Patents

Literature

30results about "Bumping prevention" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

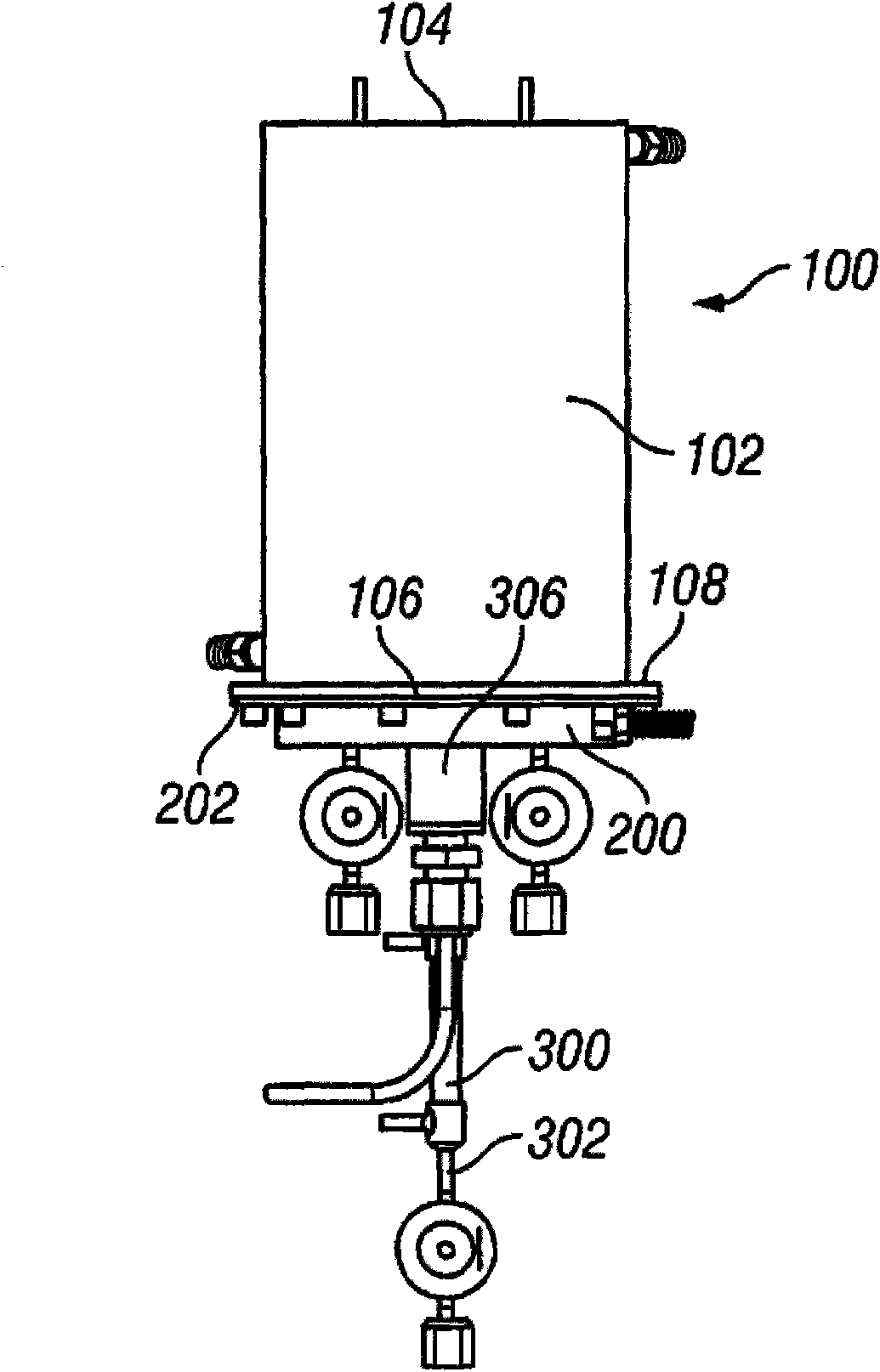

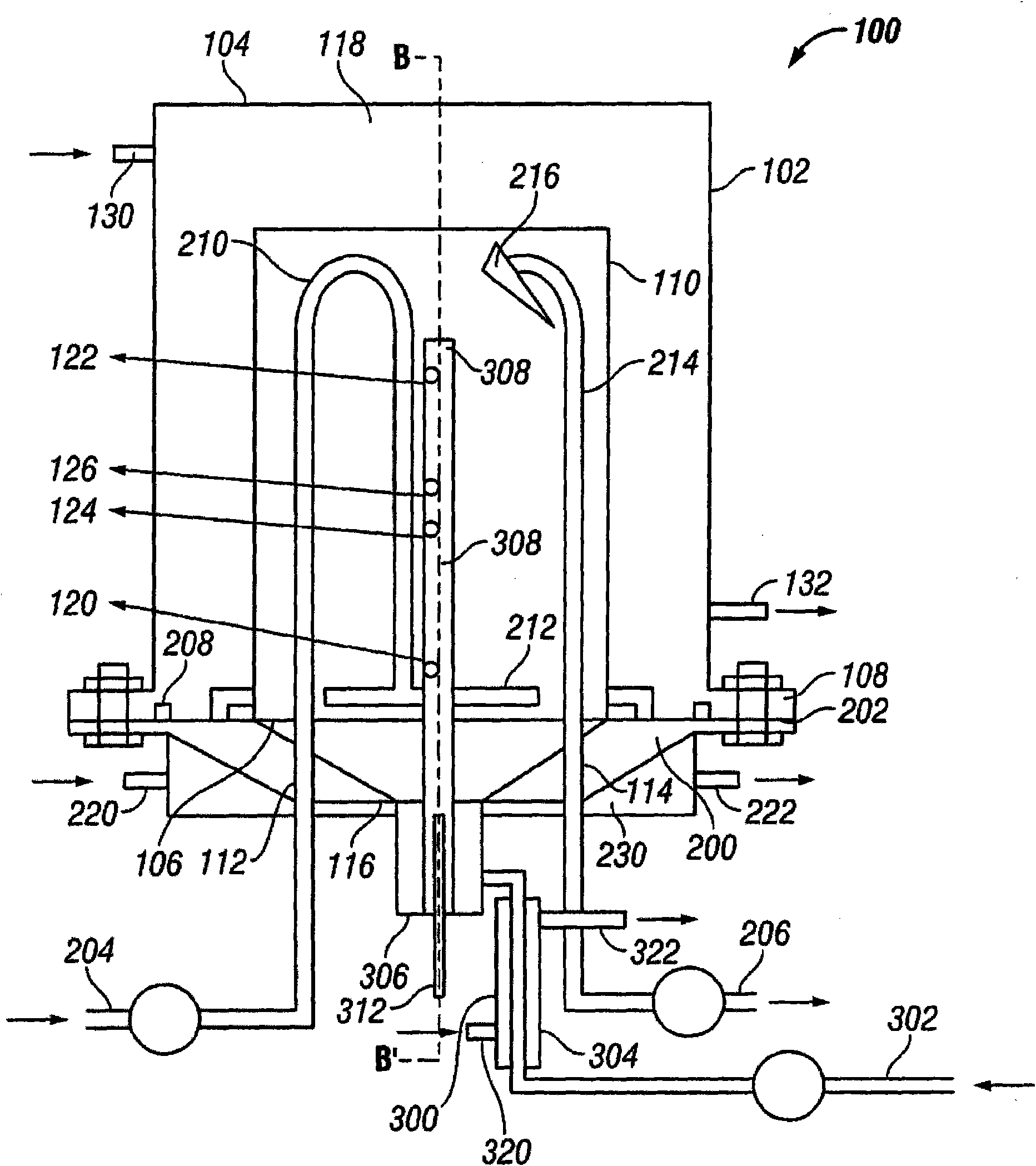

Bubbler assembly and method for vapor flow control

InactiveUS20120304935A1Mitigate and overcomeLess expensiveUsing liquid separation agentMixing methodsSource materialEngineering

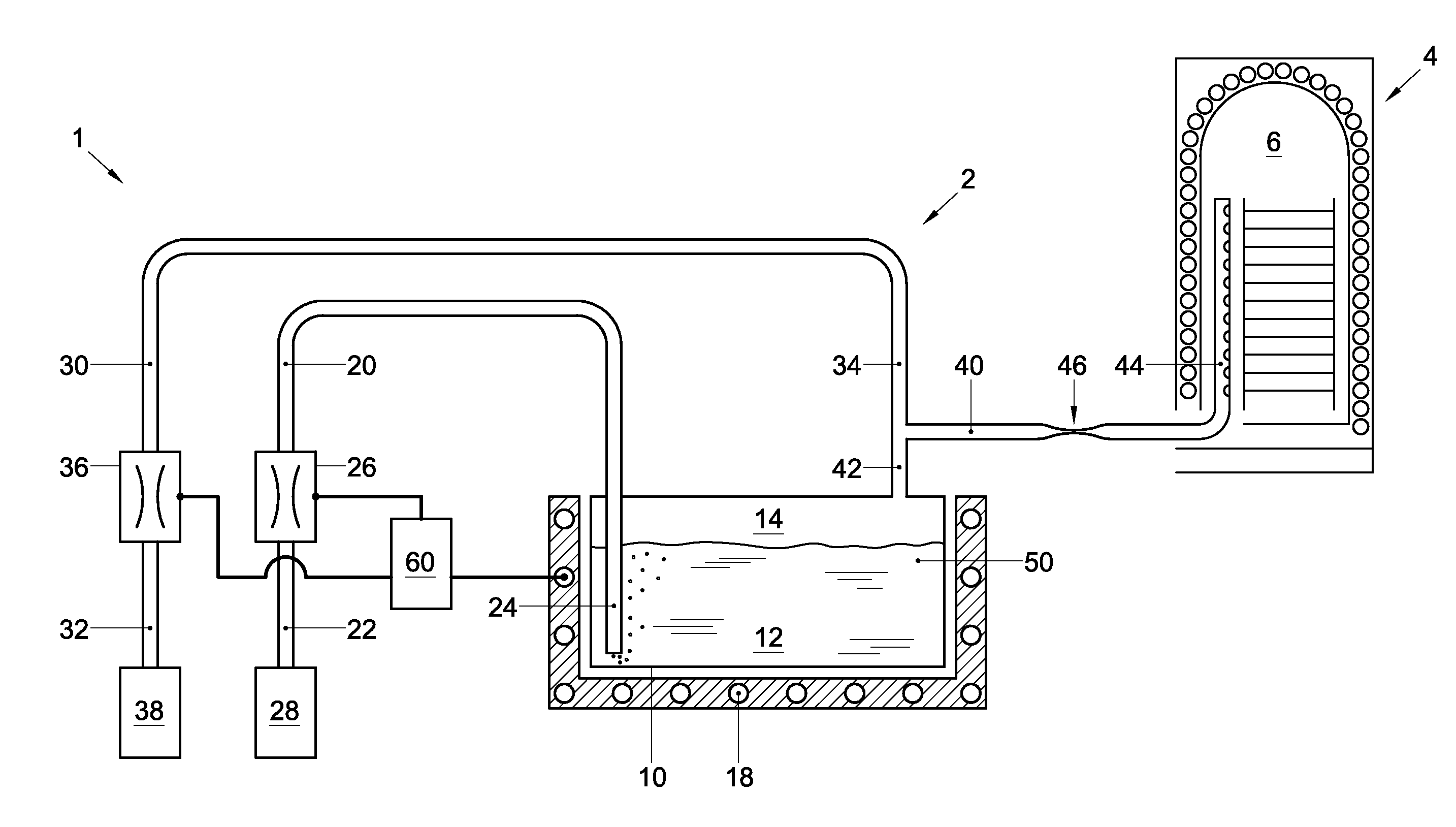

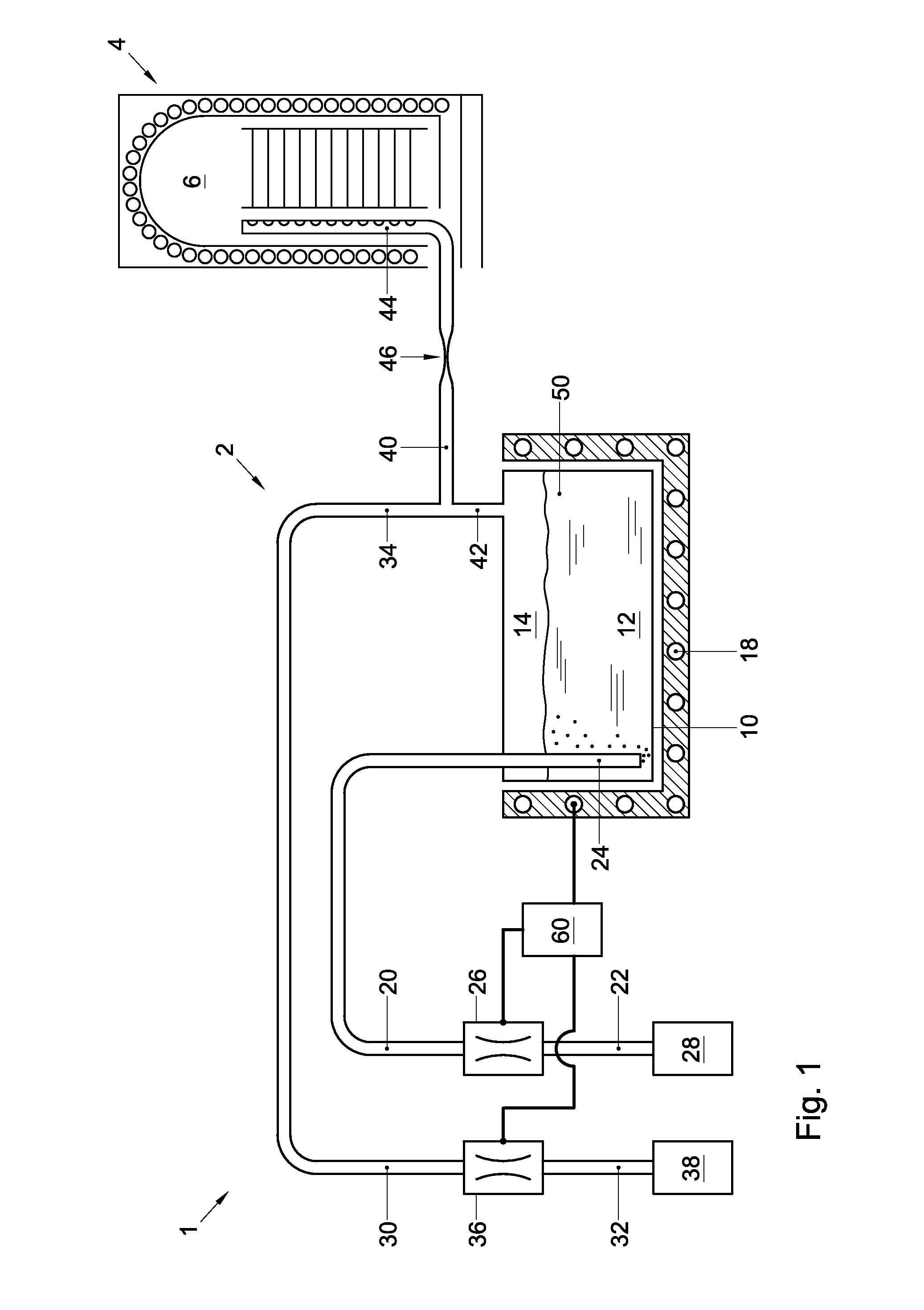

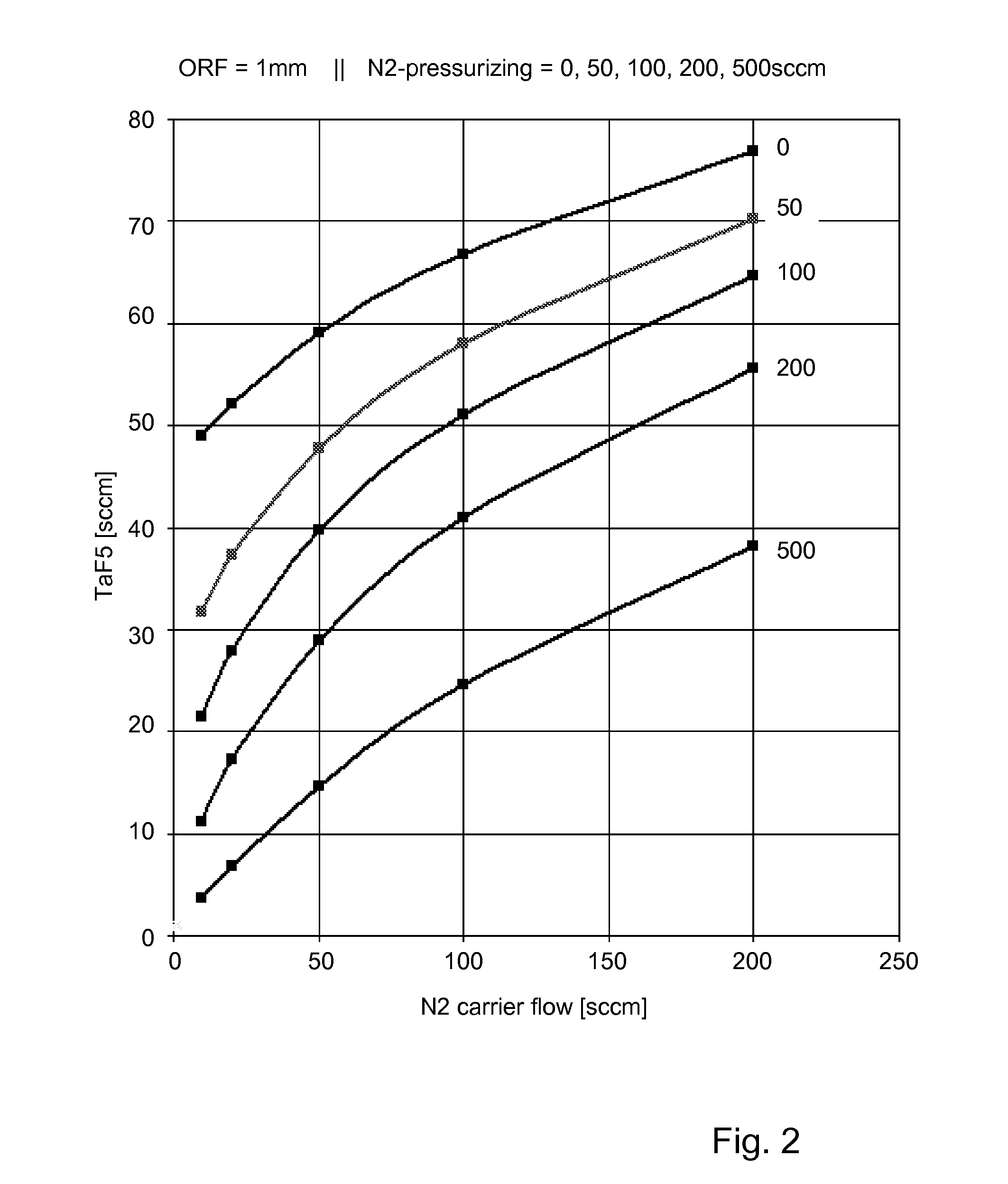

Disclosed is a bubbler assembly. The bubbler assembly includes a vessel configured to contain a liquid source material and its vapor. It also includes a carrier gas supply line, a downstream end of which discharges in a lower portion of the vessel, and a gas outlet line, an upstream end of which is in fluid communication with an upper portion of the vessel. The gas outlet line includes a constriction. The bubbler assembly further includes a pressurizing gas supply line, a downstream end of which discharges in either the upper portion of the vessel or in the gas outlet line at a point upstream of the constriction.

Owner:ASM INTERNATIONAL

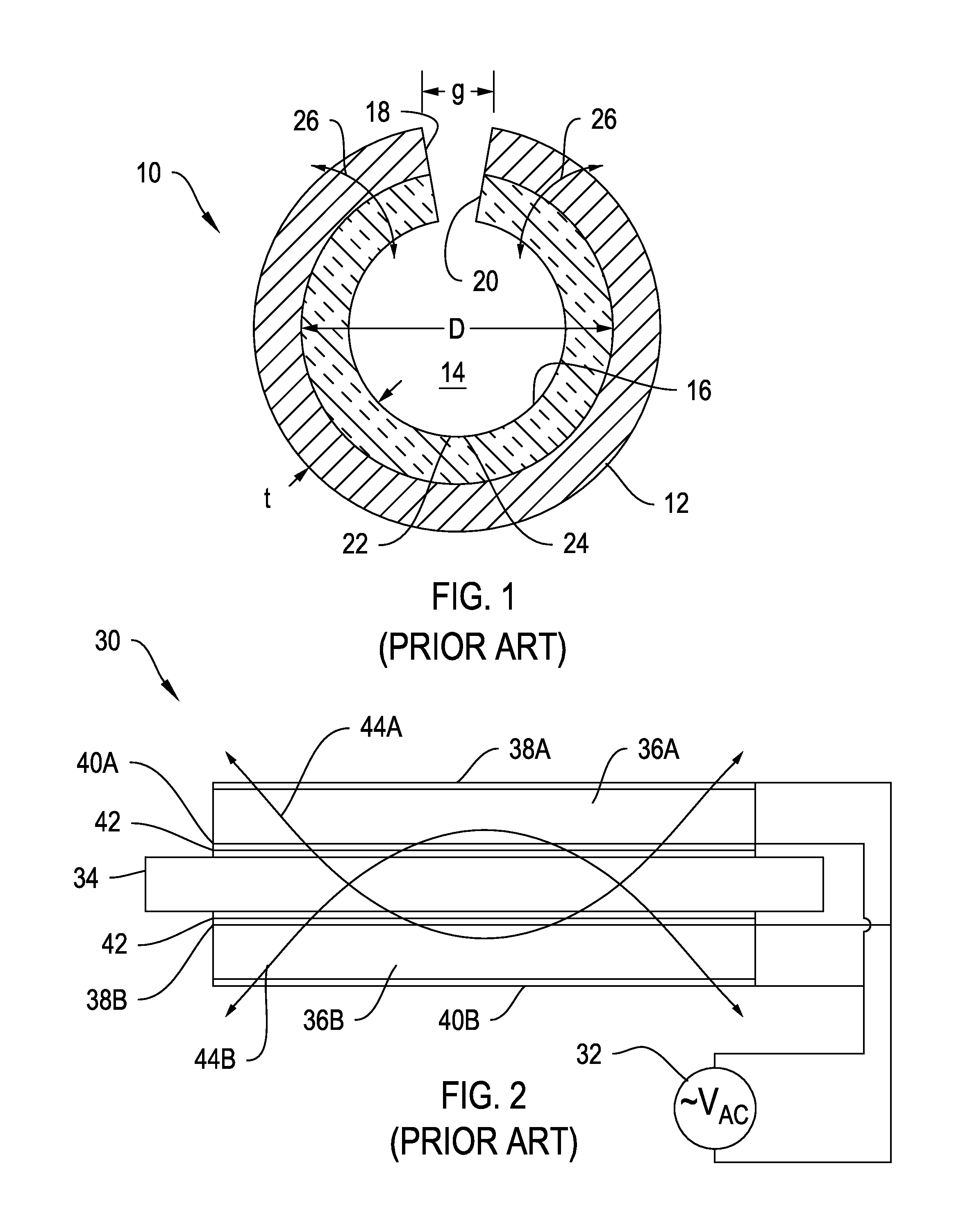

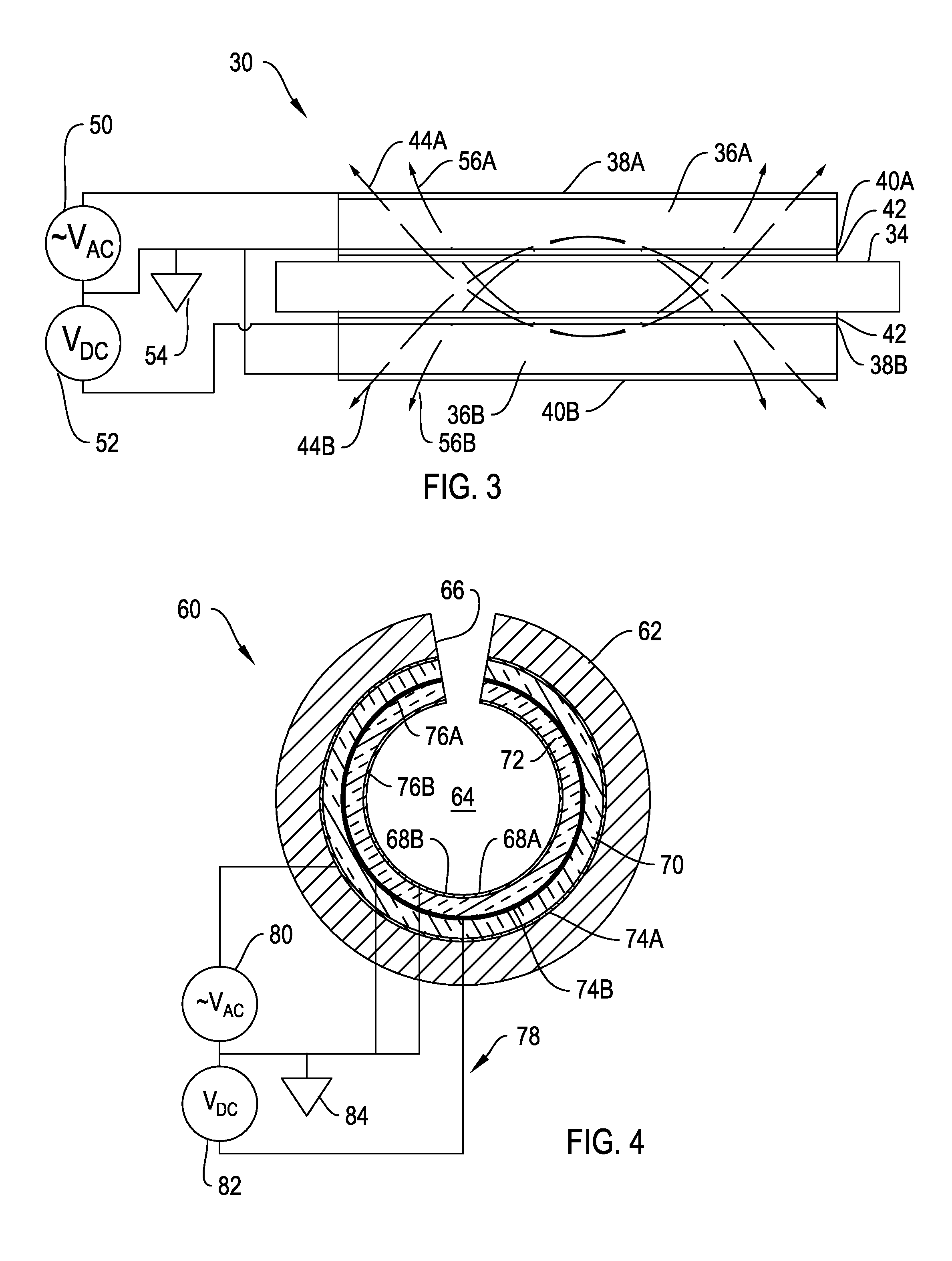

Variable resonance acoustic transducer

ActiveUS8854923B1Piezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive resonant transducersResonanceTransducer

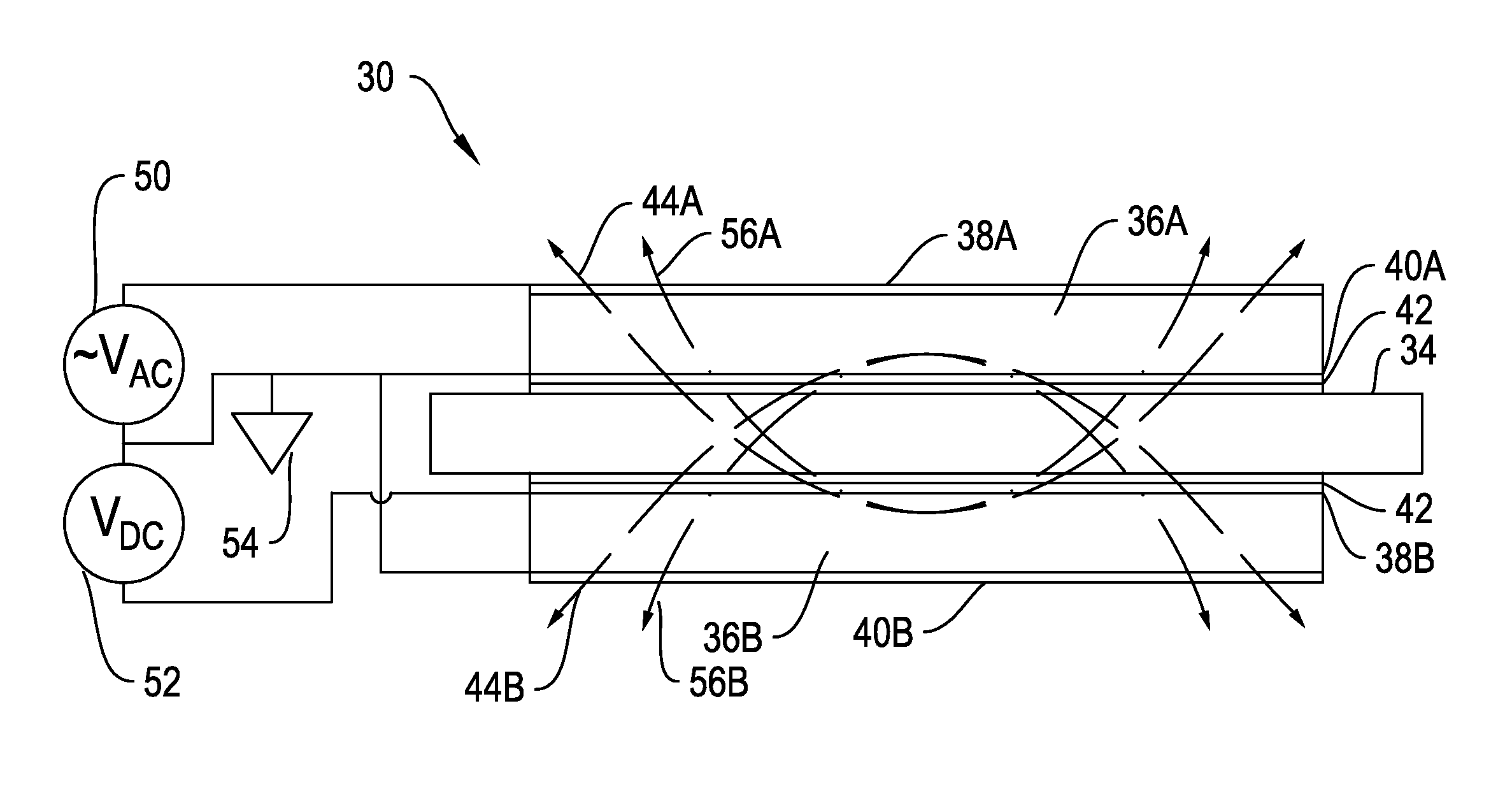

A transducer assembly is provided for projecting acoustic signals into a medium. The assembly includes a support member having first and second layers of piezoelectric material mechanically linked to the support member. The first and second layers are joined to electrical drive circuitry such that one layer receives a driving voltage signal while the other layer receives the driving voltage with a stiffening voltage. The transducer assembly can use both the 3-1 and 3-3 drive modes. Multiple configurations are supported, and both bender bar and slotted cylinder configurations are shown.

Owner:UNITED STATES OF AMERICA

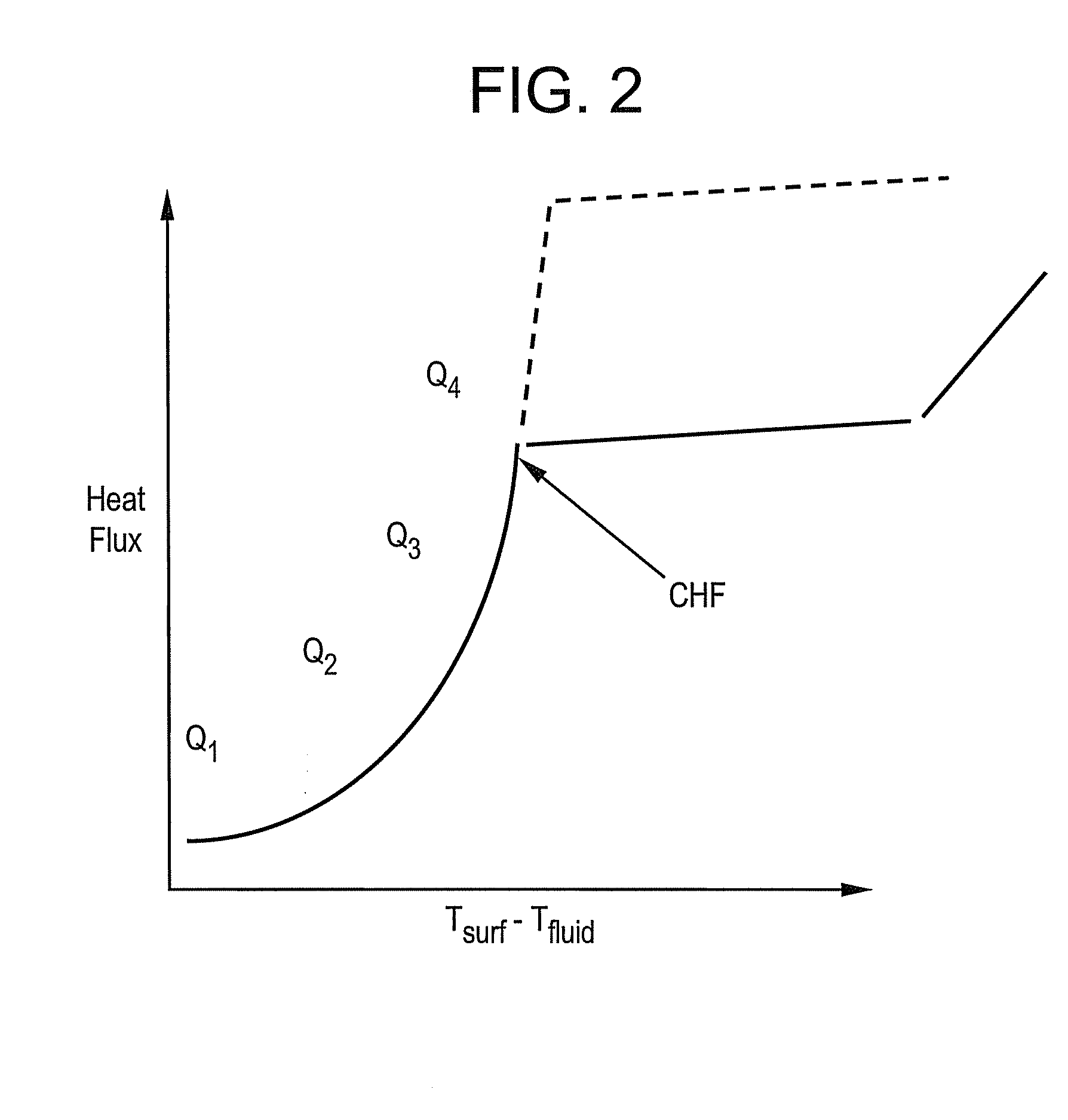

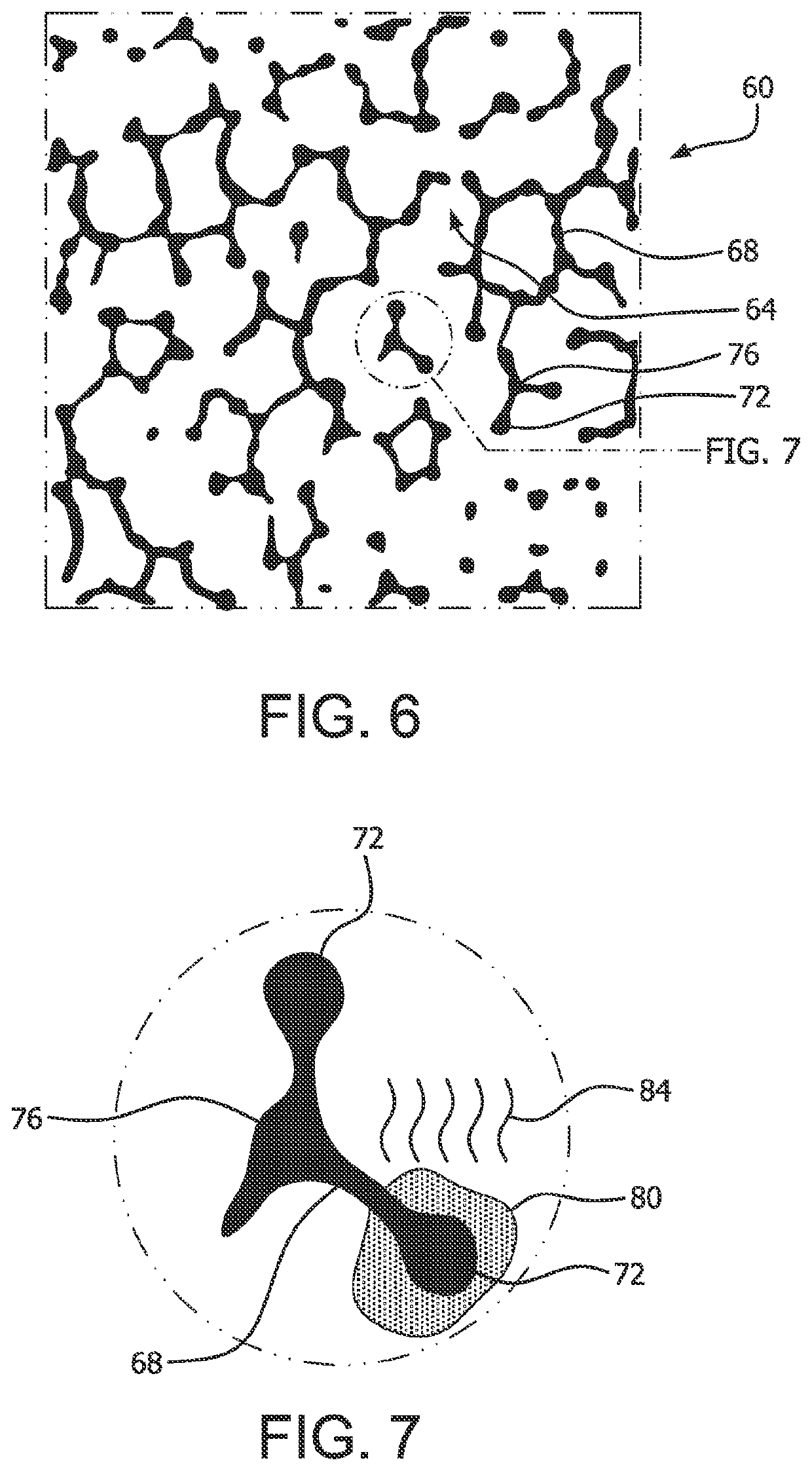

Surface having a nanoporous coating, methods of manufacture thereof and articles comprising the same

InactiveUS20100129639A1Increase critical heat fluxElectric shock equipmentsLayered productsMetallurgyMicrometer

Disclosed herein is an that includes a substrate; and a nanoporous coating disposed thereon; the nanoporous coating having a thickness of about 5 nanometers to about 10 micrometers; where an interface between the substrate and the nanoporous coating is disposed at an angle of about 60 degrees to about 120 degrees to a horizontal; the nanoporous coating being in contact with a liquid; the nanoporous coating being operative to improve the critical heat flux by an amount of about 20% to about 100% over a surface that does not have a nanoporous coating.

