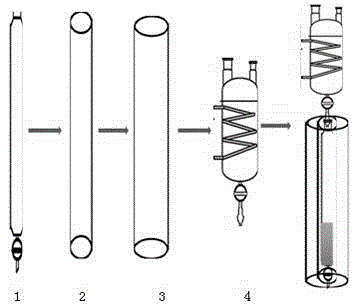

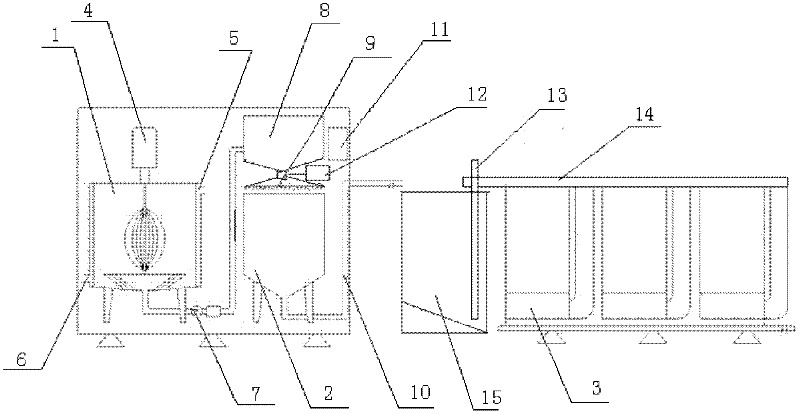

Automatic microsphere production device

InactiveCN102500276AGuaranteed preservationGuaranteed production effectGranulation by liquid drop formationMicrosphereLiquid storage tank

The invention discloses an automatic microsphere production device, which comprises a burdening tank, a pill dropping device, a microsphere producing tank, a soaking tank and at least one drying tank, wherein a stirring tank is arranged in the burdening tank; the pill dropping device comprises a liquid storage tank; the bottom of the liquid storage tank is provided with an adjustable-flow dropping disk; the bottom of the burdening tank is communicated with the liquid storage tank through a pipeline; the microsphere producing tank is arranged below the liquid storage tank, and corresponds to the dropping disk; the top of the microsphere producing tank is provided with an opening; the bottom of the microsphere producing tank is communicated with the soaking tank through a pill outlet pipeline; and the soaking tank is communicated with the drying tank. Production equipment is provided for the production of biological pesticide microsphere particles, and the requirements of large scale and automation in agricultural production are met.

Owner:INST OF MICROBIOLOGY - CHINESE ACAD OF SCI

A wall-mounted ultrasonic cleaning device

ActiveCN109137366BEasy to useThe liquid level does not changeOther washing machinesControl devices for washing apparatusMegasonic cleaningMechanical engineering

The invention belongs to the field of cleaning devices, and in particular relates to a wall-mounted ultrasonic cleaning device, which includes a body installed on the wall, an ultrasonic generator installed on the body, and a cleaning tank for holding washing liquid, and also includes a The liquid supply pipeline and the liquid discharge pipeline connected to the cleaning tank. When washing, the liquid supply pipeline supplies liquid to the cleaning tank, and at the same time, the liquid discharge pipeline discharges the liquid in the cleaning tank, so that the washing liquid in the cleaning tank keeps flowing and the liquid The bit height does not change. The invention belongs to the beneficial effect of the invention that by setting the liquid supply pipeline and the liquid discharge pipeline, the washing liquid in the cleaning tank can keep flowing and the liquid level remains unchanged, which can not only meet the needs of cleaning, but also make the washing device more efficient. It is more convenient to use, and the cleaning liquid can be replaced in time; by setting the regulating device, the liquid flow in the water supply pipeline and the drainage pipeline can be adjusted by the regulating device, so that the liquid level in the cleaning tank can be kept unchanged.

Owner:QINGDAO JIAONAN HAIER WASHING MACHINE +1

Movable overflow type hydraulic brake saline water tank

InactiveCN102360033BPlay a cooling roleAvoid load fluctuationsElectrical measurement instrument detailsDynamo-electric machine testingSaline waterBusbar

The invention provides a movable overflow type hydraulic brake saline water tank, which belongs to the field of generator experiment equipment and comprises a work tank, a water storage tank, an electrode plate and a busbar, wherein the electrode plate is positioned in the work tank, the busbar is connected with the electrode plate, the work tank is positioned above the water storage tank, the movable overflow type hydraulic brake saline water tank also comprises a water pump station and an overflow door, the overflow door consists of a door frame and a hydraulic door, the door frame is fixedat an opening part of the side surface of the work tank, the hydraulic door can move upwards and downwards along the door frame and can be fixed in any position of the door frame through a fixing element, the top end of the hydraulic door is provided with an overflow groove, the bottom of the overflow groove is provided with a pipeline communicated to the water storage tank, and the water pump station is respectively connected with the work tank and the water storage tank through pipelines. The overflow door and the water pump are adopted, water can be continuously circulated, the load can not be changed, a cooling effect is realized, the problem of load fluctuation caused by serious violent boiling is also solved, and the movable overflow type hydraulic brake saline water tank also has the advantages that the load does not need to be frequently regulated, and the carrying capability is great. The movable overflow type hydraulic brake saline water tank can be widely applied to large-scale generator tests.

Owner:GUANGZHOU WENCHONG SHIPYARD CO LTD

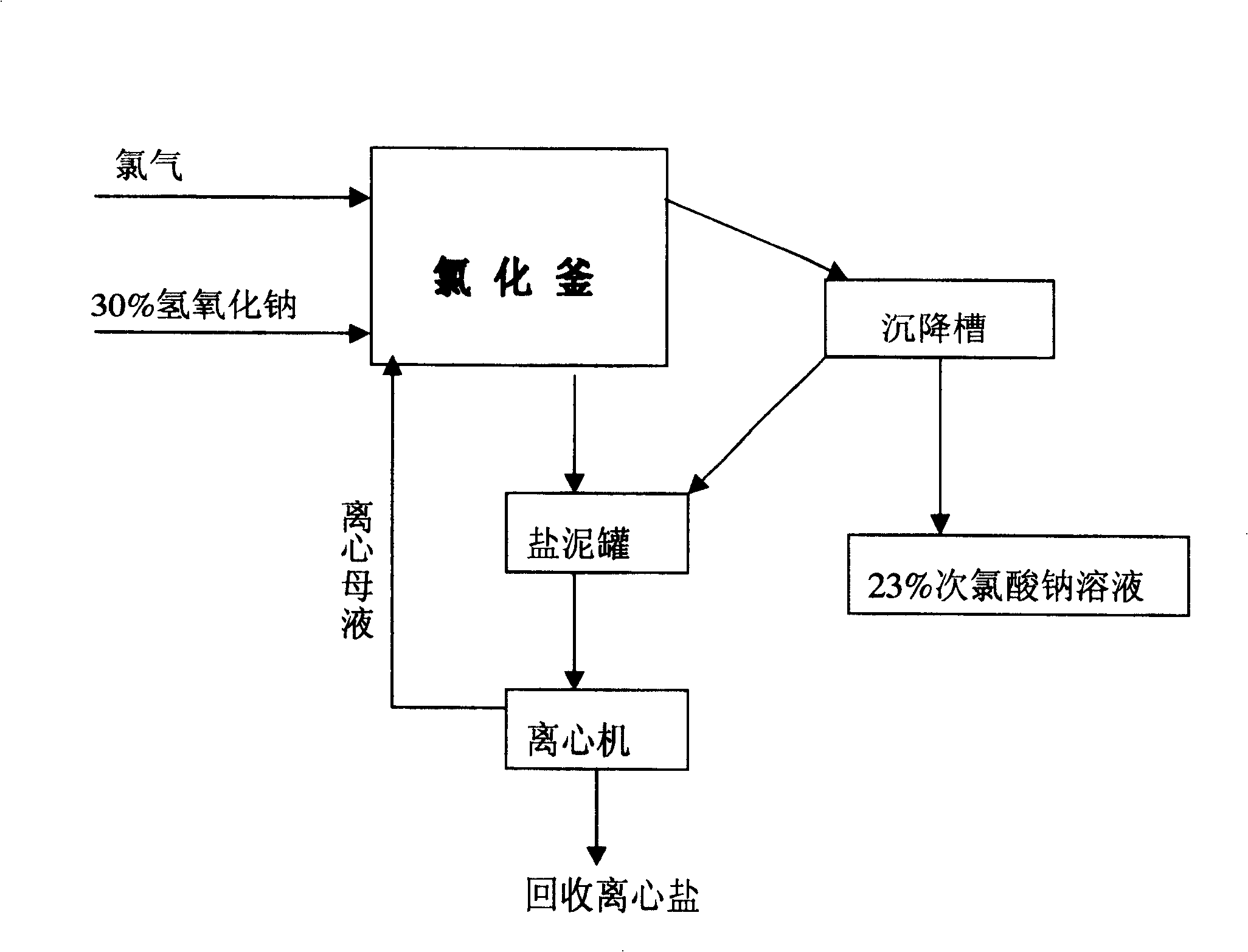

Method and apparatus for continuous production of high-concentrated sodium hypochlorite

ActiveCN100453449CCreate pollutionConstant liquid levelHypochloriteHigh concentrationSodium hypochlorite solution

Owner:YIBIN TIANYUAN GRP CO LTD

Unpowered automatic baffling type biogas generating device

PendingCN111254054AReduce generationLong processing timeBioreactor/fermenter combinationsBiological substance pretreatmentsProcess engineeringBiogas production

The invention provides an unpowered automatic baffling type biogas generating device. A solar greenhouse and a biogas generating device arranged in the solar greenhouse are included; the biogas generating device includes a sewage collection sedimentation pond, a feeding chamber, a baffling biogas digester, a biogas slurry temporary storage tank and a solid-liquid separation tank; the bottom of thebaffling biogas digester is connected to a biogas slurry discharging pipeline; the top end of the biogas slurry discharging pipeline is flush with the top of the sewage collection sedimentation pond;the baffling biogas digester includes a concrete pool, a black film and a sunlight board, wherein the black film and the sunlight board cover the top of the concrete pool; multiple baffle plates fitting with the two sides of the concrete pool are arranged in the concrete pool; the multiple baffle plates divide the concrete pool into multiple baffling chambers, and water valves are arranged at thebottoms of two adjacent baffling chambers; and the top of the concrete pool is provided with a biogas output pipe. The unpowered automatic baffling type biogas generating device is convenient in maintenance and can make biogas production performance very stable.

