Detection device of molten steel liquid level in belt spraying packet

A liquid level detection and detection device technology, applied in the direction of the buoy liquid level indicator, etc., can solve the problems of large magnetic field interference, inaccurate liquid level measurement, and the inability of the amorphous spray bag to open holes at the bottom of the molten steel, so as to improve the product quality. Stability, lower production cost, and constant molten steel level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

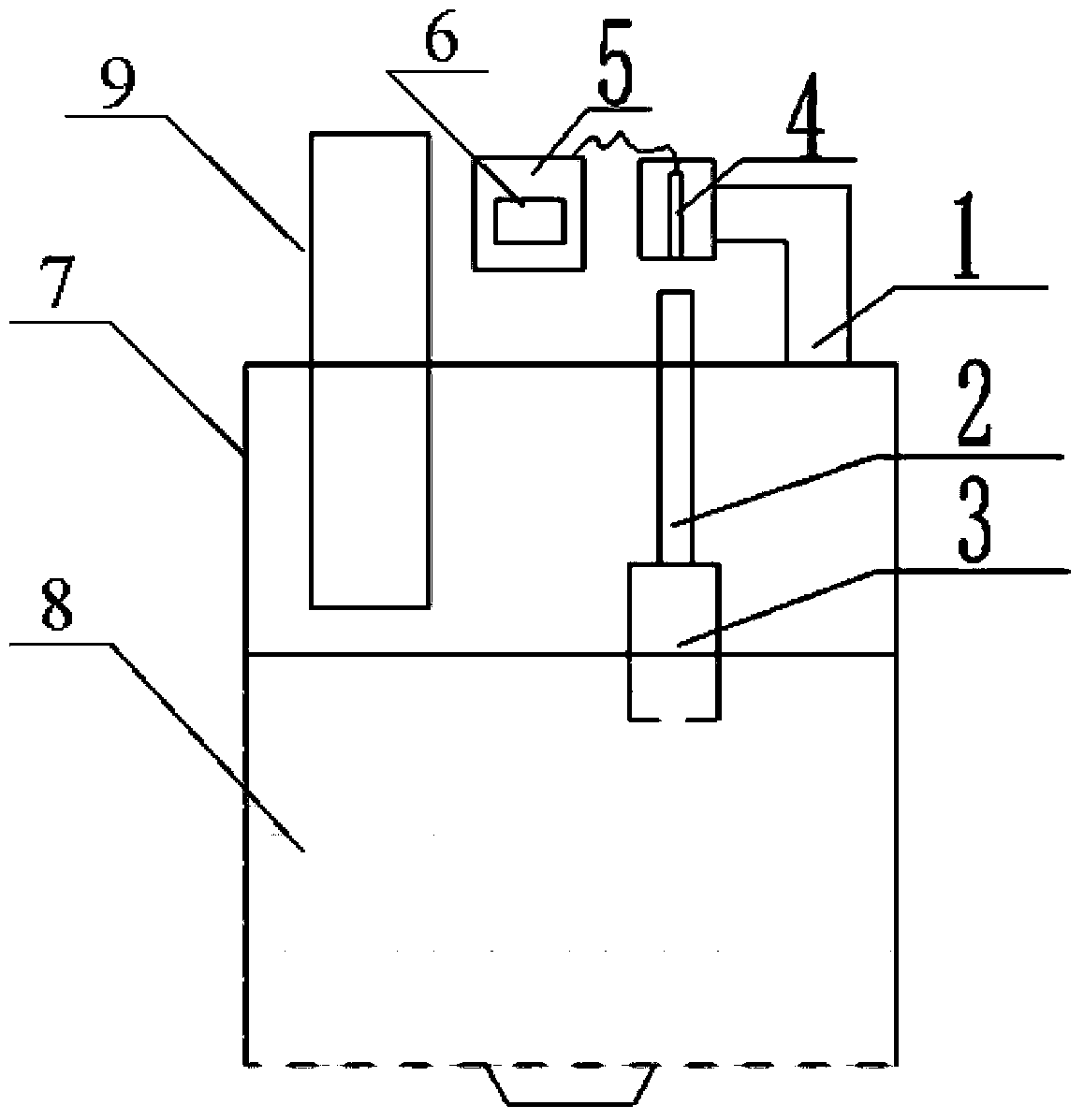

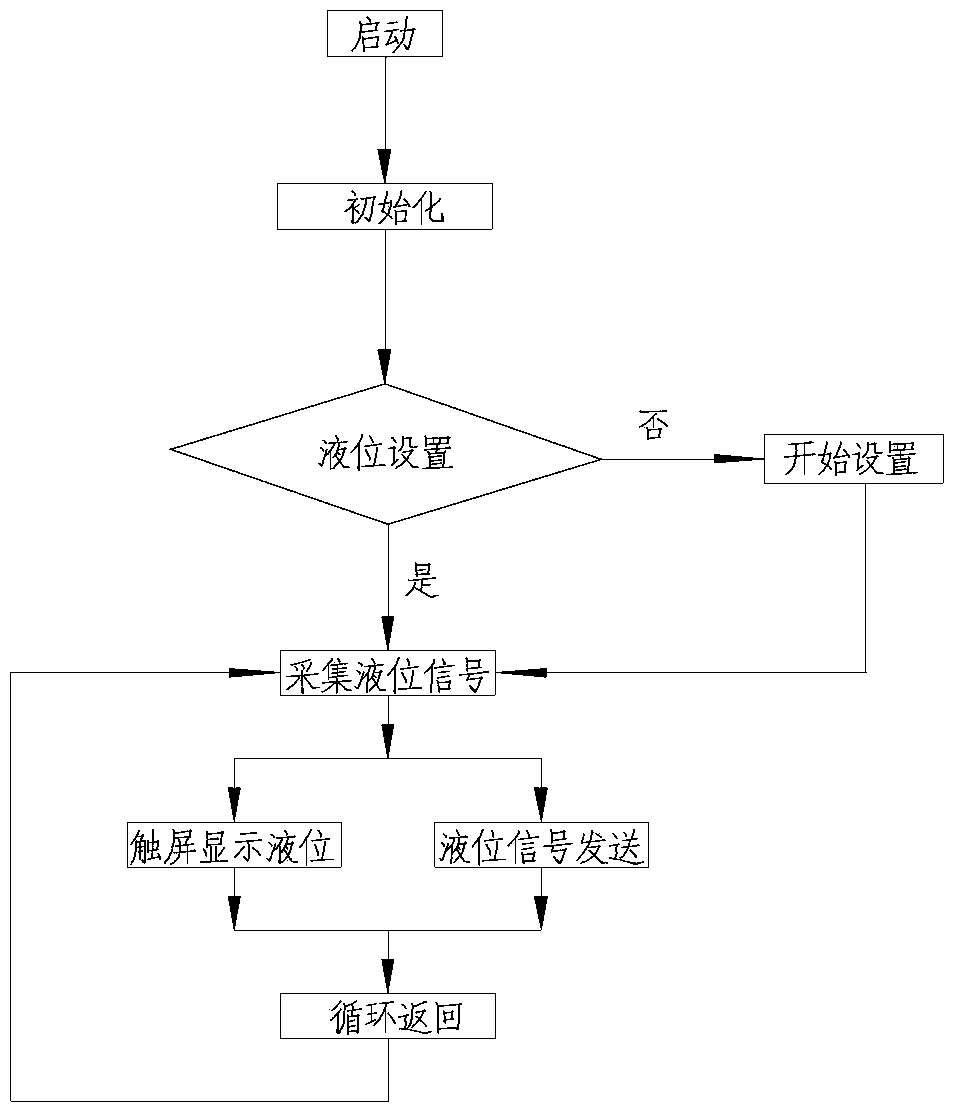

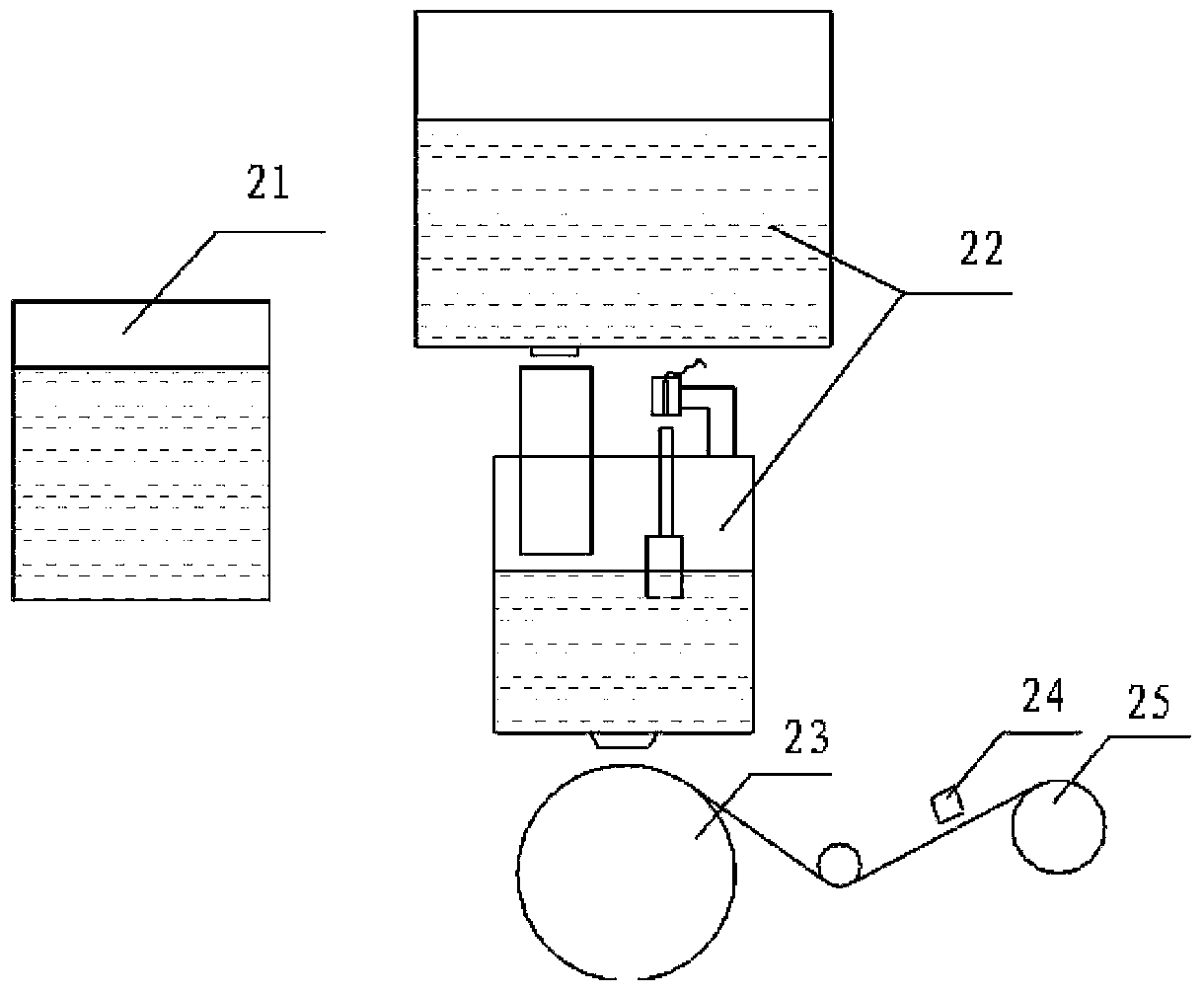

[0011] figure 1 It is a schematic structural diagram of a detection device for molten steel level in a spray ladle provided by an embodiment of the present invention. Such as figure 1 As shown, the device includes a float 3, a float rod 2, a liquid level detection mechanism 1, and a PLC system 5, wherein: the bottom of the float rod 2 is installed on the float 3, and the top passes through the guide sleeve on the spray belt bag 7; the float 3 directly Contact the molten steel 8 in the spray belt bag 7, drive the float rod 2 to reflect the liquid level of the molten steel 8; the liquid level detection mechanism 1 is provided with an optical fiber sensor 4, which is connected to the PLC system, and the optical fiber sensor 4 is designed for high temperature resistance. It can be used in the harsh environment of high te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com