Owner:GENERAL ELECTRIC CO

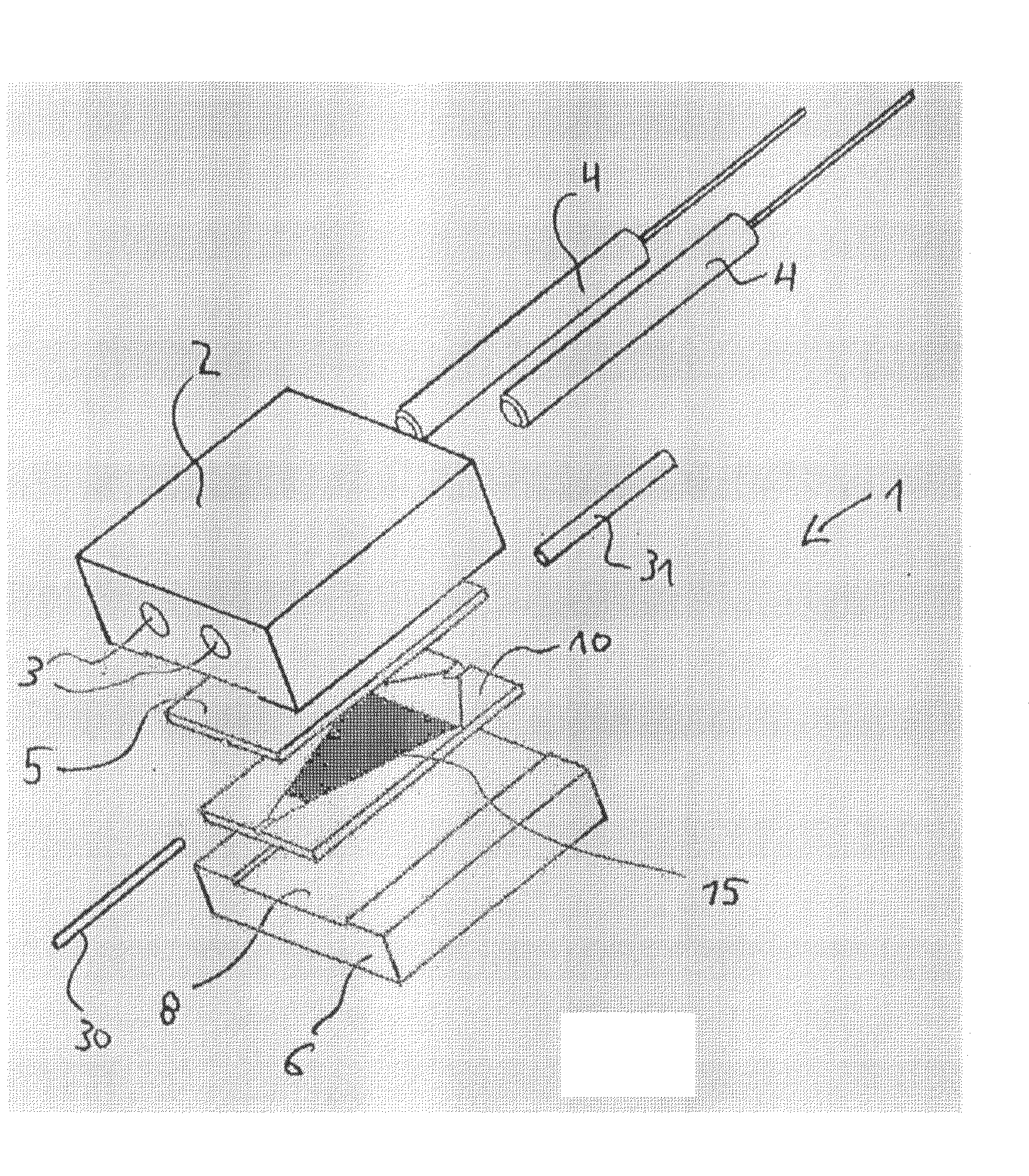

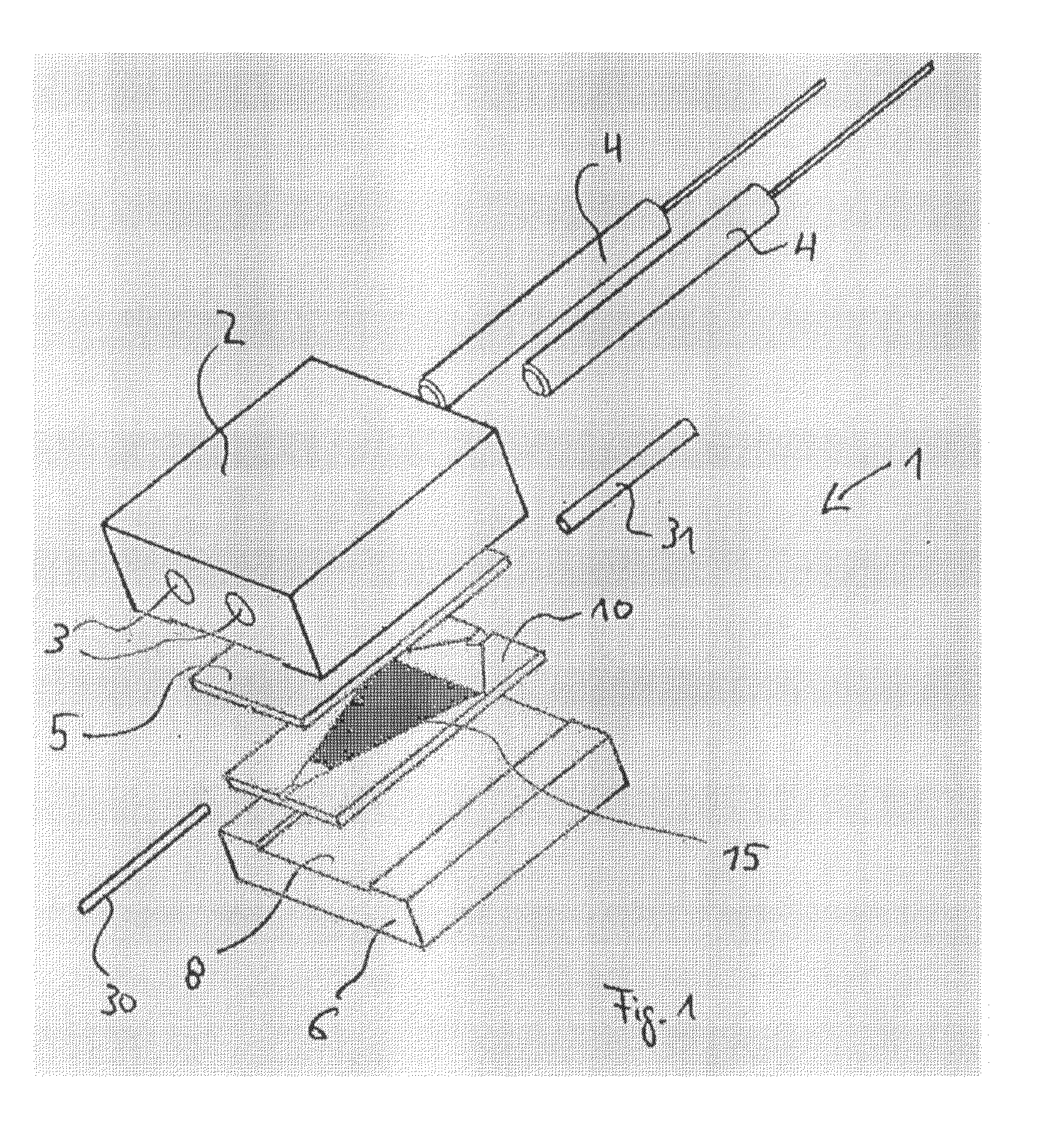

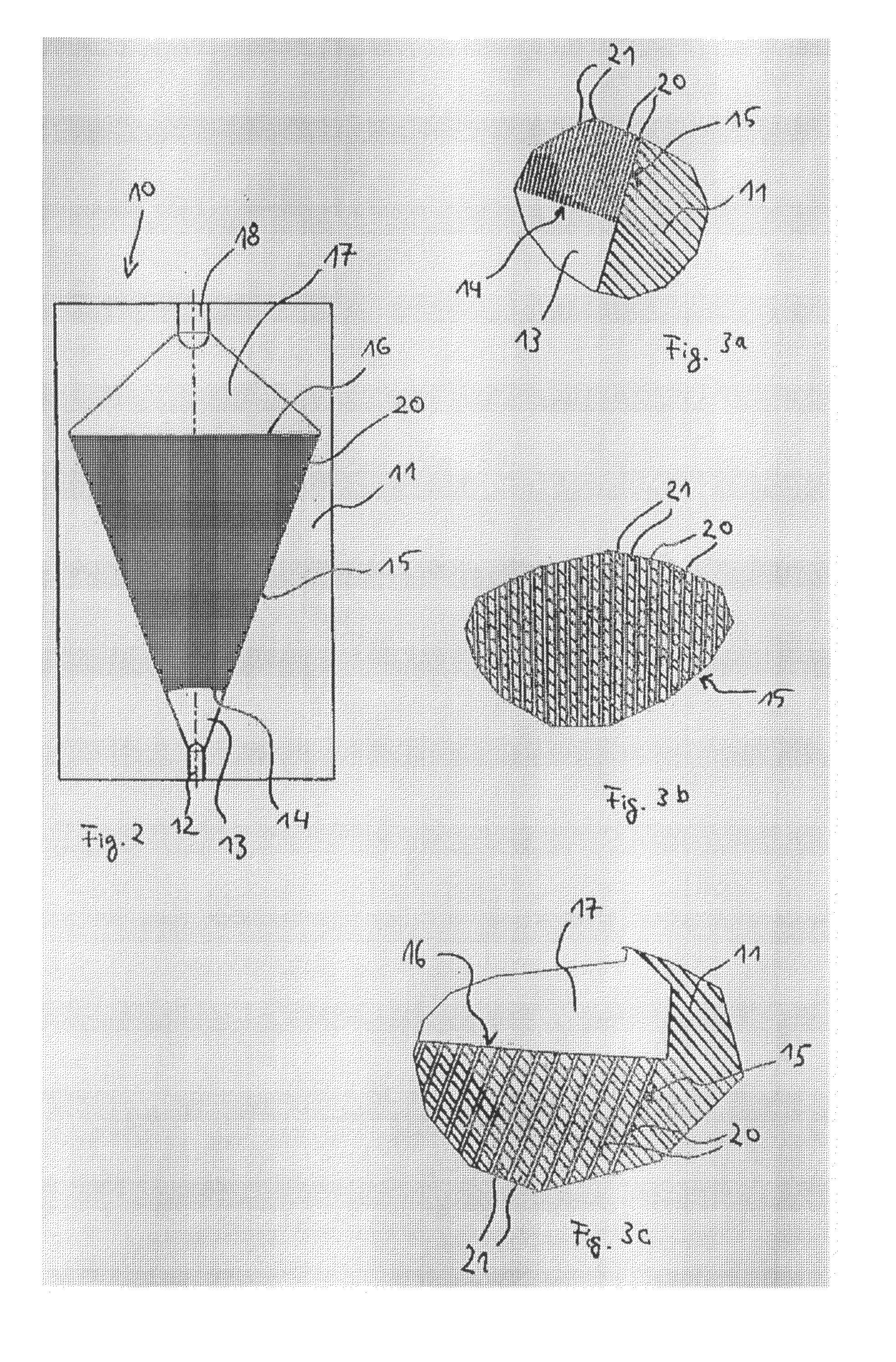

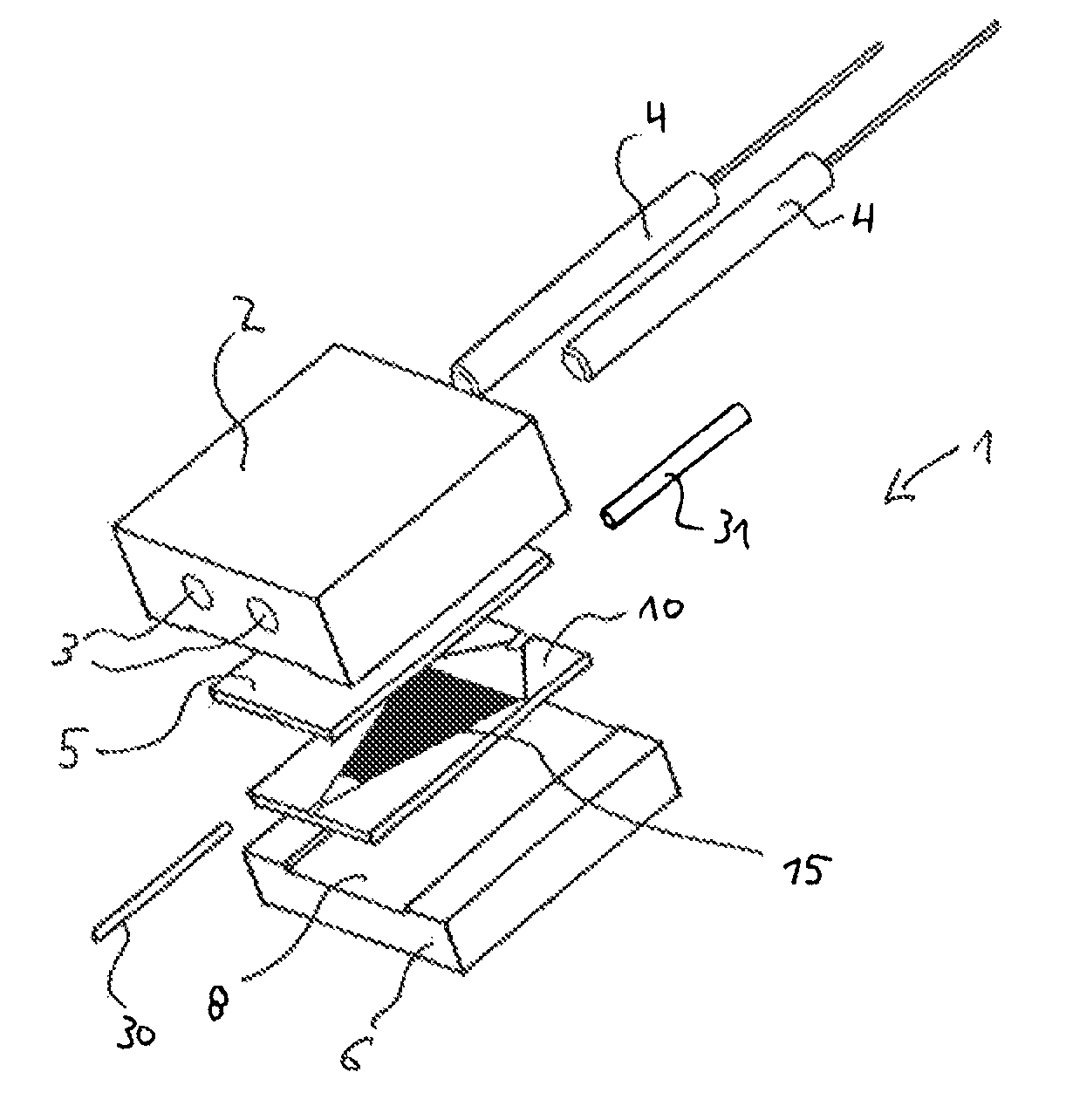

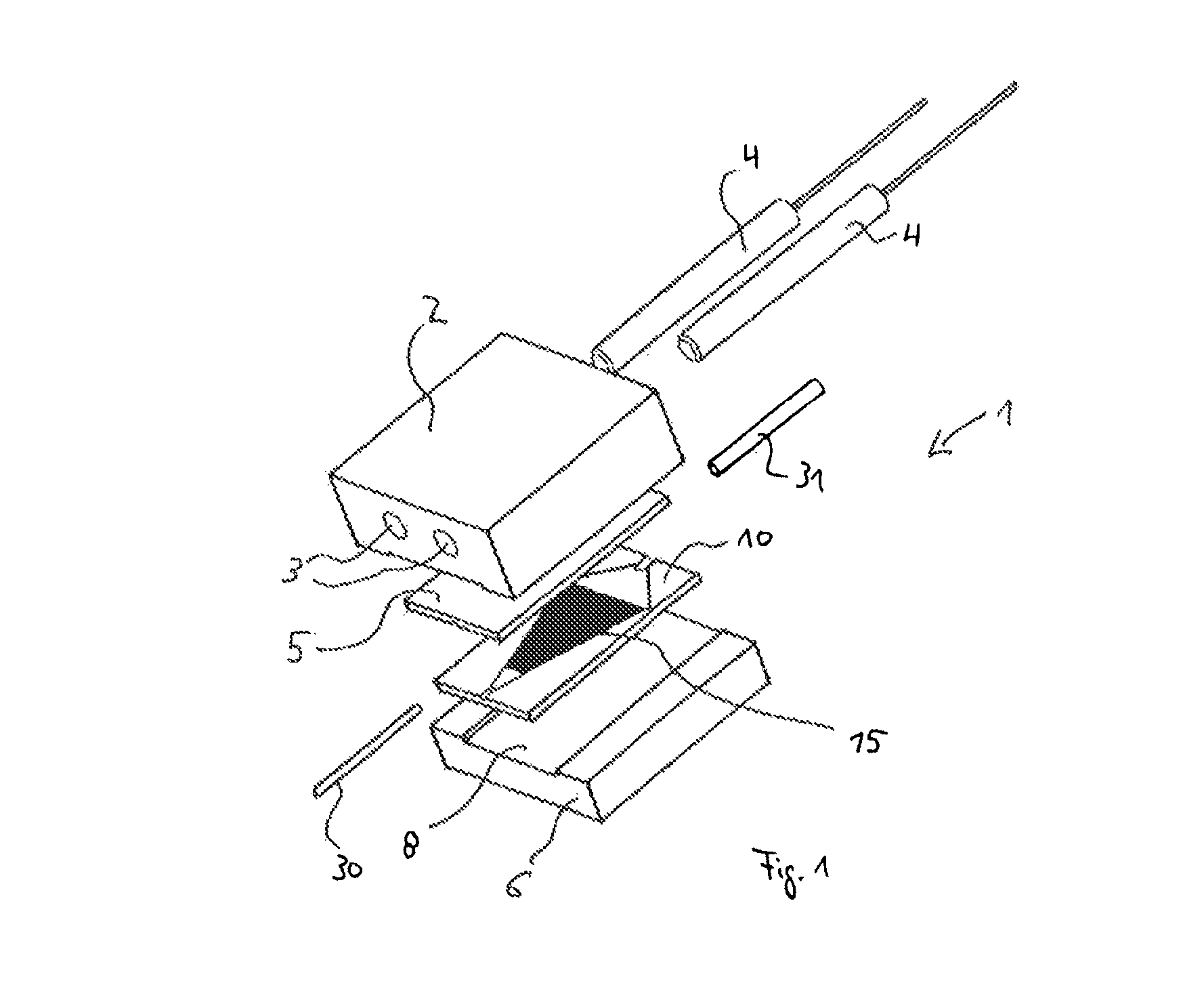

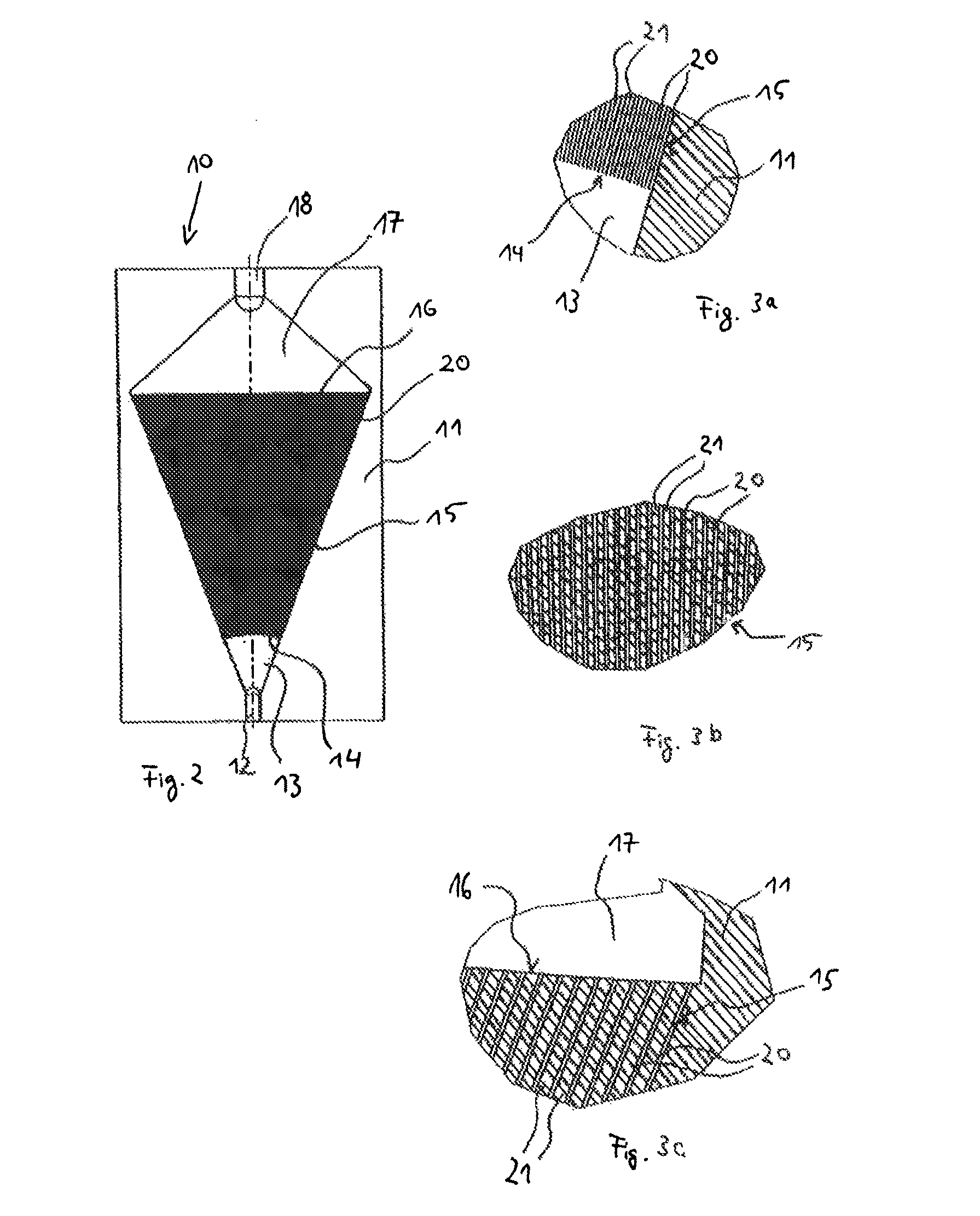

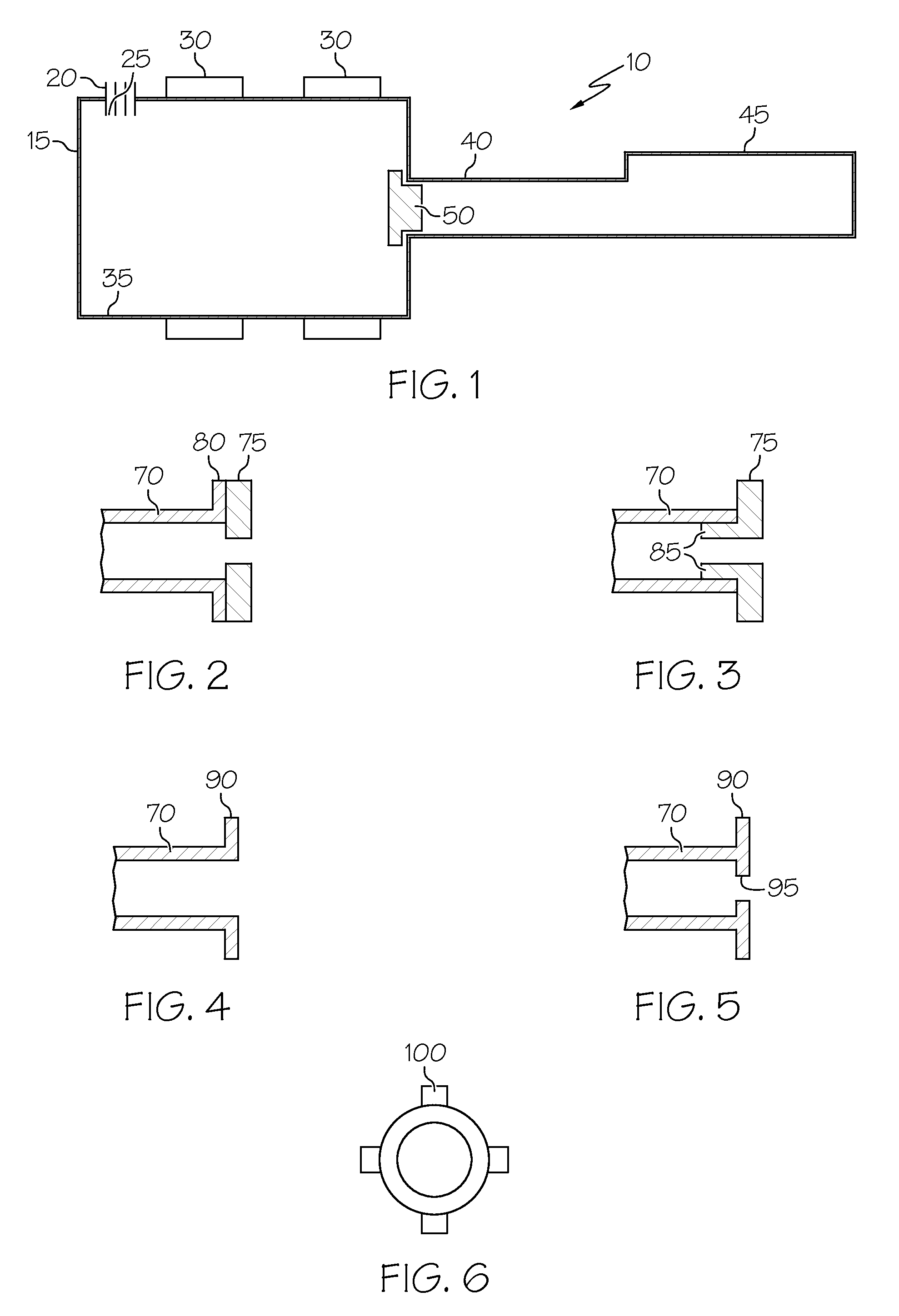

Micro-Evaporator

ActiveUS20080307825A1Effectively prevents premature evaporationEasy dischargeChemical/physical/physico-chemical microreactorsEvaporators/condensersEvaporator

A micro-evaporator is disclosed which is easy to manipulate and can be operated problem-free over a large temperature range. The micro-evaporator has micro-evaporator channels in a trapezoidal region, comprising an inlet region opening in the liquid feed chamber with a small diameter, and an outlet region opening into the vapor collecting chamber with a large diameter.

Owner:IMM INST FUR MIKROTECHNIK GMBH

Micro-evaporator

ActiveUS8167030B2Effectively prevents premature evaporationEasy dischargeChemical/physical/physico-chemical microreactorsBumping preventionEvaporator

A micro-evaporator is disclosed which is easy to manipulate and can be operated problem-free over a large temperature range. The micro-evaporator has micro-evaporator channels in a trapezoidal region, comprising an inlet region opening in the liquid feed chamber with a small diameter, and an outlet region opening into the vapor collecting chamber with a large diameter.