Owner:河南城润环境工程有限公司

Photosensitive material supply method and 3D printer system based on dlp principle

ActiveCN106827510BHigh precisionConstant liquid levelAdditive manufacturing apparatus3D object support structuresEngineering3d printer

The invention discloses a light-sensitive material supplying method and a DLP (Data Loss Prevention) principle-based 3D (three-dimensional) printer system, and belongs to the technical field of 3D printing. The liquid level height of a light-sensitive material in a controllable sample pool is constant. The volume Vi corresponding to each layer of model slice Ni is calculated and serves as the parameter for controlling the light-sensitive material added into the sample pool after finishing printing each layer of model slice Ni and before printing the next layer of model slice Ni+1, so that constant liquid level height of the light-sensitive material in the sample pool can be guaranteed when each layer of model slice is printed. The liquid depth of the light-sensitive material in the sample pool can also be guaranteed to be equal to the thickness h of the single layer of model slice during the process of printing each layer of model slice by further setting the liquid depth of the light-sensitive material in the sample pool to be consistent to the thickness h of the single layer of model slice, so that model printing precision can be greatly improved.

Owner:SICHUAN UNIV

Equipment convenient for coating of bottoms of printed circuit boards and method thereof

InactiveCN104096657AGuaranteed liquid levelGuaranteed coating effectPretreated surfacesCoatingsCoating systemSpray nozzle

The invention relates to the coating technology, in particular to equipment convenient for coating of bottoms of printed circuit boards and a method thereof. The equipment comprises a washing claw system, a horizontal flowing type coating system, a hot air circulating system, a preheating sealing system and a cooling system, all of which are connected to a double-guide rail transmission system in sequence. An air extraction system is arranged above the horizontal flowing type coating system. The horizontal flowing type coating system comprises an incoming board connecting mechanism, a photoelectric sensor, a PLC, a glue barrel and a horizontal flowing wave nozzle valve, wherein the incoming board connecting mechanism is connected with the double-guide rail transmission system; the photoelectric sensor is arranged on the incoming board connecting mechanism; the PLC is connected with the photoelectric sensor and the horizontal flowing wave nozzle valve; and the horizontal flowing wave nozzle valve is connected to the glue barrel through a pipe. The invention further includes a coating method realized based on the equipment. The equipment has the advantages of simple production process, convenience for operation, safety and reliability, low investment cost, high product yield and high production efficiency, and can coat the printed circuit boards of different types in the electronic industry.

Owner:WUXI FILIN ELECTRONICS CO LTD

Brake fluid replacing device and working method thereof

InactiveCN103241222BSimple structureLow costVehicle servicing/repairingWheel cylinderMaterial resources

The invention provides a brake fluid replacing device. The brake fluid replacing device comprises a piston cylinder body, a piston assembly, a one-way valve assembly, a communicating pipe assembly, a brake fluid barrel, a waste liquid barrel and an idler wheel, wherein the piston cylinder body uses the one-way valve assembly and the communicating pipe assembly through a piston, sucks new hydraulic drive fluid in the brake fluid barrel, and pushes the new hydraulic drive fluid into a brake fluid storage pot of a car, and simultaneously, the piston cylinder body achieves replacement of waste brake fluid by sucking the waste brake fluid in a car brake wheel cylinder through the piston and pushing the waste brake fluid into the waste liquid barrel. The brake fluid barrel and the waste liquid barrel are fixedly installed at the upper end of the piston cylinder body through supports, and the idler wheel is fixedly installed below the piston cylinder body. A working method of the brake fluid replacing device is a negative pressure suction method. The brake fluid replacing device is simple in structure and low in cost, effectively guarantees that no air enters into a brake pipeline system during the brake fluid replacing process, and therefore can not reduce brake performance of the car, facilitates judging whether a brake pipeline leaks or not, is convenient to replace and operate, and saves manpower and material resources.

Owner:JIANGSU UNIV OF TECH

System for preparing urea solution for denitration

InactiveCN107198976AReduce the burden onAdjustable dissolution in timeTransportation and packagingMixing methodsLiquid storage tankHeat losses

The invention relates to a system for preparing a solution, in particular to a system for preparing a urea solution for denitration. The system for preparing the urea solution for denitration comprises a hopper and a solution preparation tank, and is characterized in that the top of the hopper is connected with an automatic feeding device, a urea conveying device is installed between the bottom of the hopper and the solution preparation tank, a liquid storage tank is arranged under the solution preparation tank, the solution preparation tank is connected with the liquid storage tank by means of an automatic overflow device, the bottom of the liquid storage tank is connected with a urea solution output pipeline, a cylinder connecting section is arranged between the hopper and the automatic feeding device, and the cylinder connecting section and the interior of the hopper are respectively connected with the bottom of the liquid storage tank by means of a heat tracing hot water pipeline. The system has the beneficial effects of being less in running heat loss, less in investment, simple to operate, fewer in associated equipment and high in degree of automation.

