Method and apparatus for continuous production of high-concentrated sodium hypochlorite

A sodium hypochlorite, high-concentration technology, applied in the direction of hypochlorous acid, hypochlorite, etc., can solve the problems of increasing production equipment, unable to solve the problem of continuous introduction of chlorine gas, removal of salt scale, uneven distribution of chlorine gas, etc., to achieve Guaranteed continuity of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

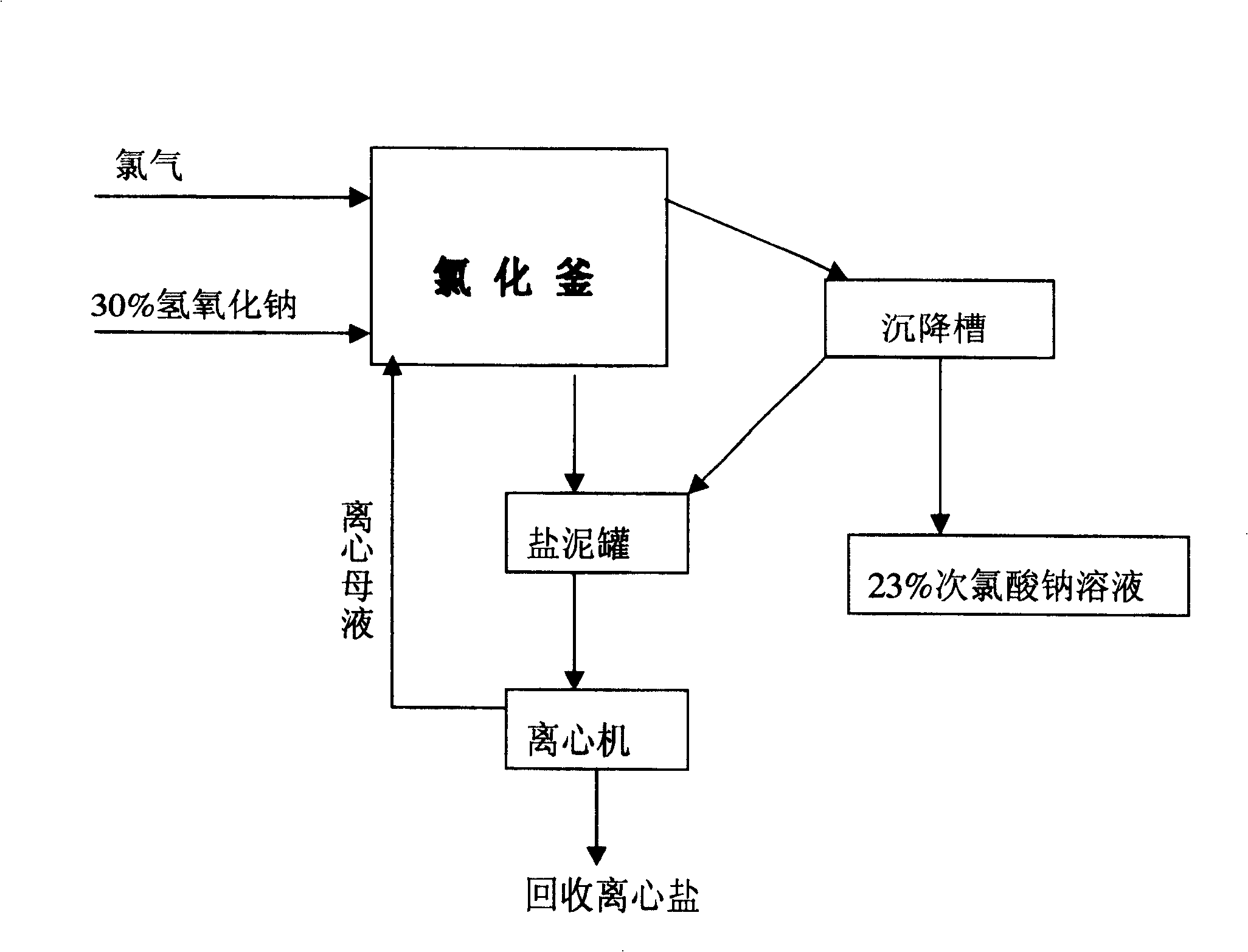

[0025] Embodiment 1: a kind of continuous production high concentration sodium hypochlorite method comprises the steps:

[0026] a, the generation of sodium hypochlorite solution: firstly, before driving, pump the sodium hydroxide solution with a concentration of 30% into the alkali distribution platform and enter the chlorination kettle through the flow meter to control the flow rate. When the sodium hydroxide solution in the chlorination kettle reaches 2.5-2.7 When the liquid level is reached, start the stirring motor of the chlorination kettle, stop the alkali feeding, and deliver the frozen brine to the inner coil of the kettle. Kettle, sodium hydroxide and chlorine are reacted, chemical reaction equation:

[0027] Cl 2 +2NaOH=NaCl0+NaCl+H 2 O+108.69KJ / mol

[0028] When the sodium hypochlorite available chlorine in the chlorination kettle is ≥130g / l and the free alkali content is ≥40g / l, start the concentrated alkali pump to add 30% sodium hydroxide solution into the ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com