Owner:IMM INST FUR MIKROTECHNIK GMBH

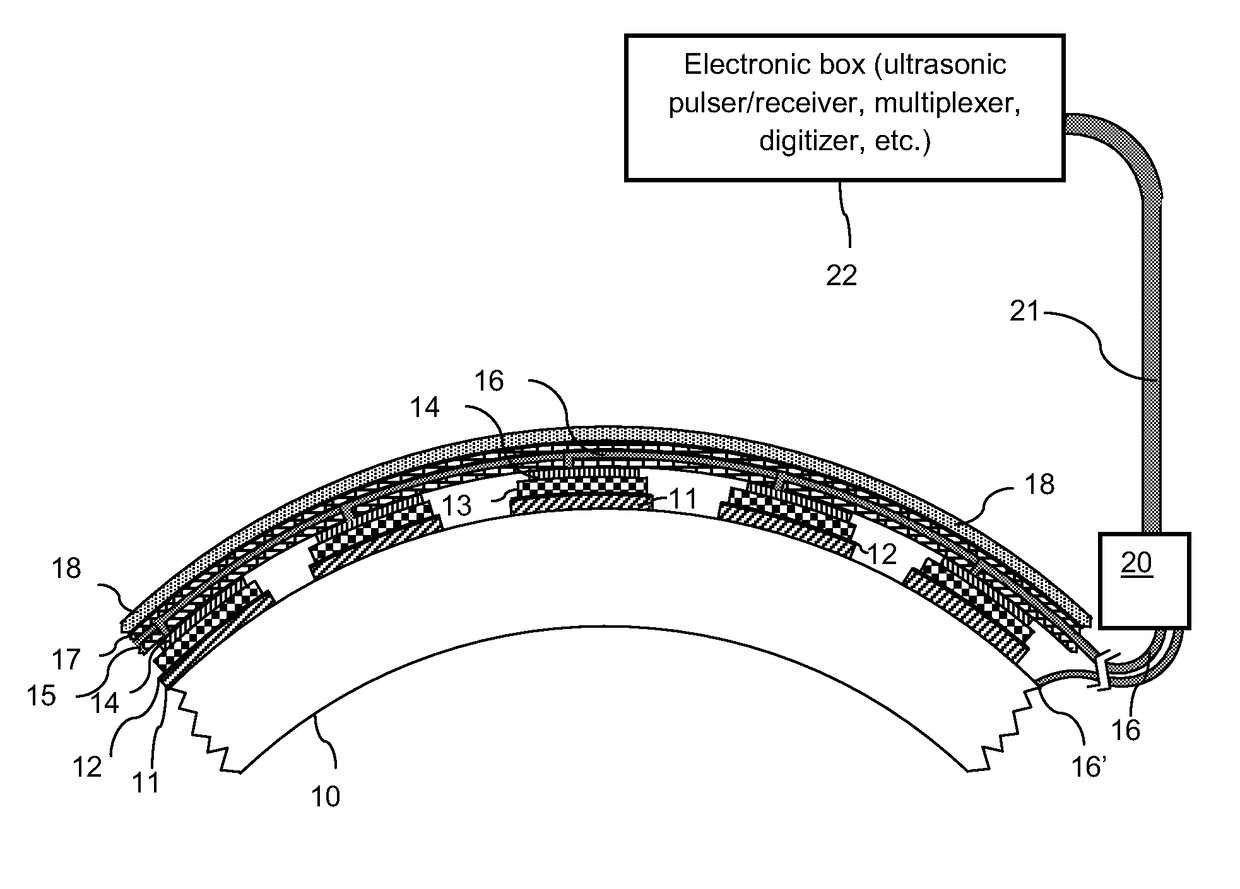

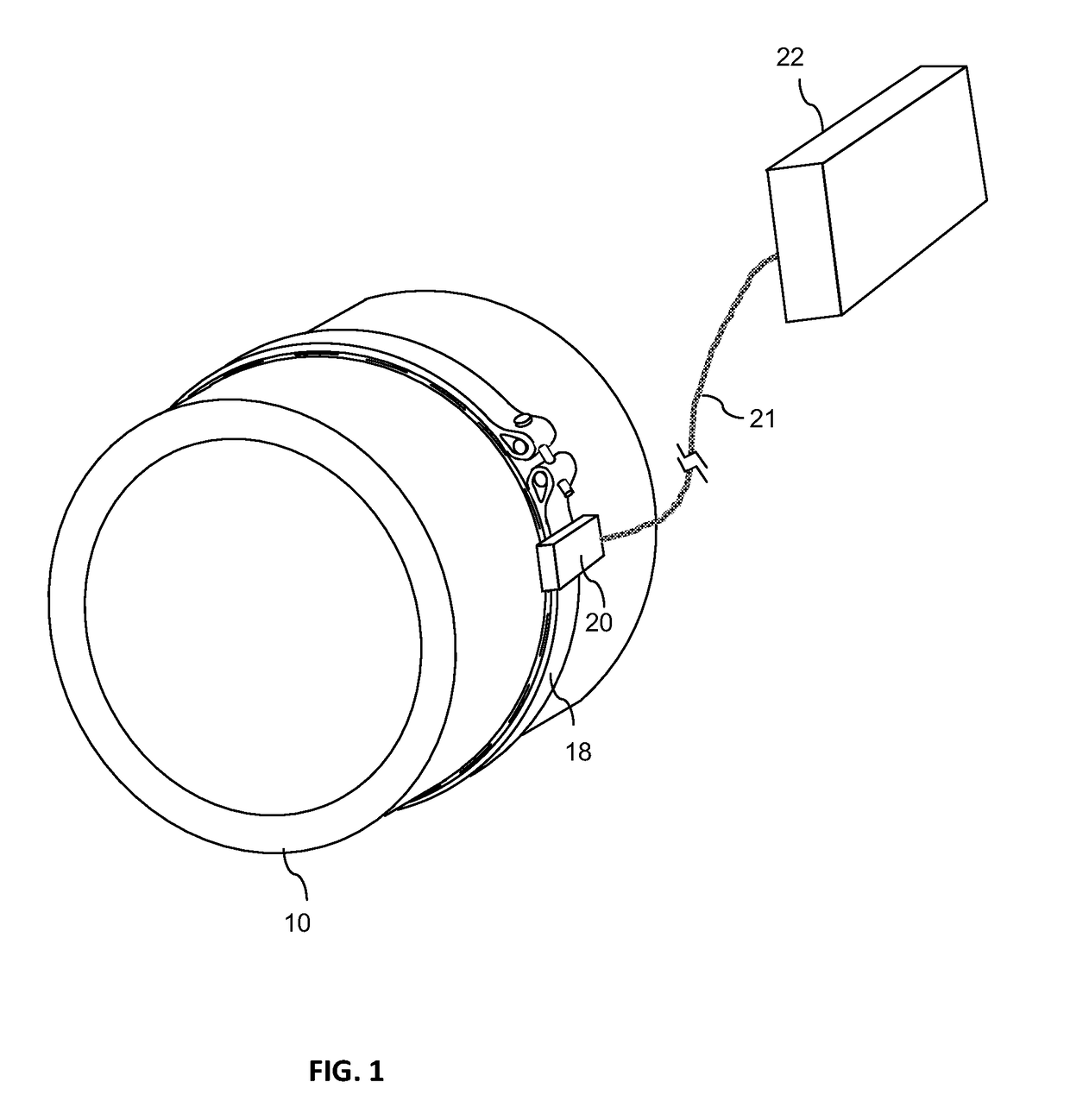

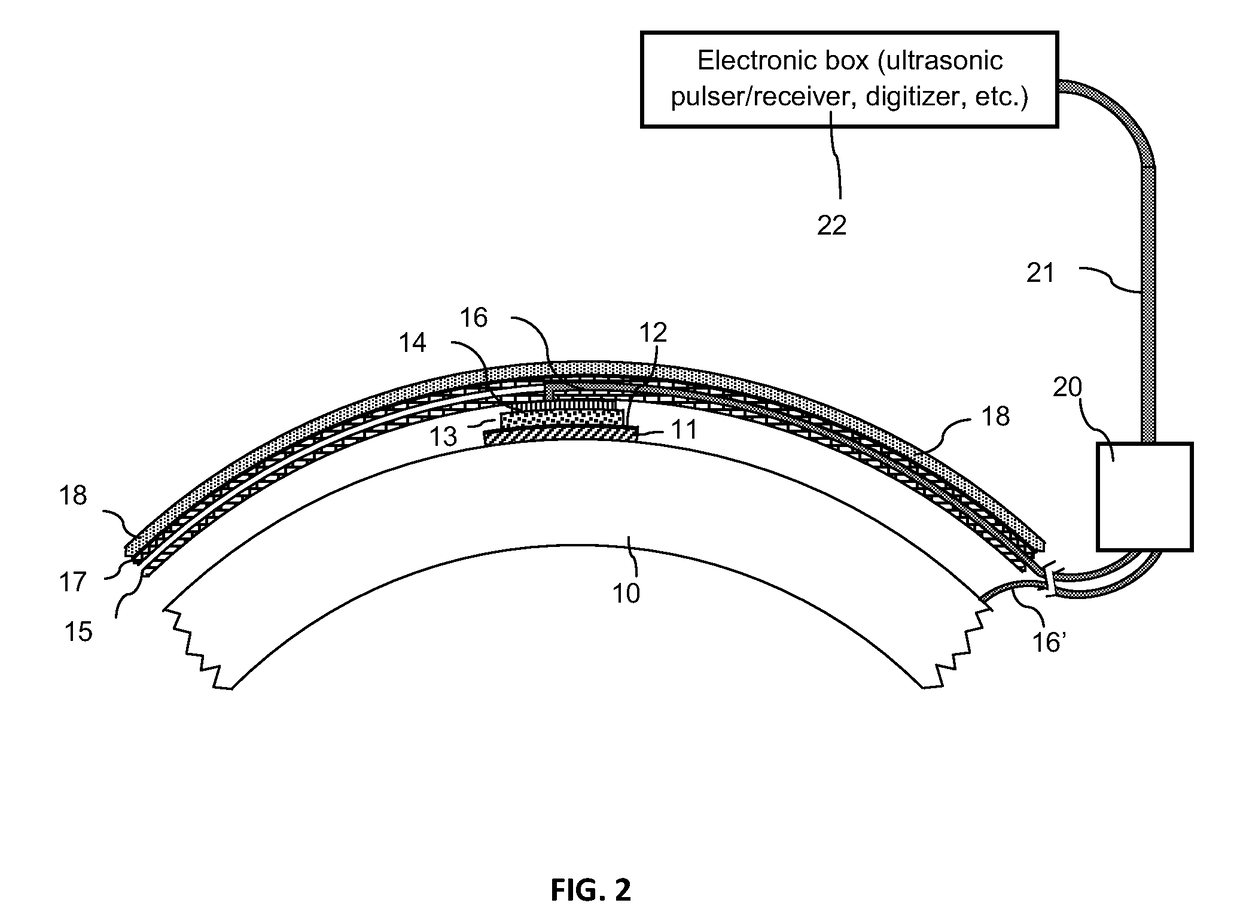

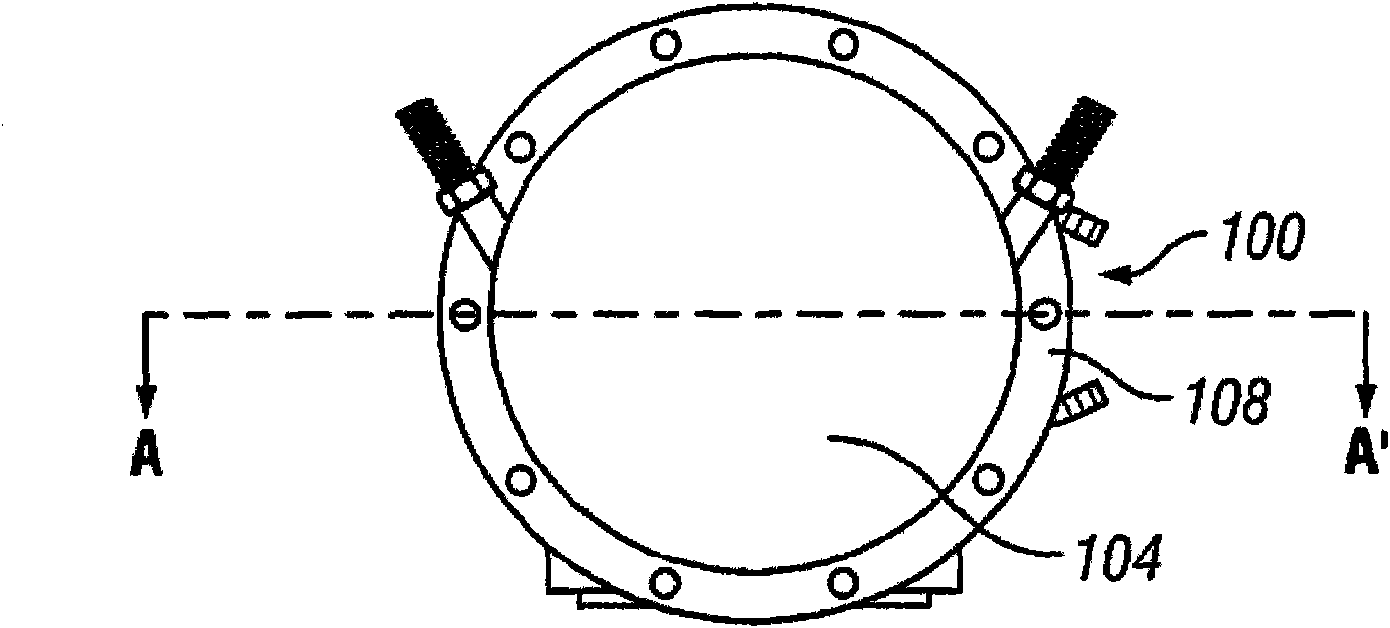

Ultrasonic transducer assembly and system for monitoring structural integrity

ActiveUS9618481B2Increased durabilityEnhanced signalMaterial analysis using sonic/ultrasonic/infrasonic wavesWeather/light/corrosion resistanceElectrical conductorUltrasonic sensor

In an ultrasonic transducer assembly, a conformable ultrasonic transducer has a piezoelectric layer and electrodes able to conform to curved surfaces, and a clamp for pressing the transducer into ultrasonic contact with a curved surface. Conformability is ensured with a thin, porous piezoelectric layer and suitable electrical conductors and insulators. The ultrasonic transducer may operate without further thermal shielding under harsh environments and / or at high temperatures.

Owner:NAT RES COUNCIL OF CANADA

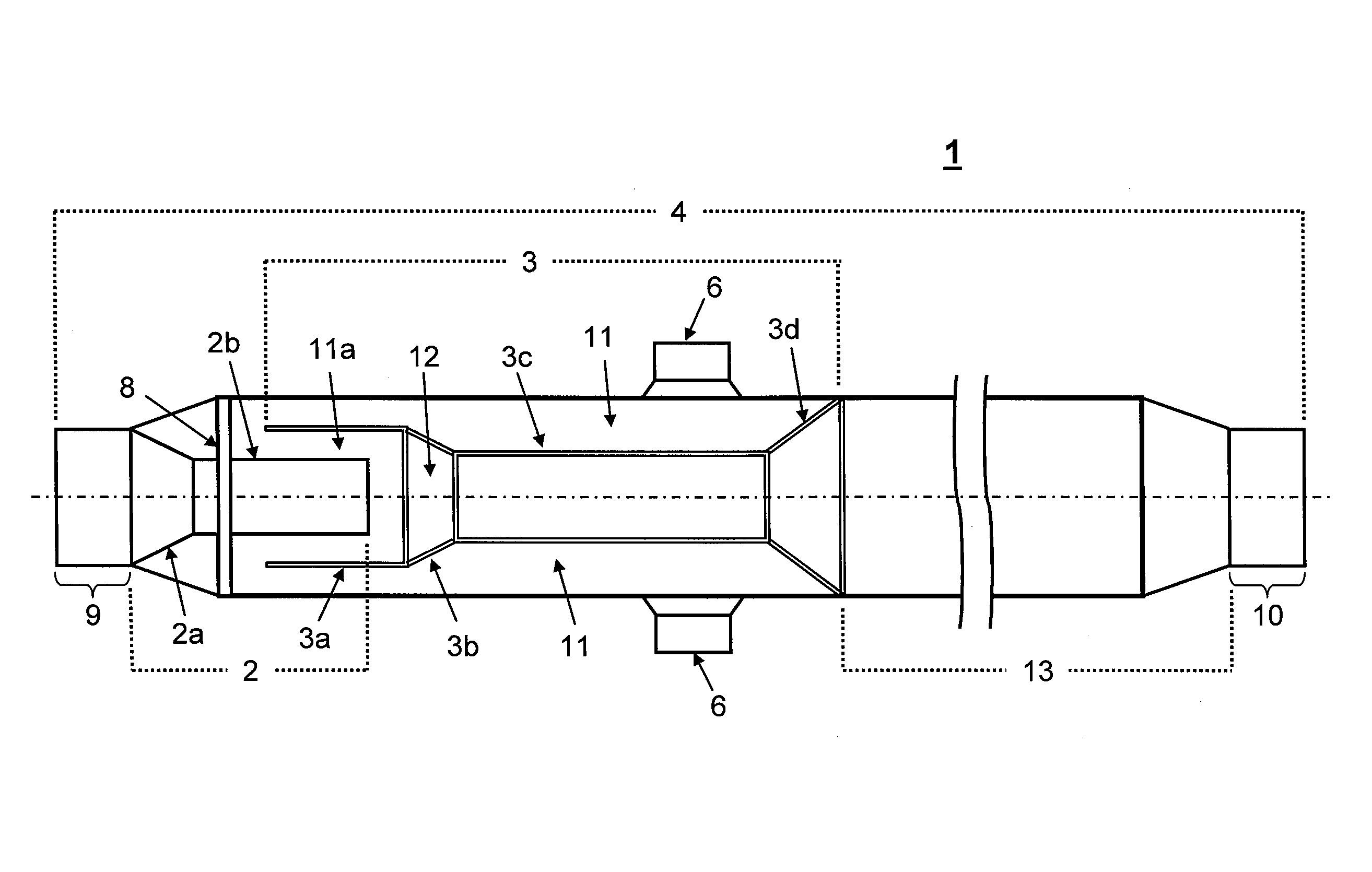

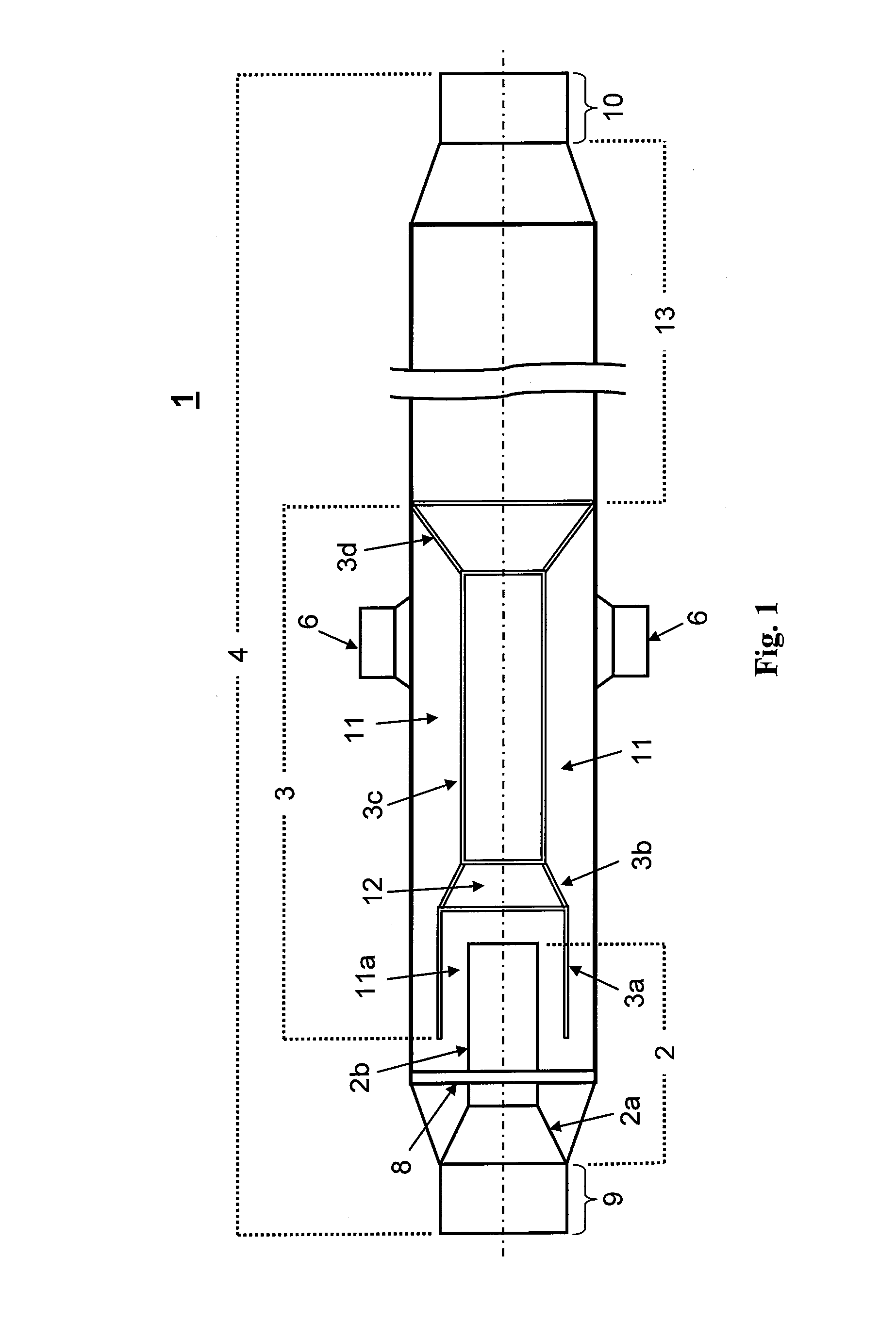

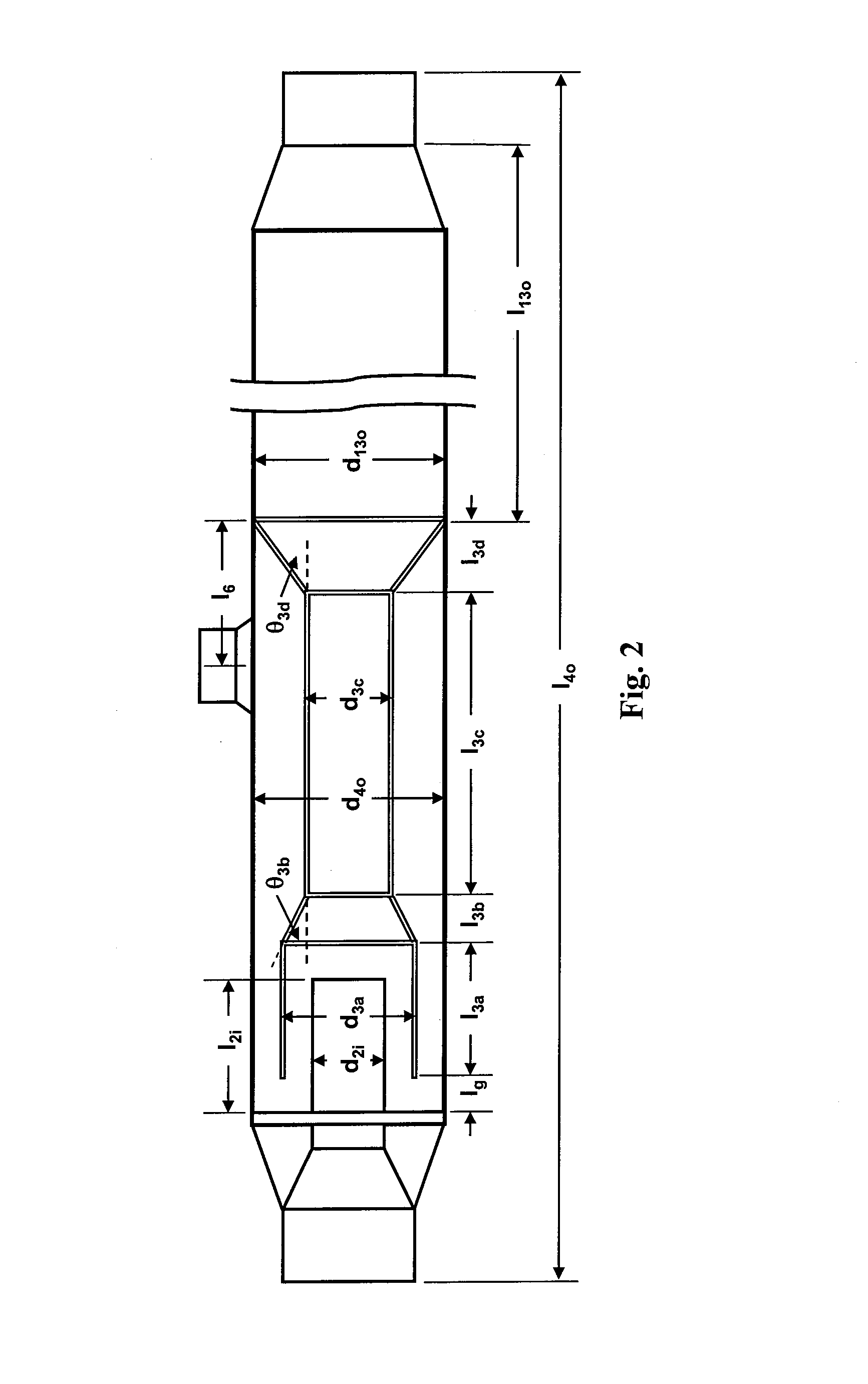

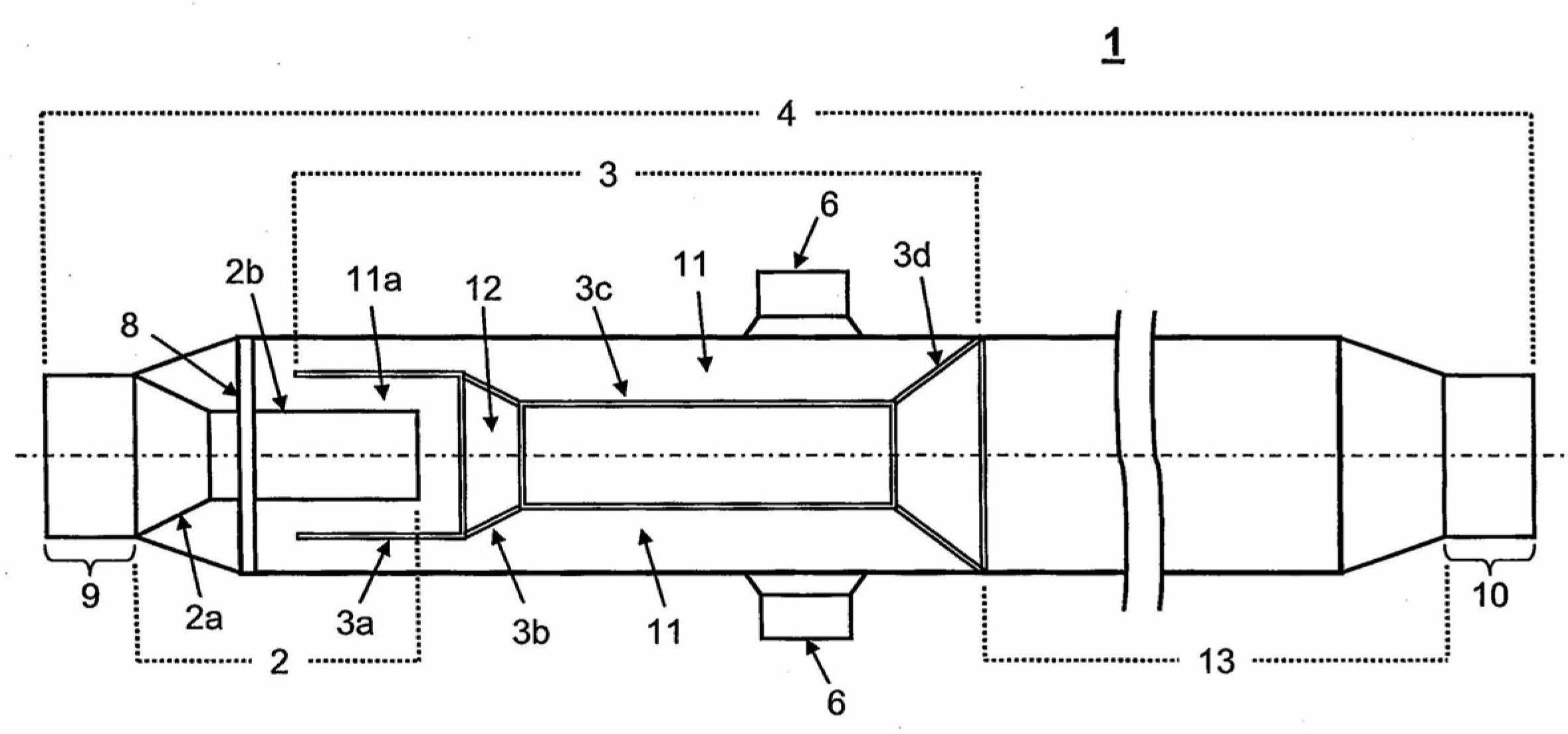

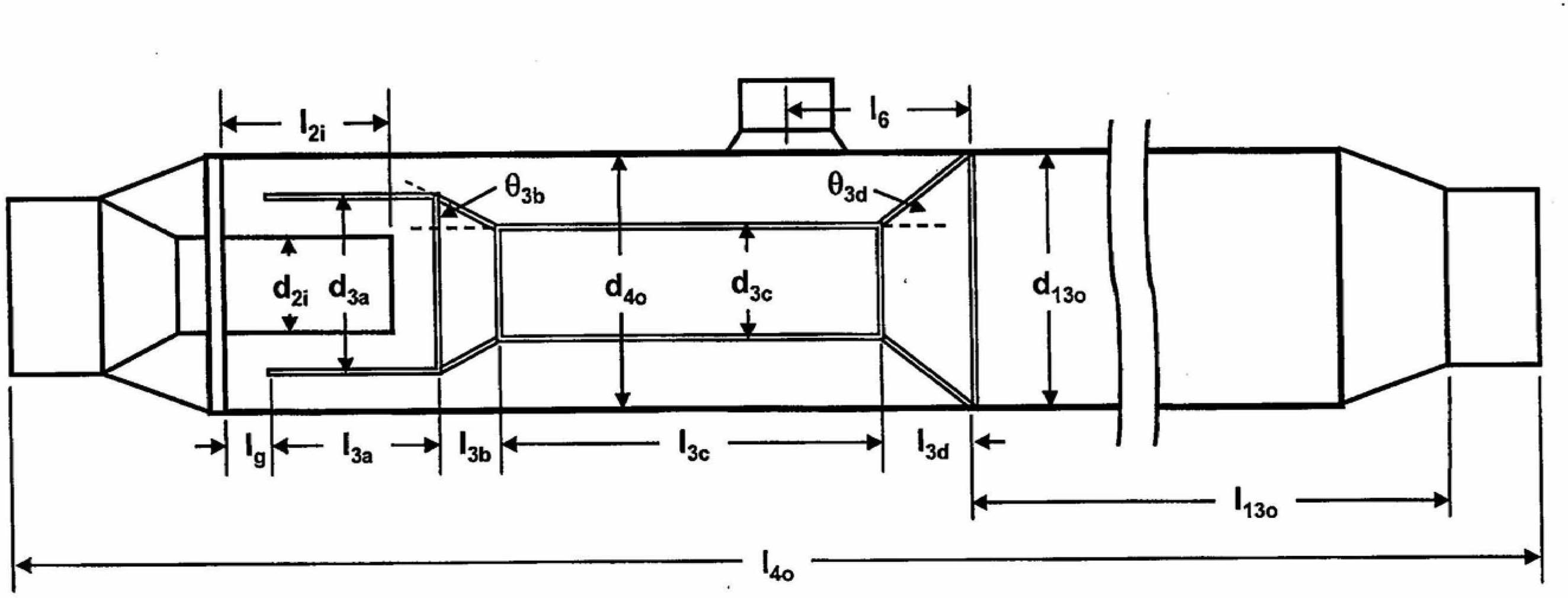

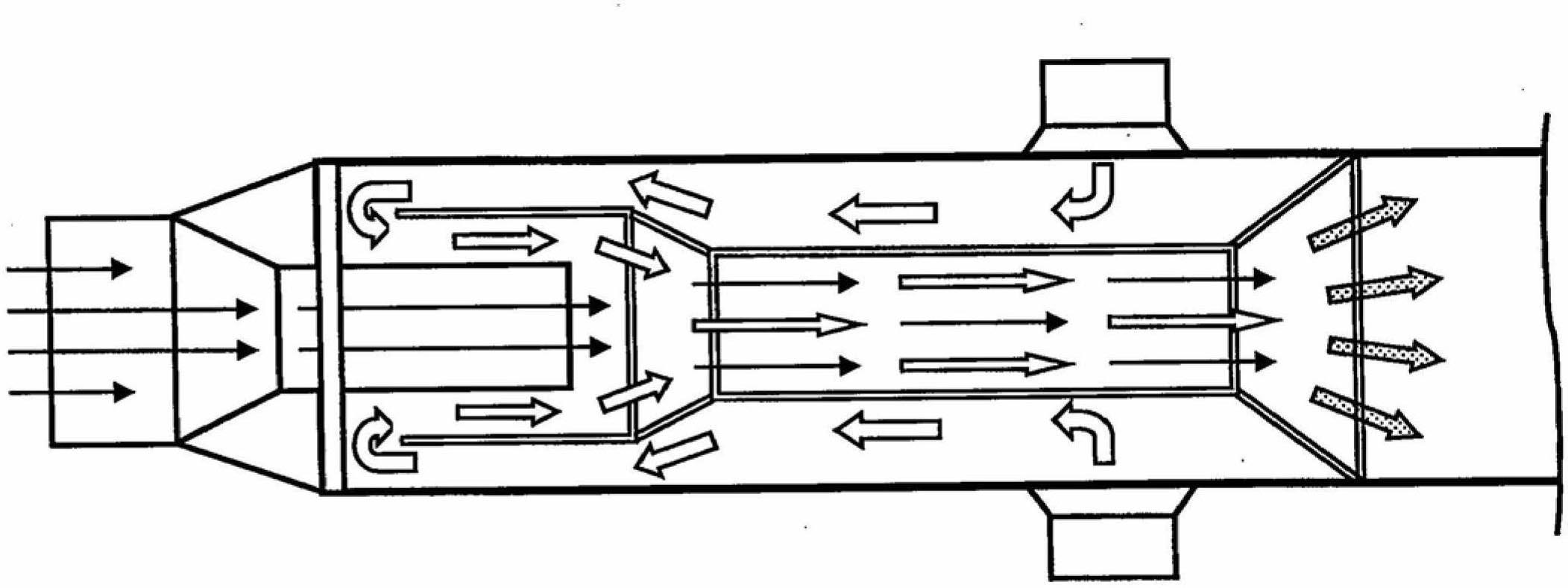

Heavy feed mixer

ActiveUS8496786B2Simple and compact and economicMinimizes and reduces problemThermal non-catalytic crackingHydrocarbon distillationEngineeringVaporization

An apparatus designed to completely vaporize an intake of heavy hydrocarbon feedstock is described. The apparatus, a so-called heavy feed mixer, is comprised of pipes being disposed coaxially about a common longitudinal axis. The inner tubular section delivers a two-phase liquid-vapor mixture of hydrocarbon feedstock and dilution steam to the apparatus. The converging / diverging tubular section has a unique structure which converges to a throat section and then diverges to an outlet section. The converging section directs a uniform shroud of superheated steam onto the hydrocarbon stream delivered by the inner tubular section. Impingement of the superheated steam with the intake stream initiates mixing and further vaporization within the throat section. The mixture traverses the converging / diverging tubular section and passes into the outlet section where vaporization is complete. The completely vaporized stream is directed out of the apparatus for further processing downstream.

