System for preparing urea solution for denitration

A urea and solution technology, applied in the directions of dissolution, mixer accessories, mixers, etc., can solve the problems of high power consumption, water consumption and steam consumption, low degree of automation, poor operating environment, etc., to reduce comprehensive energy consumption and labor intensity. , The effect of reducing equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

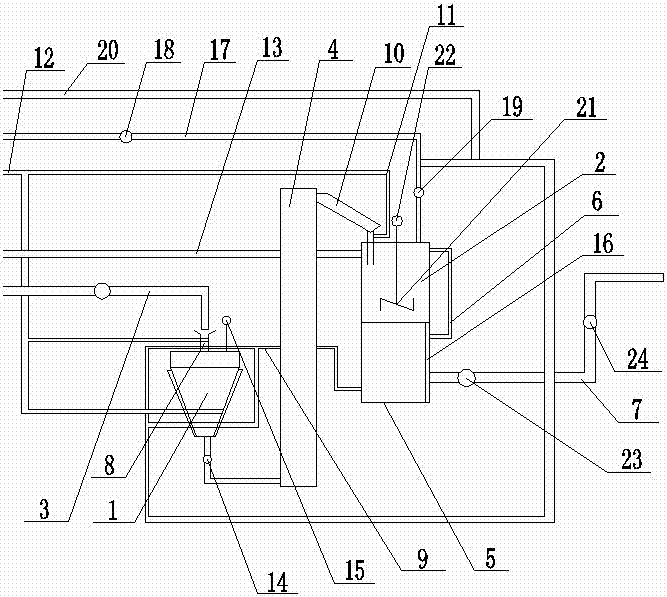

[0021] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes a hopper 1 and a liquid distribution tank 2, an automatic feeding device 3 is connected to the top of the hopper 1, a urea delivery device 4 is installed between the bottom of the hopper 1 and the liquid distribution tank 2, and a liquid storage tank 5 is arranged below the liquid distribution tank 2 , the liquid distribution tank 3 and the liquid storage tank 5 are connected through an automatic overflow device 6, the bottom of the liquid storage tank 5 is connected with a urea solution output pipeline 7, and a cylindrical connecting section 8 is provided between the hopper 1 and the automatic feeding device 3, The cylindrical connecting section 8 and the inside of the hopper 1 are respectively connected to the bottom of the liquid storage tank 5 through the heating hot water pipeline 9 . A dosing feed chute 10 is provided between the end of the urea delivery device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com