Unpowered automatic baffling type biogas generating device

A biogas generating device and baffle-type technology, applied in biochemical cleaning devices, enzymology/microbiology devices, gas production bioreactors, etc., can solve daily operations, management troubles, and farm profits cannot be supported and reduced Anaerobic fermentation space and other problems, to achieve the effect of no need for frequent maintenance, convenient maintenance, and long residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

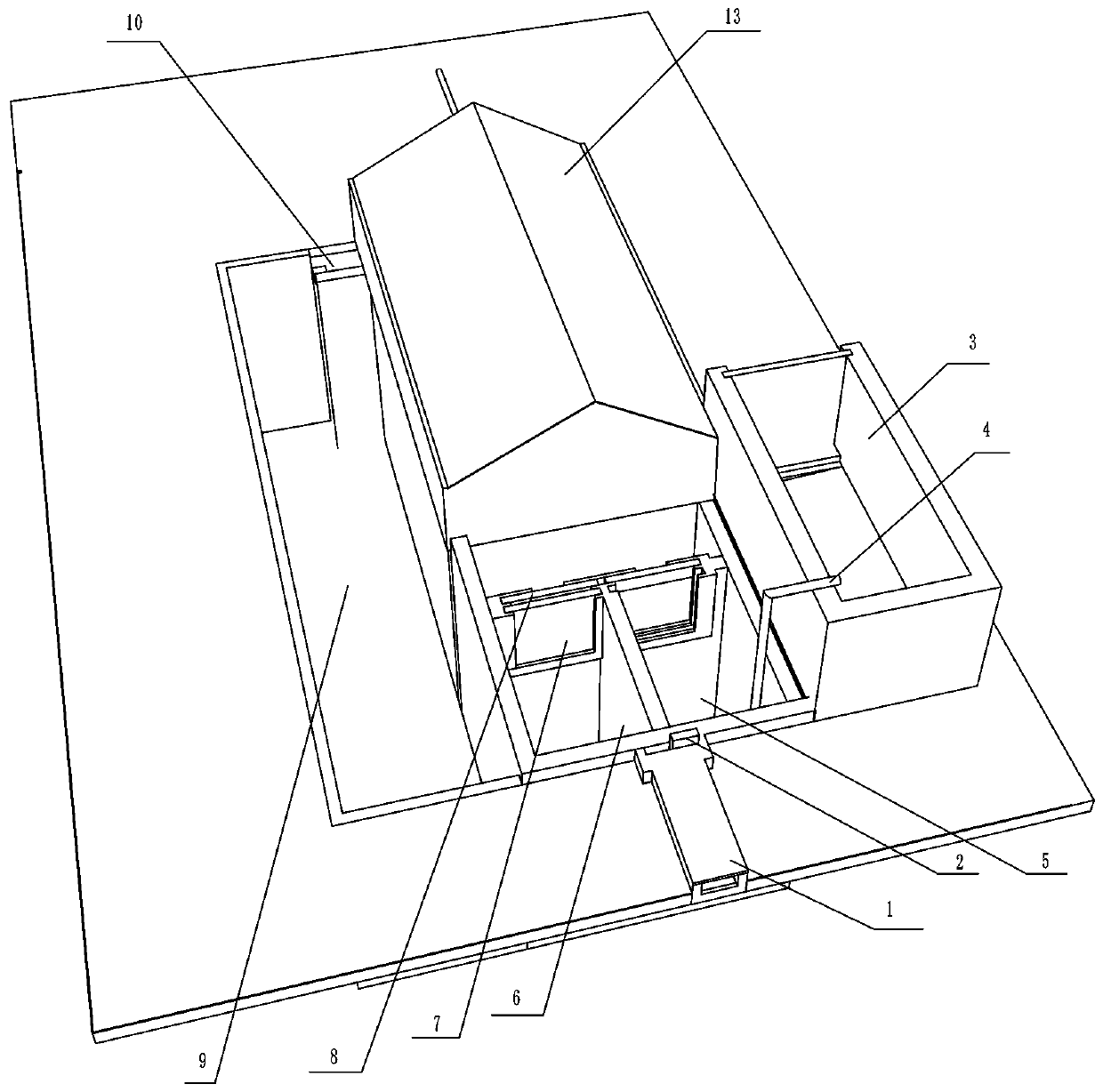