Owner:SHANDONG AONENG ELECTRIC POWER SCI & TECH

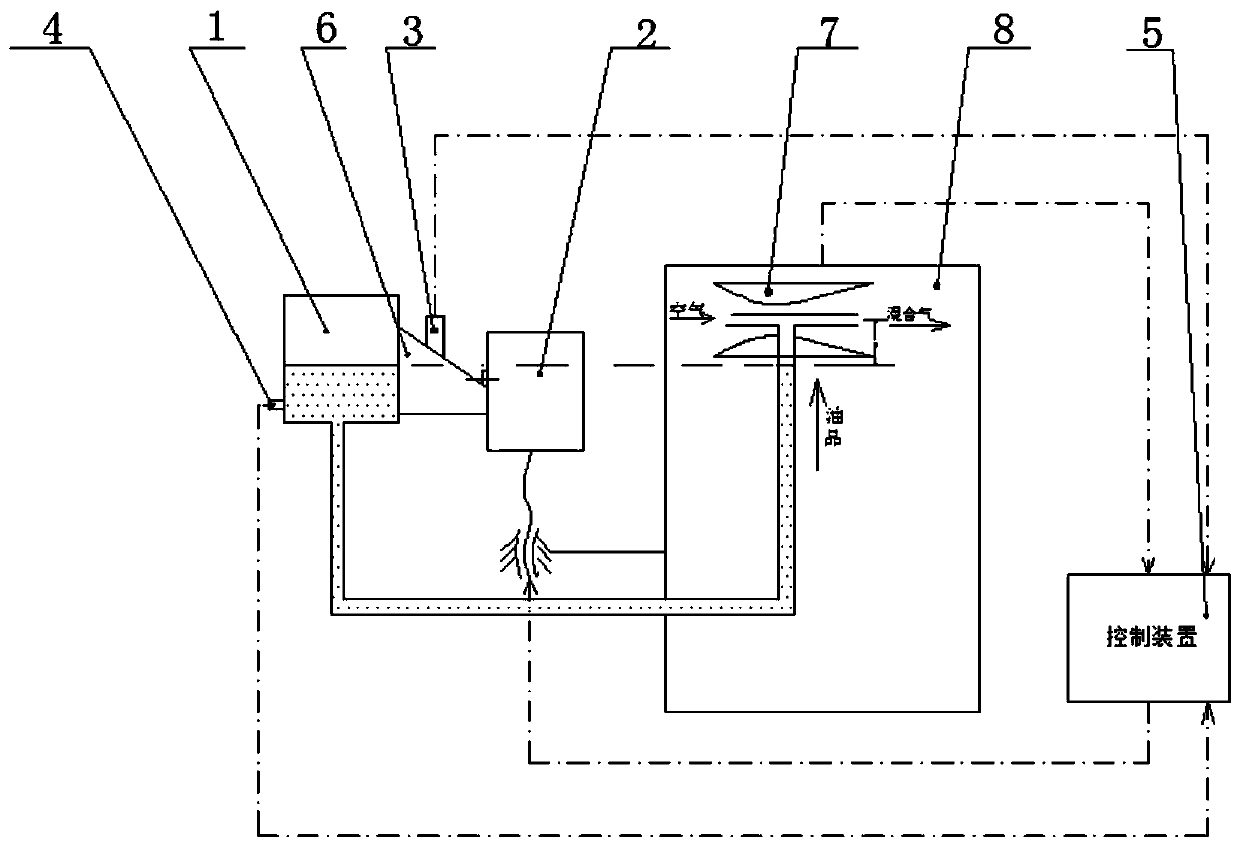

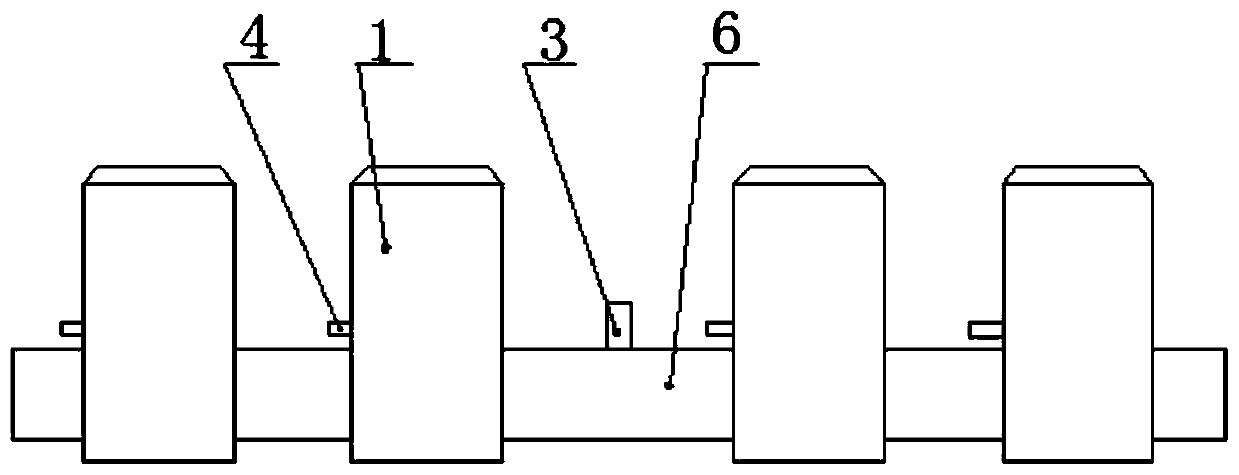

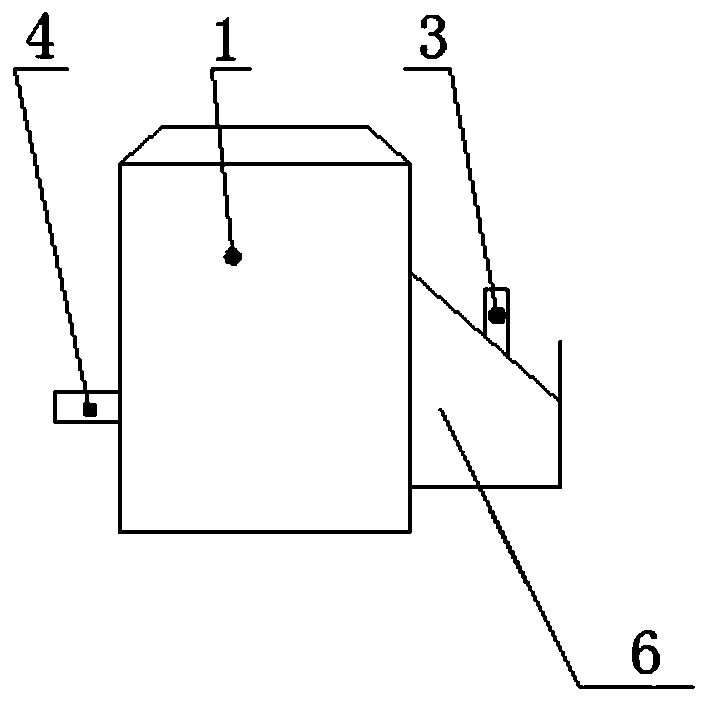

Engine carburetor liquid level control device

ActiveCN106812631BConstant liquid levelSave adjustment timeMachines/enginesCarburettorsGasolineCarburetor

The invention discloses an engine carburetor liquid level height regulating device. The engine carburetor liquid level height regulating device comprises an oil storage cup, a lifting mechanism, a displacement sensor, a liquid level sensor, a control device and an oil storage cup support, wherein one side of the lifting mechanism is movably connected with the oil storage cup support, the other side of the lifting mechanism is fixedly connected with a gasoline octane value measuring machine body, the displacement sensor and the liquid level sensor are connected to the oil storage cup support and the oil storage cup, and the control device controls the movement of the lifting mechanism relative to a carburetor and measures the liquid level height of the oil surface of the oil storage cup in real time according to signals input by the displacement sensor and the liquid level sensor. Compared with the prior art, the device has the advantages that the liquid level height of the carburetor is regulated through the displacement sensor and the liquid level sensor, so that the problem of testing lag is effectively controlled, and reliability and sensitivity of a system are improved. In addition, the device is suitable for the technical field of gasoline octane value measurement.

Owner:SHANGHAI UNIV

Device and method for growing silicon carbide crystals by liquid phase method

ActiveCN113718337BStable growthQuality improvementPolycrystalline material growthFrom melt solutionsCarbide siliconCrucible

The invention relates to a device and method for growing silicon carbide crystals by a liquid phase method. The device includes: a crucible for containing the Si alloy auxiliary solution and a seed rod for fixing the silicon carbide seed crystal; the device also includes a liquid level maintaining device, which includes a liquid level maintaining ring and The driving device used to push the liquid level to keep the ring down to the Si alloy auxiliary solution. The method is as follows: melting the growth raw material containing Si and metal elemental substance into a Si alloy co-solution; lowering the silicon carbide seed crystal and contacting the co-solution phase to grow the silicon carbide crystal; during the growth process of the silicon carbide crystal, The liquid level maintenance ring is pushed down by the pushing device into the Si alloy auxiliary solution to keep the liquid level of the Si alloy auxiliary solution constant. The invention can keep the height of the liquid level constant and the temperature field constant during the growth process of the silicon carbide crystal, can also maintain the stability of the auxiliary solution components and increase the thickness of the generated silicon carbide crystal.

Owner:北京晶格领域半导体有限公司

Electric heating pool for generating bubbles with fixed sizes

The invention belongs to the technical field of liquid heating, and particularly relates to an electric heating pool capable of generating bubbles with fixed sizes. The electric heating pool comprisesa stainless steel pool and a water supplementing tank, wherein the stainless steel water tank is arranged on an electromagnetic heater and is connected with the water supplementing tank through a pipeline; an electric valve A is arranged on a connecting pipeline of the stainless steel water tank and the water supplementing tank; an annular metal tray is welded to the upper portion of the stainless steel pool; and a metal grid is placed on the metal tray. According to the invention, the sizes of bubbles passing through the grid can be controlled by changing the size of the metal grid near a liquid level, so the sizes of the bubbles reaching the liquid level are fixed; by adjusting the structure of the bottom of the pool and using bases of different shapes and specifications, the positionsand the number of the bubbles can be changed; and an aqueous solution is continuously supplied to the electric heating pool through a temperature-controllable water storage tank, so the electric heating pool can maintain a constant liquid level, and bubbles are continuously generated.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Negative-pressure liquid nitrogen subcooler and method thereof for reducing liquid nitrogen temperature

InactiveCN102374708BImprove the pumping effectImprove efficiencySubcoolersLiquid nitrogen containerHeat sink

The invention provides a negative-pressure liquid nitrogen subcooler and a method therefore for reducing liquid nitrogen temperature. The negative-pressure liquid nitrogen subcooler comprises a liquid nitrogen conveying system, a subcooler system, a negative-pressure air exhausting system and a discharging system, wherein the liquid nitrogen conveying system is used for supplying liquid nitrogen to the subcooler system; the negative-pressure air exhausting system is used for reducing pressure for the subcooler; and the discharging system is used for discharging gasified nitrogen. In the negative-pressure liquid nitrogen subcooler, an electric heater is adopted to raise the temperature of gaseous nitrogen to 20-30 DEG C, so that the subcooler is not limited to the weathers; a liquid level sensor is adopted to automatically regulating the opening of a pneumatic regulating valve, so that the height of the liquid level is maintained. The method comprises the steps of: firstly, injecting the liquid nitrogen for a liquid nitrogen container and regulating pressure; then injecting the liquid nitrogen for the subcooler, wherein the height of the liquid level of the liquid nitrogen in the subcooler is kept constant; then starting the negative-pressure air exhausting system, and cooling the liquid nitrogen through a heat exchanger; and finally, recovering the liquid nitrogen and discharging the liquid nitrogen. According to the invention, the temperature of a heat sink can be further reduced, the temperature of the heat sink is regulatable within a range of 70-77k, and the advantages of simple equipment, good effect and low operating cost are achieved.

