Equipment convenient for coating of bottoms of printed circuit boards and method thereof

A technology for printed circuit boards and circuit boards, which is applied to devices for coating liquids on surfaces, coatings, pretreatment surfaces, etc., can solve the problems of increasing the cost of consumables, low production efficiency, and large labor costs, and reduce labor costs. , Reduce equipment cost, reduce the effect of manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

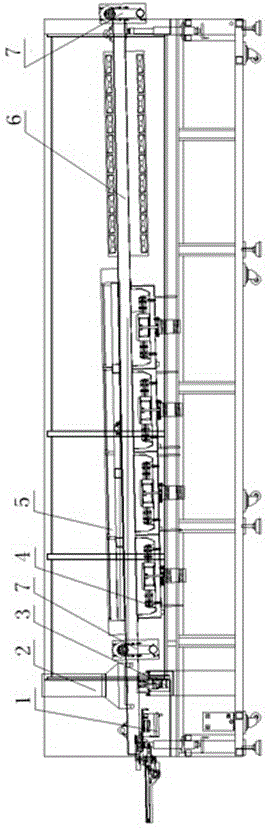

Image

Examples

Embodiment

[0013] Embodiment: This embodiment is based on the coating equipment described above to illustrate a method for the bottom coating of printed circuit boards. The method includes the following steps: first, board loading and cleaning, first open the coating equipment, Put the tested circuit board on the double guide rail transmission system 7, after being transported by the double guide rails, the circuit board flows through the claw washing system 1, and the circuit board is cleaned by the claw washing system 1; the cleaned circuit board is passed through The double guide rails are transported to the bottom of the exhaust system 2, and dried by the exhaust system 2; the cleaning liquid level is kept constant by using the claw washing system 1 and the exhaust system 2 at the same time to ensure the cleaning effect; the second is the line after coating and drying The board is connected to the advection coating system 3 by the board-in connection mechanism. At the same time, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com