Movable overflow type hydraulic brake saline water tank

A sluice salt and overflow type technology, applied in the field of brine tanks, can solve the problems that cannot meet the test requirements of large-scale ship power station power, small carrying capacity of movable brine tanks, large fluctuations in power generation load, etc., to meet the requirements of large-scale The effects of chemical test requirements, increased size, and increased current-carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

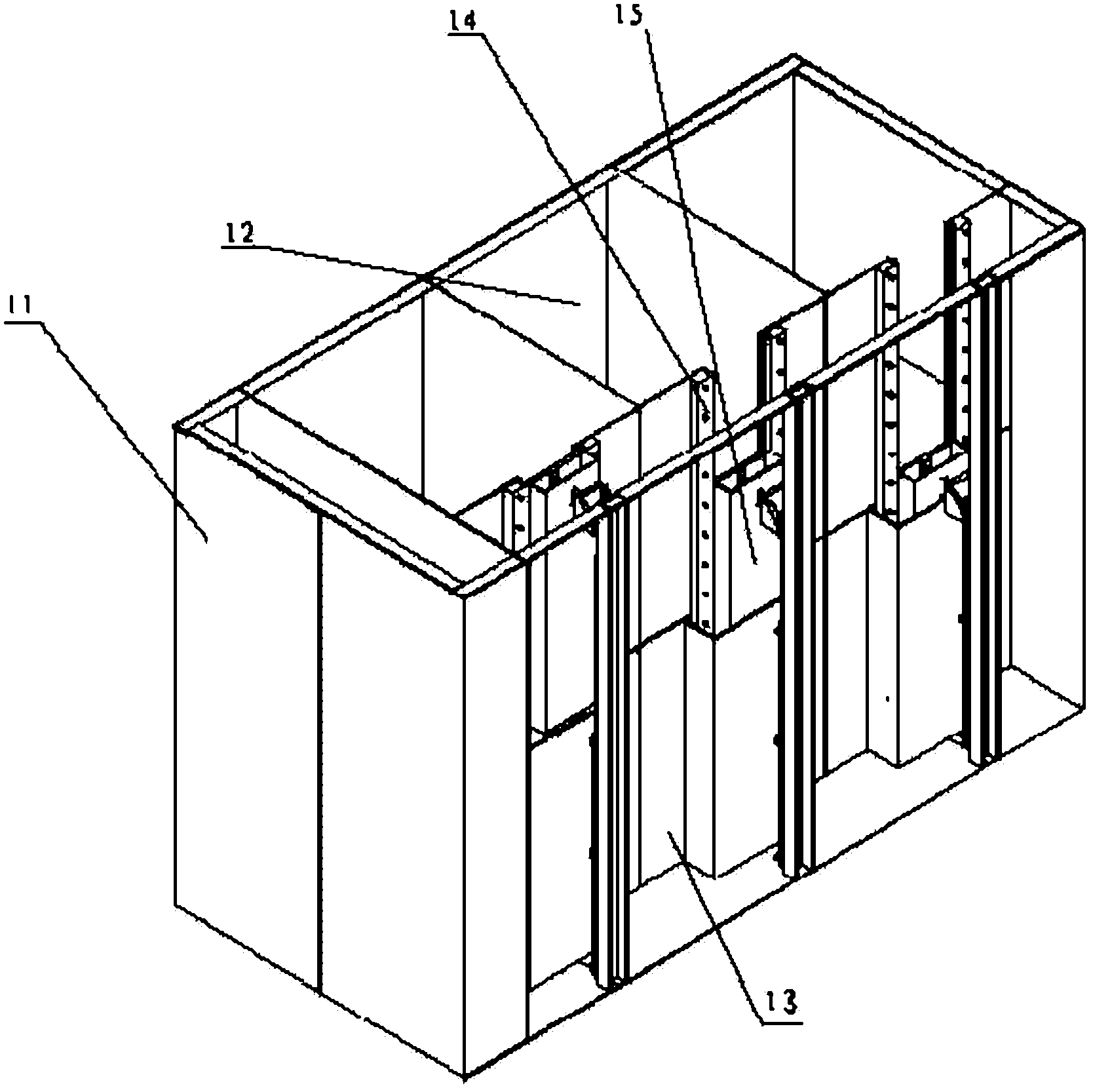

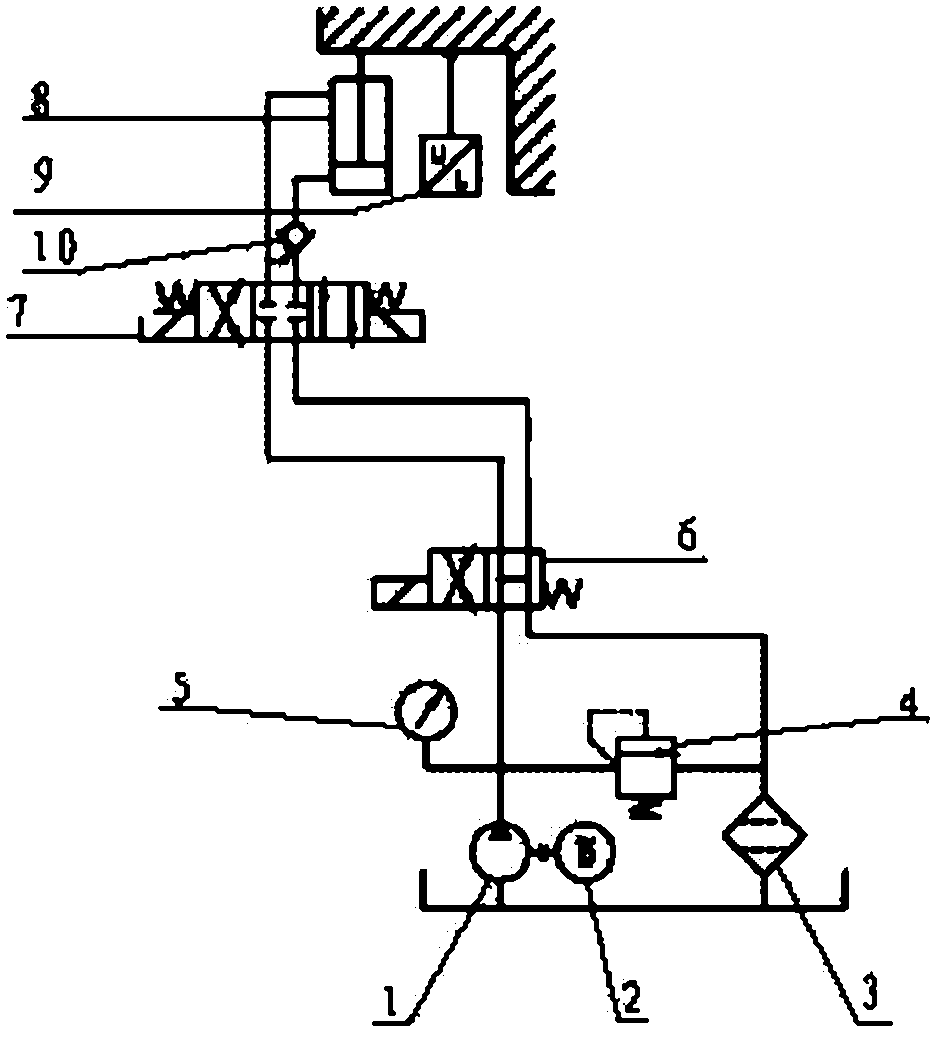

[0028] The movable overflow hydraulic gate brine cylinder mainly includes a box body 11, a working cylinder 12, a water storage cylinder 13, a three-phase electrode plate located in the working cylinder, and a bus bar connected to the three-phase electrode plate; the working cylinder 12 It is located above the water storage tank; it also includes a water pump station and an overflow door; the overflow door is composed of a door frame 14 and a hydraulic door 15, the door frame 14 is fixed at the opening on the side surface of the working cylinder, and the hydraulic door 15 can go up and down along the door frame 14 Move, and can be fixed on any position of the door frame 14 by the fixing piece, so that the opening of the side surface of the working cylinder is completely or partially closed; the top of the hydraulic door 15 is provided with an overflow tank, and there is a pipe at the bottom of the overflow tank leading to the water storage tank 13. The water pumping station is ...