Owner:BEIHANG UNIV

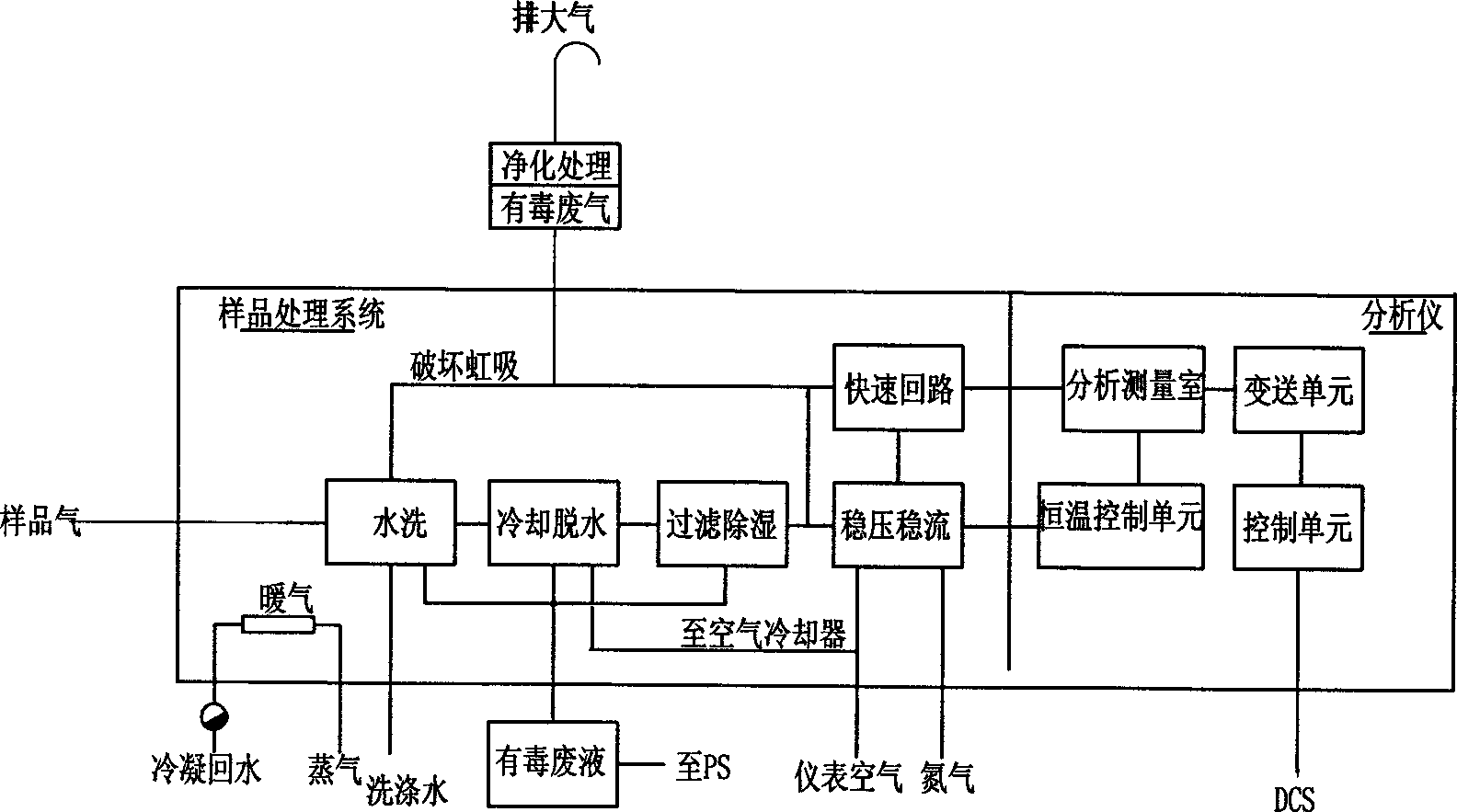

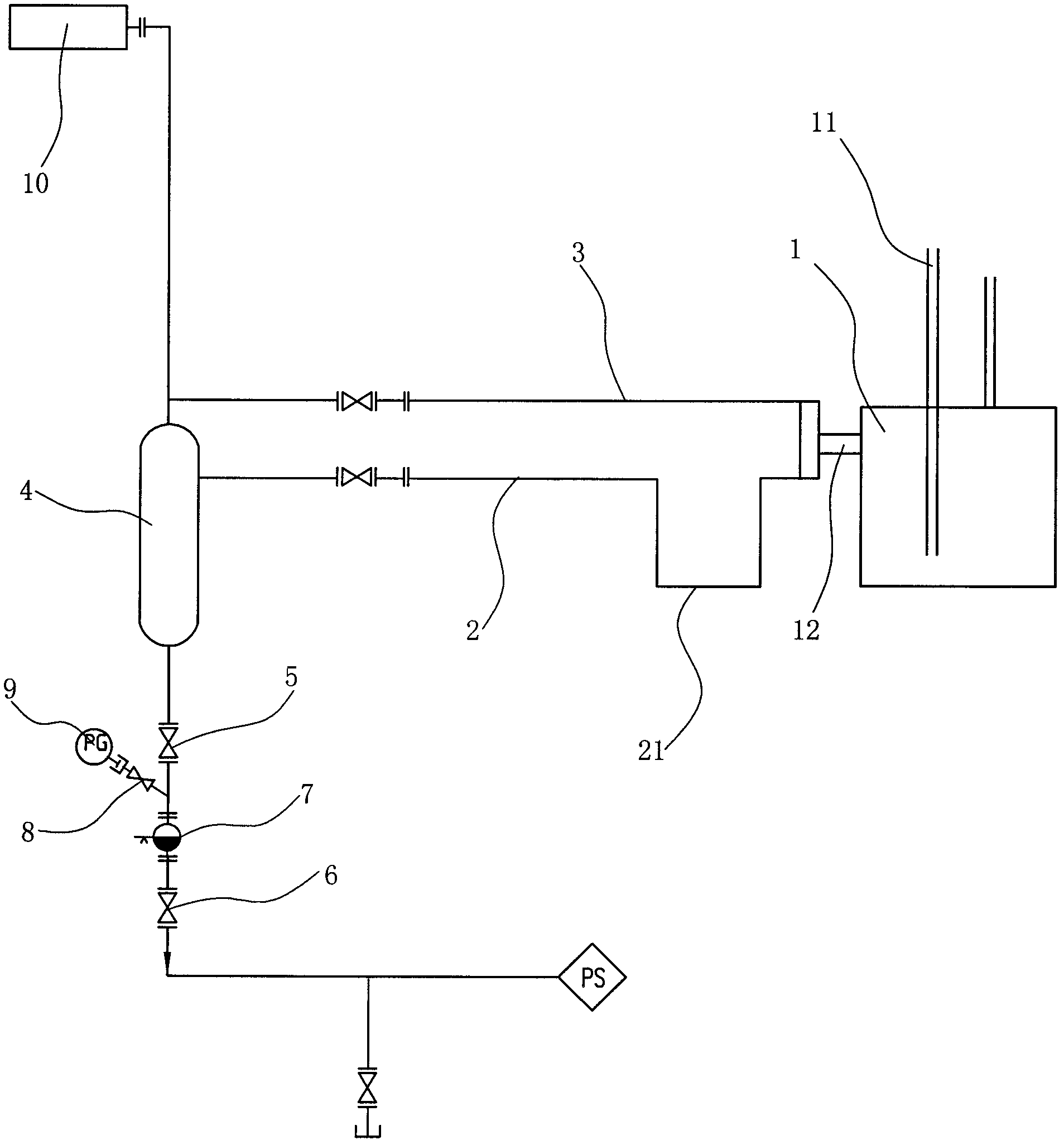

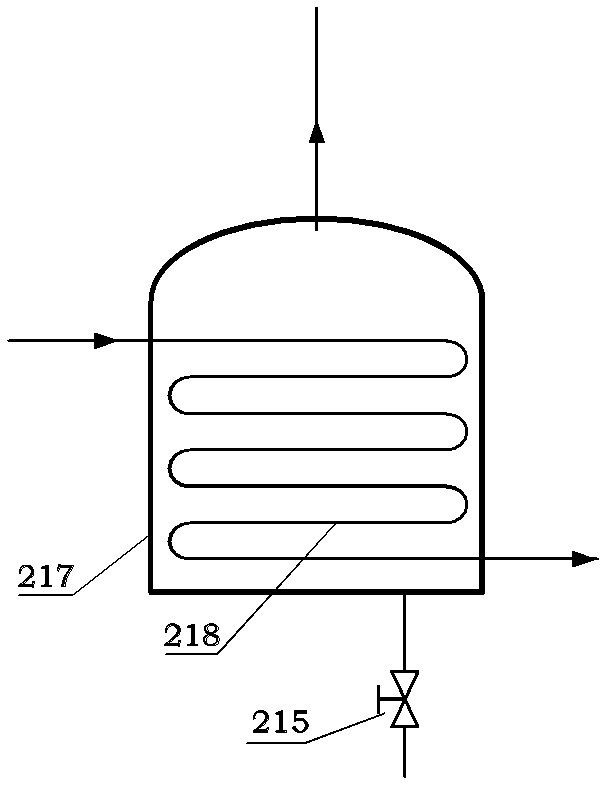

Sample pretreatment system of magnetic mechanical oxygen analyzer

ActiveCN102393324BBroken siphon phenomenonEnvironmental protectionPreparing sample for investigationLine tubingCollection system

The invention relates to a sample pretreatment system of a magnetic mechanical oxygen analyzer. The system comprises a washing tank and a waste liquid discharge pipeline, wherein the washing tank is provided with a liquid feed pipe connected with a sample pipeline and a washing water pipeline and a liquid discharge pipe for discharging washed waste liquid; the liquid discharge pipe is connected with the waste liquid discharge pipeline through a U-shaped pipe; and the waste liquid discharge pipeline is connected with a closed waste liquid collection system. The sample pretreatment system is characterized in that the liquid discharge pipe is provided with two outlets, wherein one of the two outlets is a liquid discharge port and the other one of the two outlets is an exhaust port; the liquid discharge port is connected with the waste liquid discharge pipeline; a gas-liquid separation tank is arranged between the waste liquid discharge pipeline and the waste liquid collection system; the mounting elevation of the gas-liquid separation tank is lower than that of an oxygen analyzer; the gas outlet of the gas-liquid separation tank is communicated with the atmosphere through a gas pipeline; the liquid outlet of the gas-separation tank is connected with the waste liquid collection system; and the exhaust port is connected with the gas pipeline through an exhaust pipe. The sample pretreatment system provided by the invention can ensure stable operation of an analysis unit of the oxygen analyzer.

Owner:CHINA PETROLEUM & CHEM CORP +2

Negative-pressure liquid nitrogen subcooler and method for liquid nitrogen temperature reduction

InactiveCN102393107BImprove the pumping effectImprove efficiencySubcoolersLiquid nitrogen containerNitrogen