Owner:STONE & WEBSTER PROCESS TECH

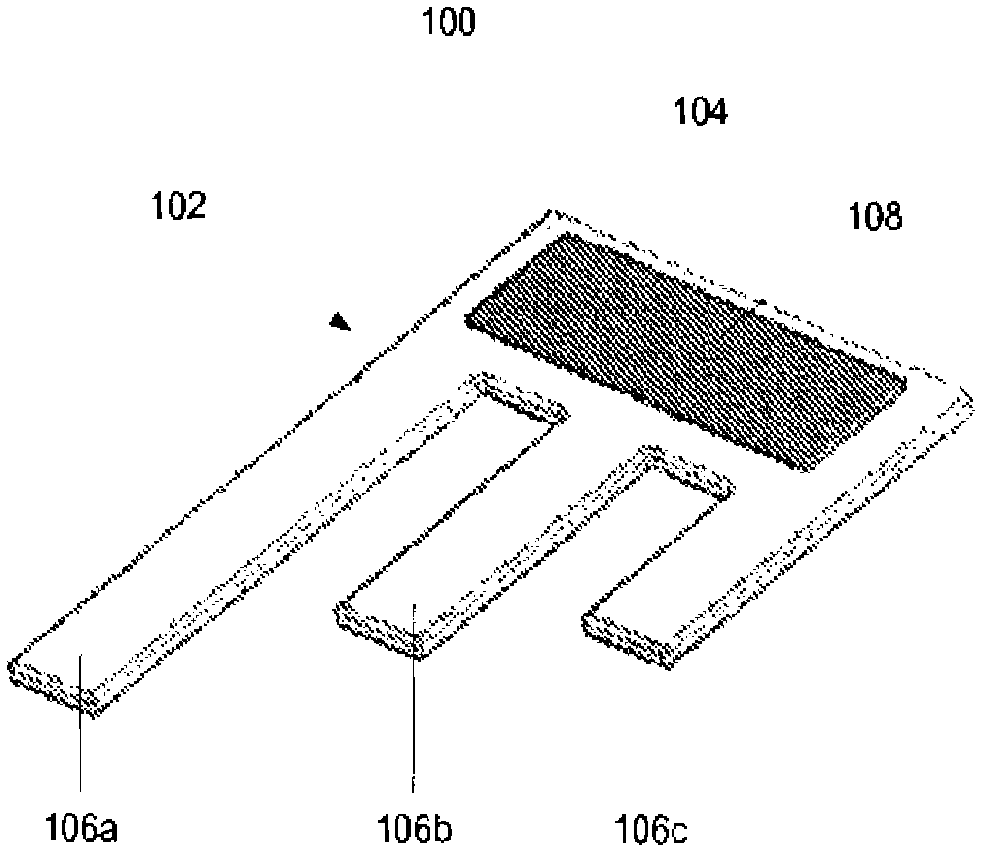

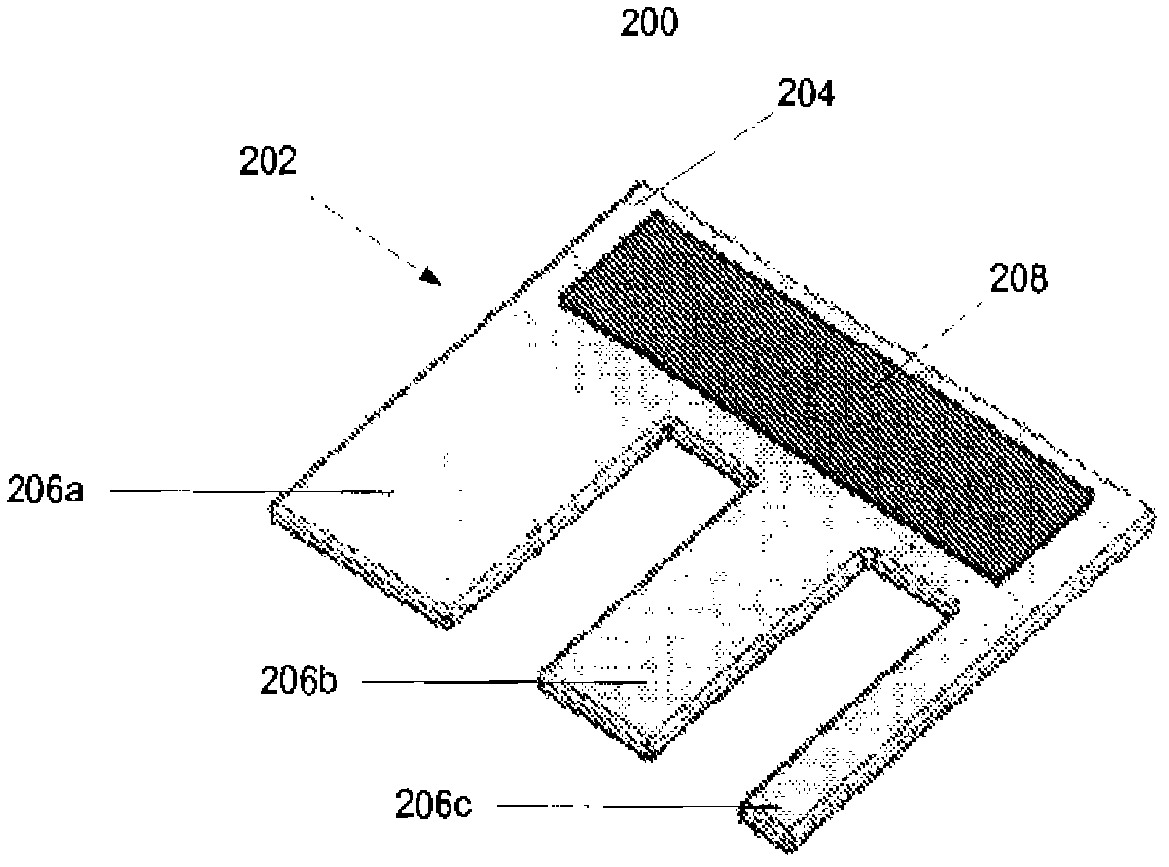

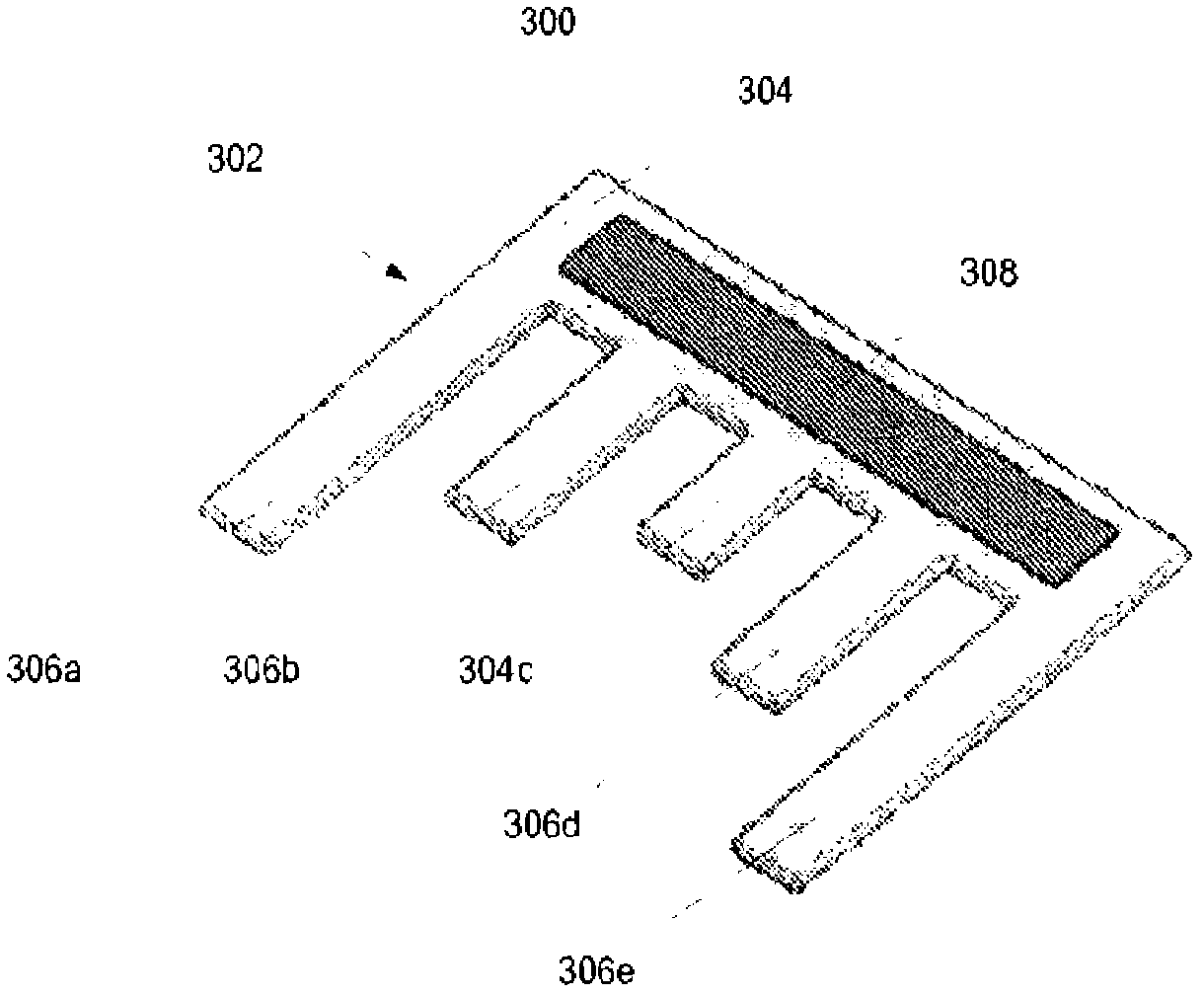

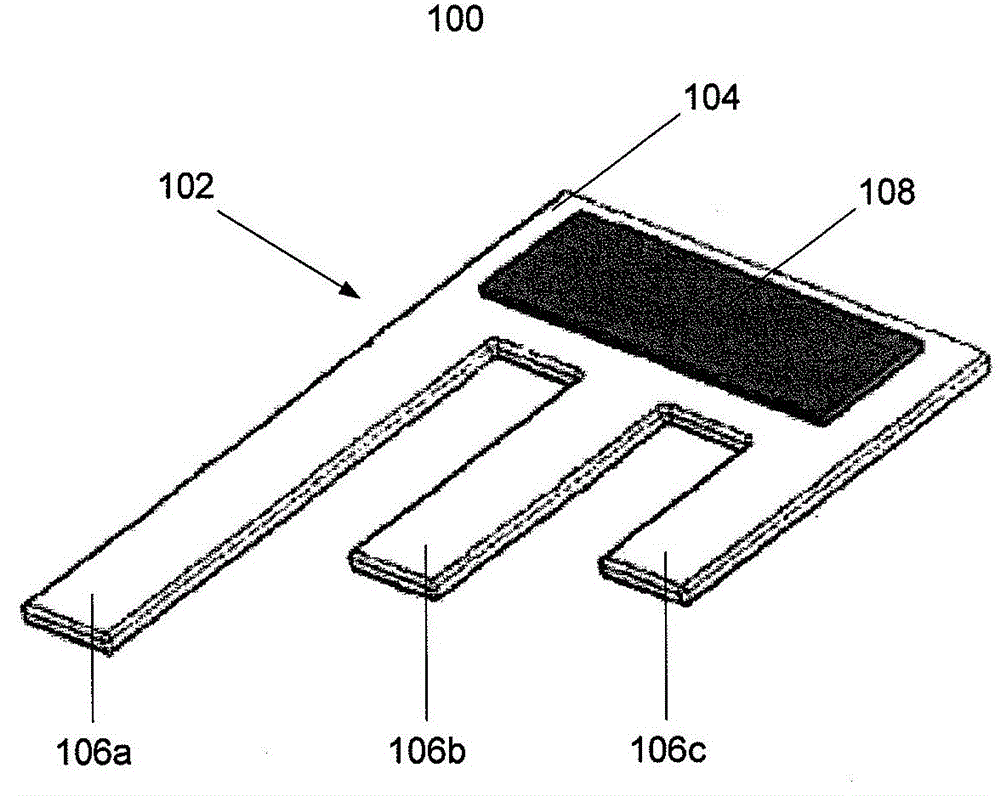

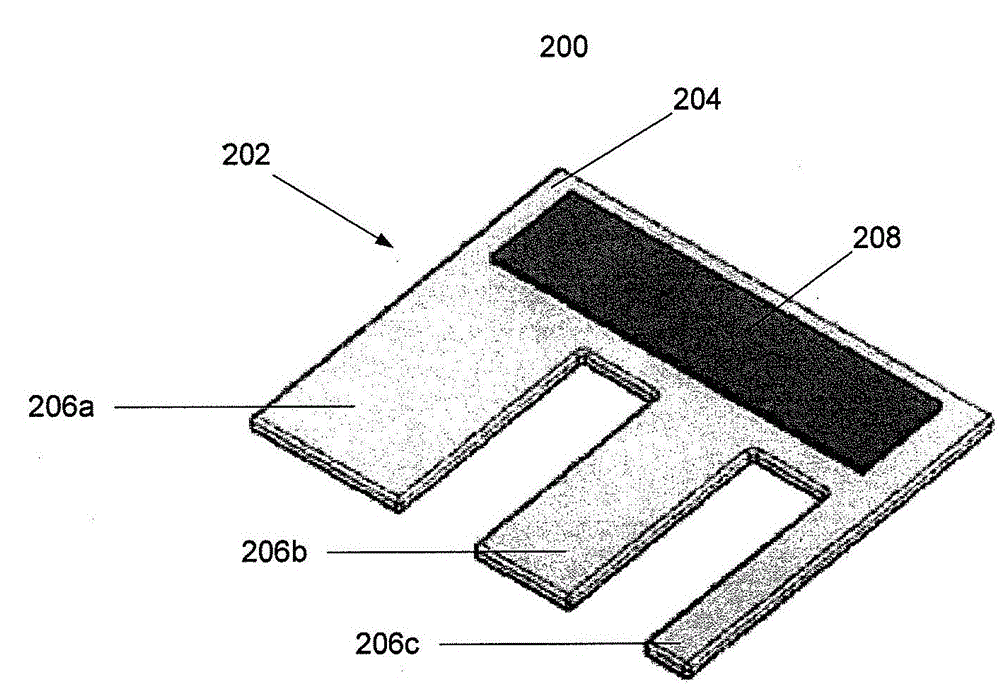

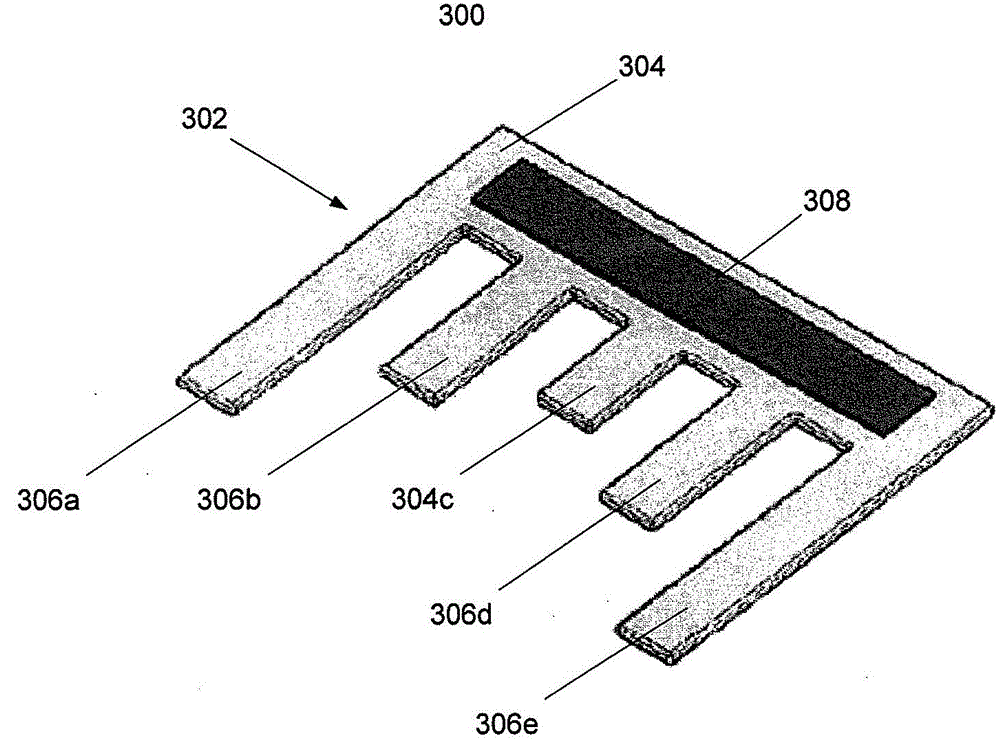

Systems and methods for providing haptic feedback at multiple resonance frequencies

InactiveCN102762265ADigital data processing detailsDevices with sensorFeedback effectPiezoelectric actuators

Systems and methods for providing haptic feedback at multiple resonance frequencies are disclosed. For example, one disclosed apparatus includes a resonator with a base and a plurality of projections, a first projection of the plurality of projections having a first resonance frequency and a second projection of the plurality of projections having a second resonance frequency, and a piezoelectric actuator coupled to the resonator and operable to output a haptic feedback effect at the first resonance frequency and at the second resonance frequency.

Owner:IMMERSION CORPORATION

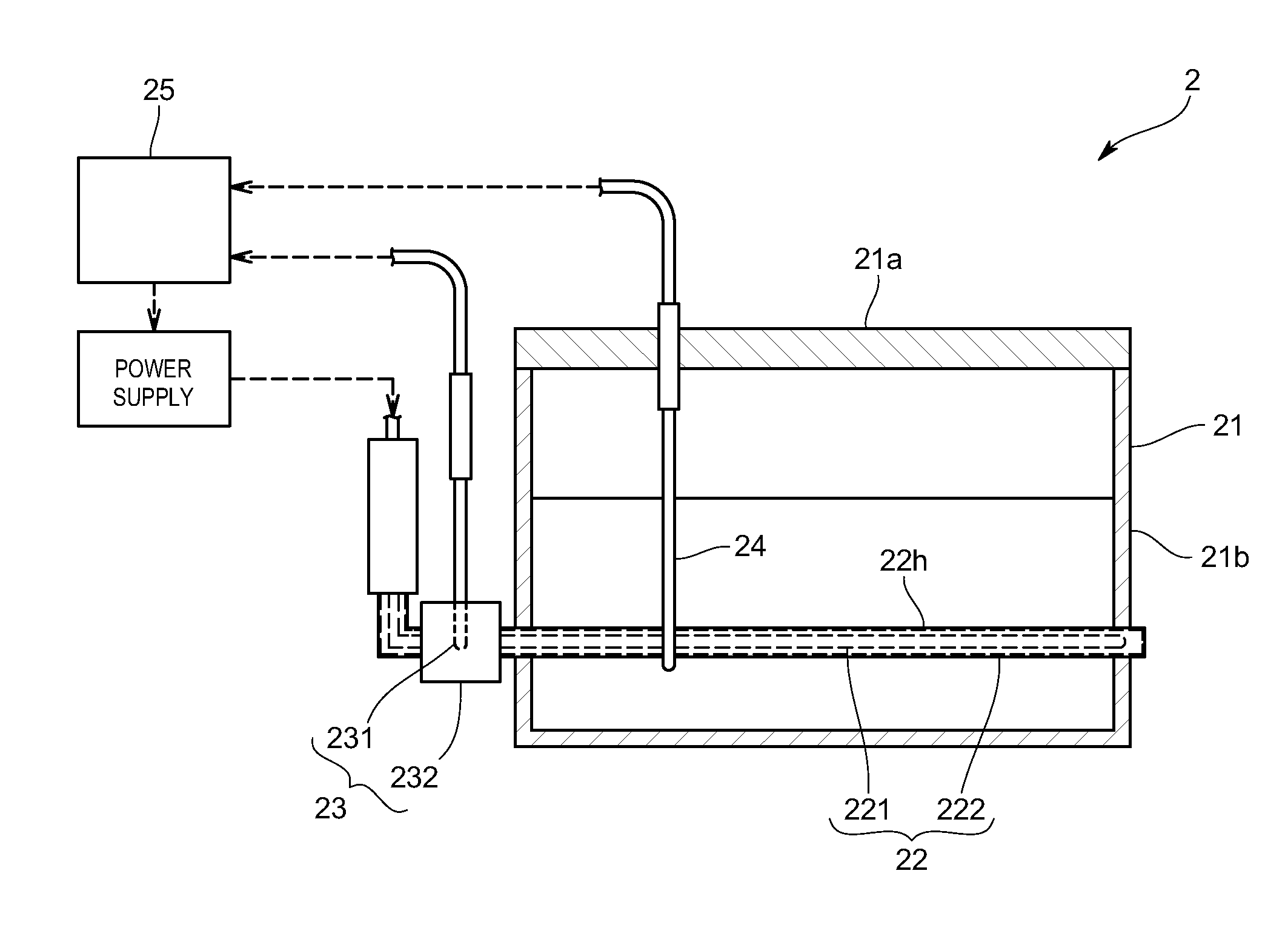

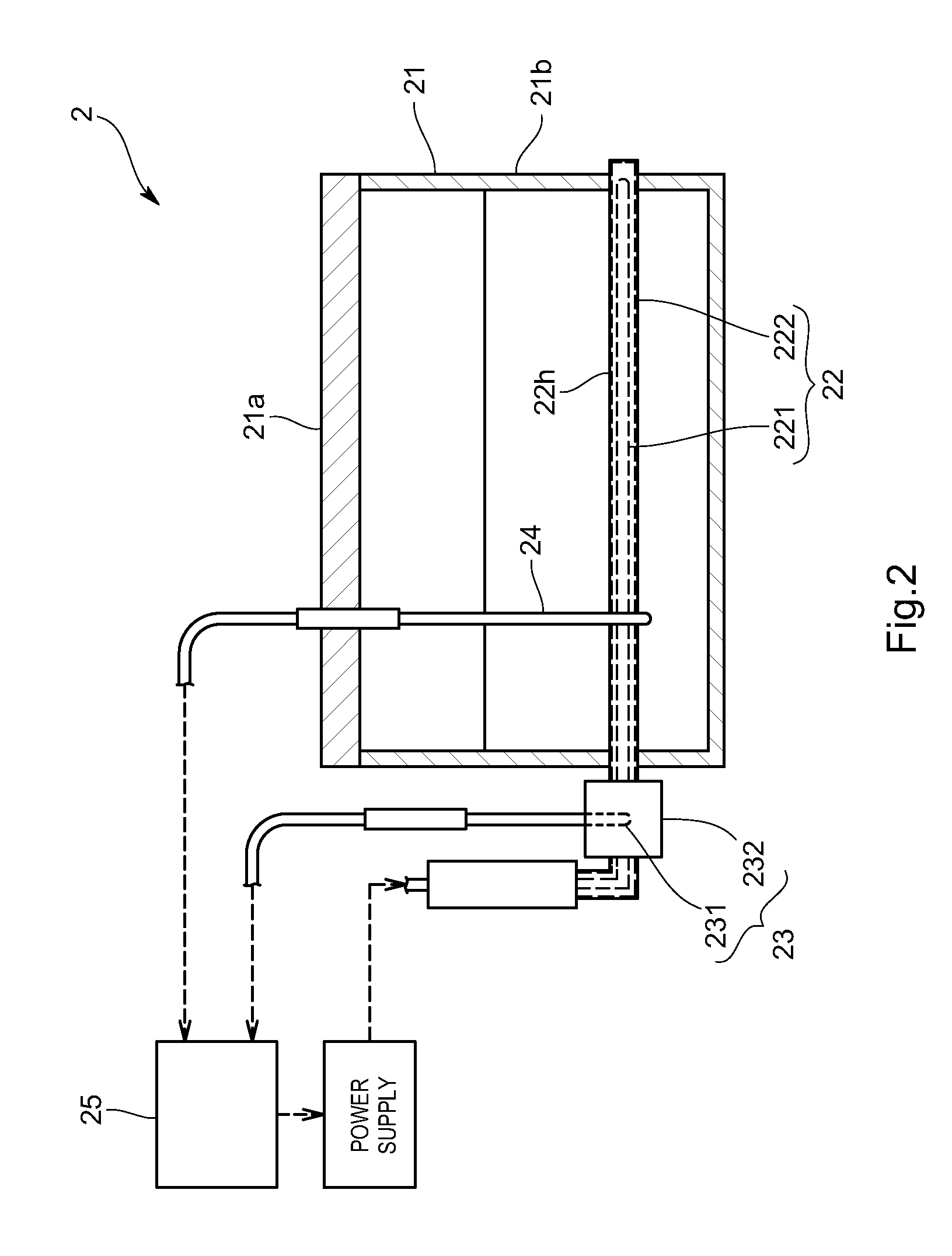

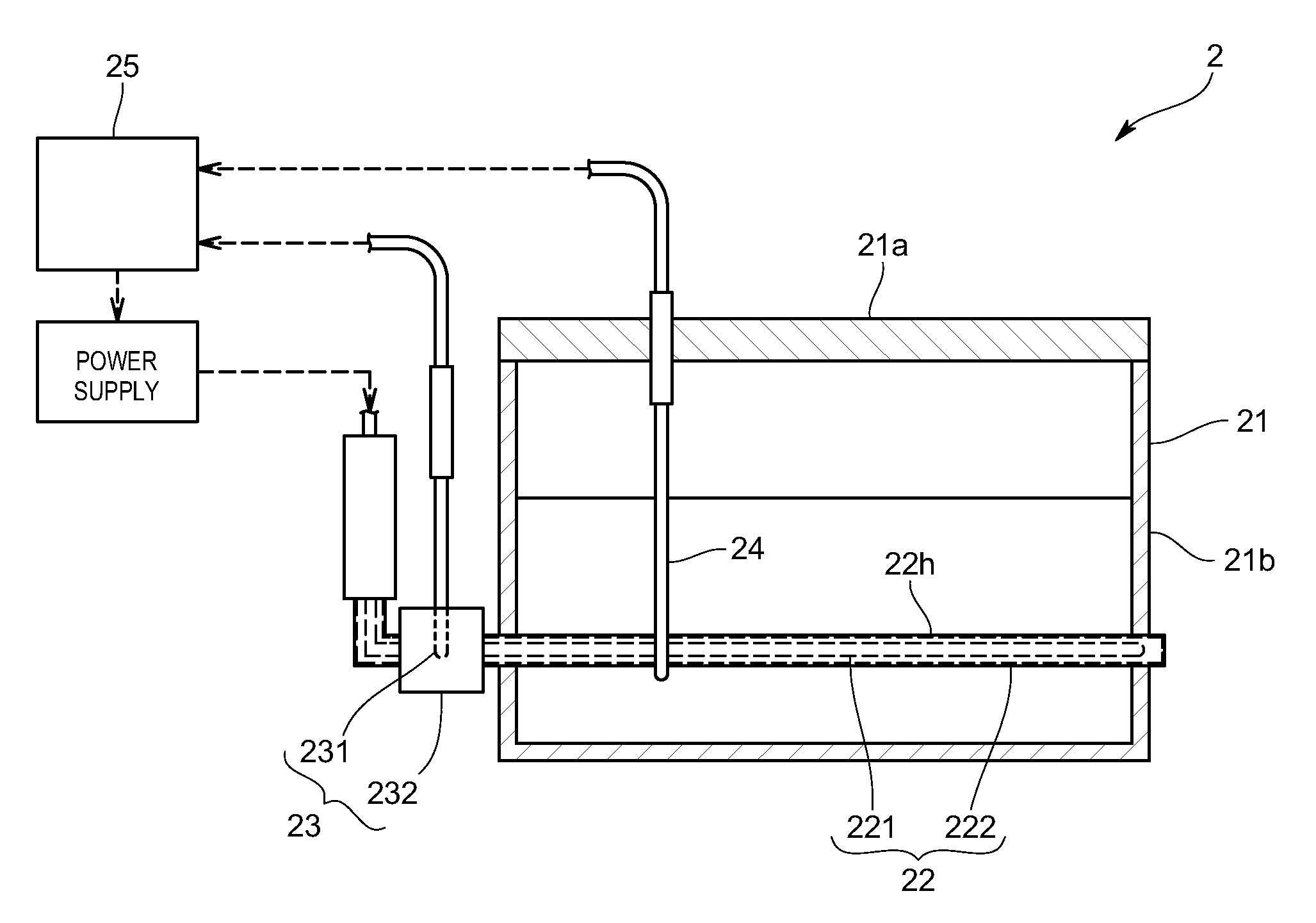

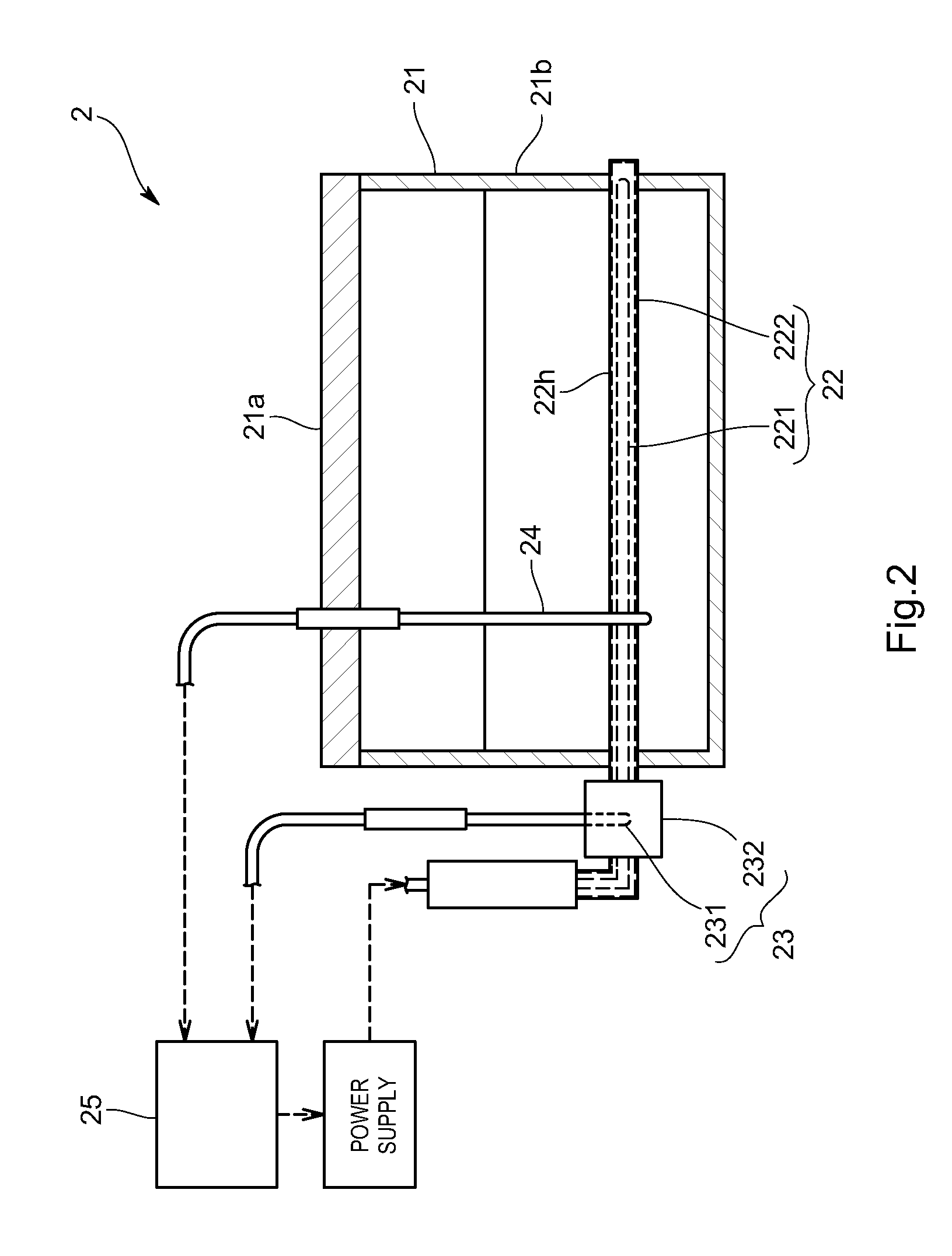

Liquid sample heating vaporizer

ActiveUS8661919B2Improve accuracyImprove propertiesThermometer detailsLighting and heating apparatusTemperature controlEngineering

The present invention is intended to improve response property and accuracy of temperature control of a liquid sample, and is provided with a vaporization tank that retains the liquid sample, one or more heaters that are provided in the vaporization tank and respectively have heating parts that come into contact with the liquid sample to heat the liquid sample, a temperature detection part that is provided in contact with an outer surface including the heating part of any of the heaters and detects a temperature of the outer surface, and a control part that receives a temperature detection signal from the temperature detection part to control electric power supplied to the heaters.