Embodiment 2

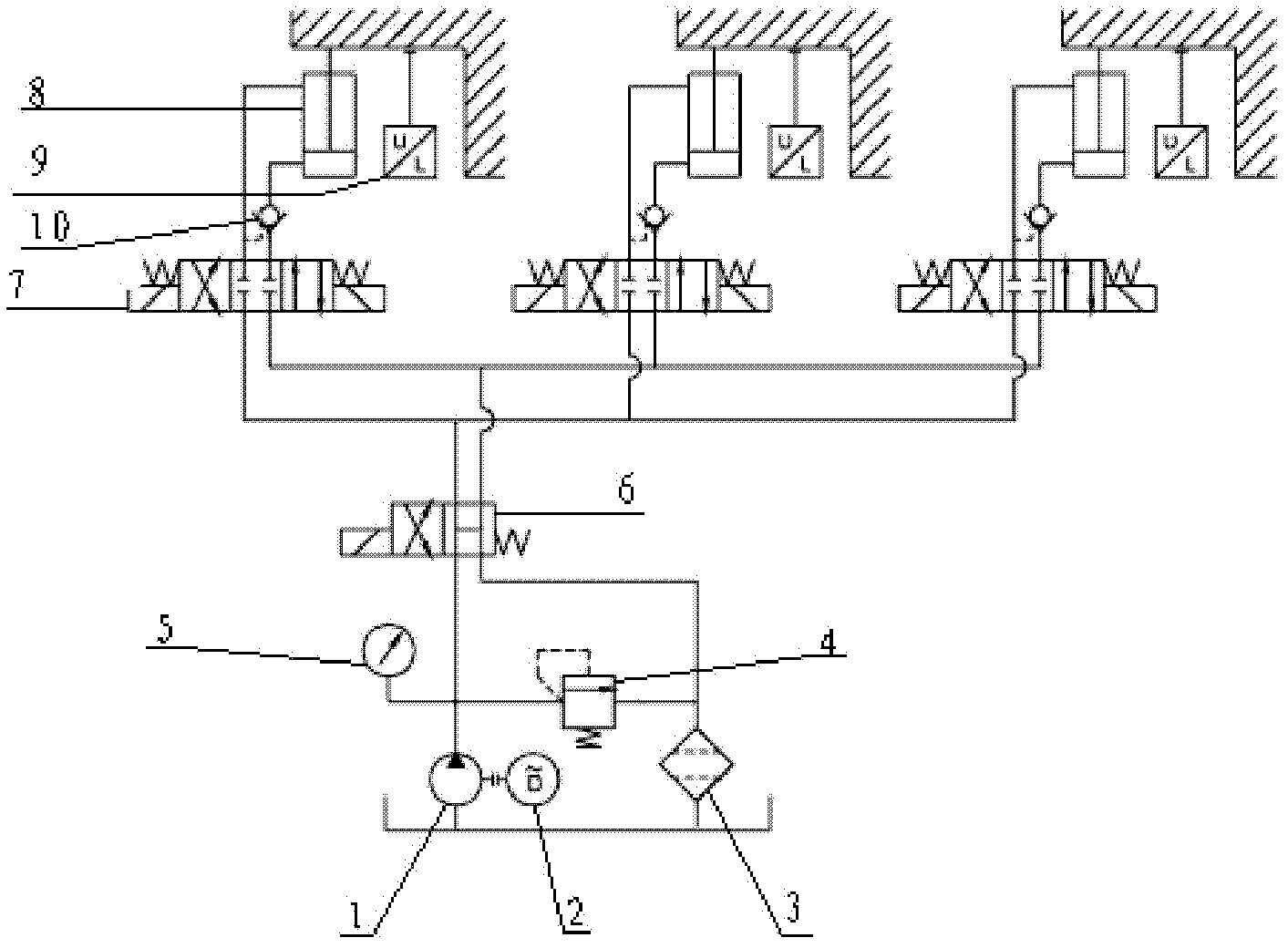

[0032] The movable overflow hydraulic gate brine cylinder mainly includes a box body 11, a working cylinder 12, a water storage cylinder 13, a three-phase electrode plate located in the working cylinder, and a bus bar connected to the three-phase electrode plate; the working cylinder 12 It is located above the water storage tank; it also includes a water pump station and an overflow door; the overflow door is composed of a door frame 14 and a hydraulic door 15, the door frame 14 is fixed at the opening on the side surface of the working cylinder, and the hydraulic door 15 can go up and down along the door frame 14 Move, and can be fixed on any position of the door frame 14 by the fixing piece, so that the opening of the side surface of the working cylinder is completely or partially closed; the top of the hydraulic door 15 is provided with an overflow tank, and there is a pipe at the bottom of the overflow tank leading to the water storage tank 13. The water pumping station is ...

Embodiment 3

[0039]The movable overflow hydraulic gate brine cylinder mainly includes a box body 11, a working cylinder 12, a water storage cylinder 13, a three-phase electrode plate located in the working cylinder, and a bus bar connected to the three-phase electrode plate; the working cylinder 12 It is located above the water storage tank; it also includes a water pump station and an overflow door; the overflow door is composed of a door frame 14 and a hydraulic door 15, the door frame 14 is fixed at the opening on the side surface of the working cylinder, and the hydraulic door 15 can go up and down along the door frame 14 Move, and can be fixed on any position of the door frame 14 by the fixing piece, so that the opening of the side surface of the working cylinder is completely or partially closed; the top of the hydraulic door 15 is provided with an overflow tank, and there is a pipe at the bottom of the overflow tank leading to the water storage tank 13. The water pumping station is r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com