Owner:BEIHANG UNIV

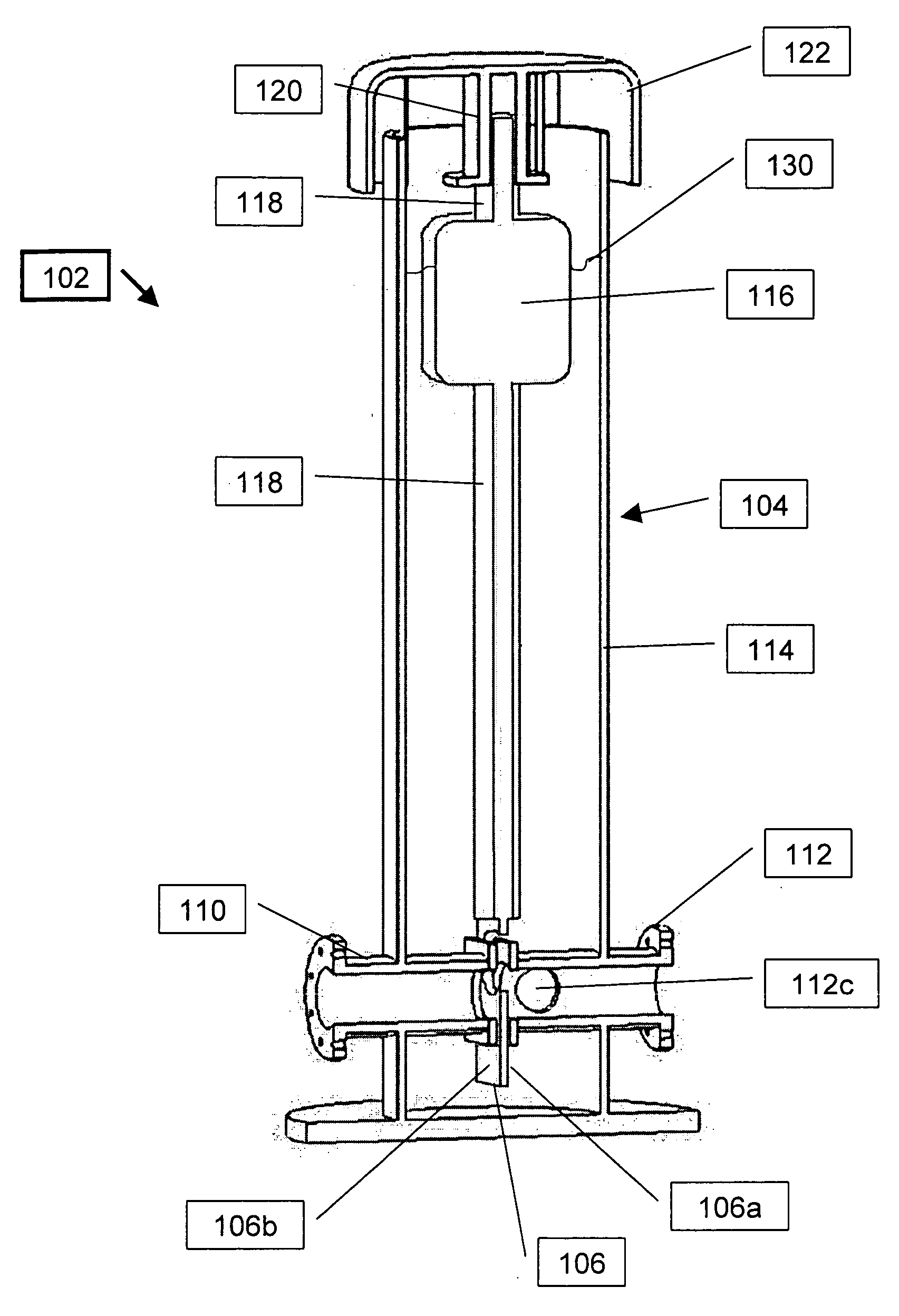

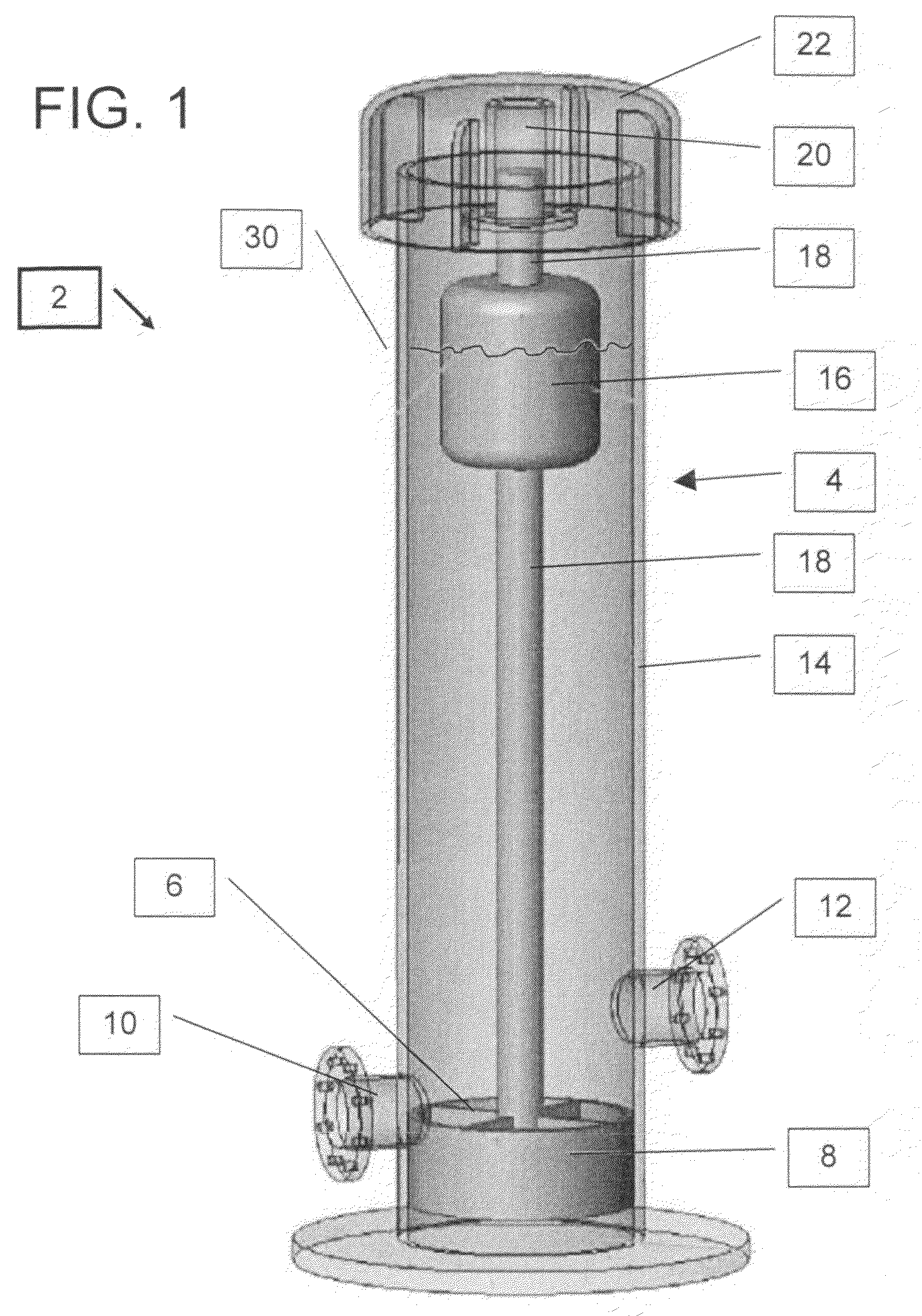

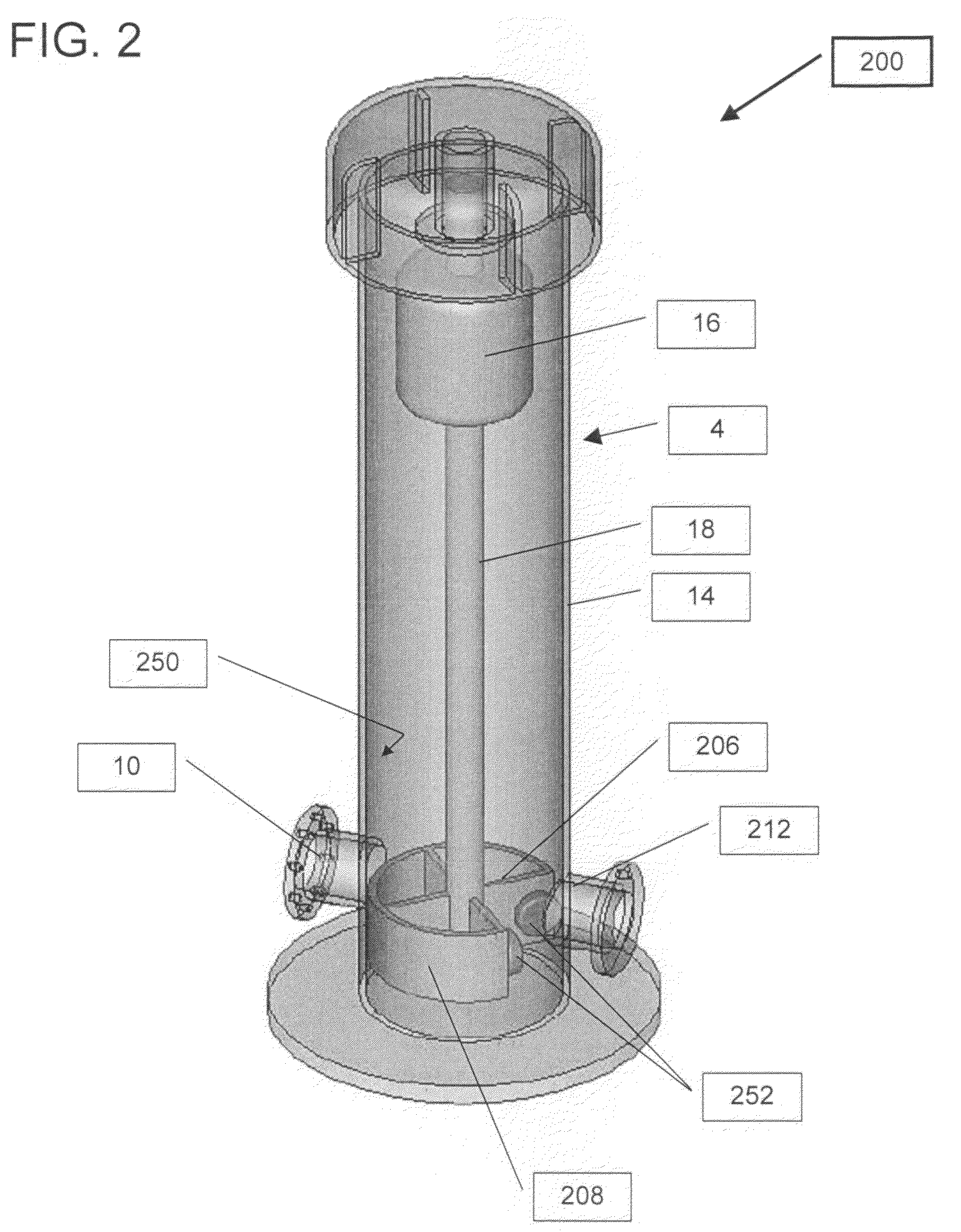

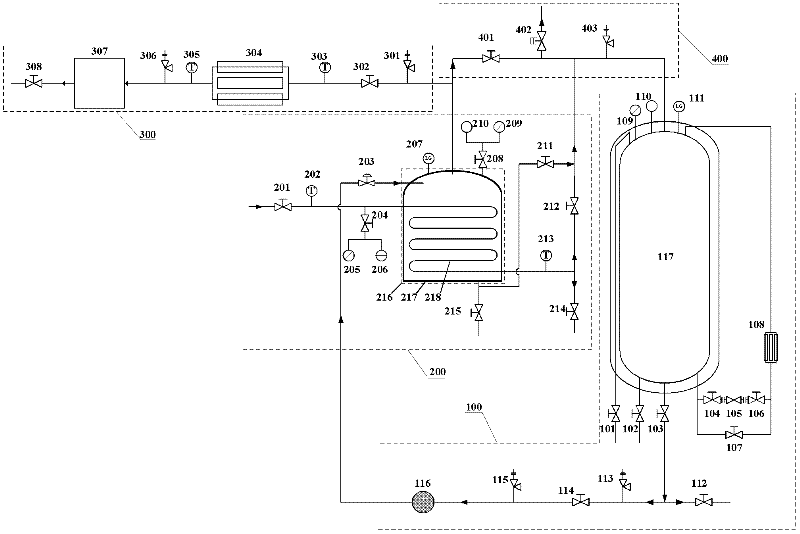

