Device and method for growing silicon carbide crystals via liquid phase method

A technology of silicon carbide and liquid phase method, applied in chemical instruments and methods, single crystal growth, crystal growth, etc., can solve the problem of reducing the quality of growing crystals, sustainable crystal growth, increasing crystal growth costs, and reducing temperature gradients, etc. problem, to achieve long-term stable growth, increase output, and improve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

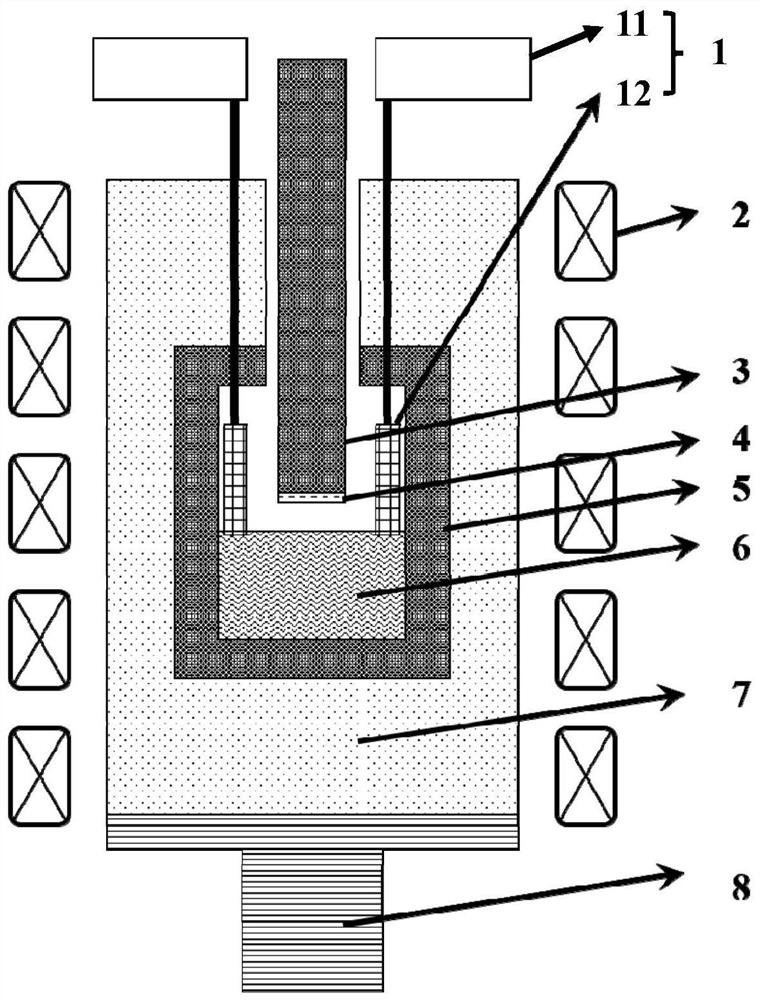

[0052] The Si alloy auxiliary solution used in this embodiment is composed of three phases of Si, Cr, and Al, and its atomic ratio is Si: 50%, Cr: 40%, and Al: 10%. Mix the elemental particles of the three raw materials evenly, place them in a graphite crucible, and figure 1 The structure shown is placed in a device for growing silicon carbide crystals by the liquid phase method, and the air in the crucible is evacuated to 2×10 by a molecular pump. -4 After the Pa is lower than 1.5 atm Ar gas is introduced as a protective gas and the crucible is heated. When the temperature in the crucible reaches the melting temperature of the growth raw material, Si, Cr and Al in the graphite crucible are all melted to obtain a Si alloy auxiliary solution. In the embodiment, the initial position of the liquid level maintaining ring of the liquid level maintaining device should be adjusted to a position where its lower end is 1-3mm lower than the Si alloy solution level when the furnace is in...

Embodiment 2

[0056] Embodiment 2 is basically the same as Embodiment 1, the difference is:

[0057] During the growth of silicon carbide crystals, the silicon carbide seed crystal is slowly pulled at a speed of 0.2 mm / h, and the liquid level maintaining ring of the liquid level maintaining device is lowered into the Si alloy auxiliary solution at a speed of 0.2 mm / h.