Owner:HORIBA STEC CO LTD

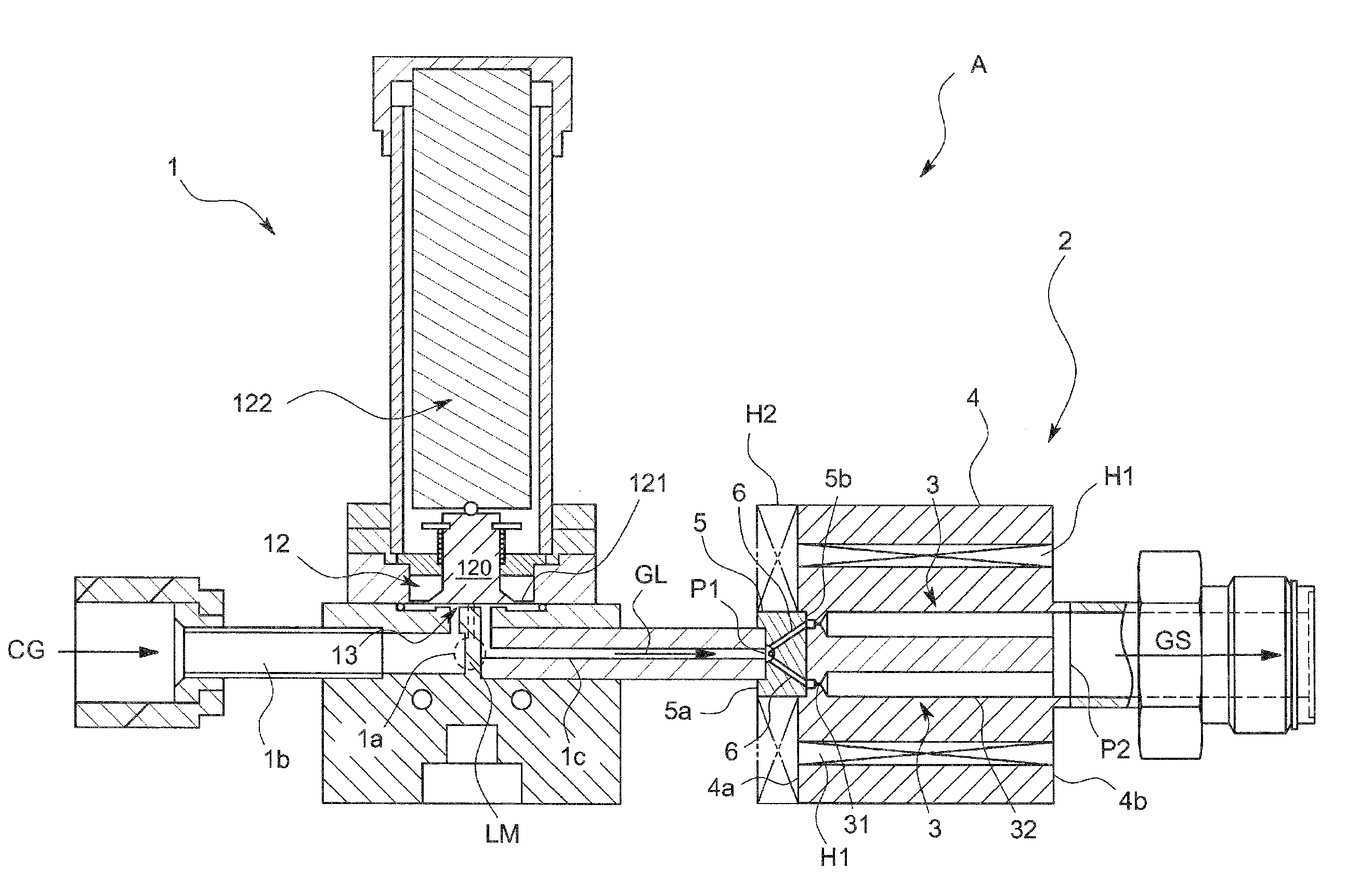

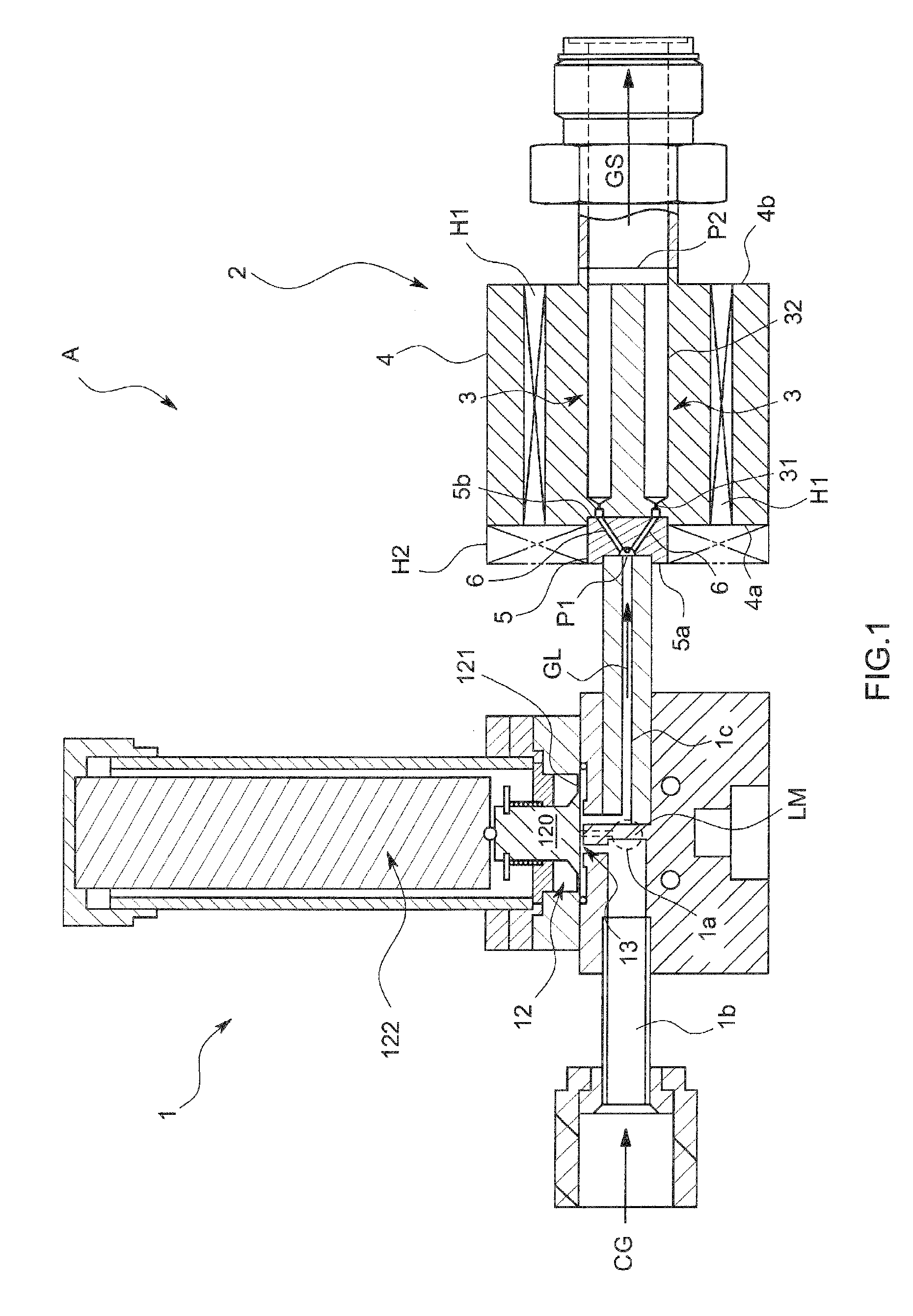

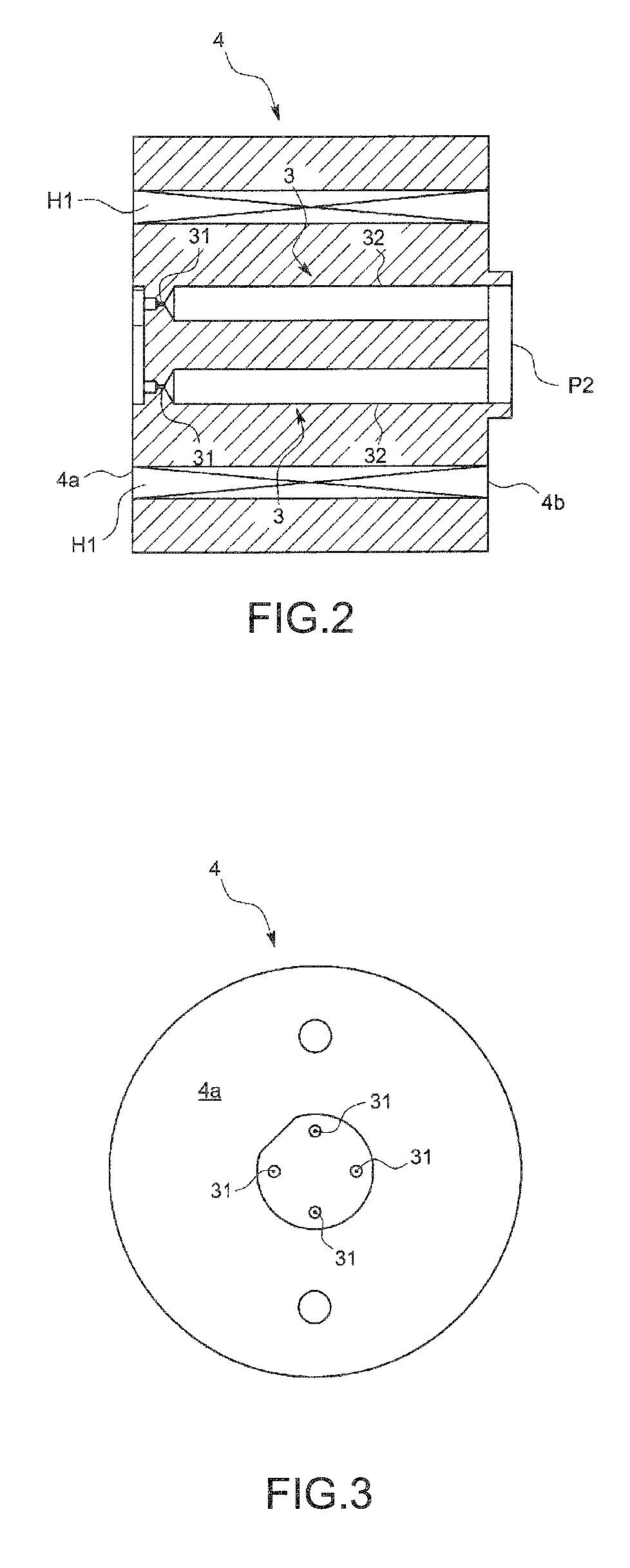

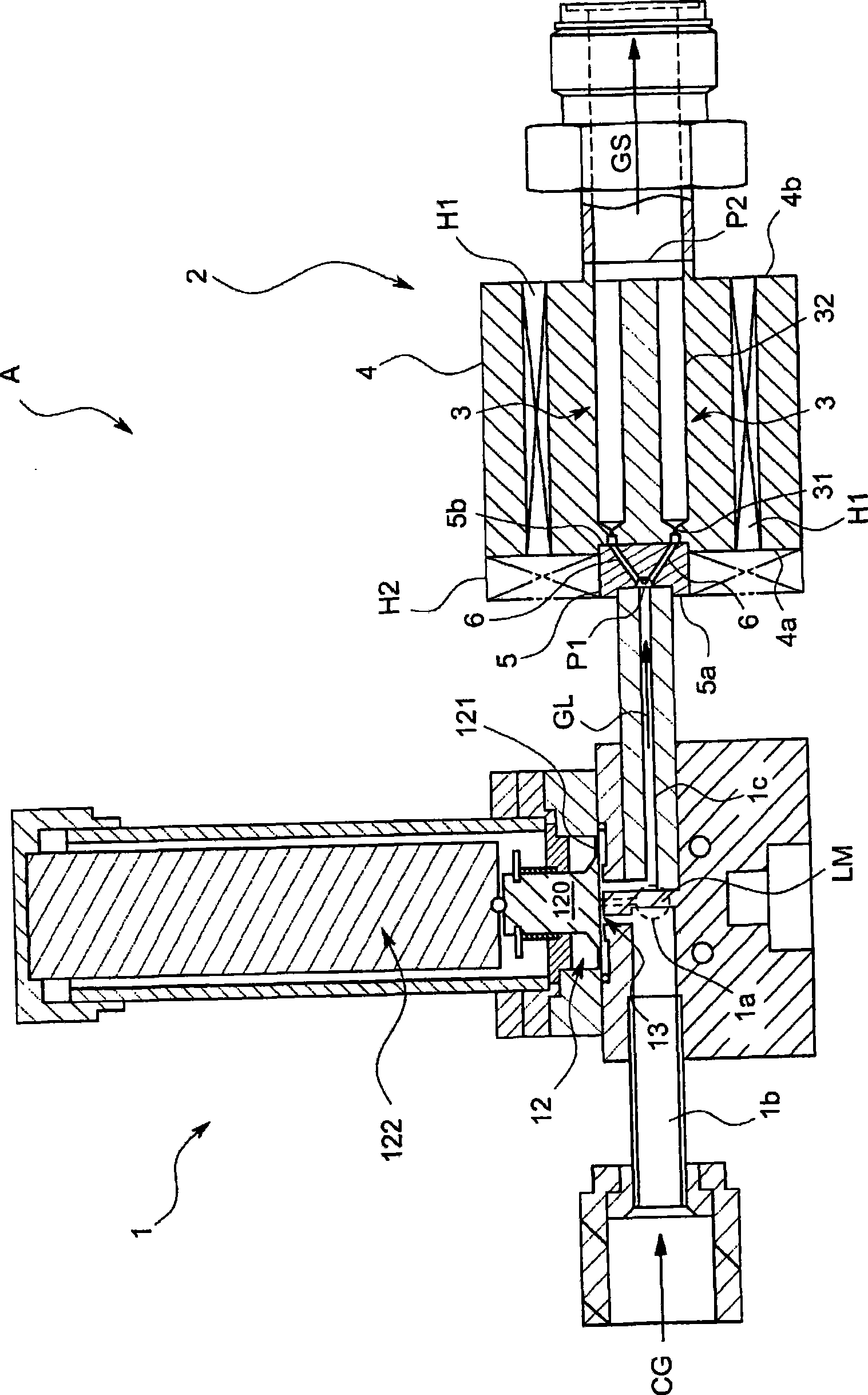

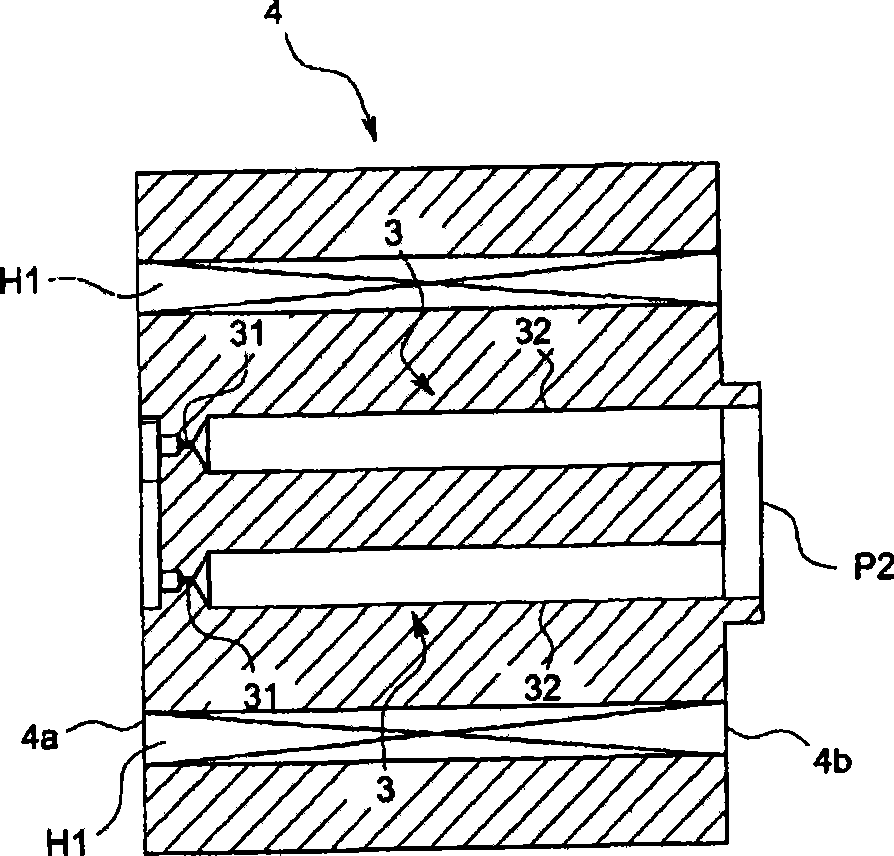

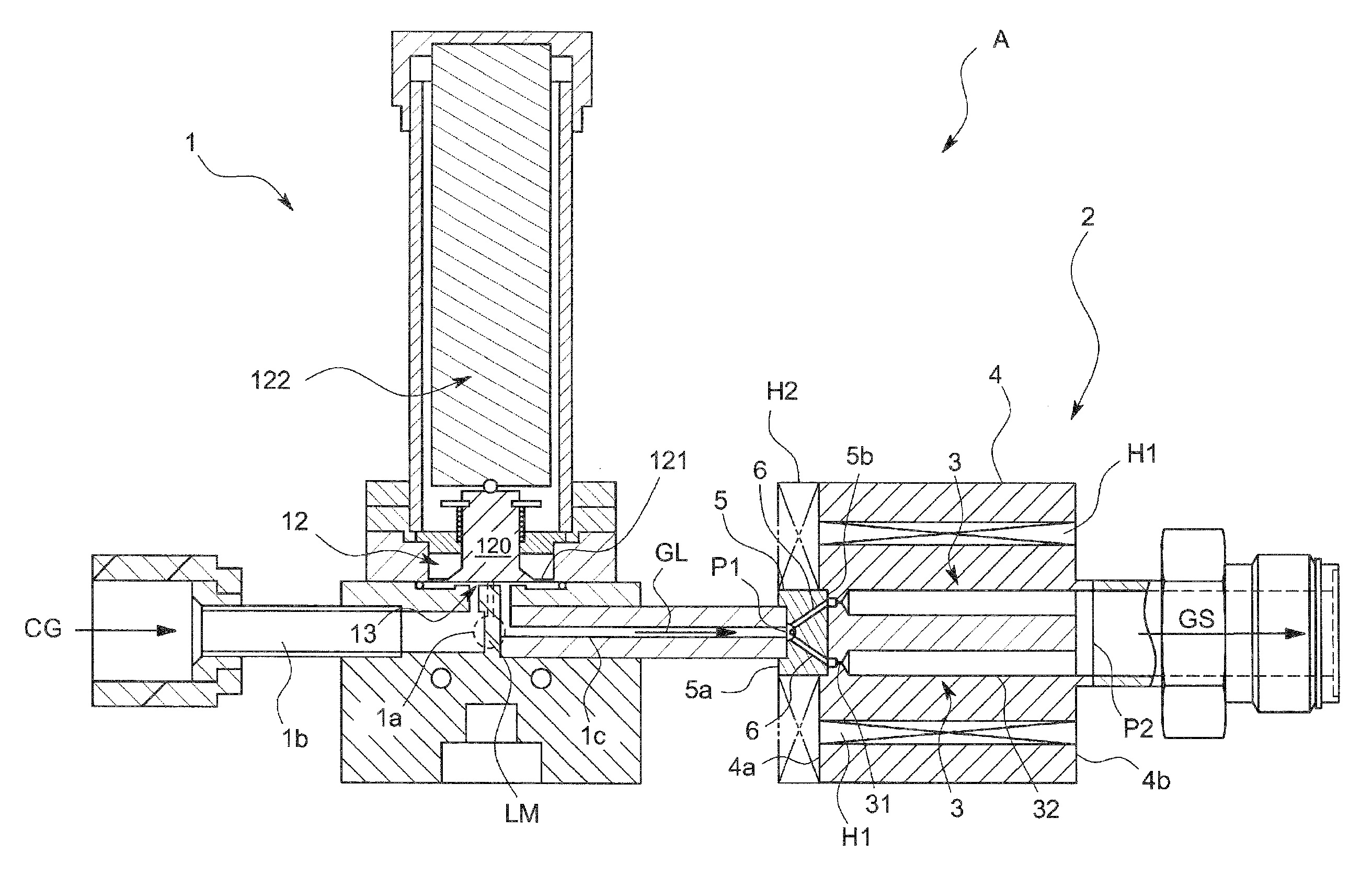

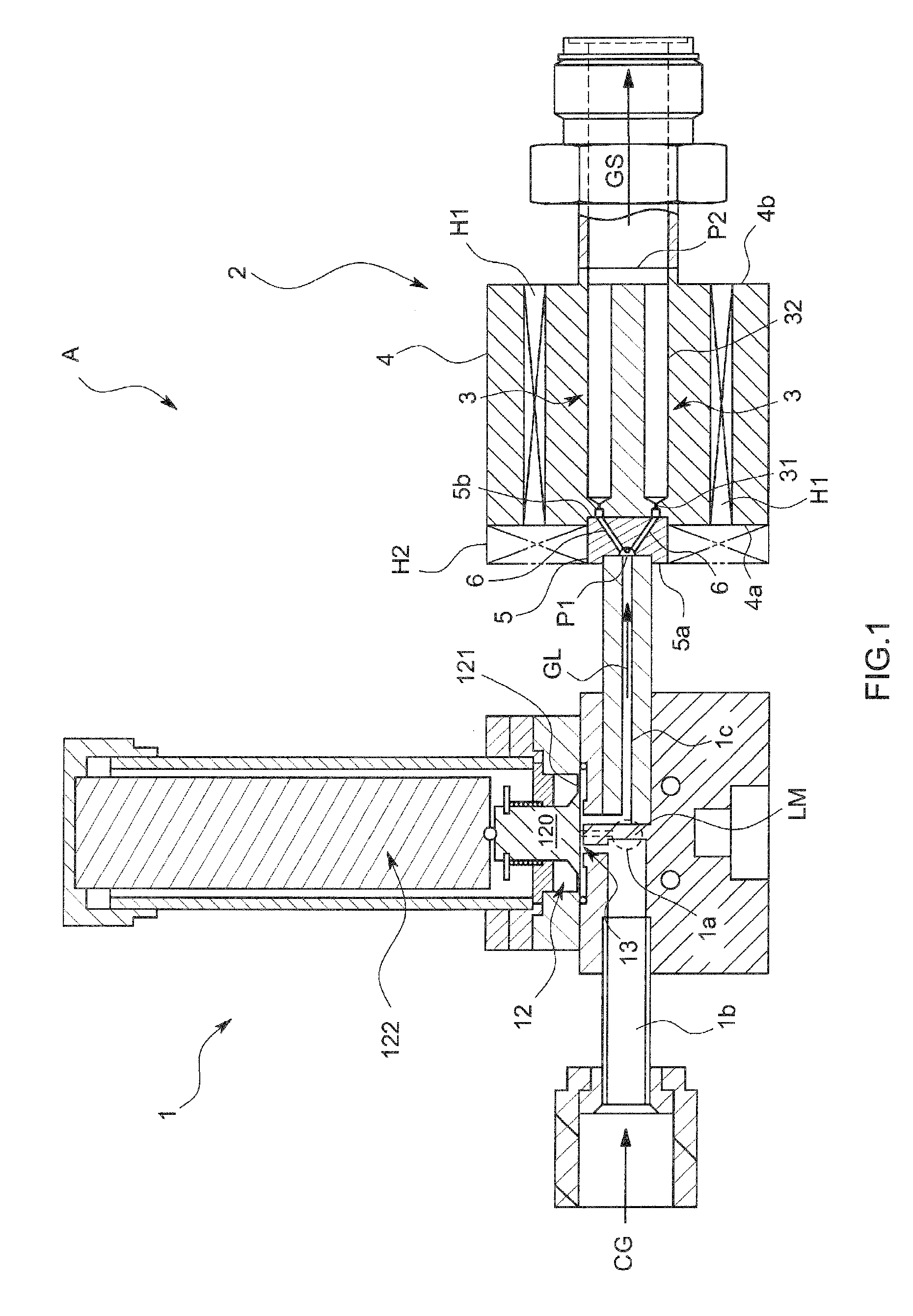

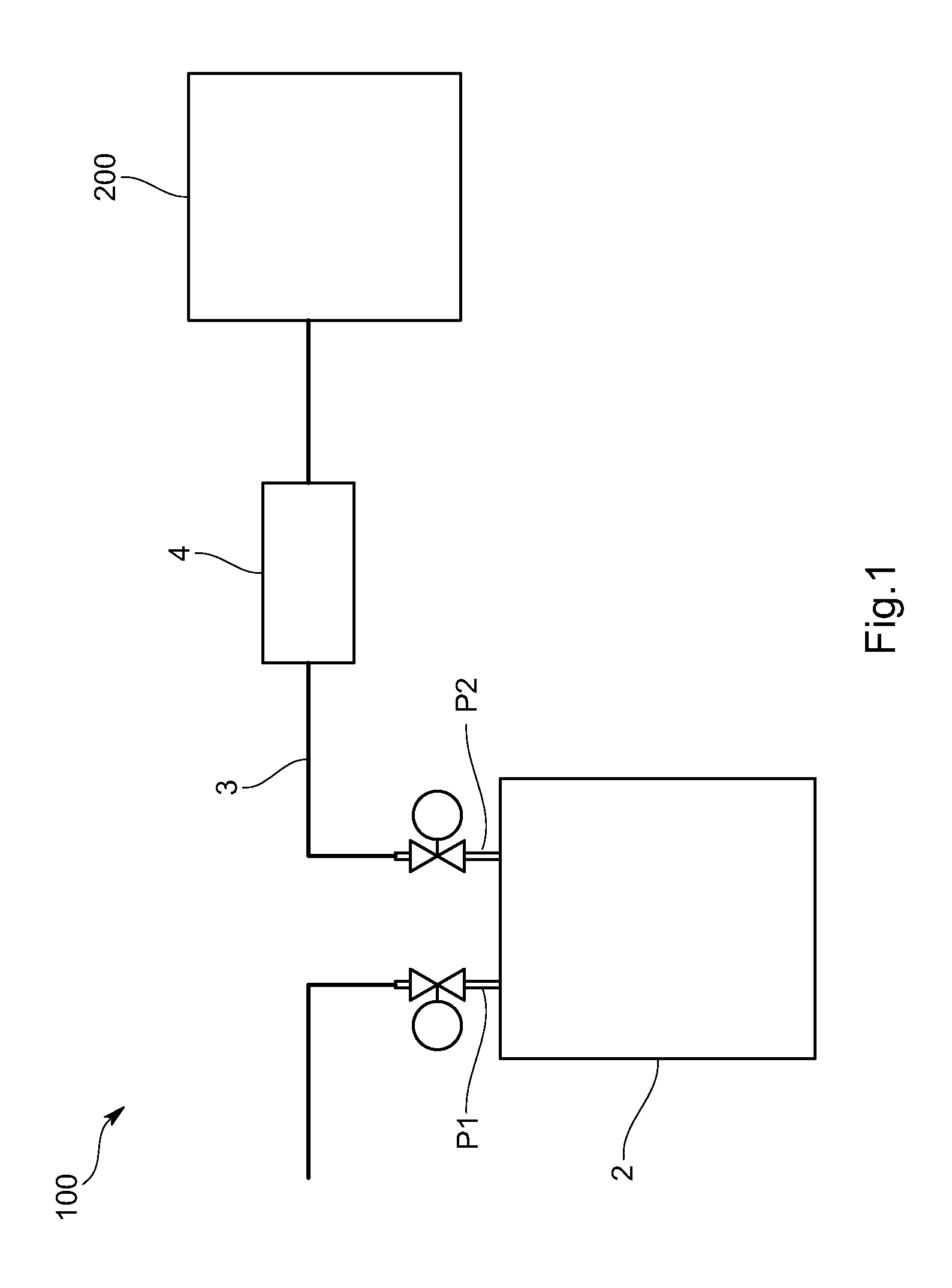

Liquid material vaporizer

ActiveUS8763928B2Prevent nozzle cloggingAvoid cloggingLiquid surface applicatorsSpray nozzlesEngineeringVaporization

This invention provides a vaporizer that prevents deterioration of a precursor while reducing a residue, that can expect reduction in risk of clogging, and that can increase vaporization flow easily. The vaporizer comprises an inlet port for introducing a precursor in a liquid phase or a gas-liquid mixture phase, a vaporizing section for vaporizing the precursor arranged on the downstream side of the inlet port, and an outlet port for delivering the precursor vaporized at the vaporizing section, wherein the vaporizing section is of a flow channel type comprising a nozzle for spraying the precursor and a heating channel arranged on the downstream side of the nozzle continuously thereto. A plurality of vaporizing sections are arranged in parallel between the inlet port and the outlet port, and arranged such that each vaporizing section can distribute the precursor independently of each other.

Owner:HORIBA STEC CO LTD

Liquid material vaporizer

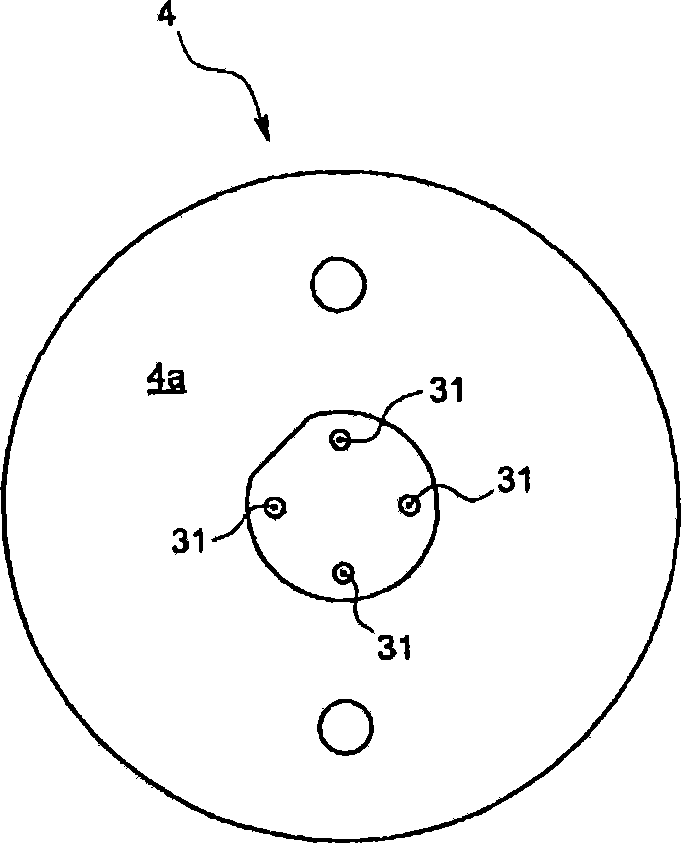

ActiveCN101523572AAvoid cloggingFlow through bigSemiconductor/solid-state device manufacturingBumping preventionLiquid stateVaporization

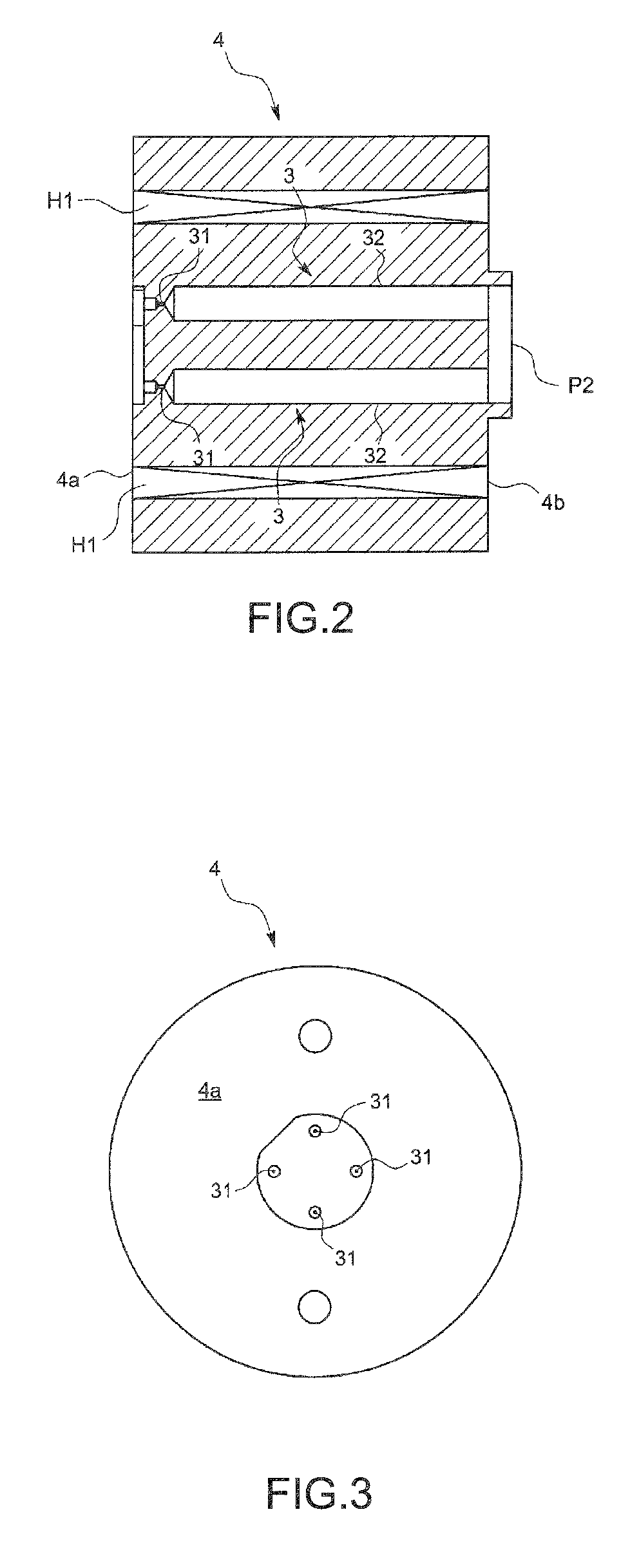

A vaporizer comprises an introduction port (P1) for introducing material in liquid phase or gas-liquid mixture phase, a vaporizing section (3) for vaporizing the material provided on the downstream side of the introduction port (P1), and a delivery port (P2) for delivering the material vaporized at the vaporizing section (3), wherein the vaporizing section (3) is of a channel type and consists of a nozzle (31) for spraying the material and a heating path (32) provided on the downstream side of the nozzle (31) continuously thereto. A plurality of vaporizing sections (3) are provided in parallel between the introduction port (P1) and the delivery port (P2), and arranged such that each vaporizing section (3) can distribute the material independently of each other. The vaporizer which prevents deterioration of raw material while reducing residue, can expect reduction in risk of choking, and can increase vaporization flow rate easily.

Owner:HORIBA STEC CO LTD

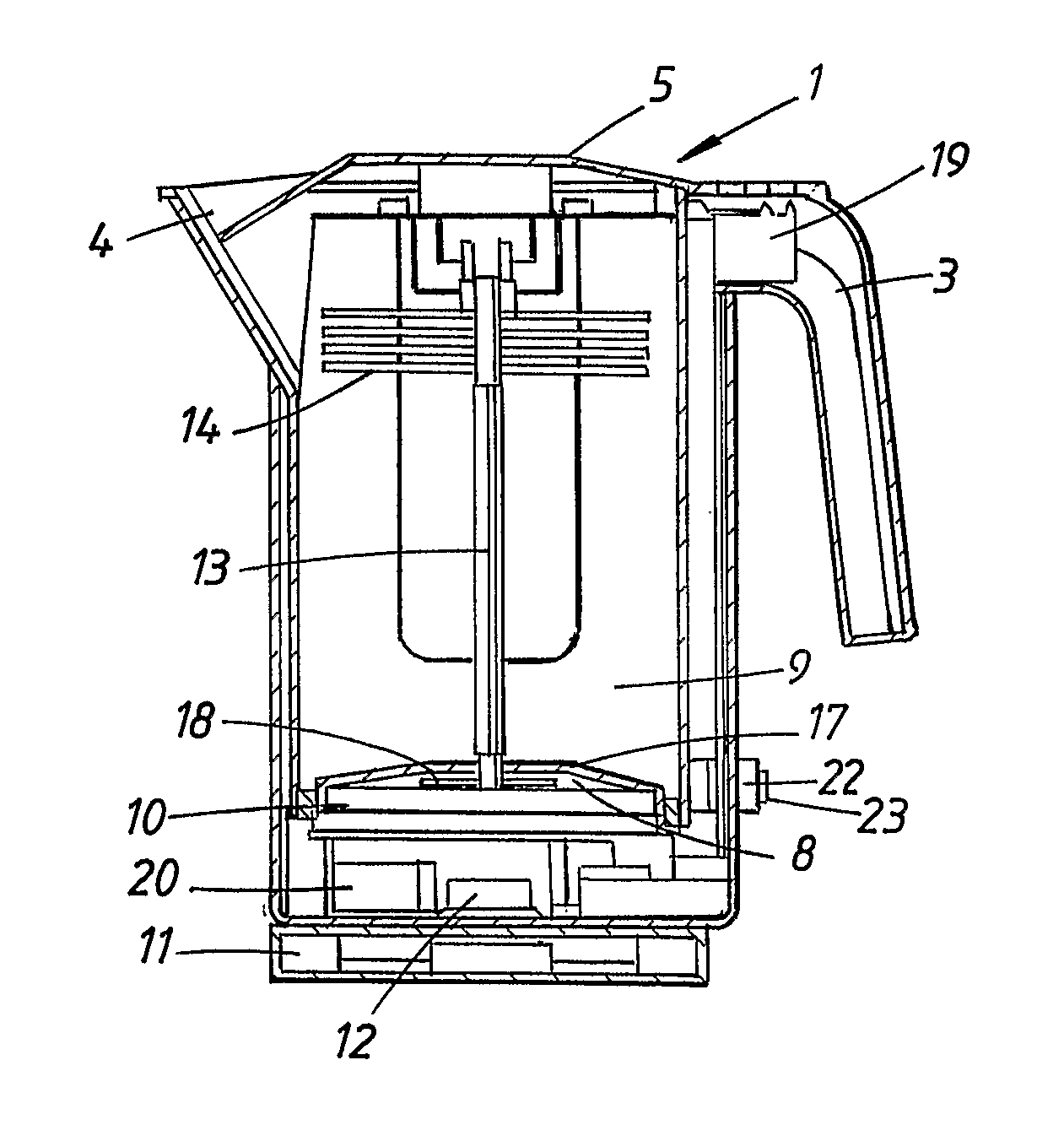

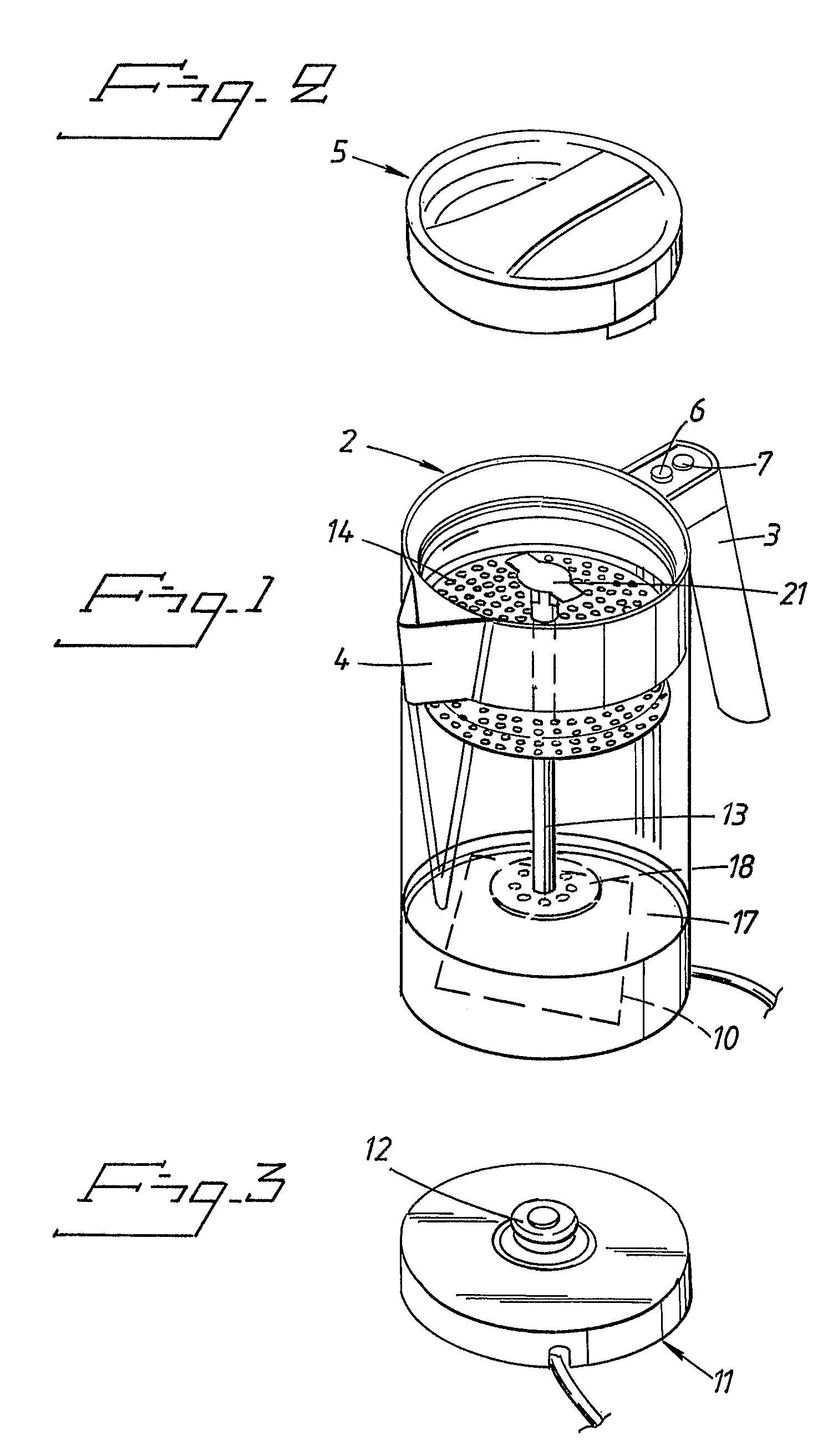

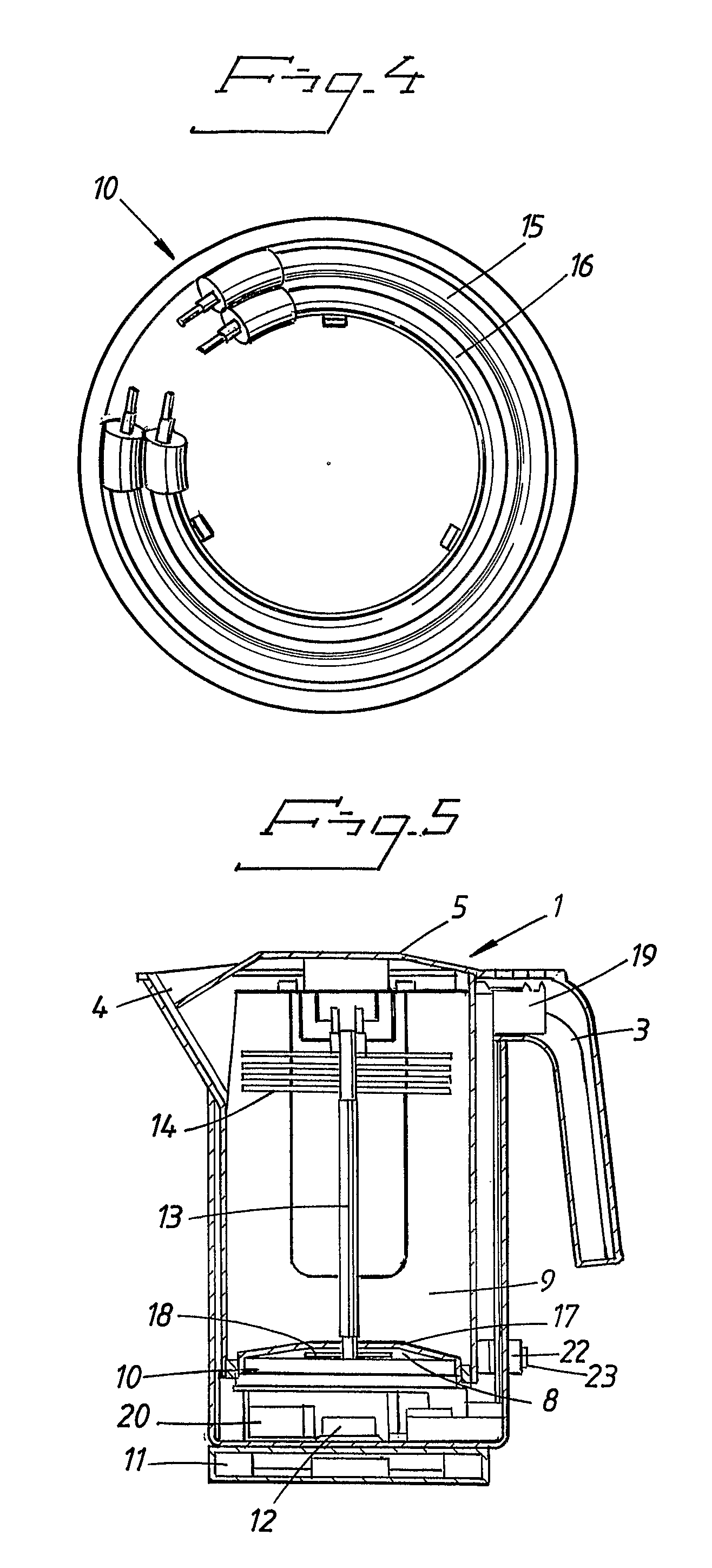

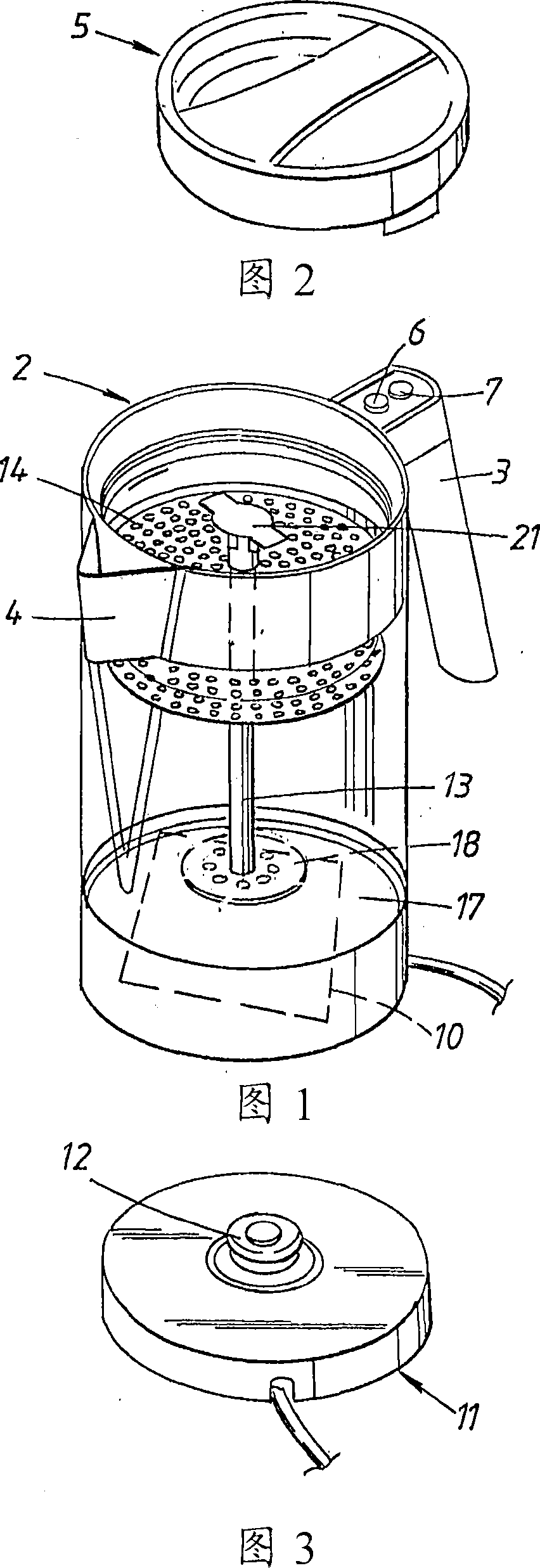

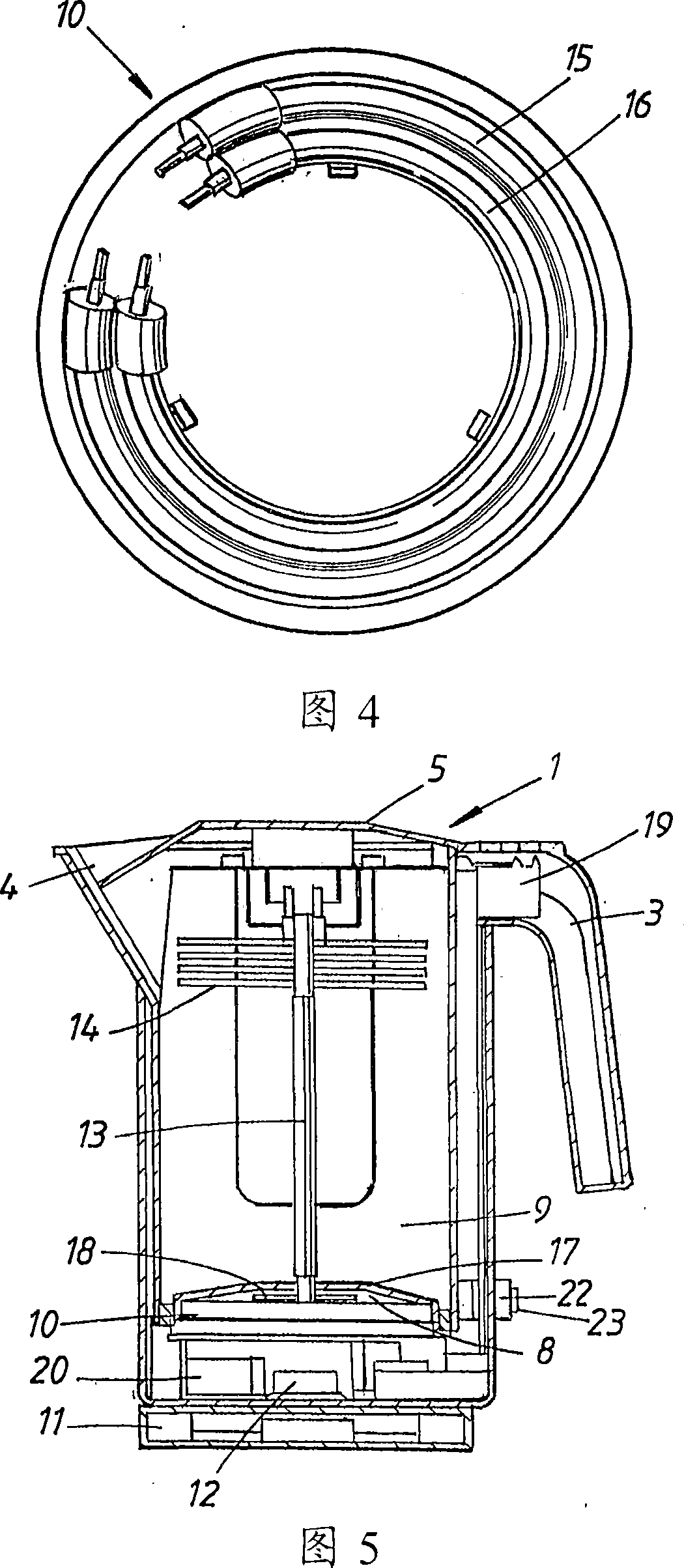

Liquid cleaning device

InactiveUS8052846B2Satisfied with the resultQuick cleanCharging-discharging device combinationsAuxillariesLiquid liquid partitionDistributor

