Device and method for growing silicon carbide crystals by liquid phase method

A silicon carbide and liquid phase method technology, applied in chemical instruments and methods, single crystal growth, single crystal growth and other directions, can solve the problem of reducing the quality of growing crystals, sustainable crystal growth, increasing crystal growth costs, and reducing temperature gradients. and other problems, to achieve the effect of long-term stable growth, increased output, and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

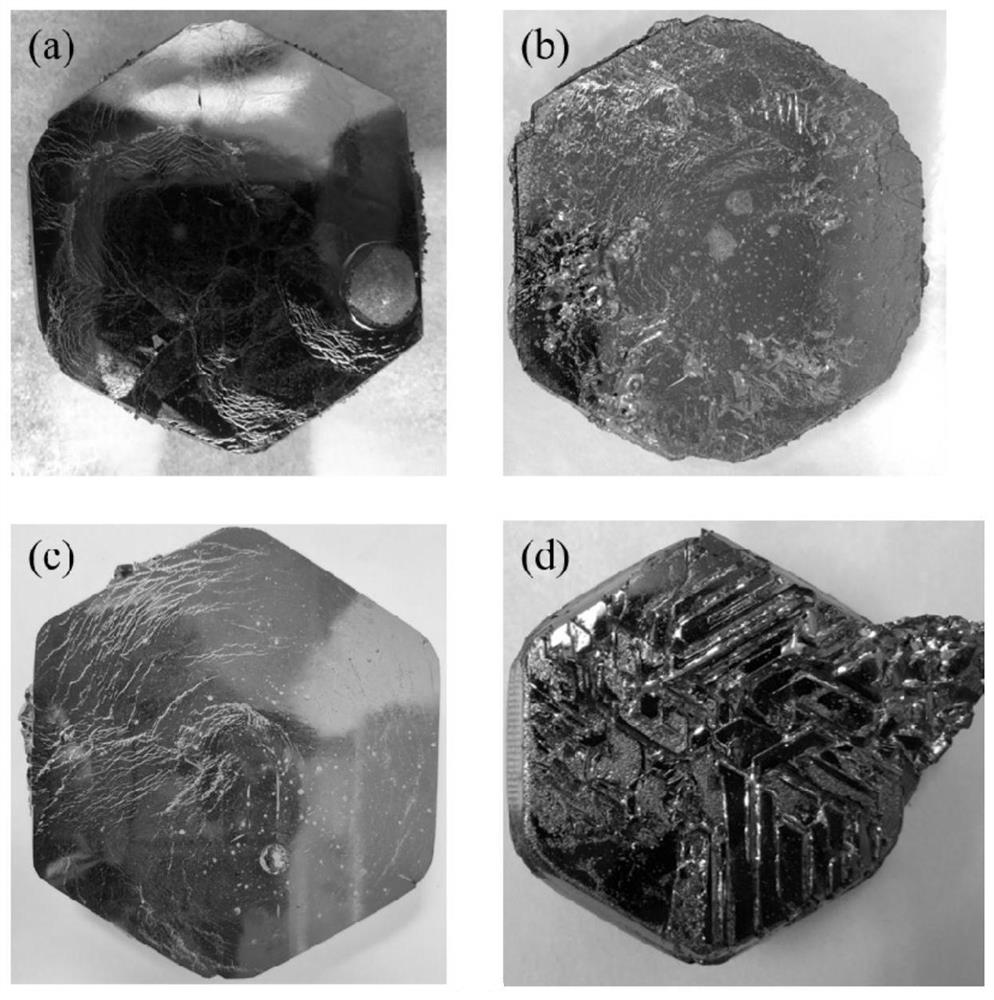

[0053] The outline view (top view) of the silicon carbide crystal grown in this example is shown in Figure 2(a); from Figure 2(a), it can be seen that

Embodiment 2

[0058] The outline view (top view) of the silicon carbide crystal grown in this embodiment is shown in Figure 2(b); from Figure 2(b), it can be seen that

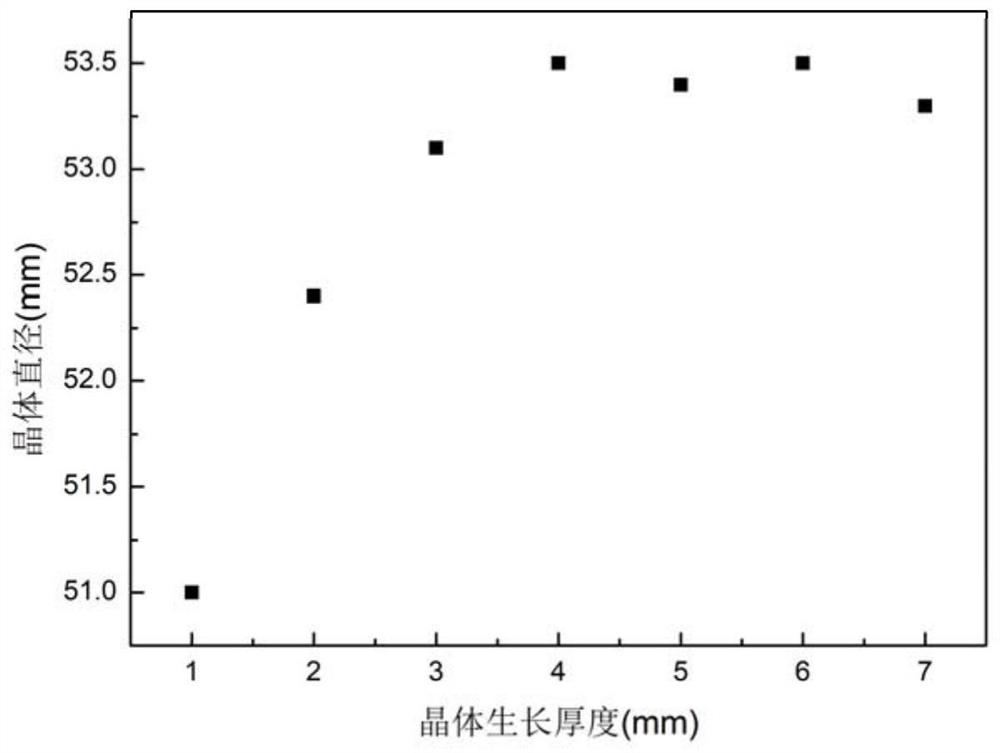

[0059] The diameter variation diagram of the silicon carbide crystal grown in the present embodiment is shown in Figure 4; it can be seen from Figure 4 that the entire

Embodiment 3

[0063] The variation of the diameter of the grown crystal in this embodiment with the growth thickness is shown in FIG. 5. The carbon obtained by the growth of this embodiment

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com