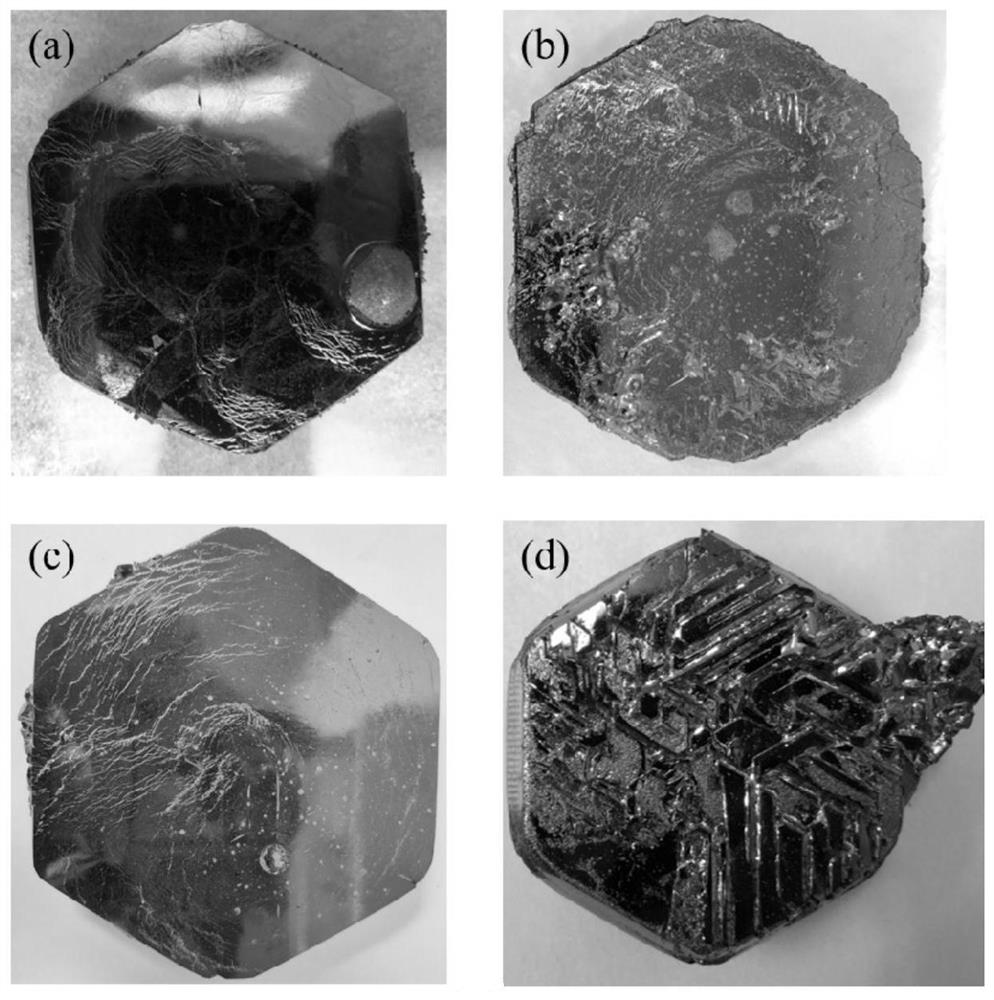

[0058] The appearance figure (top view) of the silicon carbide crystal that present embodiment grows obtains, as figure 2 as shown in (b); from figure 2 (b) It can be seen that the surface of the silicon carbide crystal in this example has many undulations and ravines, which are mixed with Si alloy co-solution and silicon carbide polycrystalline particles, and the quality of the silicon carbide crystal deteriorates.

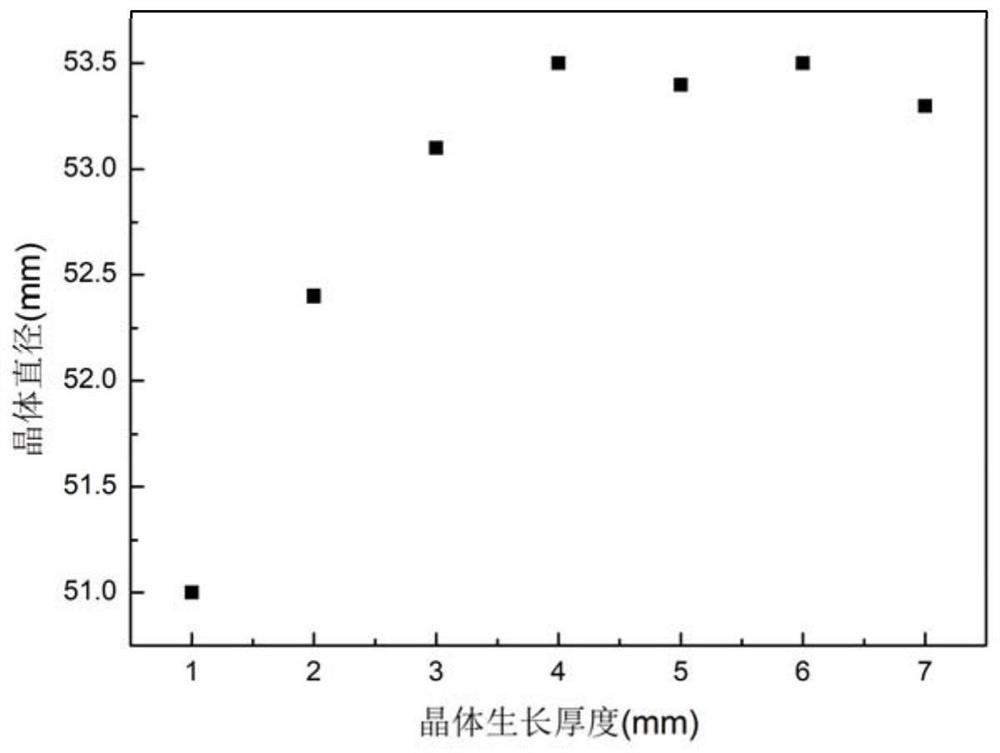

[0059] Diameter change diagram of the silicon carbide crystal grown in the present embodiment, such as Figure 4 shown; from Figure 4 It can be seen that during the whole growth process, the diameter of s...

Embodiment 3

[0061] Embodiment 3 is basically the same as Embodiment 1, the difference is:

[0062] After the entire growth process lasted for 90 hours, the silicon carbide seed crystal was pulled up at a speed of 3 mm / h to separate the grown silicon carbide crystal from the liquid surface of the Si alloy co-solution, and slowly cooled to room temperature, that is, the entire liquid-phase method of silicon carbide The crystal growth process is completed, and silicon carbide crystals are obtained.

[0063] In this embodiment, the growth crystal diameter varies with the growth thickness as Figure 5 As shown, the outline view (top view) of the surface of the silicon carbide crystal grown in this embodiment is as figure 2 Shown in (c); As can be seen from the growth results, the growth thickness of the silicon carbide crystal grown in this embodiment reaches 10.5mm, and the surface of the silicon carbide growth crystal is neat and clean, and the diameter of the silicon carbide growth crysta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com