Owner:PURITY AB

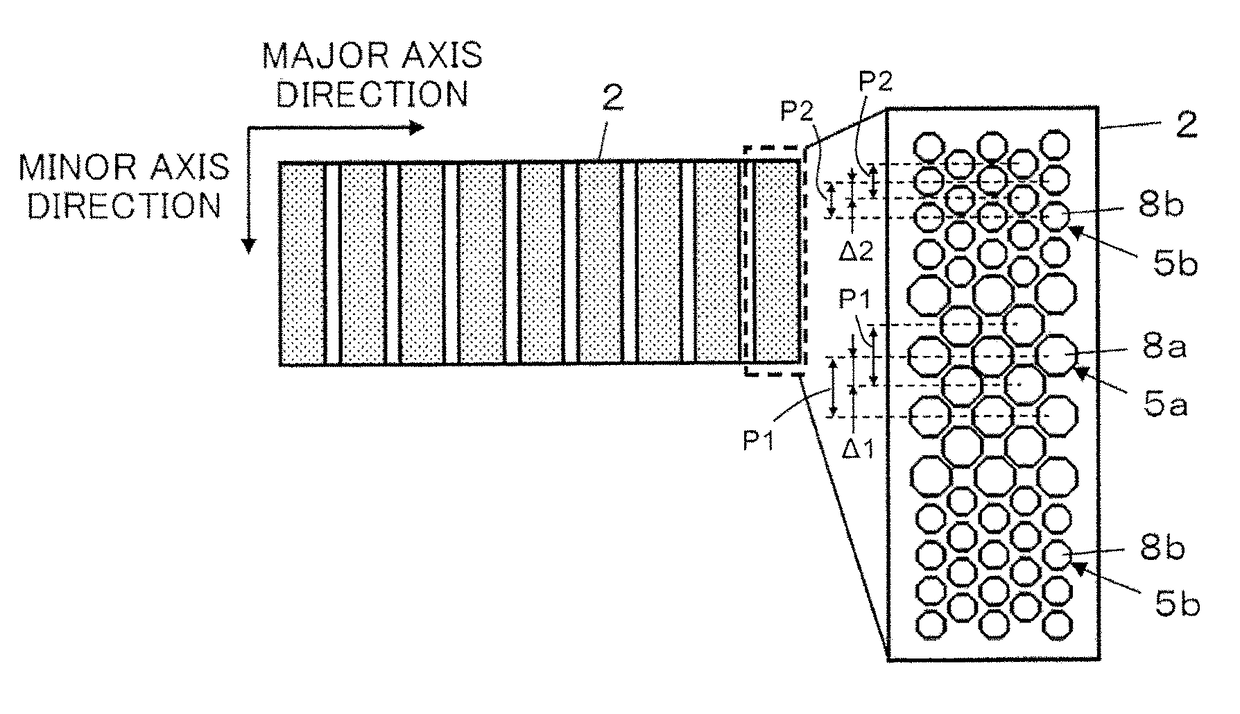

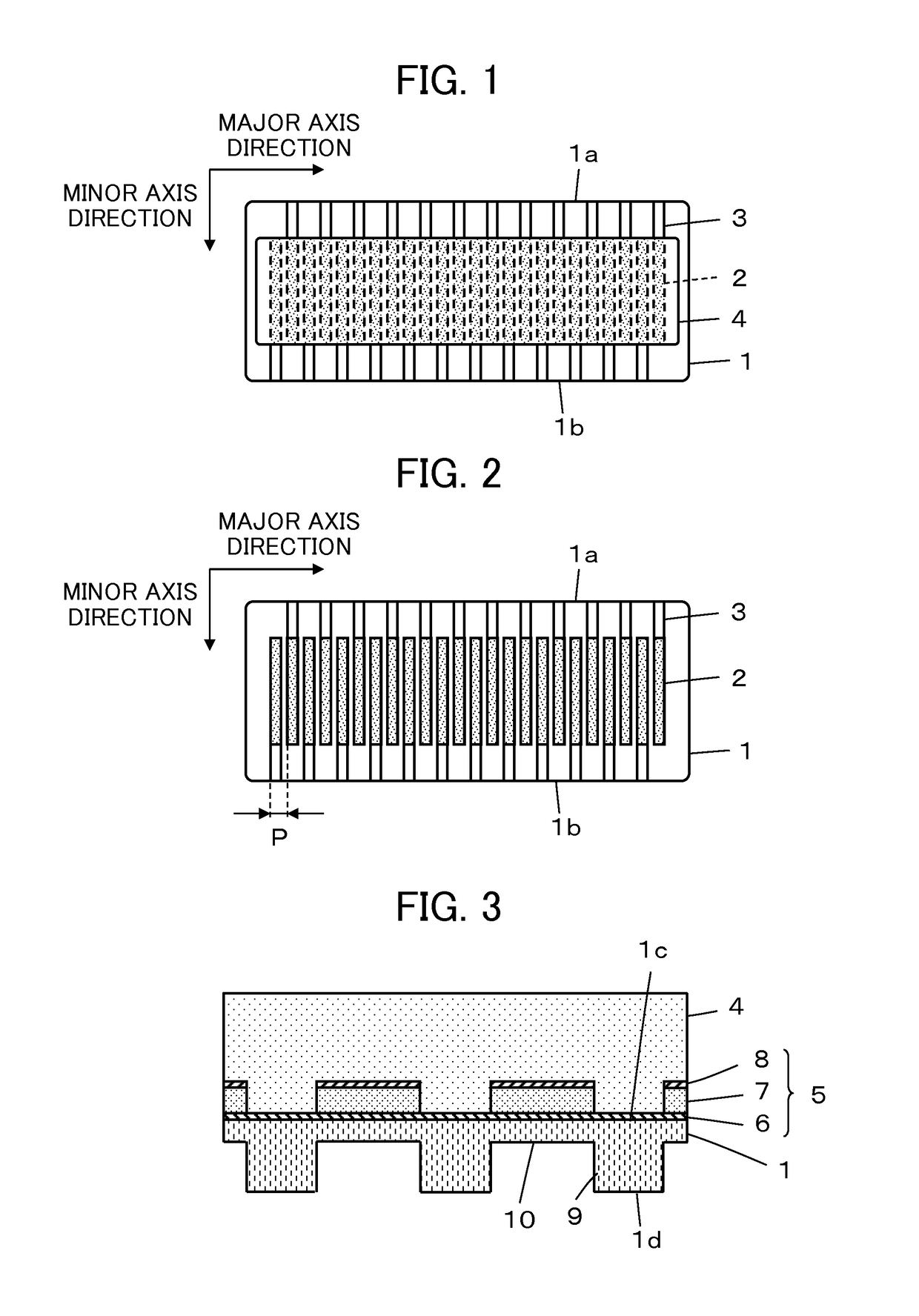

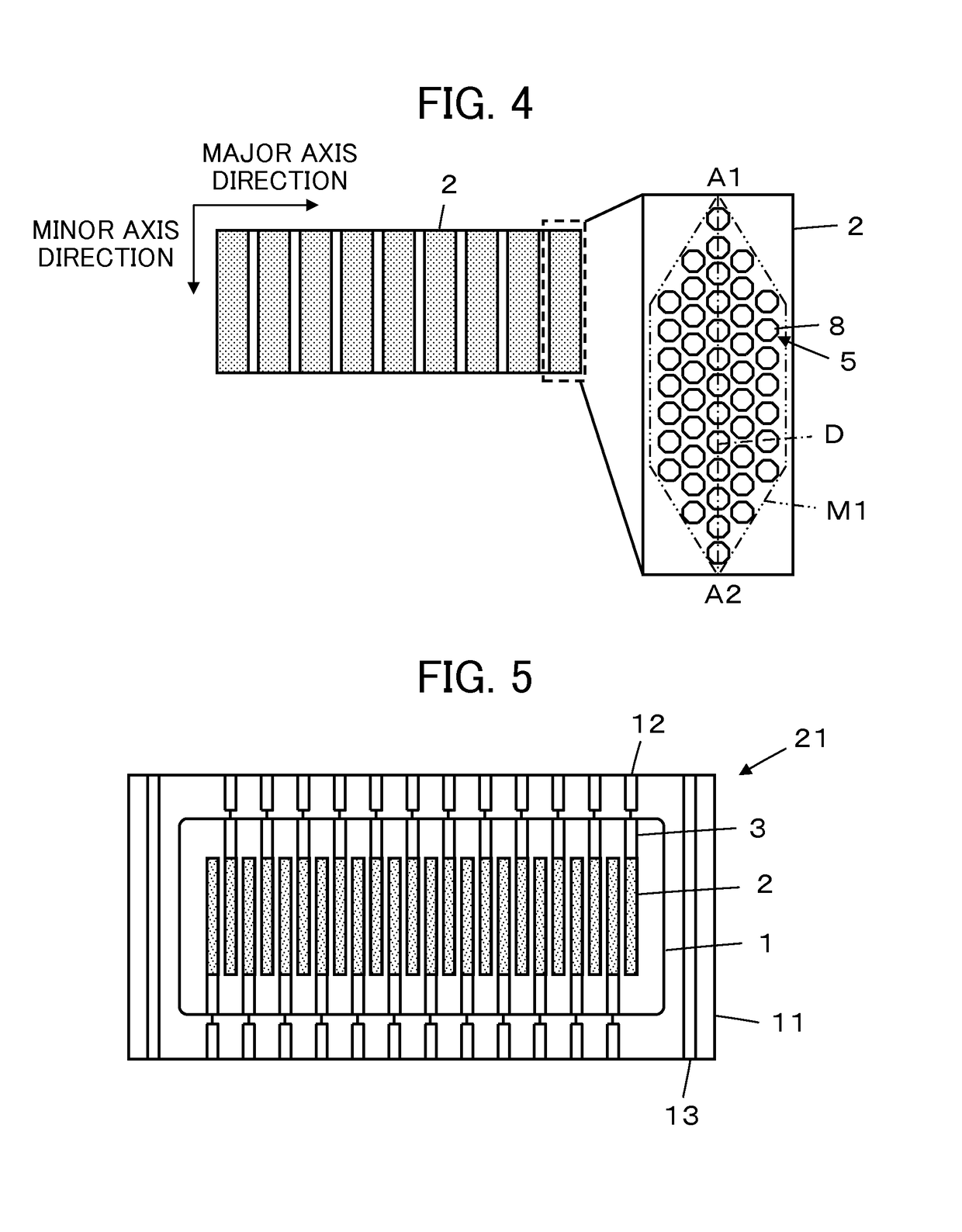

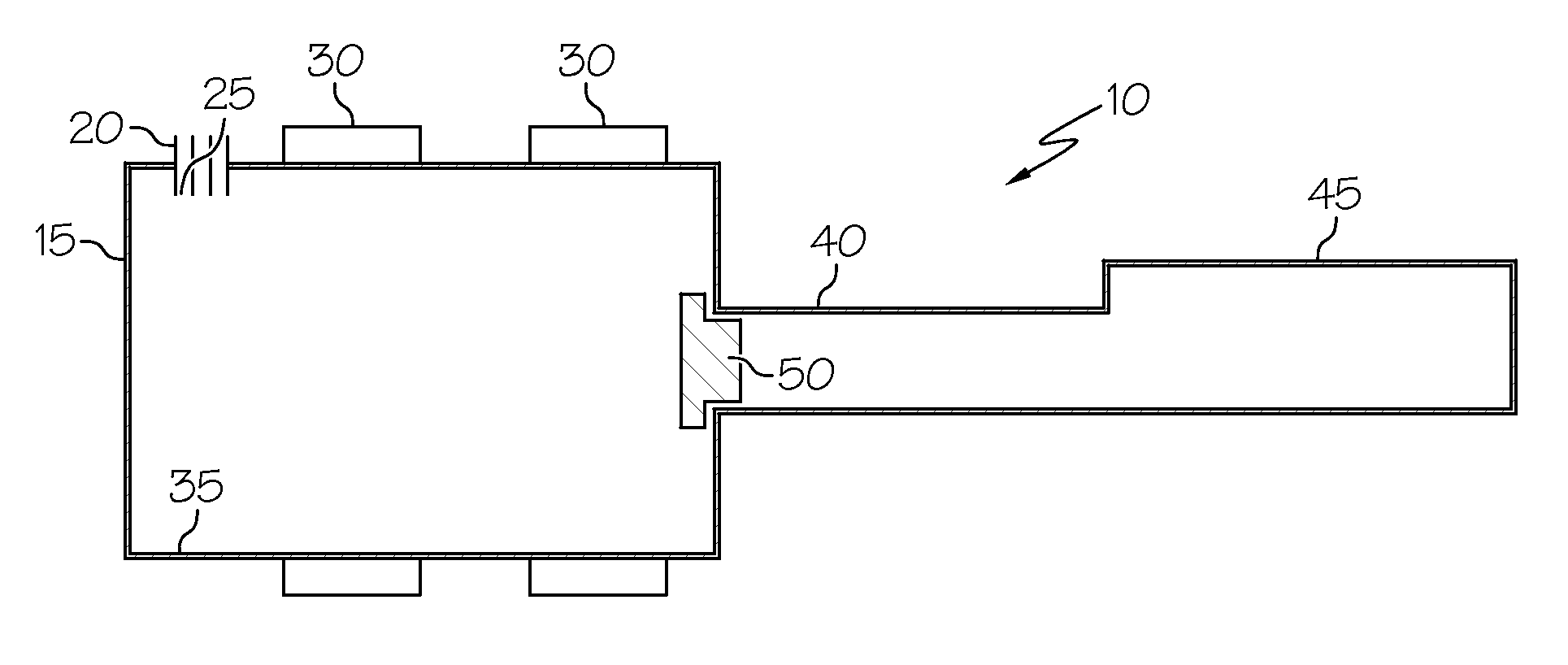

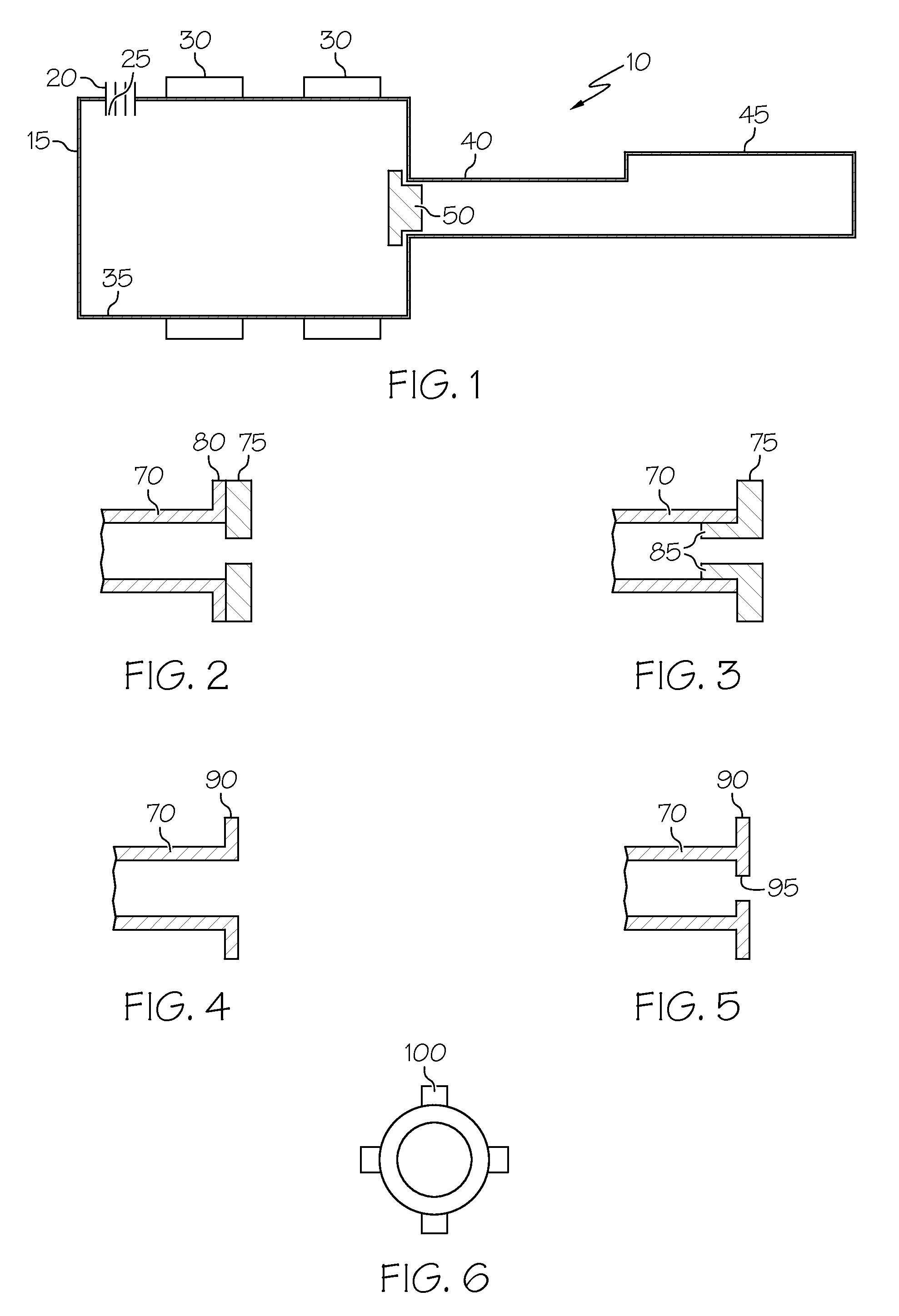

Unimorph-type ultrasound probe

ActiveUS9656300B2Easy to manufactureReduce sidelobeMechanical vibrations separationBumping preventionEngineeringUnimorph

A unimorph-type ultrasound probe has a plurality of piezoelectric element regions which extend in a minor axis direction and are arranged at a predetermined arrangement pitch in a major axis direction, a plurality of minute piezoelectric element portions are formed so as to be arranged in each piezoelectric element region, the size of the plurality of minute piezoelectric element portions is changed in the minor axis direction, the plurality of minute piezoelectric element portions are arranged such that the size of the piezoelectric element portions in both end portions in the minor axis direction becomes smaller than the size of the piezoelectric element portions in a central portion in the minor axis direction, and ultrasonic waves having different frequencies are radiated from the piezoelectric element portions having different sizes.

Owner:FUJIFILM CORP

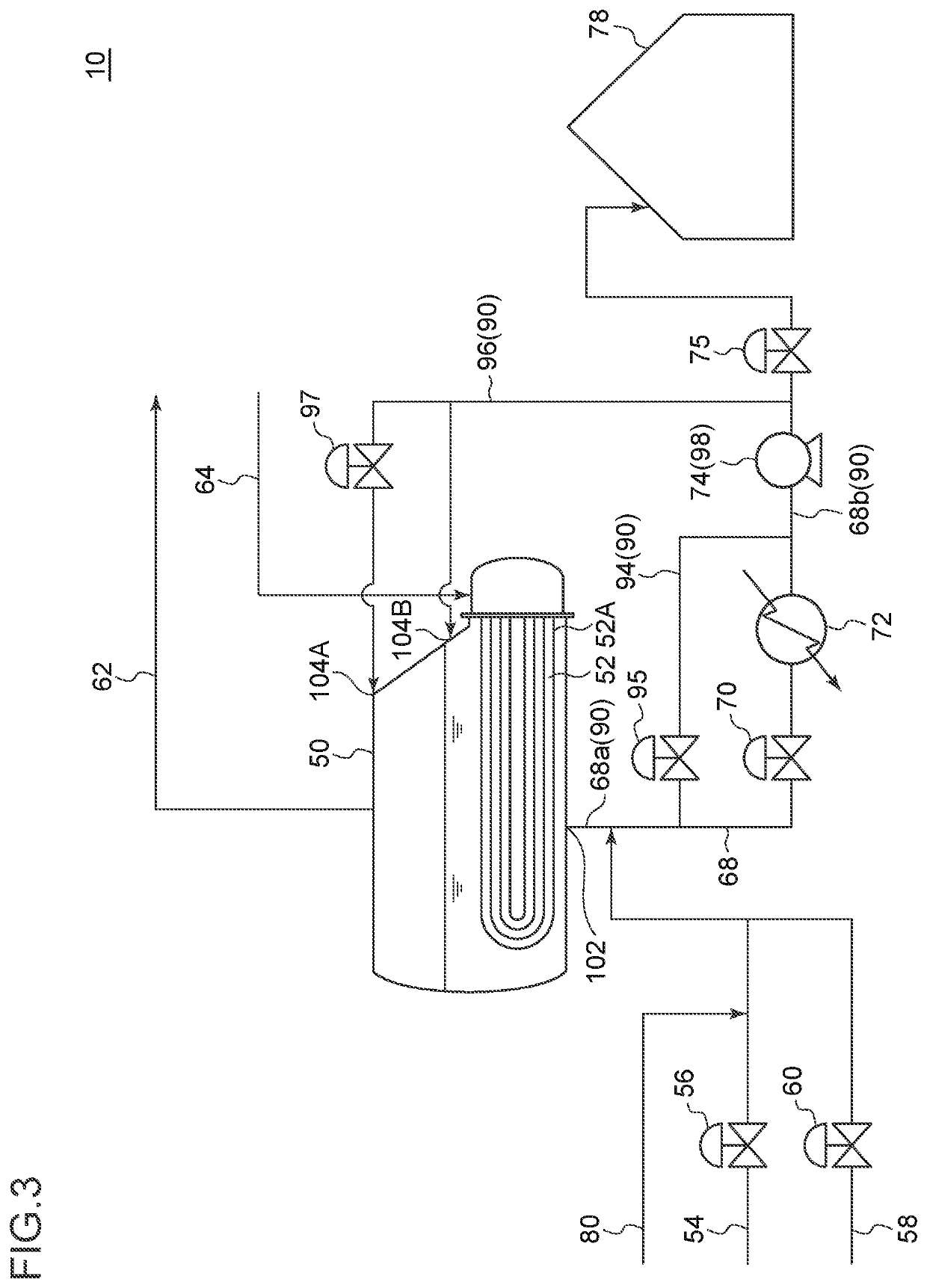

Vaporization Apparatus

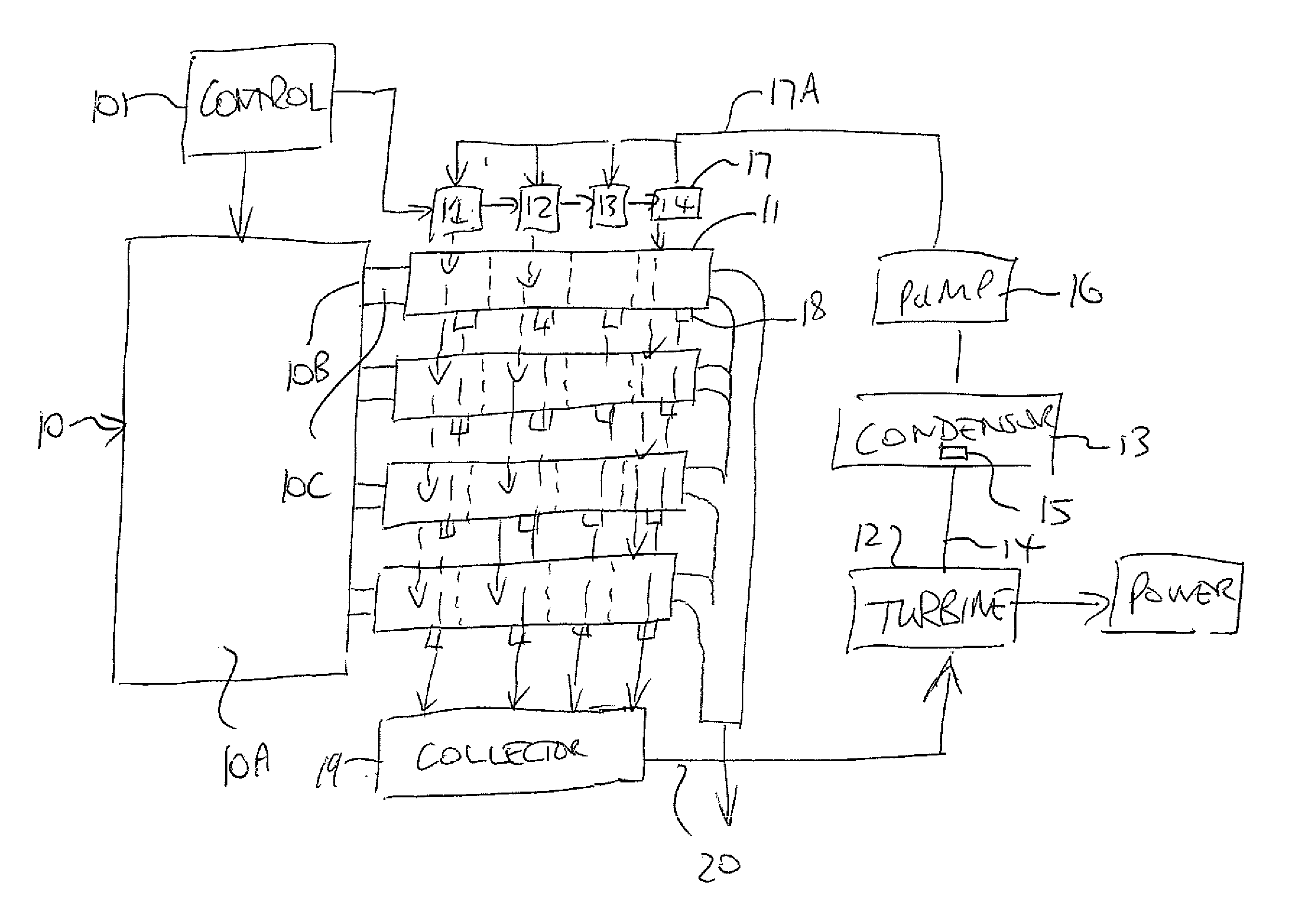

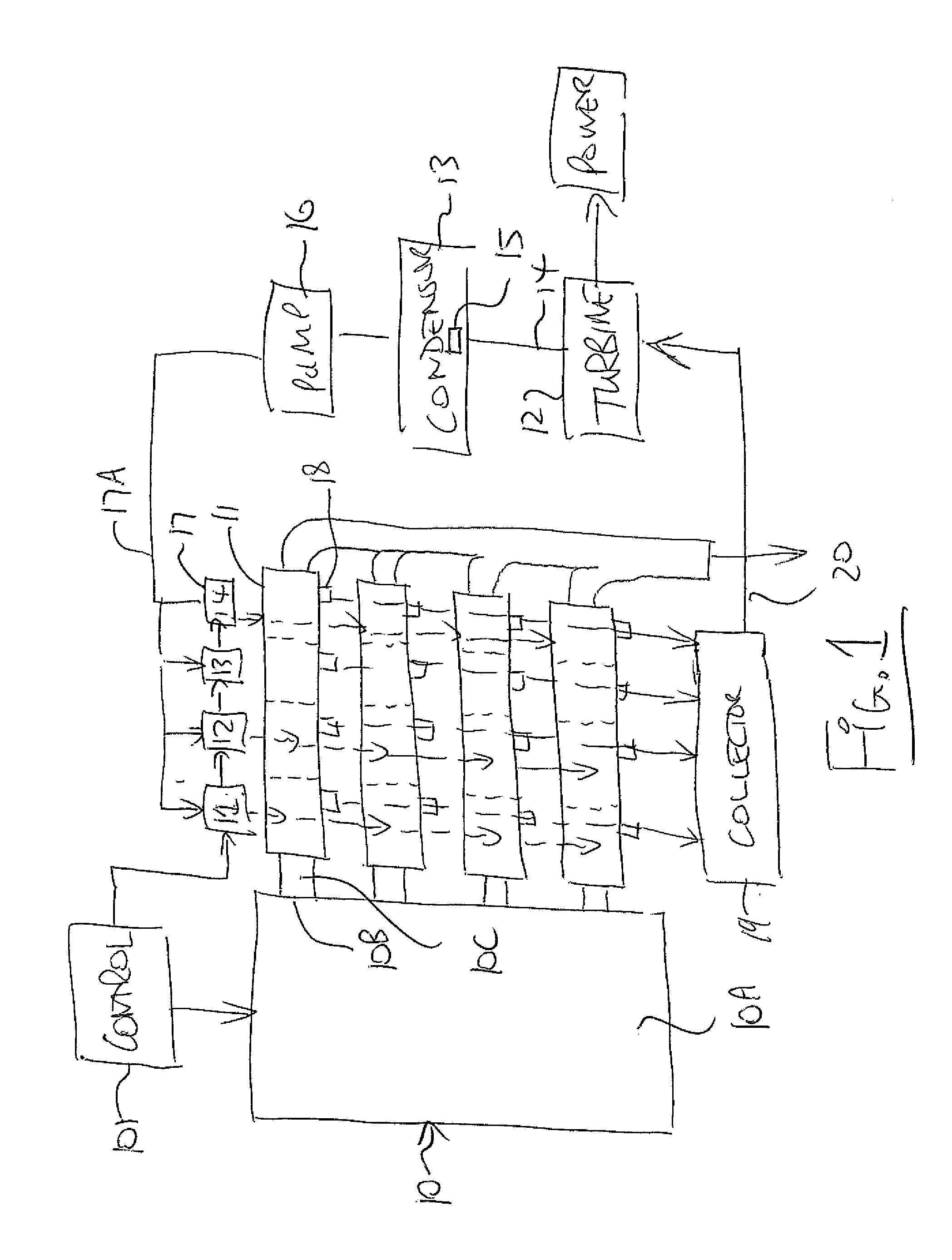

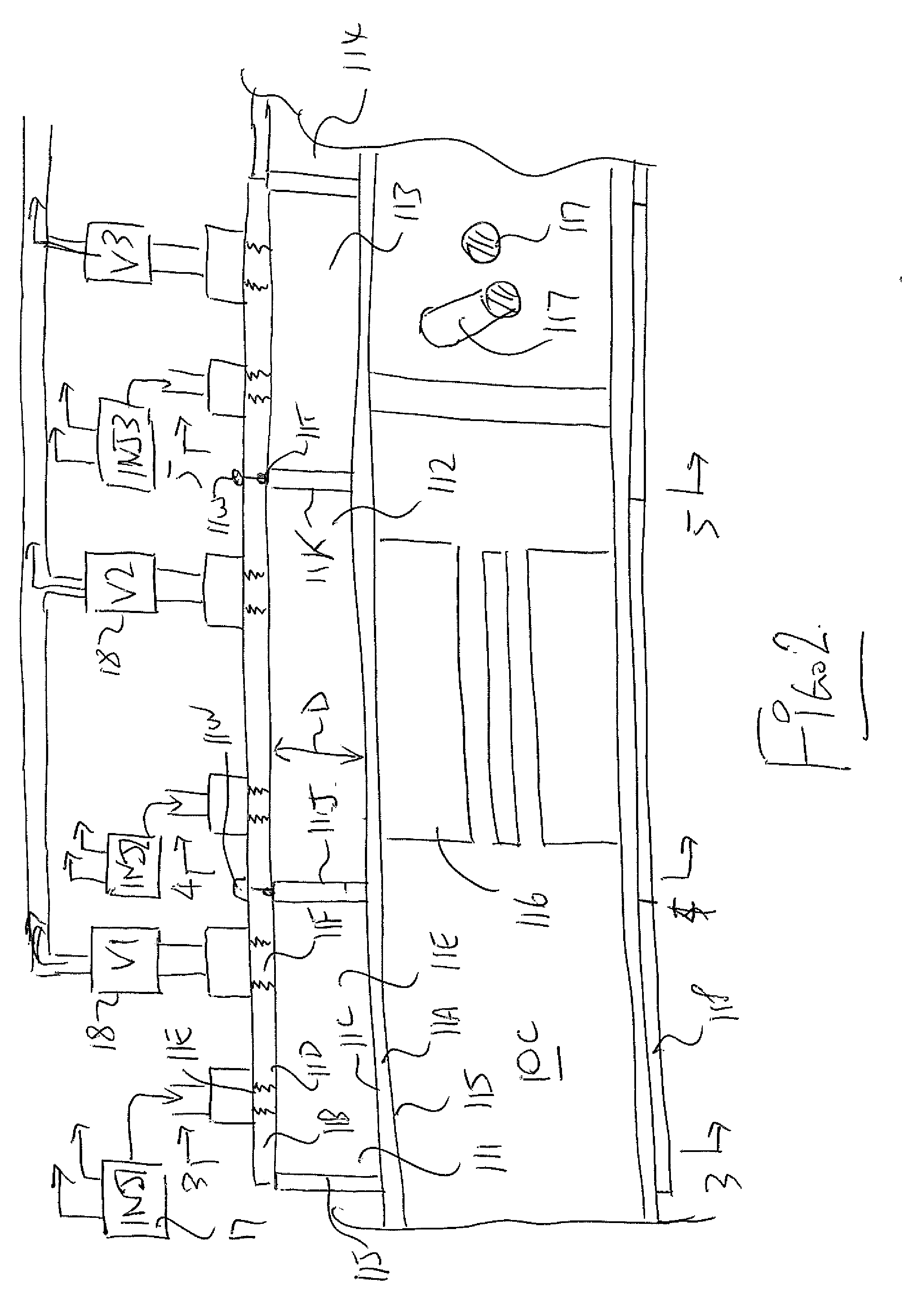

ActiveUS20130276448A1Inexpensive source of energyFacilitate contact areaExhaust apparatusSteam useEngineeringSuperheated steam