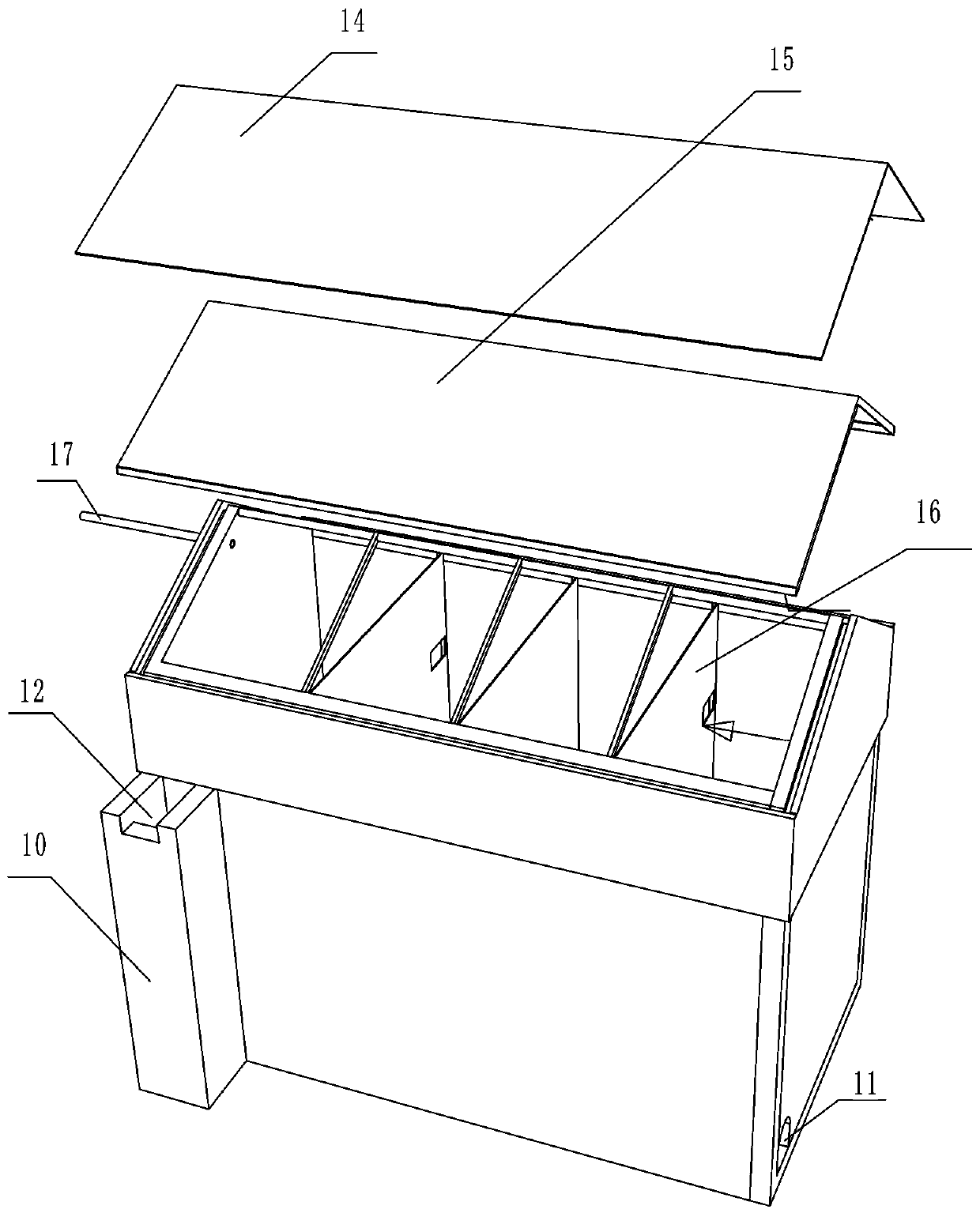

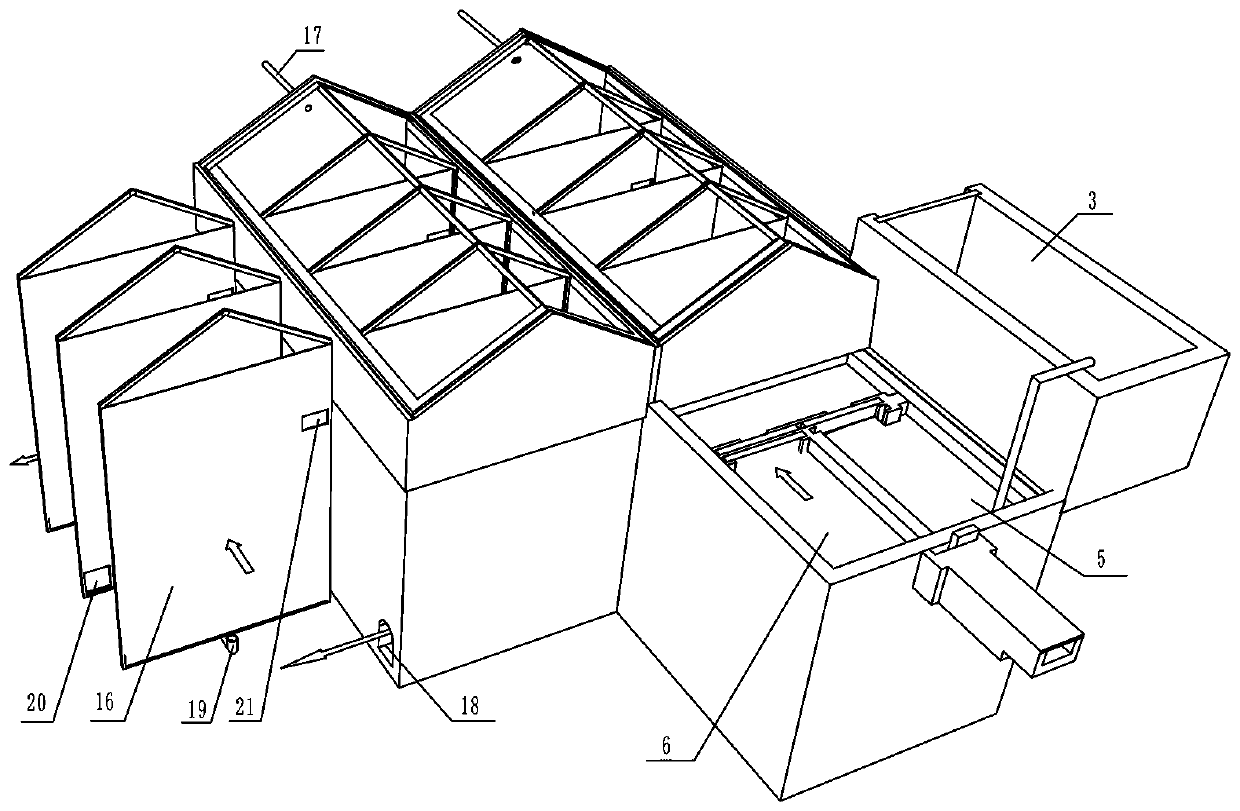

[0034] like figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the present embodiment provides an unpowered automatic deflecting type biogas generating device, which includes a solar greenhouse and a biogas generating device arranged inside the solar greenhouse;

[0035] The biogas generating device includes a sewage collection settlement tank, a feed chamber 23, a baffle biogas digester 13, a biogas slurry temporary storage tank 9, and a solid-liquid separation tank 3; the sewage collection settlement tank communicates with the feed chamber 23, and the One side of the bottom of the baffled biogas digester 13 is provided with a feed port 11, the feed port 11 communicates with the feed chamber 23, and the other side of the bottom of the baffled biogas digester is connected with a biogas slurry discharge pipeline 10. The end of the biogas slurry discharge pipe 10 is a biogas slurry discharge upper port 12 . The biogas slurry discharge upper port 12 is flush...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com