Liquid material vaporizer

A technology of gasification device and gasification part, which is applied in the direction of gas generation device, evaporation device, gaseous chemical plating, etc., can solve the problem of uneven spray concentration, achieve the effect of inhibiting the clogging of pores and reducing the risk of complete stop of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

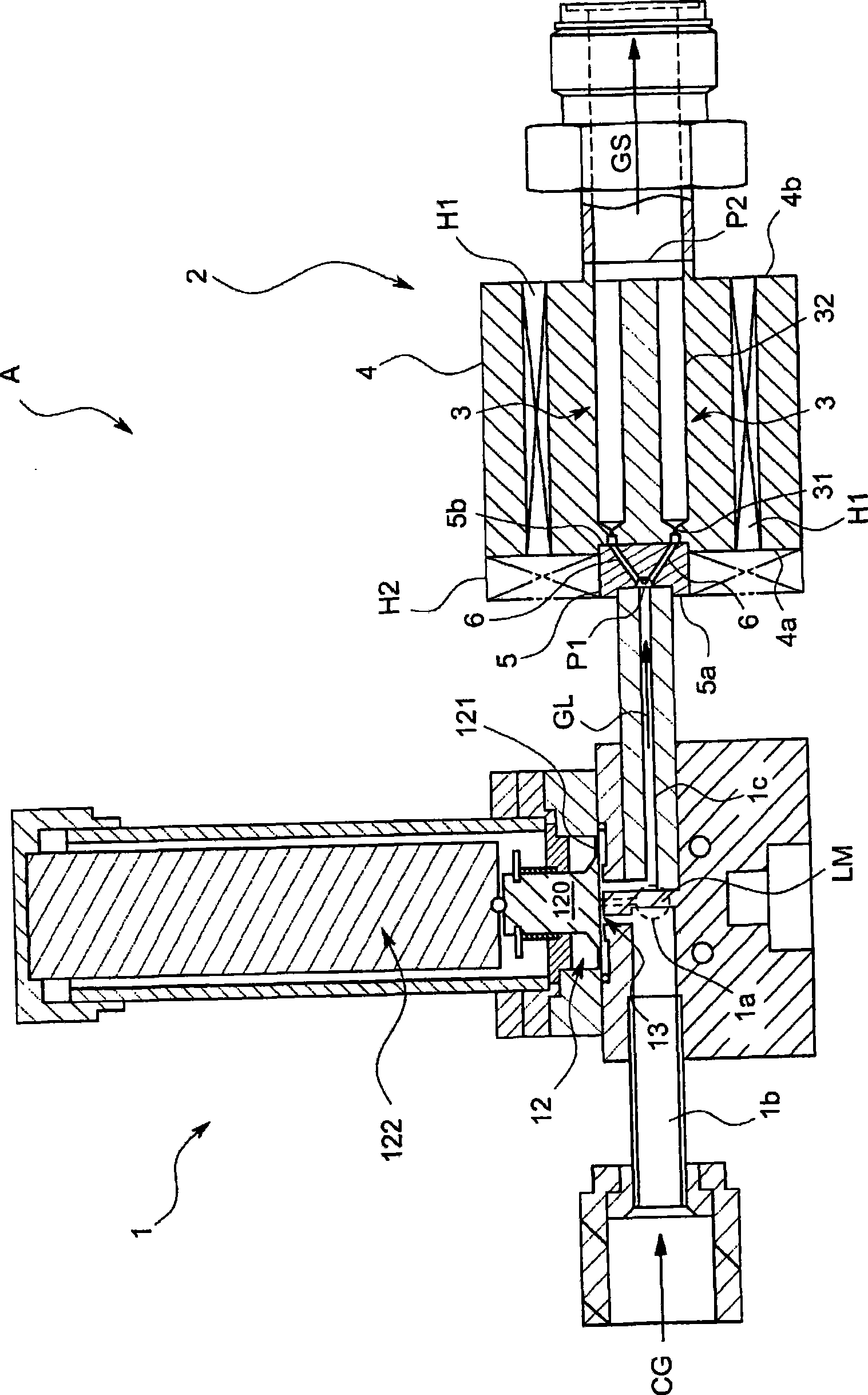

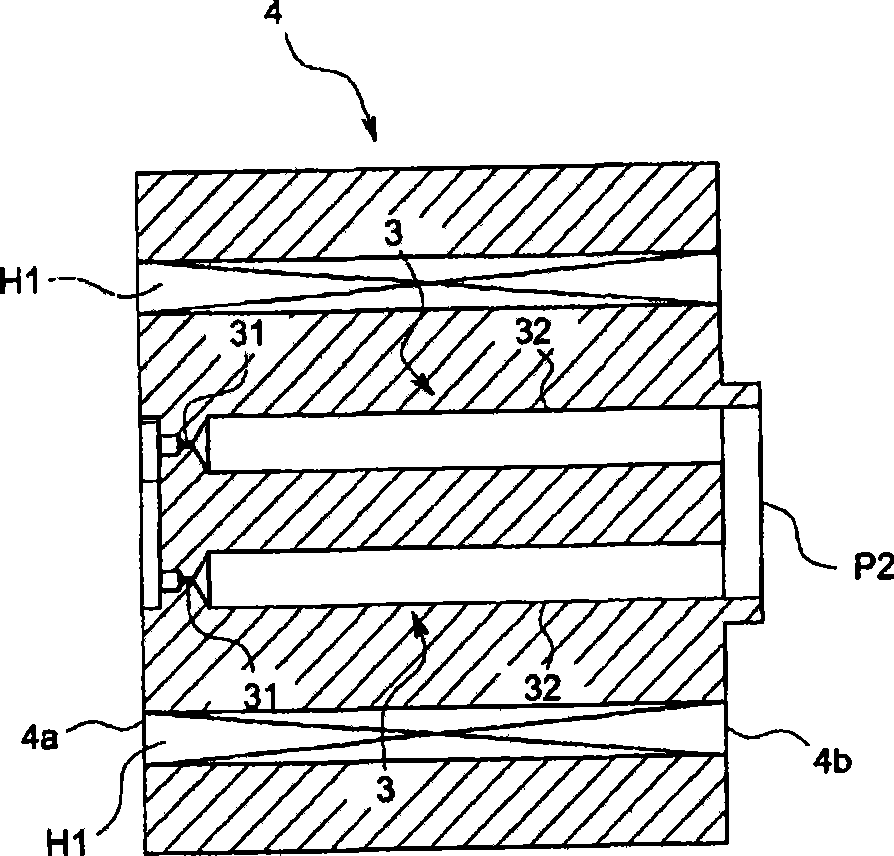

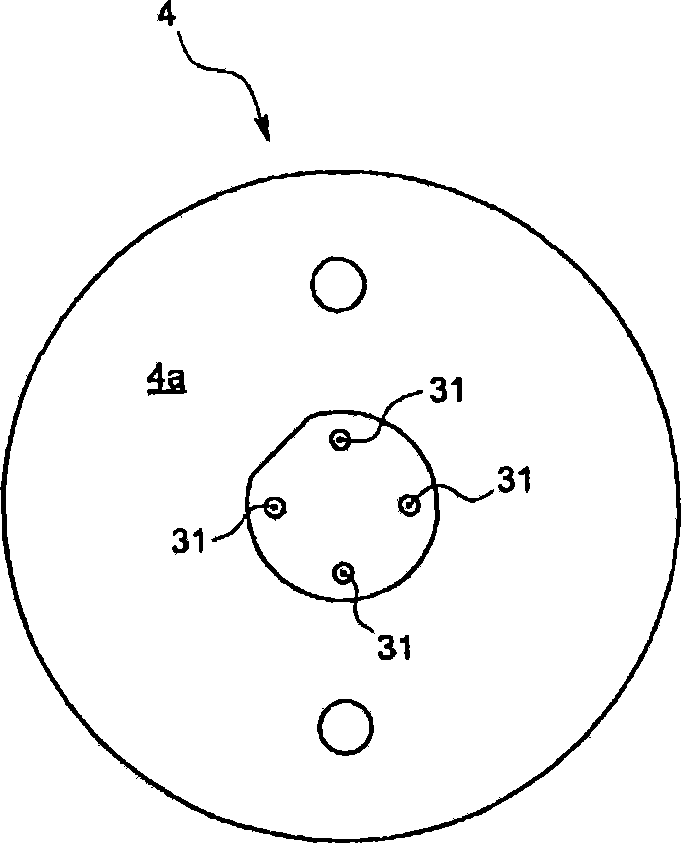

[0035] An embodiment of the present invention will be described below with reference to the drawings.

[0036] The gasification device A of this embodiment constitutes, for example, a part of a semiconductor manufacturing system (not shown), is connected to a vacuum chamber (not shown) for film formation, and supplies raw materials for forming semiconductor elements in a gaseous state. role.

[0037] Such as figure 1 As shown, specifically, the gasification device is equipped with: a gas-liquid mixing mechanism 1 that mixes the raw material (hereinafter also referred to as liquid raw material) LM in a liquid state with a carrier gas CG to generate a gas-liquid mixture GL; and The liquid raw material LM contained in the gas-liquid mixture GL is vaporized so that it is in a gaseous state (hereinafter also referred to as raw material gas), and the raw material gas GS is led out together with the carrier gas CG to the outside, that is, to the vacuum chamber. Main Body 2.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com