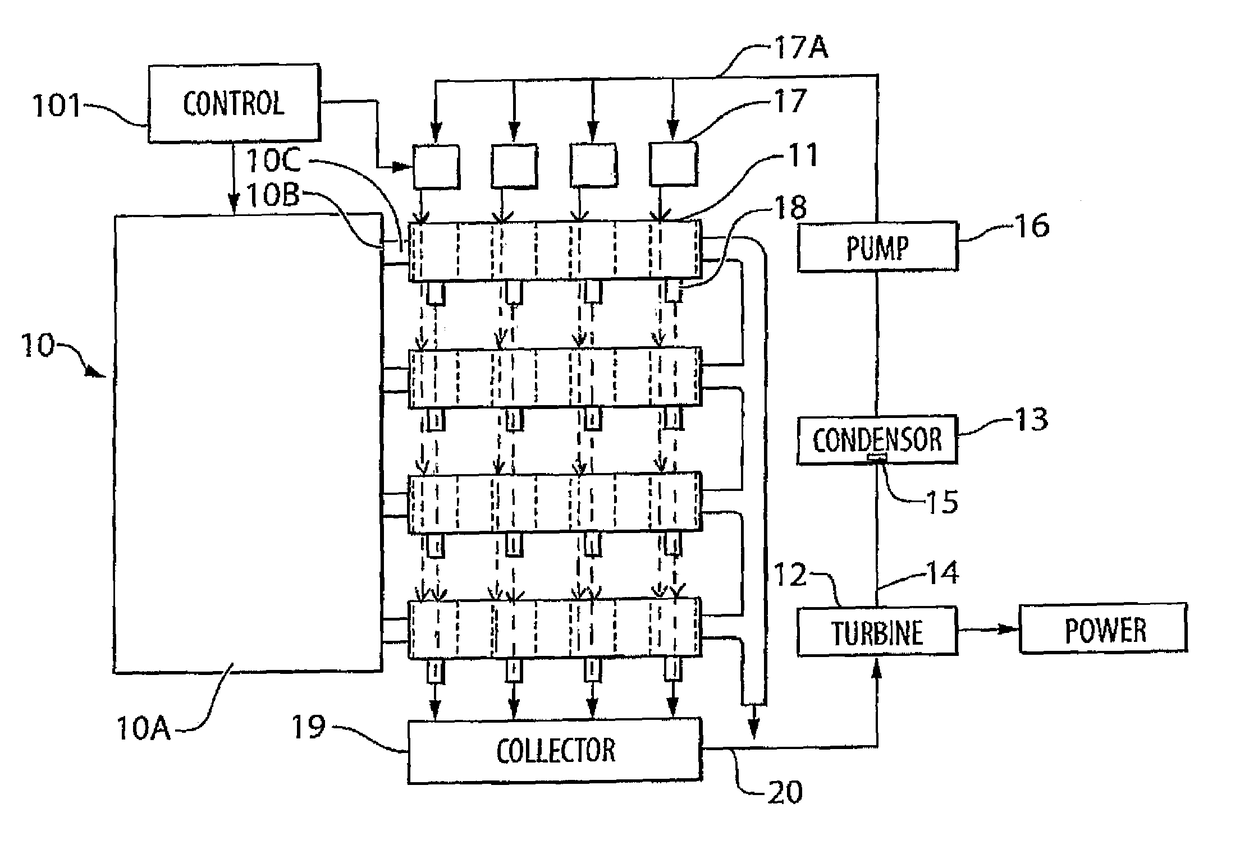

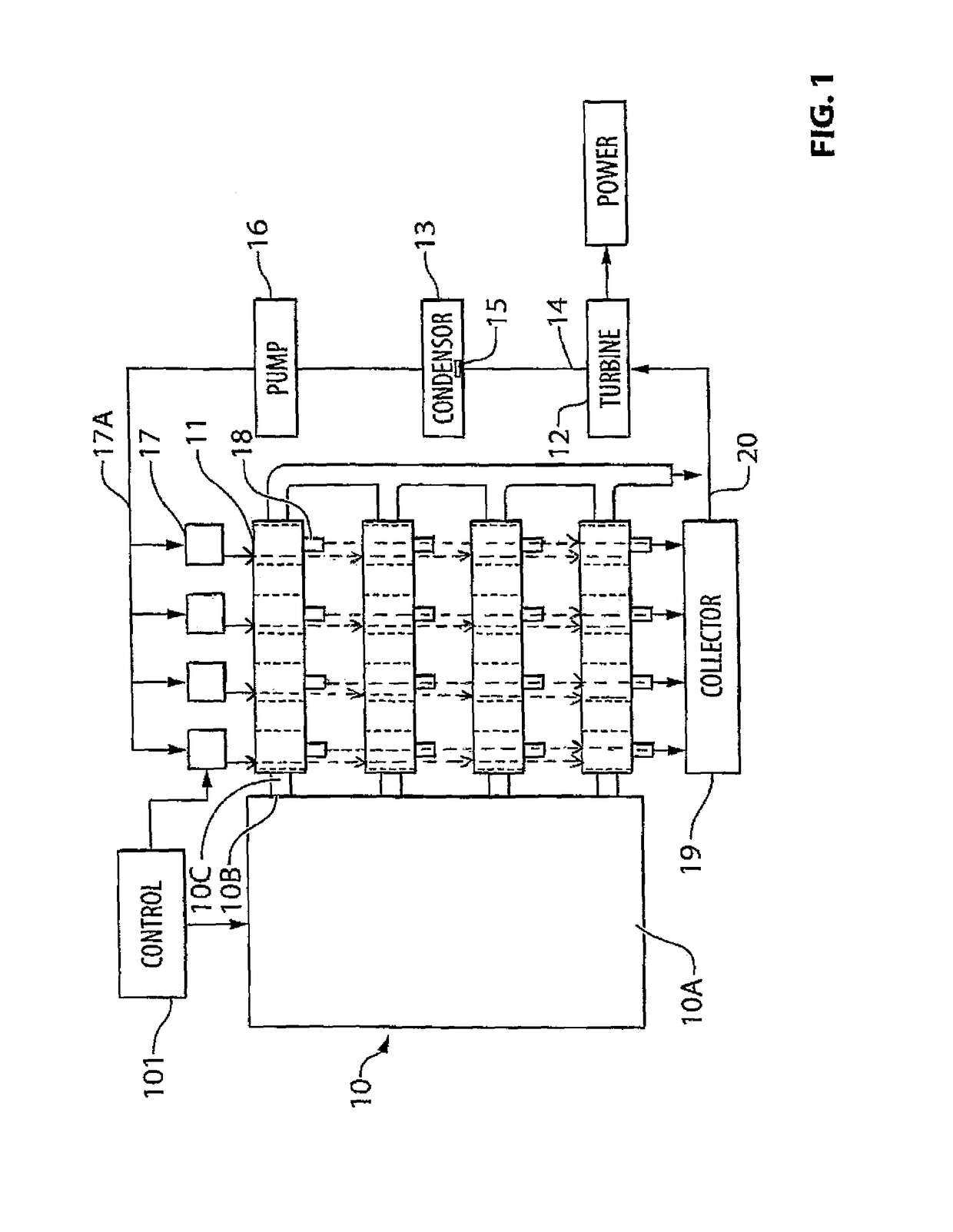

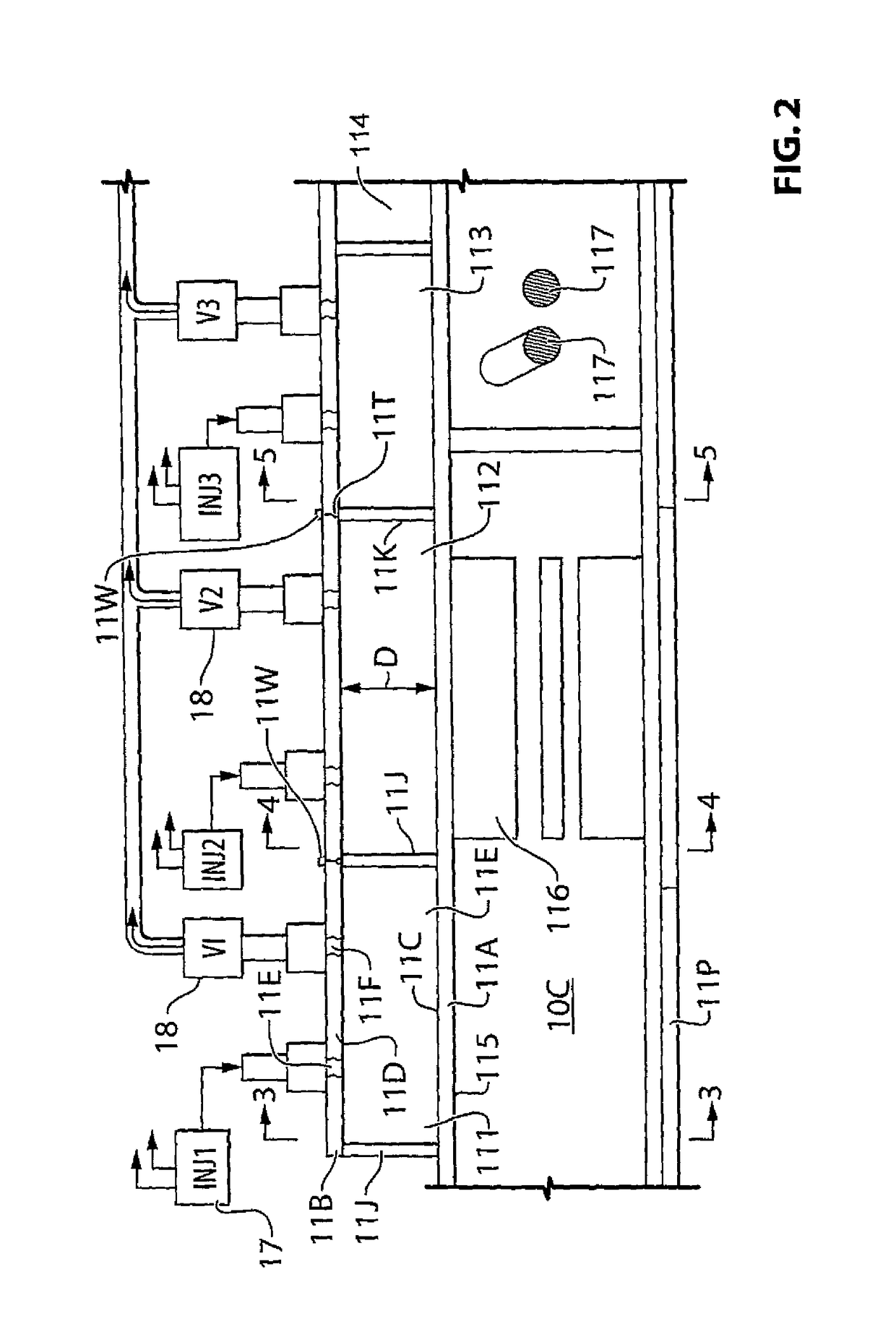

Liquid is flash evaporated in a series of cells along and surrounding an exhaust duct to generate a pressurized vapor where at least one of the surfaces is in communication with the source of heat sufficient to maintain the surface at a temperature such that the liquid injected into the chamber is substantially instantly converted to a superheated vapor with no liquid pooling within the chamber. The liquid is introduced by controlled injectors operating at a required rate. Each of the cells is periodically discharged by a pressure controlled relief valve and the vapor from the cells combined to form a continuous stream feeding a turbine or other energy conversion device. The outer wall of the cell is offset so that it contacts the inner wall at one point around the periphery. Heat transfer ribs and bars can be provided in the duct to provide increased heat transfer where necessary.

Owner:TINMAN +1

Liquid material vaporizer

ActiveUS20100044461A1Avoid residuePrevent nozzle cloggingLiquid surface applicatorsSemiconductor/solid-state device manufacturingEngineeringVaporization

This invention provides a vaporizer that prevents deterioration of a precursor while reducing a residue, reducing risk of clogging, and easily increasing vaporization flow. The vaporizer comprises an inlet port (P1) for introducing a precursor in a liquid phase or a gas-liquid mixture phase, a vaporizing section (3) for vaporizing the precursor arranged on the downstream side of the inlet port (P1), and an outlet port (P2) for delivering the precursor vaporized at the vaporizing section (3), wherein the vaporizing section (3) is of a flow channel type comprising a nozzle (31) for spraying the precursor and a heating channel (32) arranged on the downstream side of the nozzle (31) continuously thereto. A plurality of vaporizing sections (3) are arranged in parallel between the inlet port (P1) and the outlet port (P2), and arranged such that each vaporizing section (3) can distribute the precursor independently of each other.

Owner:HORIBA STEC CO LTD

Method of steam generation by spraying water onto a duct within a chamber having divider walls

ActiveUS9945554B2Facilitate contact areaIncrease surface areaExhaust apparatusSteam useEngineeringTurbine

Liquid is flash evaporated in a series of cells along and surrounding an exhaust duct to generate a pressurized vapor where at least one of the surfaces is in communication with the source of heat sufficient to maintain the surface at a temperature such that the liquid injected into the chamber is substantially instantly converted to a superheated vapor with no liquid pooling within the chamber. The liquid is introduced by controlled injectors operating at a required rate. Each of the cells is periodically discharged by a pressure controlled relief valve and the vapor from the cells combined to form a continuous stream feeding a turbine or other energy conversion device. The outer wall of the cell is offset so that it contacts the inner wall at one point around the periphery. Heat transfer ribs and bars can be provided in the duct to provide increased heat transfer where necessary.

Owner:TINMAN +1

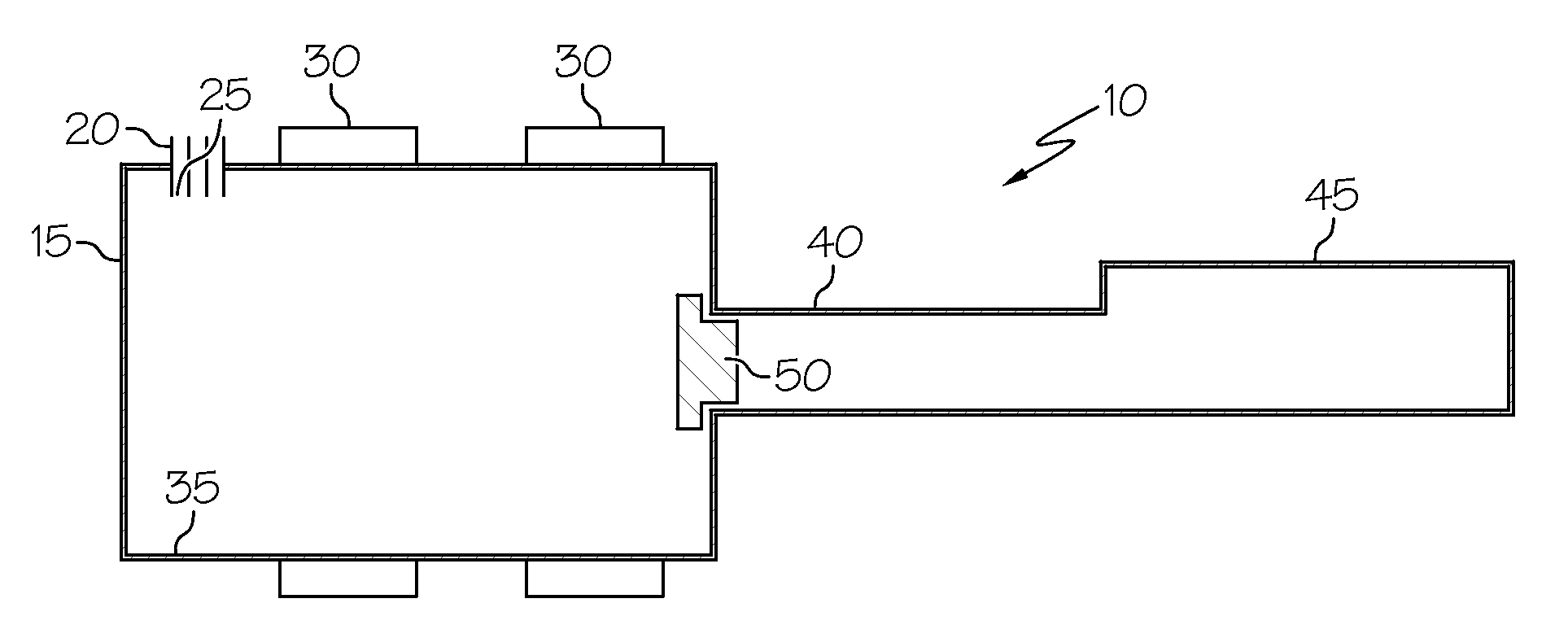

Evaporator with internal restriction

ActiveUS20110154854A1Reduce the impactIncrease pressureDomestic stoves or rangesElectrical heating fuelEvaporation chamberPhysics

An evaporator includes a vaporization chamber having a monomer inlet and a vapor outlet. There is a vapor nozzle in the vapor outlet. The evaporator also includes a collar positioned between the vaporization chamber and the vapor nozzle which increases the pressure in the evaporation chamber while the conductance through the nozzle is substantially unchanged.

Owner:SAMSUNG DISPLAY CO LTD

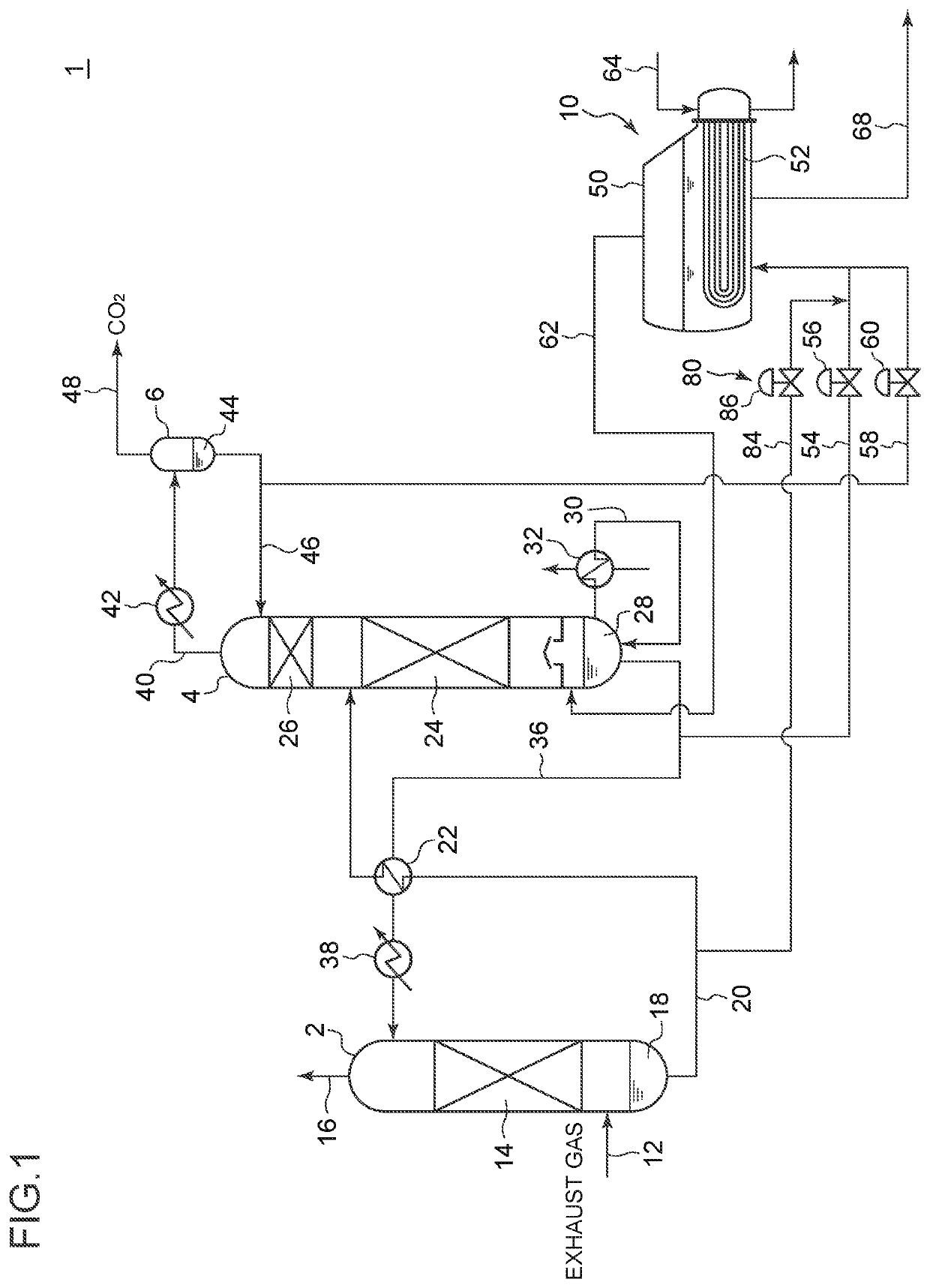

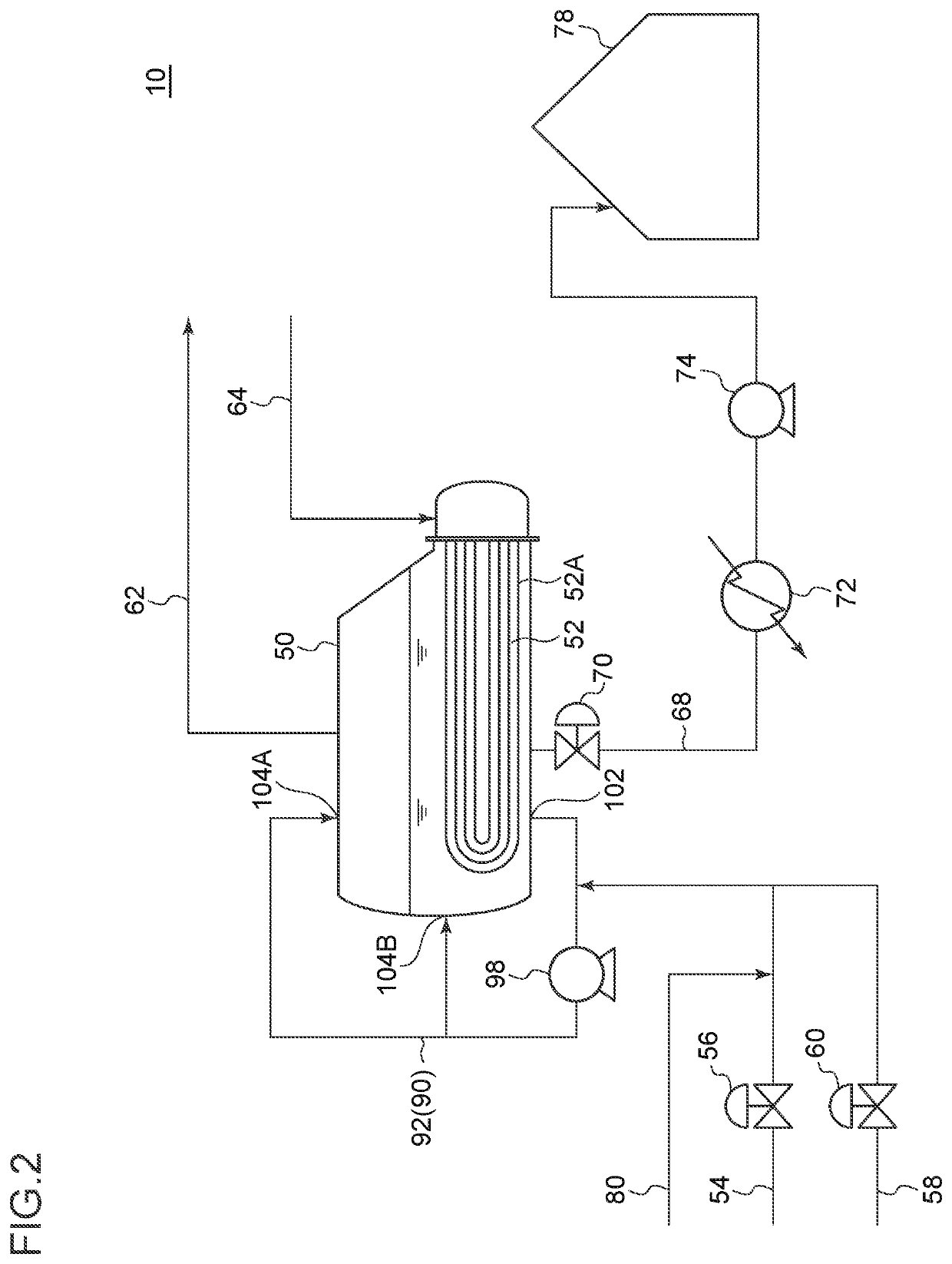

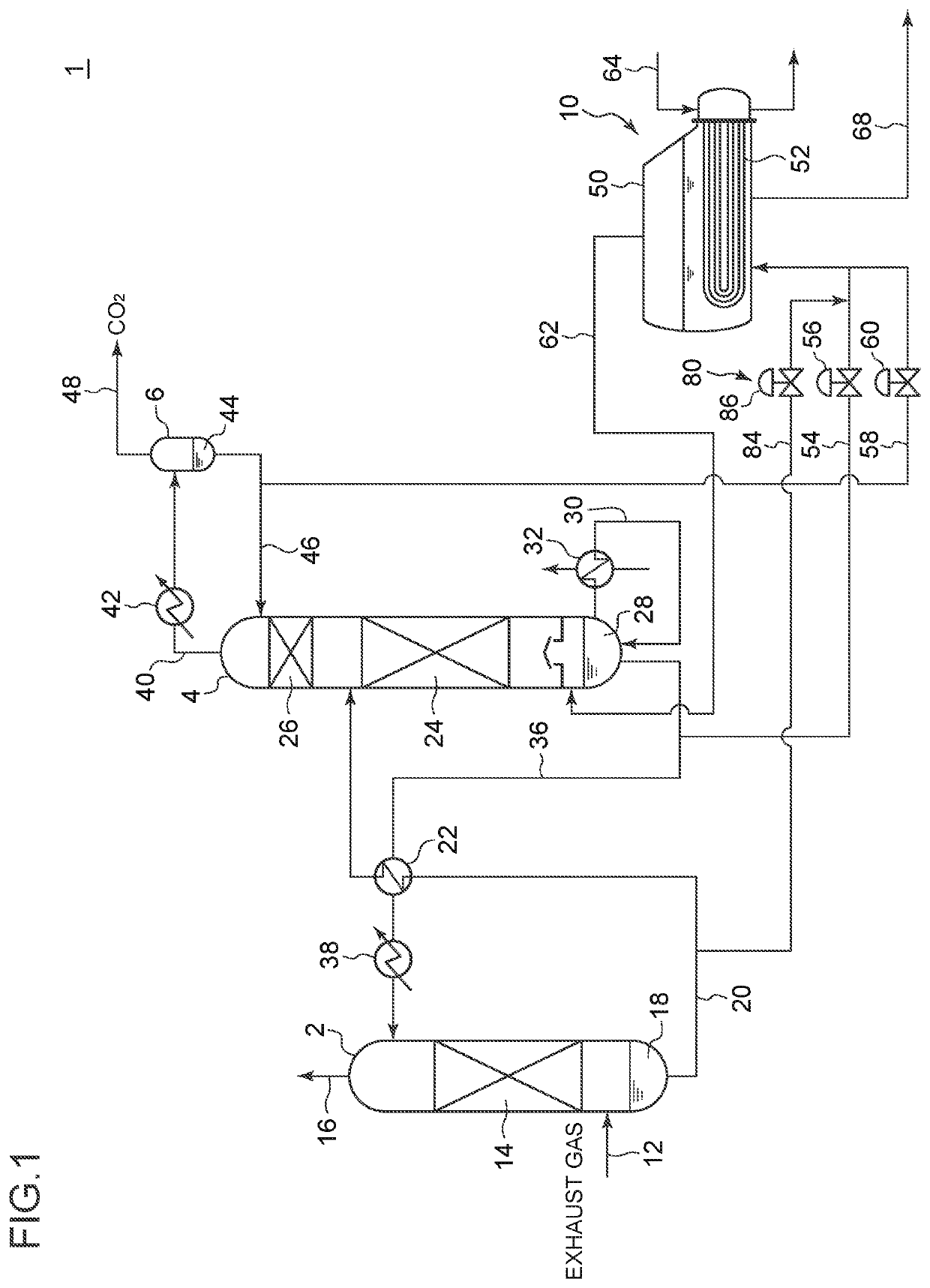

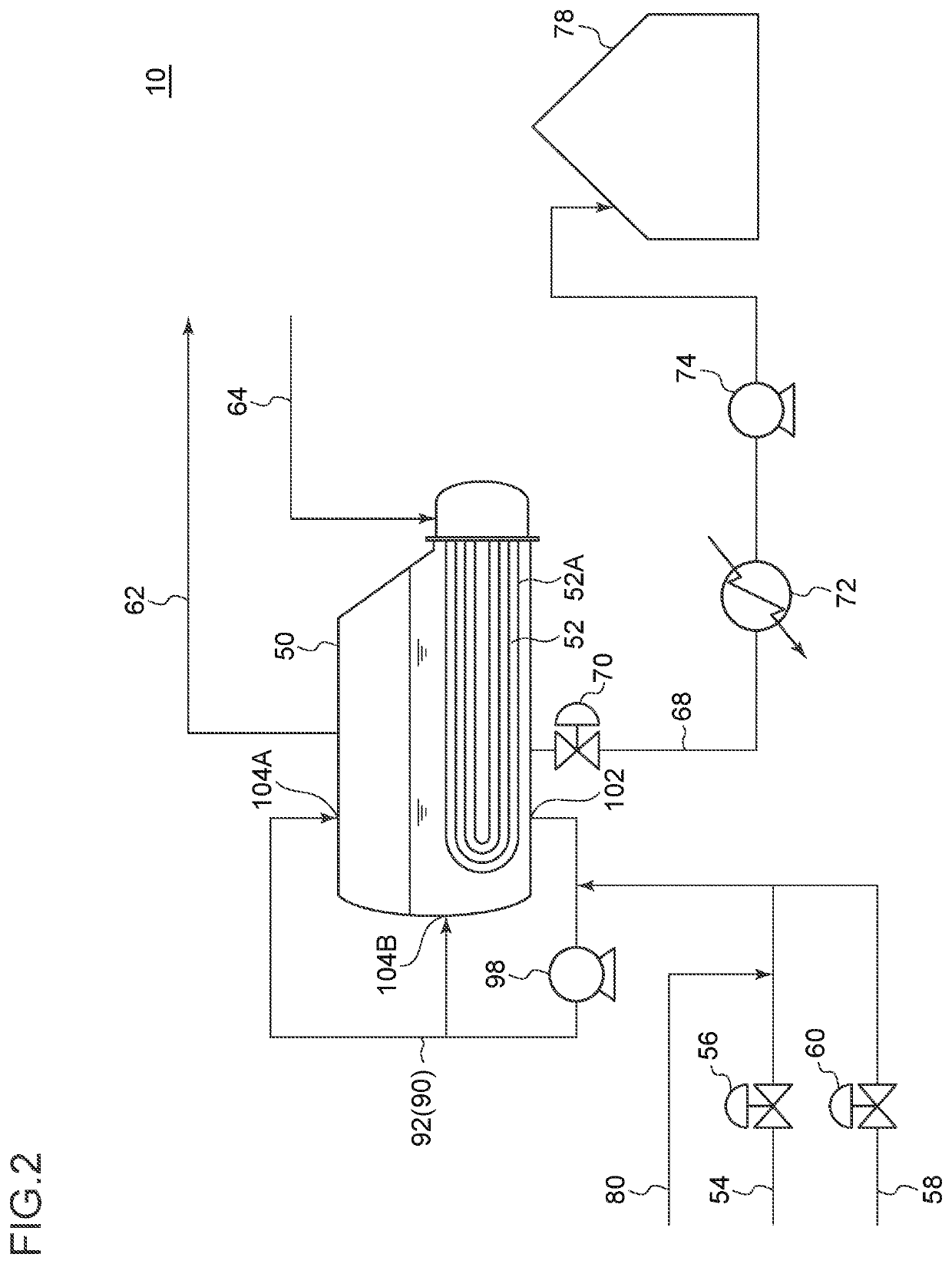

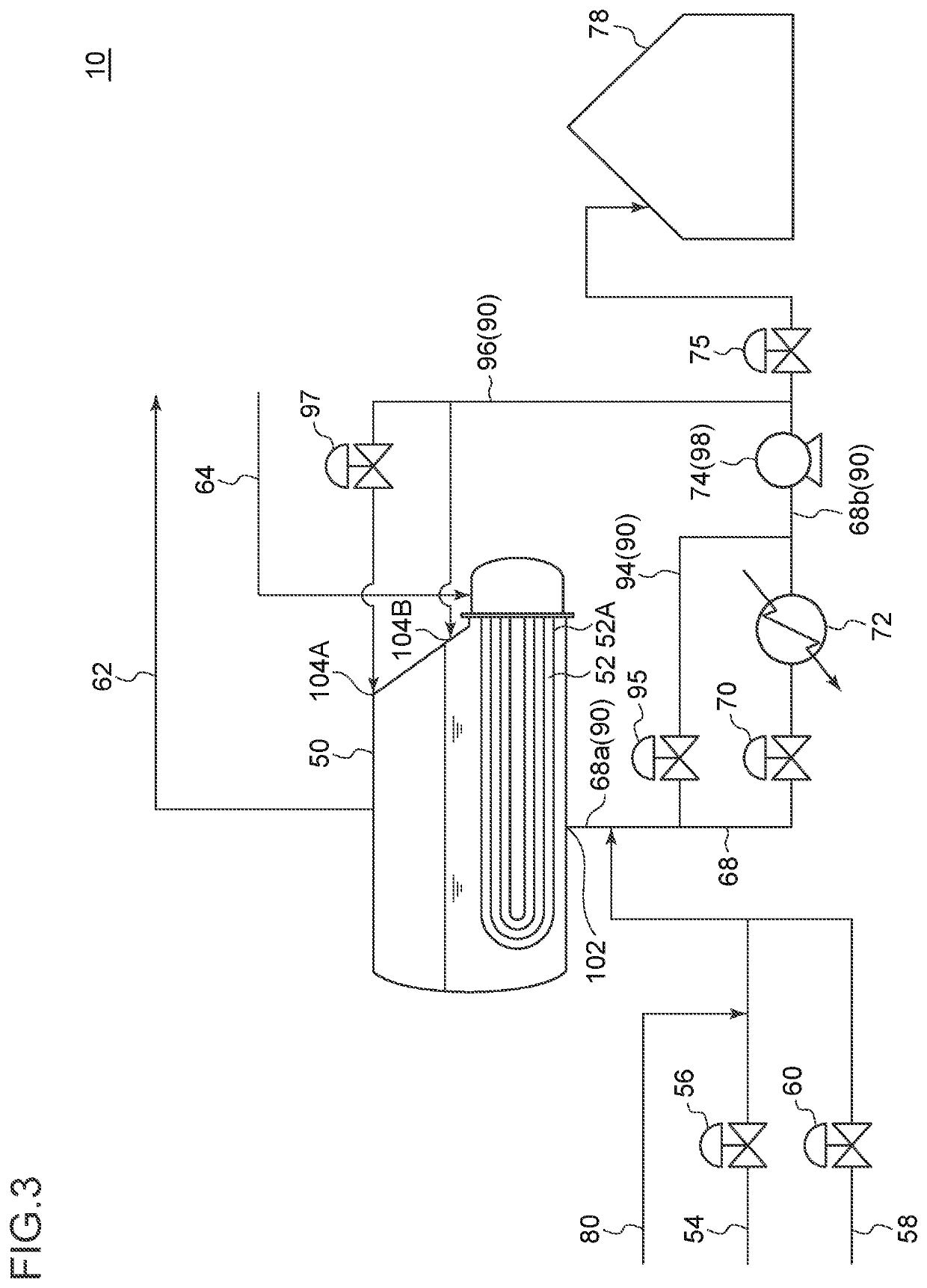

Reclaiming apparatus and method, and CO2 recovery apparatus and method

Owner:MITSUBISHI HEAVY IND ENG LTD

Liquid cleaning device

InactiveCN101137582ALess quantityPower level reductionWater treatment parameter controlTreatment involving filtrationEngineeringDistributor

The invention relates to a liquid cleaning device (1) that is intended for purifying liquid from pollutants, which liquid cleaning device (1) comprises a vessel (2), having a lower chamber (8) and an upper chamber (9), which lower chamber (8) is connected to a heating member (10) arranged to heat the liquid in said lower chamber (8), as well as further comprising a riser (13) and liquid-distributor member (14), which riser (13) is arranged to transport heated liquid from said lower chamber (8) up to the upper part of said upper chamber (9), where the liquid-distributor member (14) is arranged to impart the heated liquid an increased area of exposure to surrounding air, the liquid then, by means of the gravity, running back downward outside the riser (13) and being collected in the lower part of the upper chamber (9) of the vessel (2), said upper chamber (9) and lower chamber (8) being in at least conditioned communication with each other in order to allow transfer of the liquid from the upper chamber (9) to the lower chamber (8). According to the invention, the heating member (10) is arranged to be capable of assuming at least two power levels and that a change-over member is arranged to automatically reduce the power level of the heating member (10).

Owner:PURITY AB

Liquid sample heating vaporizer

ActiveUS20120011943A1Improve accuracyImprove propertiesThermometer detailsWithdrawing sample devicesTemperature controlVaporization

The present invention is intended to improve response property and accuracy of temperature control of a liquid sample, and is provided with a vaporization tank that retains the liquid sample, one or more heaters that are provided in the vaporization tank and respectively have heating parts that come into contact with the liquid sample to heat the liquid sample, a temperature detection part that is provided in contact with an outer surface including the heating part of any of the heaters and detects a temperature of the outer surface, and a control part that receives a temperature detection signal from the temperature detection part to control electric power supplied to the heaters.

Owner:HORIBA STEC CO LTD

Heat exchange apparatus and method

PendingUS20210389061A1Increase cell diameterIncrease layer thicknessBoiler water tubesEvaporationEngineeringMechanical engineering

A heat exchanger apparatus includes a tube having a wall with an inner surface and an outer surface. The tube is configured to receive heat exchange fluid at one end, and output, when heated through the wall, vapor of the heat exchange fluid at the opposing end. A first layer of thermally conductive porous material is disposed on the inner surface of the tube. Heating equipment, a heat exchanger, and a method of heating are also disclosed.

Owner:UT BATTELLE LLC

Heavy feed mixer

ActiveCN102656254AHigh speedSpeed up entryThermal non-catalytic crackingEvaporationVaporizationSuperheated steam

An apparatus designed to completely vaporize an intake of heavy hydrocarbon feedstock is described. The apparatus, a so-called heavy feed mixer, is comprised of pipes being disposed coaxially about a common longitudinal axis. The inner tubular section delivers a two-phase liquid-vapor mixture of hydrocarbon feedstock and dilution steam to the apparatus. The converging / diverging tubular section has a unique structure which converges to a throat section and then diverges to an outlet section. The converging section directs a uniform shroud of superheated steam onto the hydrocarbon stream delivered by the inner tubular section. Impingement of the superheated steam with the intake stream initiates mixing and further vaporization within the throat section. The mixture traverses the converging / diverging tubular section and passes into the outlet section where vaporization is completed. The completely vaporized stream is directed out of the apparatus for further processing downstream.