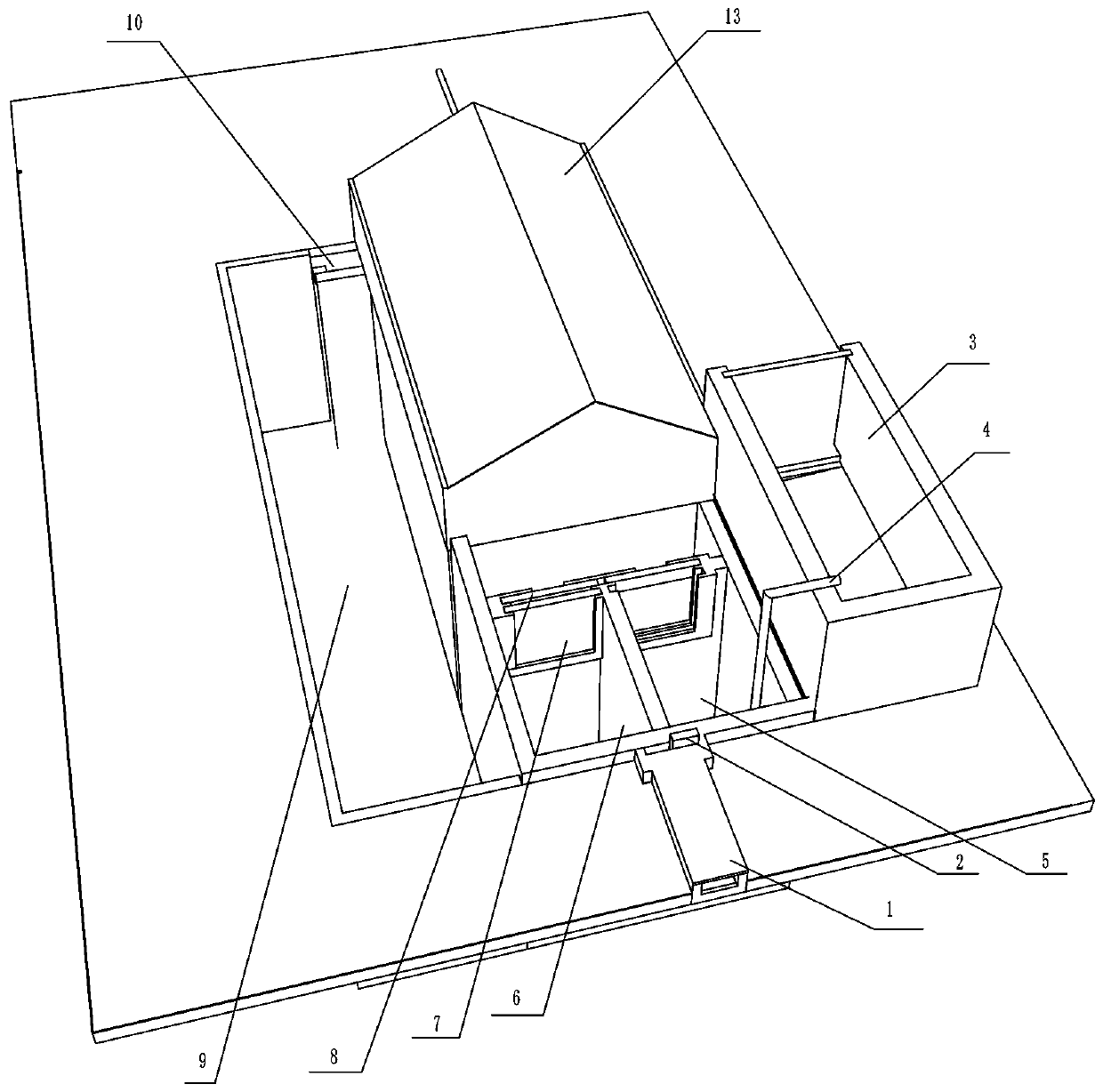

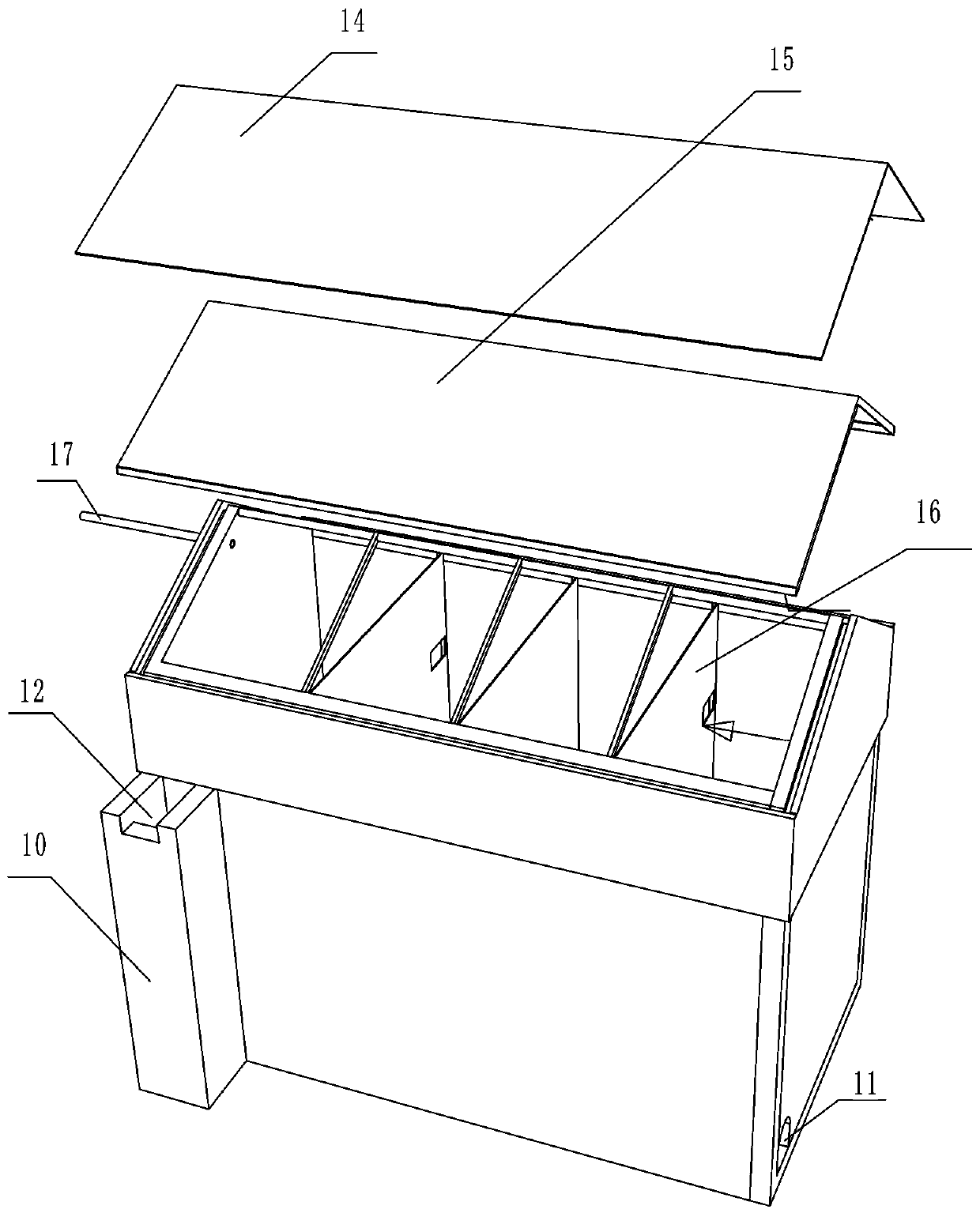

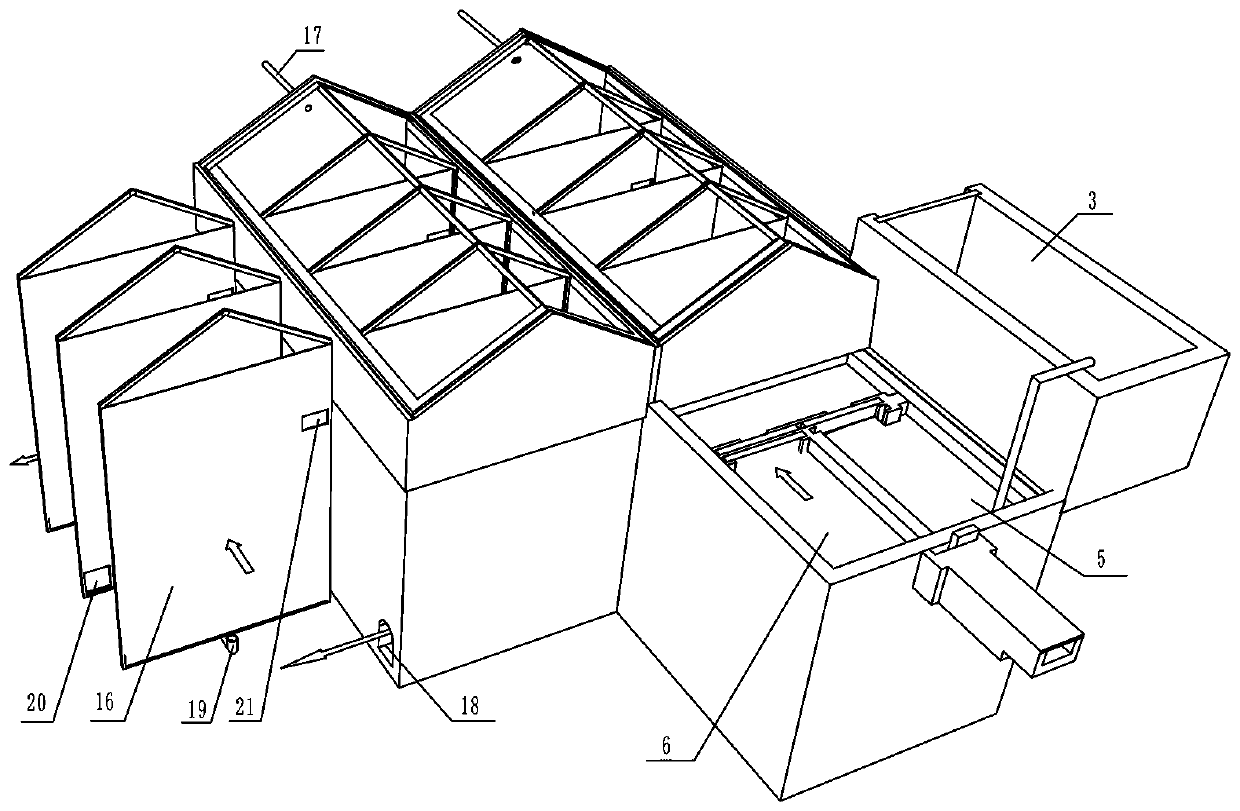

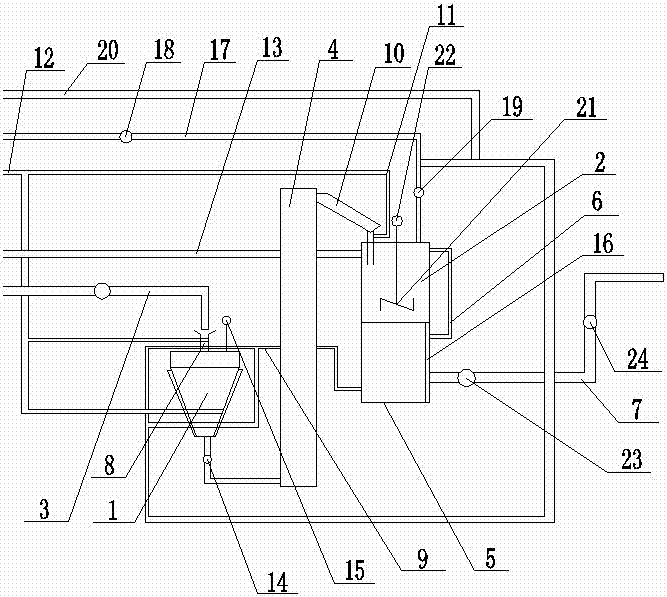

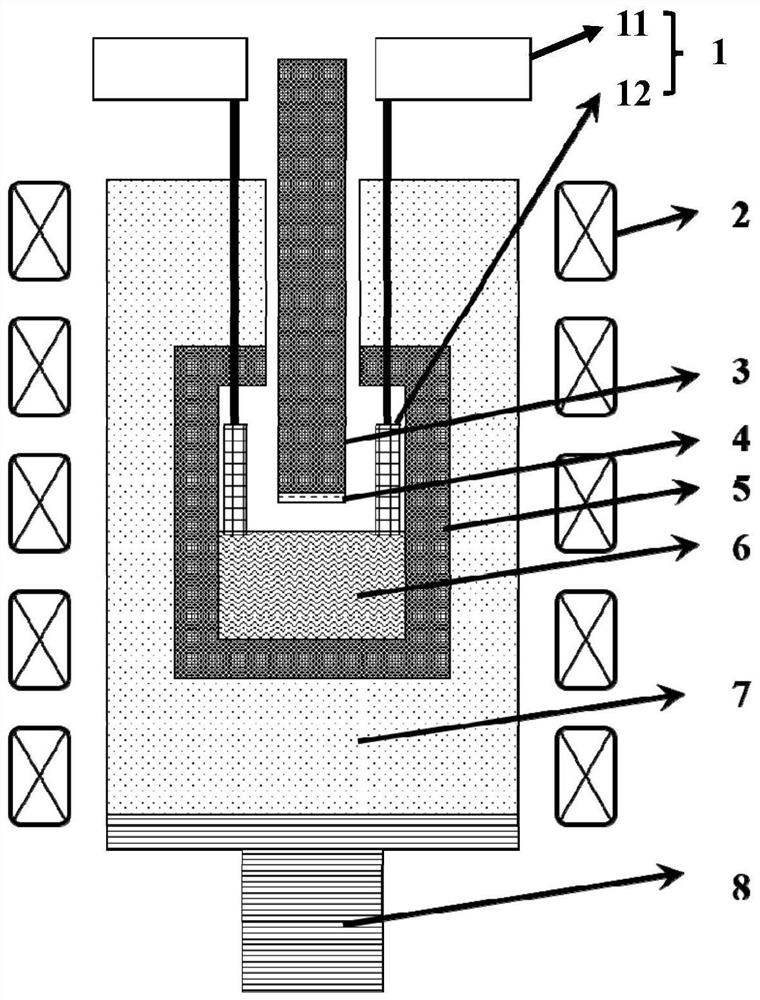