Owner:STONE & WEBSTER PROCESS TECH

Reclaiming apparatus and method, and co2 recovery device and method

Owner:MITSUBISHI HEAVY IND ENG LTD

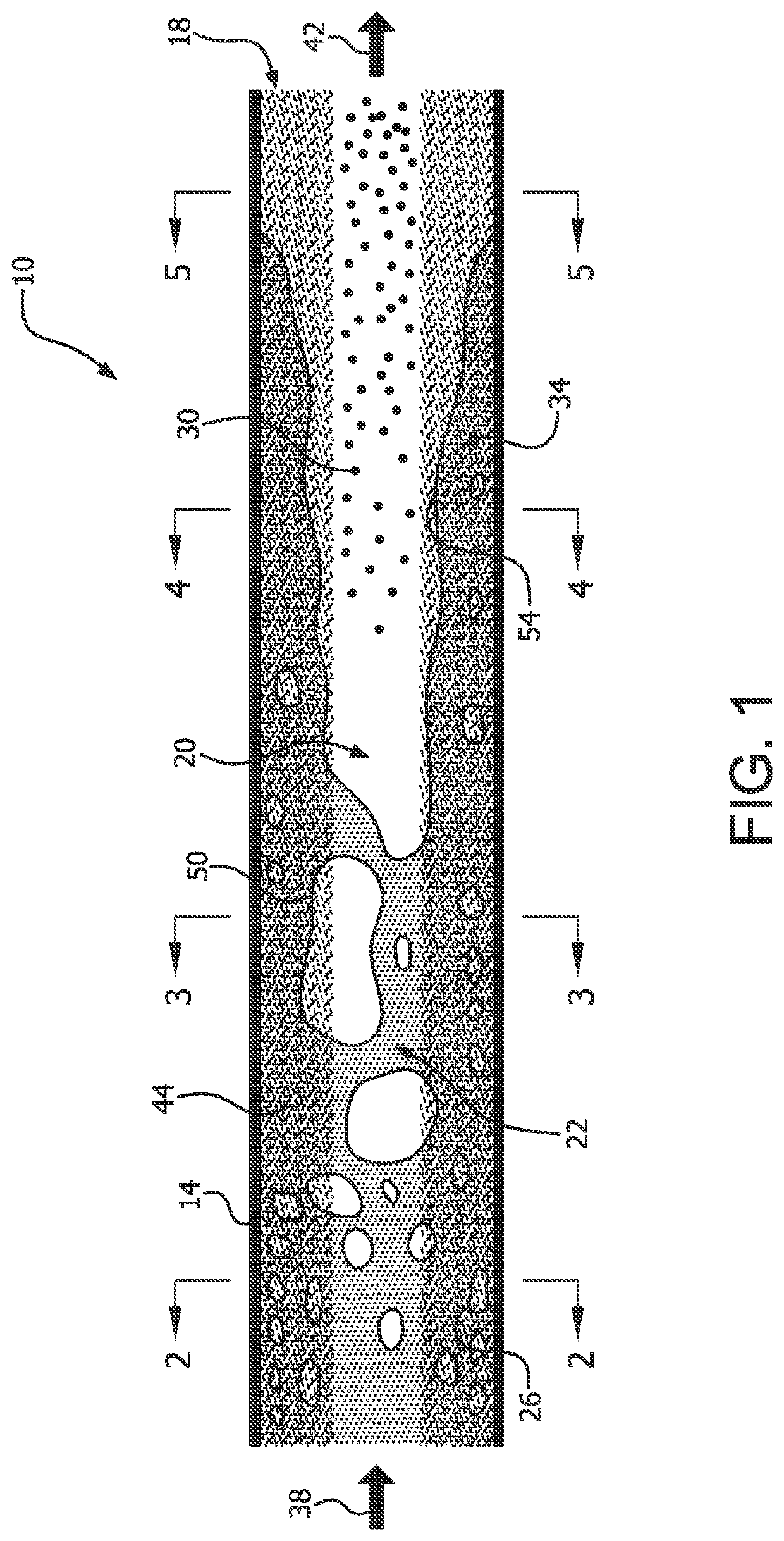

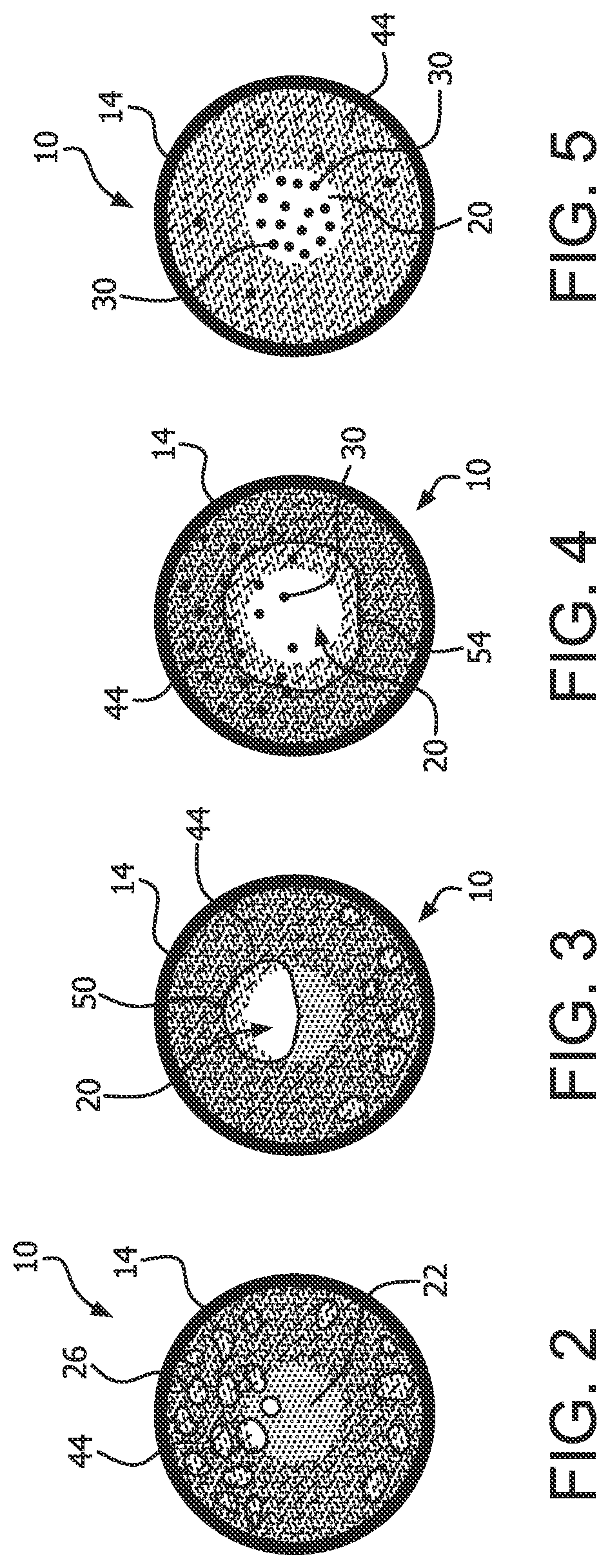

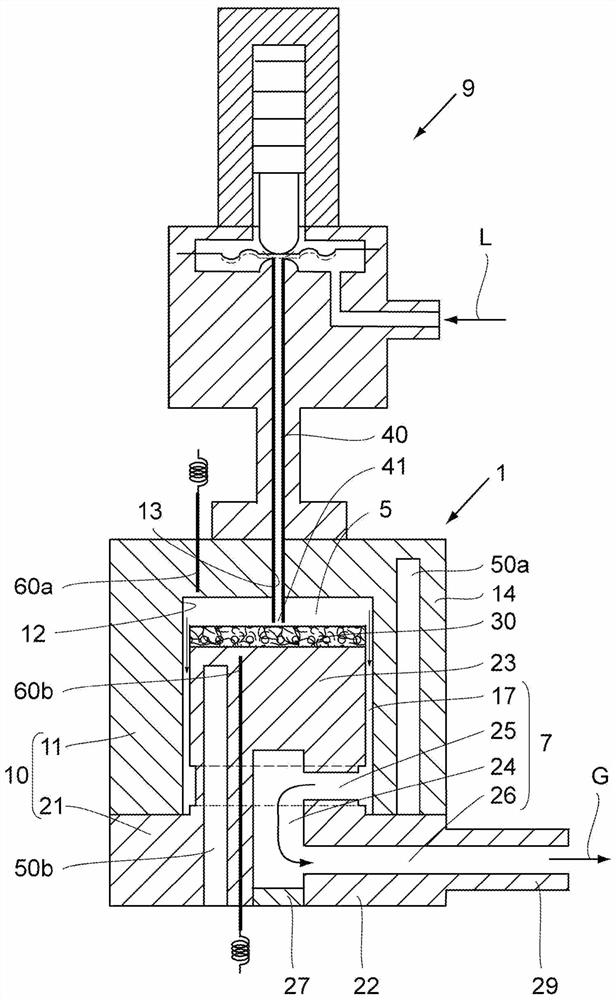

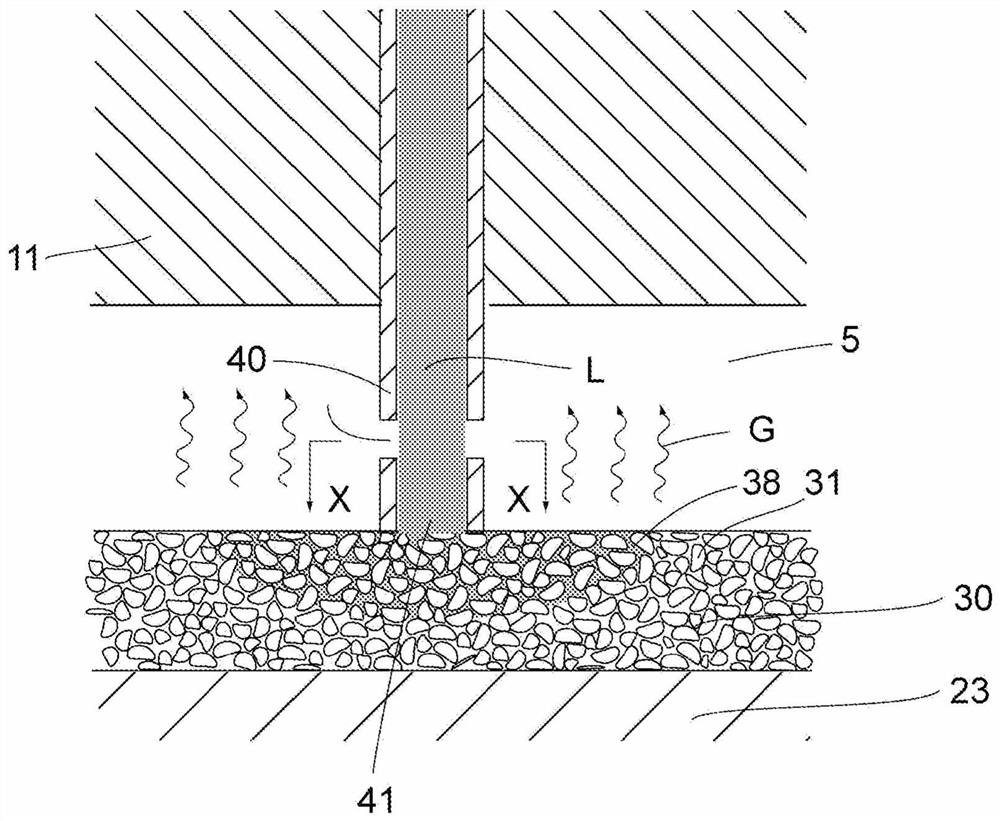

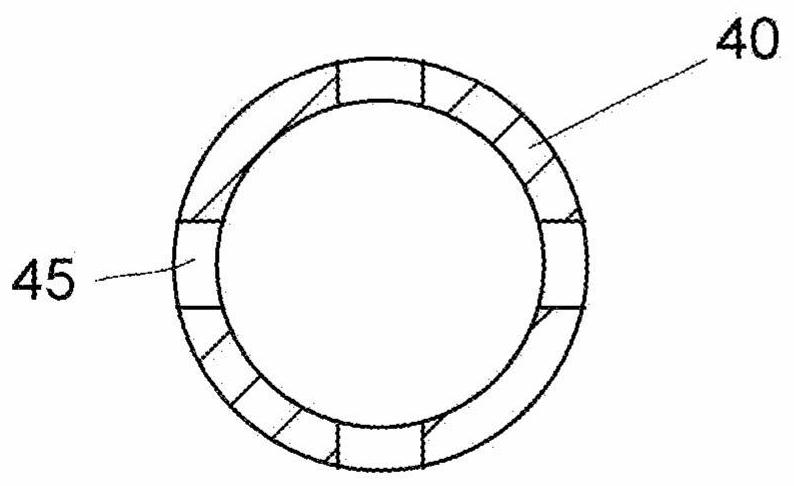

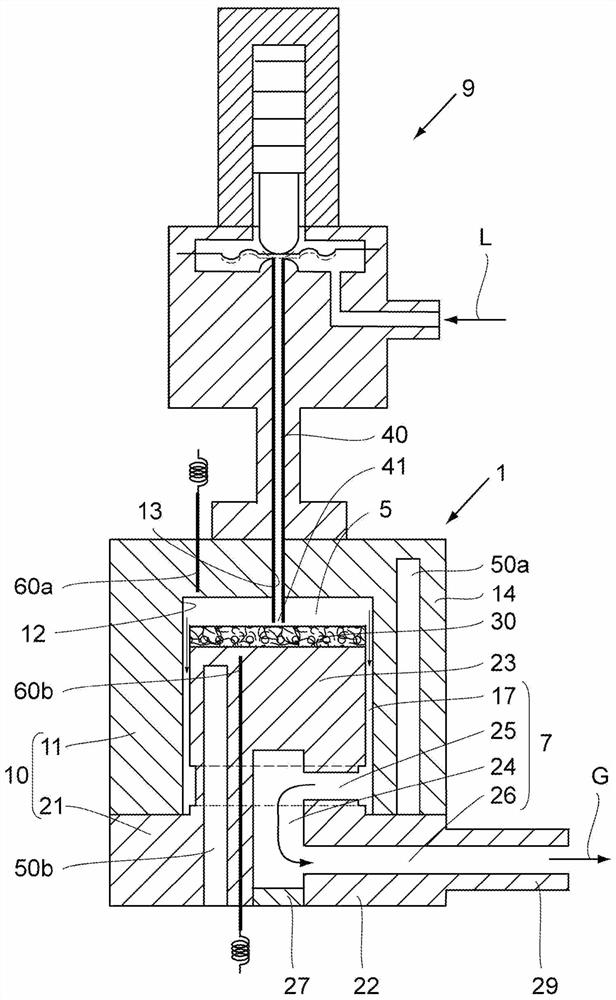

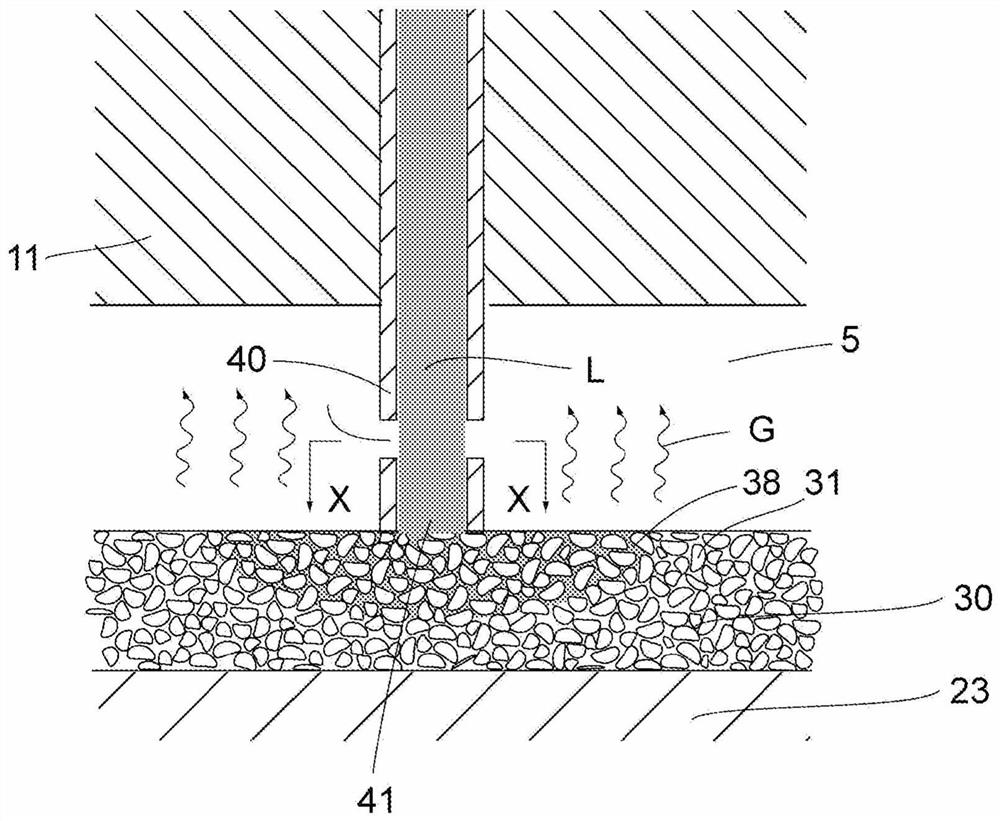

Vaporizer

ActiveCN112585298ARapid spreadSuppress pressure fluctuationsSpray nozzlesSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

Provided is a vaporizer which causes very little pressure fluctuation in a vaporization space by suppression of bumping when a method not using an atomizer is used. The vaporizer 1 comprises: a container body 10; a heated porous member 30 disposed inside the vaporizer 1; an introduction pipe 40 for supplying a liquid raw material L to the porous member 30; and a gas discharge path 7 for discharging a vaporized raw material gas G to the outside. An outlet 41 of the introduction pipe 40 is disposed in contact with or in close proximity to the porous member 30. When the outlet 41 is disposed in close proximity to the porous member 30, the clearance H from the outlet 41 to the porous member 30 is in a range not exceeding the distance from the outlet 41 to the bottom of a drop of the liquid rawmaterial L hanging from the outlet 41 due to surface tension.

Owner:LINTEC CORP

Evaporator with internal restriction

ActiveUS8590338B2Reduce impactIncrease pressureDomestic stoves or rangesElectrical heating fuelEngineeringVaporization

An evaporator includes a vaporization chamber having a monomer inlet and a vapor outlet. There is a vapor nozzle in the vapor outlet. The evaporator also includes a collar positioned between the vaporization chamber and the vapor nozzle which increases the pressure in the evaporation chamber while the conductance through the nozzle is substantially unchanged.

Owner:SAMSUNG DISPLAY CO LTD

Systems and methods for providing haptic feedback at multiple resonance frequencies

InactiveCN102762265BDigital data processing detailsDevices with sensorFeedback effectPiezoelectric actuators

Systems and methods for providing haptic feedback at multiple resonance frequencies are disclosed. For example, one disclosed apparatus includes a resonator with a base and a plurality of projections, a first projection of the plurality of projections having a first resonance frequency and a second projection of the plurality of projections having a second resonance frequency, and a piezoelectric actuator coupled to the resonator and operable to output a haptic feedback effect at the first resonance frequency and at the second resonance frequency.

Owner:IMMERSION CORPORATION

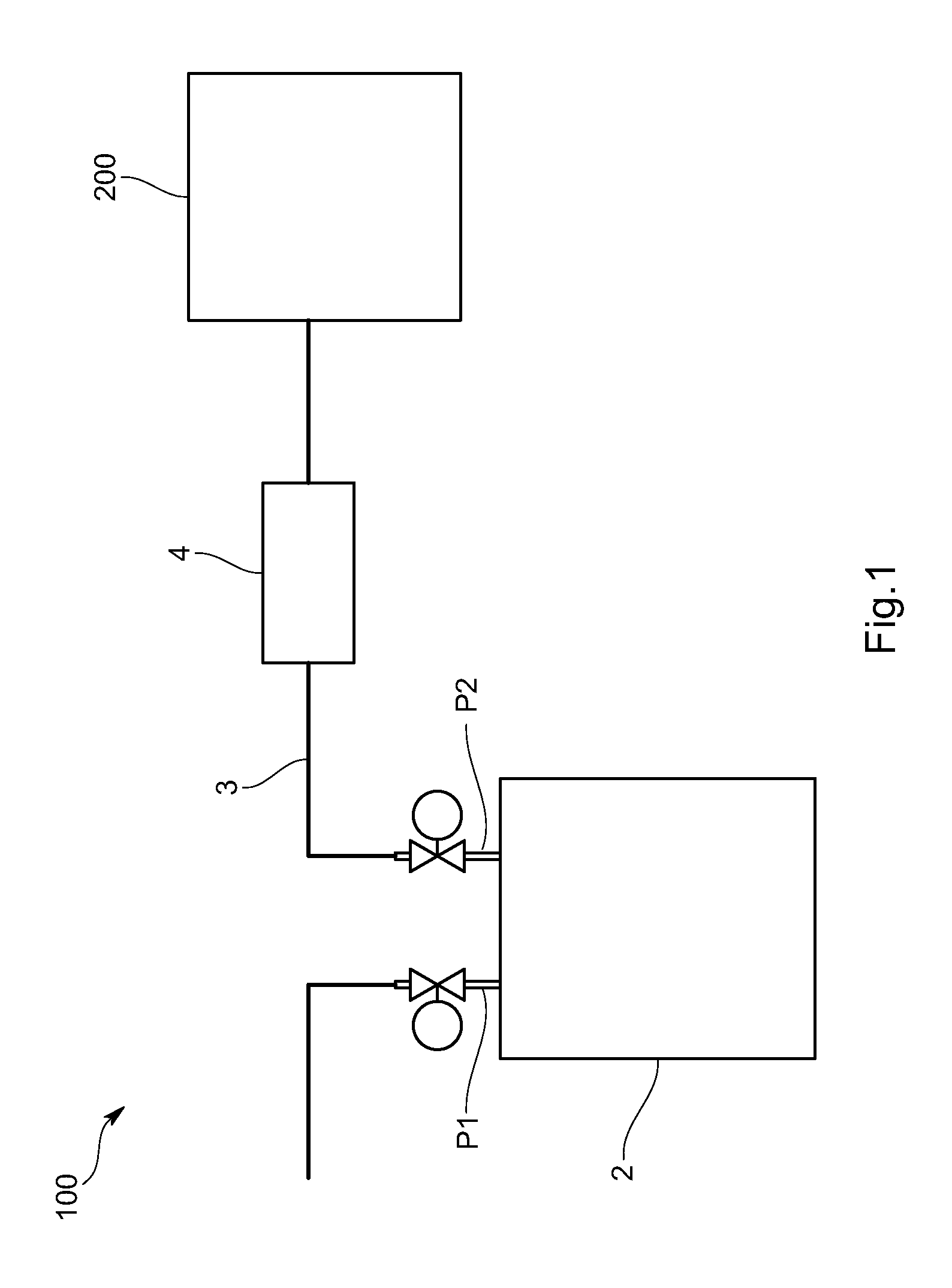

Method for constant concentration evaporation and device using same

ActiveCN102162092BSemiconductor/solid-state device manufacturingBumping preventionEvaporationEngineering

Disclosed herein is a device comprising an evaporator (100); and a heat exchanger (300); the heat exchanger being in fluid communication with evaporator (100); evaporator comprising an outer casing (102); and an inner casing (110) that is disposed within the outer casing (102); the inner casing (110) contacting a plate (200); wherein the inner casing (110) encloses a first conduit (210) that is operative to introduce a carrier fluid into evaporator (100); and a second conduit (214) that is operative to remove carrier fluid entrained with a precursor; wherein the outer casing (102) is detachably attached to the plate (200); the plate (200) contacting a first precursor conduit (306) that is operative to introduce the precursor into evaporator (100) from the heat exchanger (300); where the heat exchanger (300) is disposed proximate to evaporator (100) at a distance effective to maintain the precursor in evaporator (100) at a substantially constant temperature when the ambient temperature around the heat exchanger (300) and evaporator (100) fluctuates by an amount of up to about ± 35°C.

Owner:EDWARDS SEMICON SOLUTIONS LLC

Vaporizer

ActiveCN112585298BRapid spreadSuppress pressure fluctuationsSemiconductor/solid-state device manufacturingSpray nozzlesNebulizerPipe

Owner:LINTEC CORP

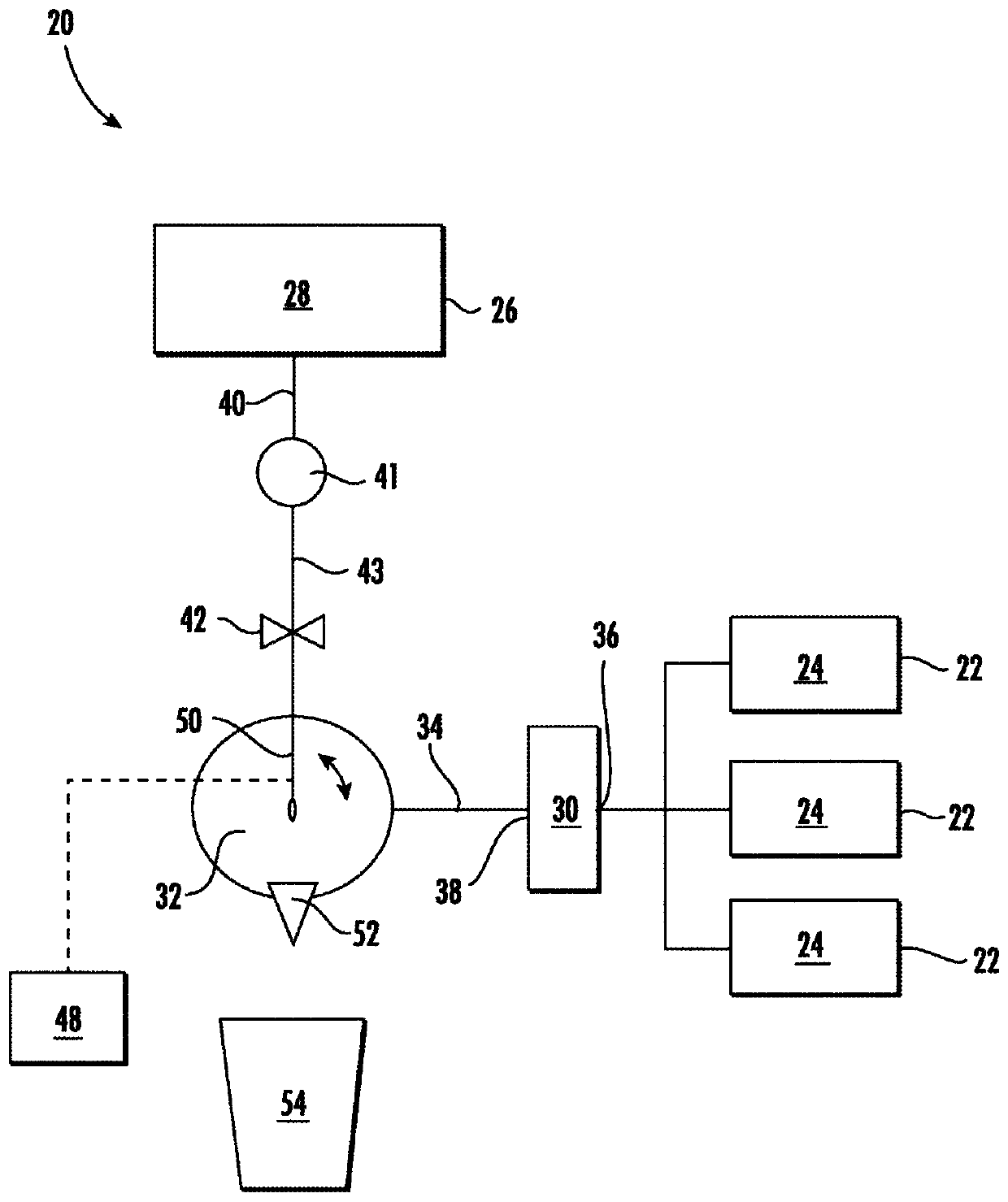

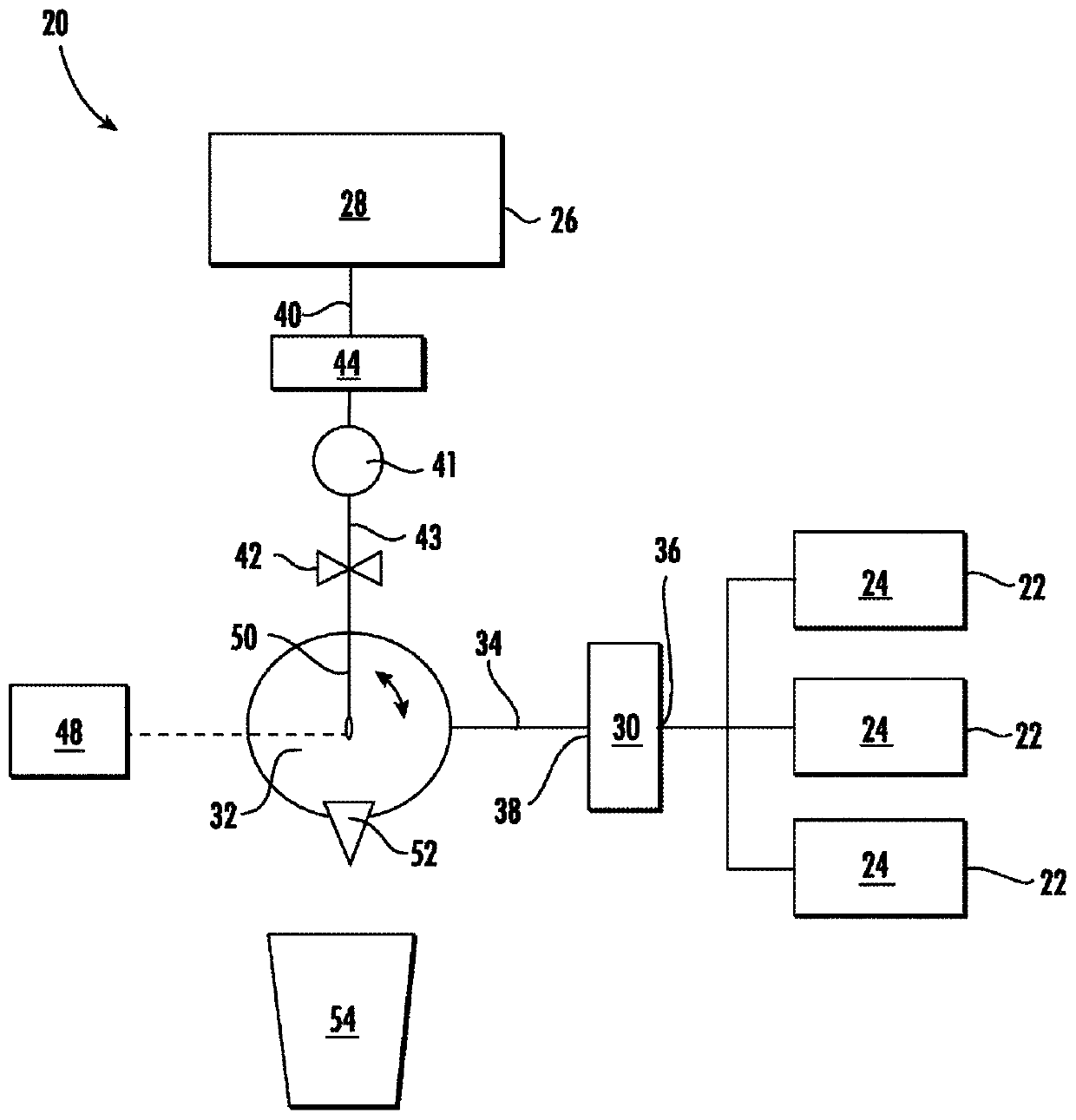

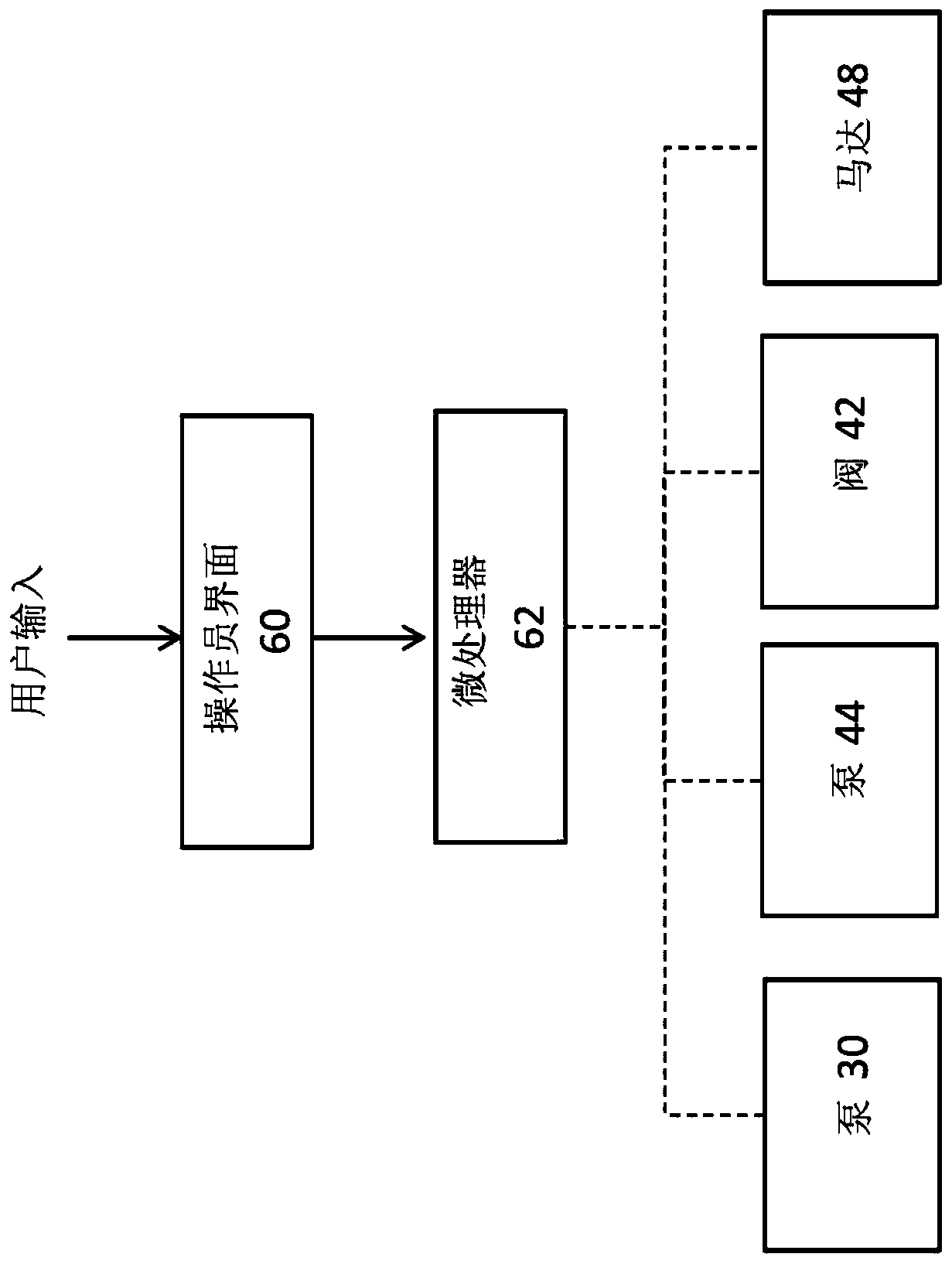

Shake product blending process

An apparatus for dispensing a frozen confection includes a mixing chamber within which an ice cream and at least one flavored concentrate are mixed. A valve assembly is operable to control a flow of the mixture of ice cream into the mixing chamber. A pump provides said at least one flavored concentrate to the mixing chamber. A dispensing nozzle is arranged in fluid communication with the mixing chamber. The dispensing nozzle has a flow channel through which a mixture of the ice cream and at least one flavored concentrate is dispensed. The flow channel has a first diameter adjacent an inlet endof the dispensing nozzle and a second diameter adjacent an outlet end of the dispensing nozzle. The second diameter is greater than the first diameter.

Owner:TAYLOR COMML FOODSERVICE LLC

Multilayer Polymertic Containers for Bioreactors

InactiveUS20190276786A1Improve heat transfer performanceAvoid cross contaminationBioreactor/fermenter combinationsBiological substance pretreatmentsUltrasonic sensorEngineering

A bioreactor utilizing a multilayer disposable bag that may include at least one ultrasonic transducer that can acoustically generate a multi-dimensional standing wave. The standing wave can be used to retain cells in the bioreactor, and can also be utilized to dewater or further harvest product from the waste materials produced in a bioreactor.

Owner:FLODESIGN SONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com