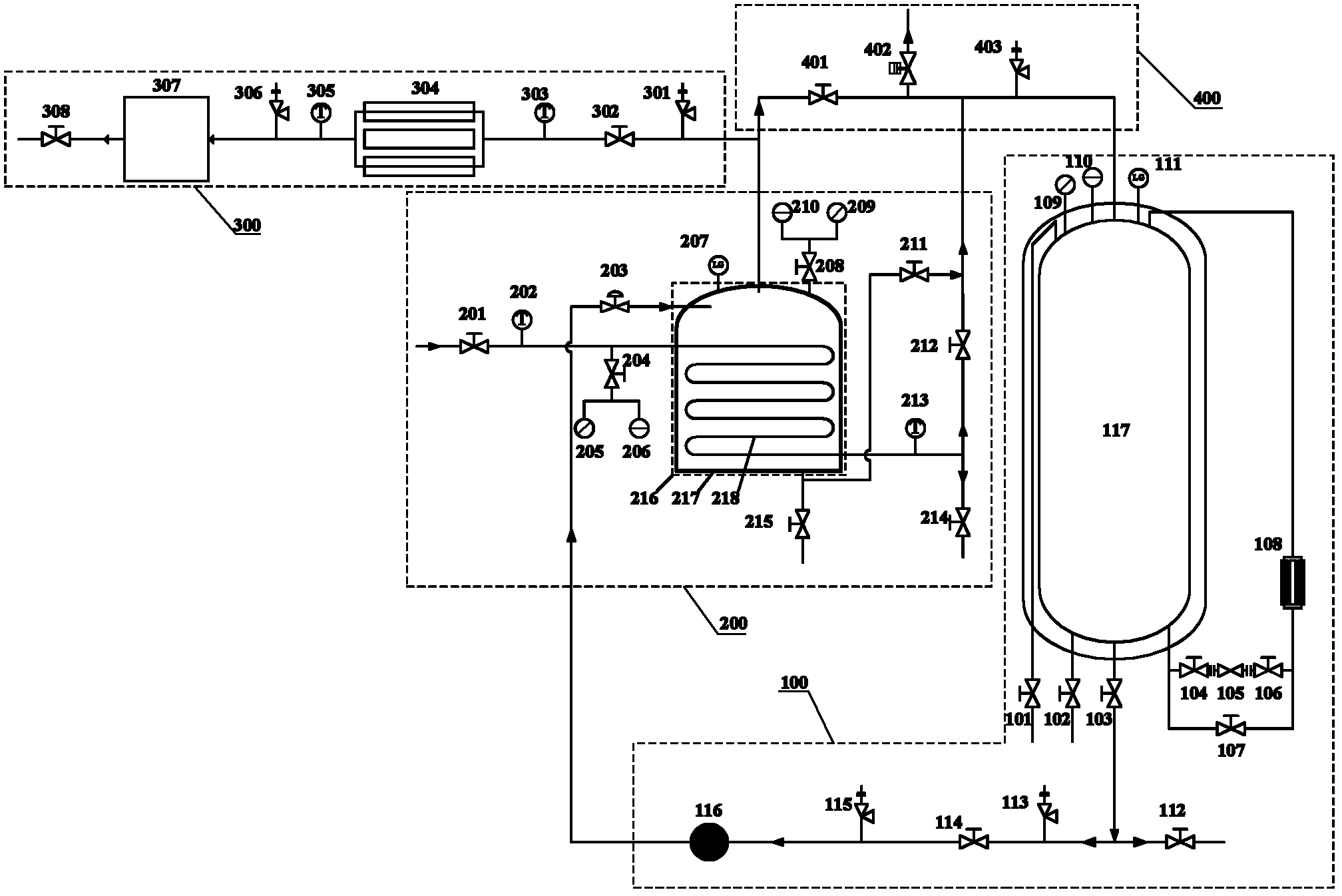

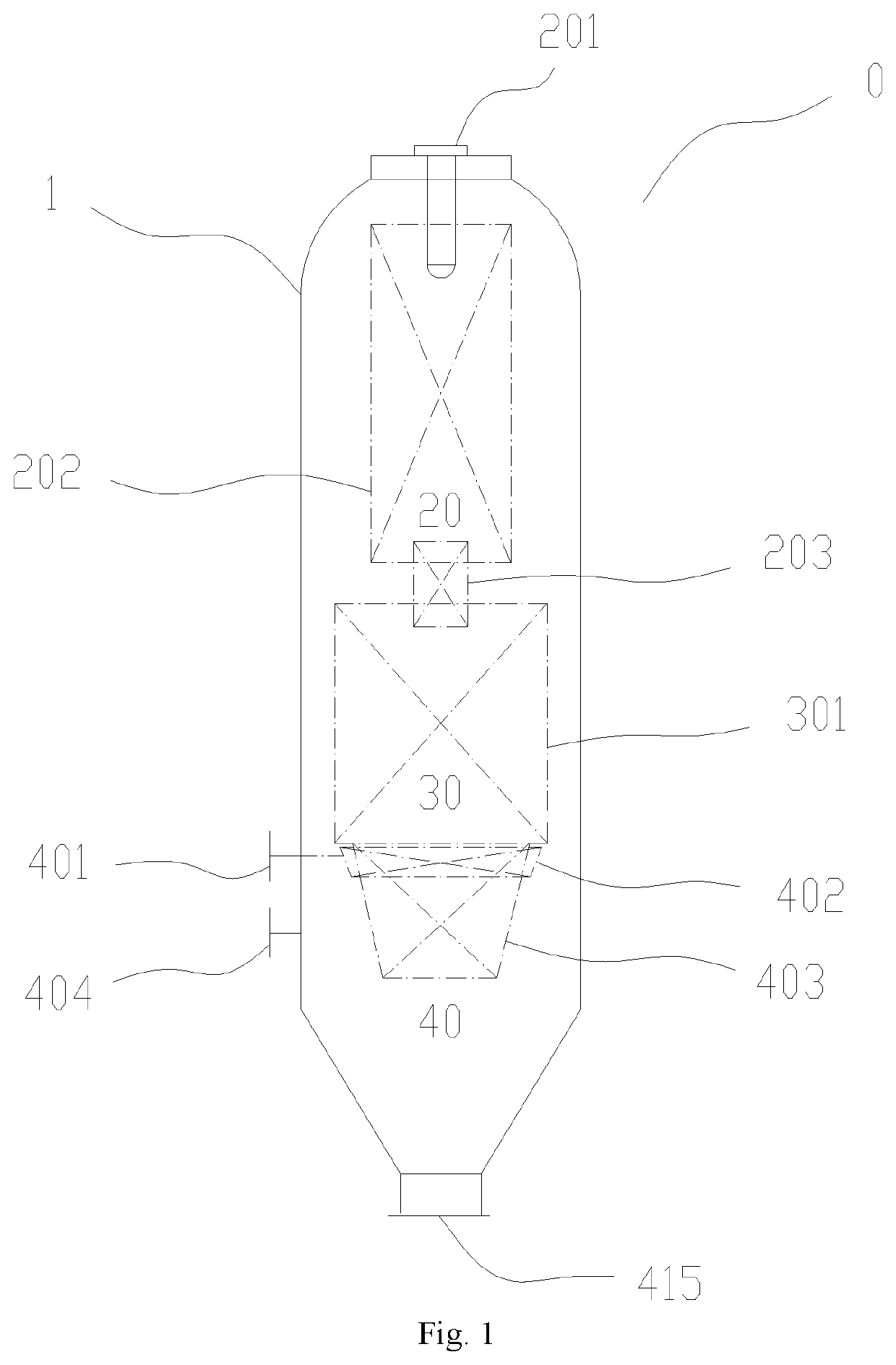

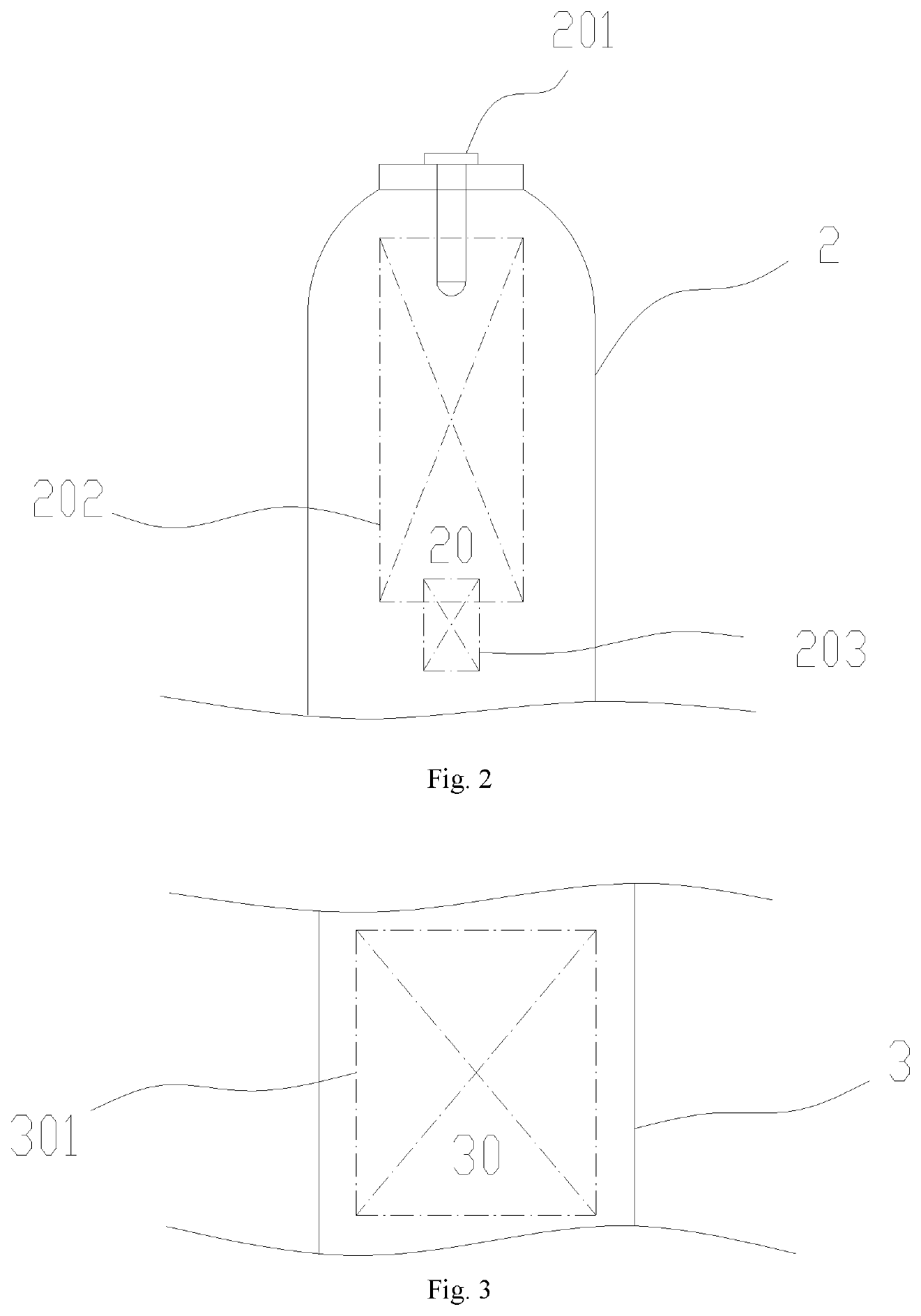

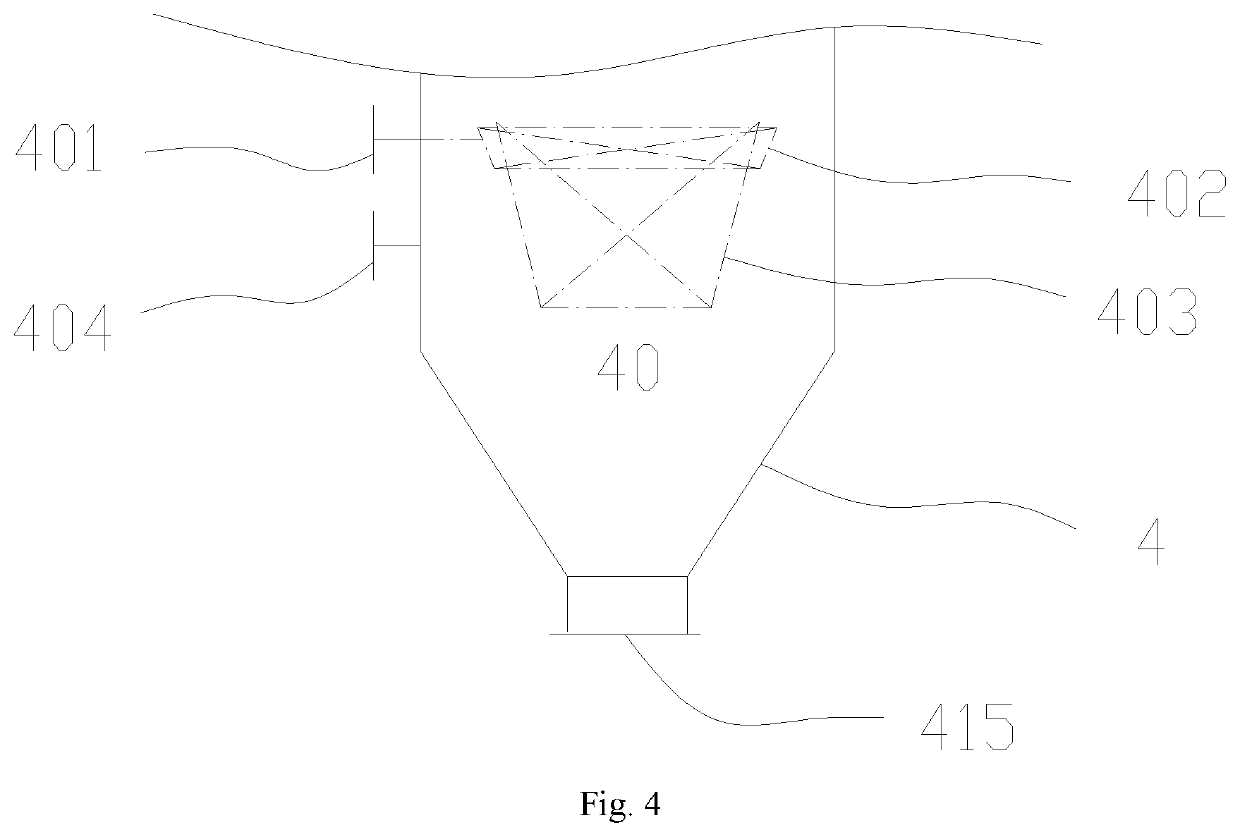

Constant liquid level gasification furnace with waste boiler

ActiveUS10611975B2Ensure safetyEasy to installEnergy inputGasification processes detailsThermodynamicsExhaust fumes

Owner:BEIJING QING CHUANG JIN HUA TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com