Brake fluid replacing device and working method thereof

A technology of brake fluid and changer, which is applied in vehicle maintenance, vehicle maintenance/repair, transportation and packaging, etc. It can solve the problem of brake pipeline damage, brake master cylinder, brake wheel cylinder, high flow rate of brake fluid, The flow is difficult to control and other problems, to achieve the effect of ensuring braking safety, saving manpower and material resources, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

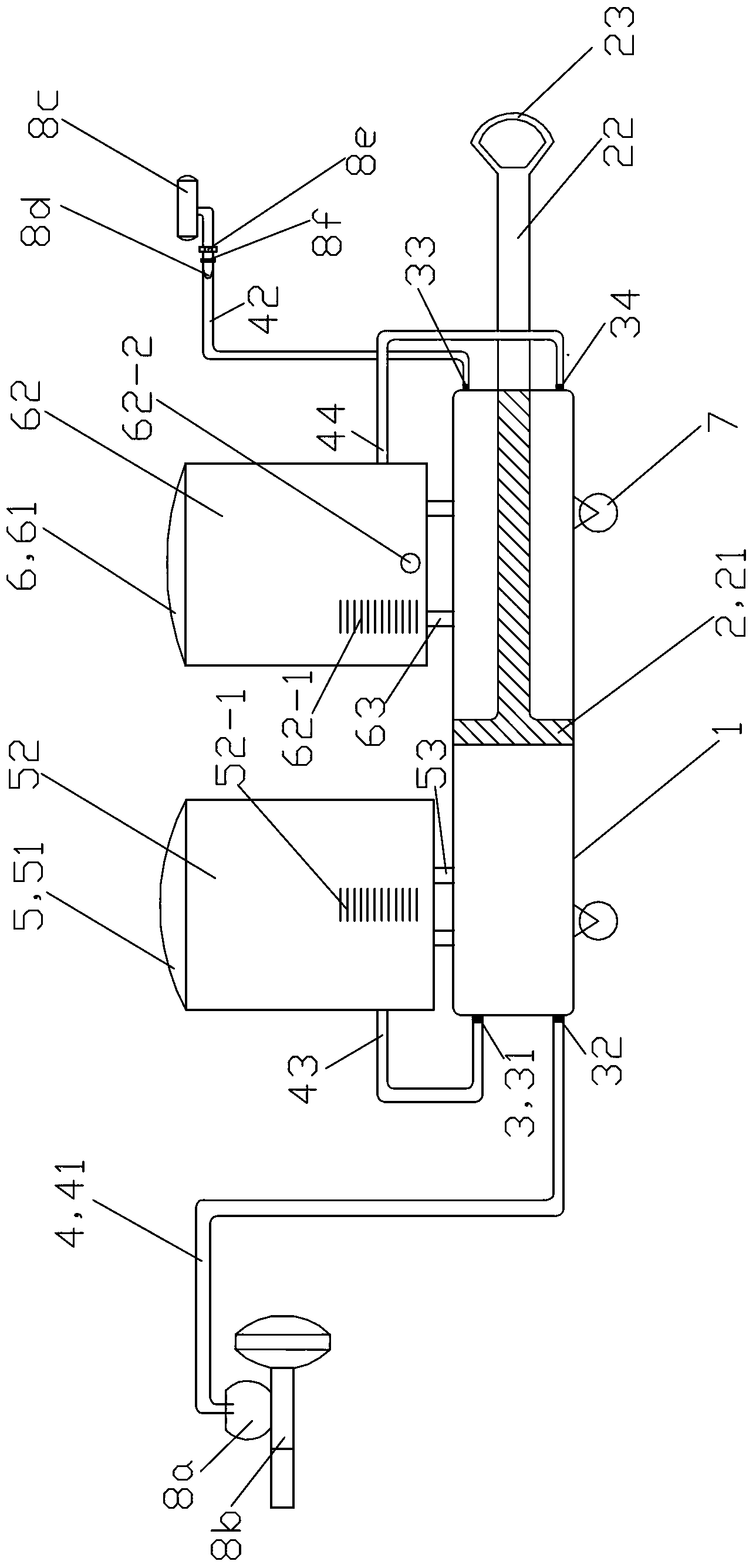

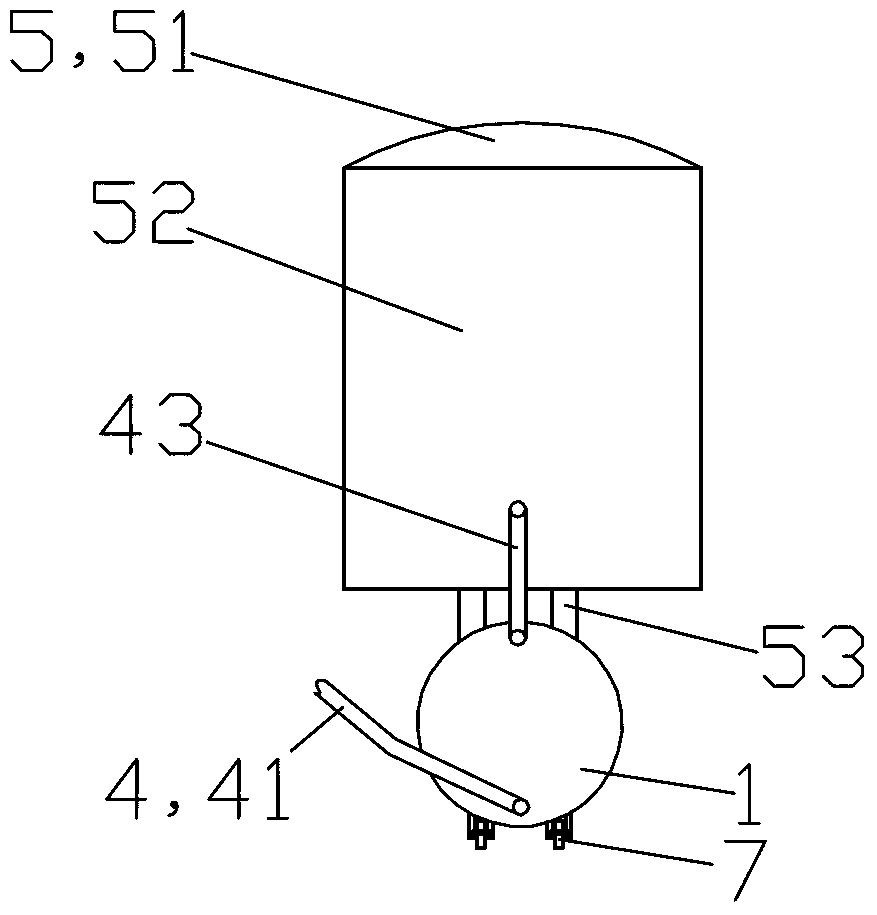

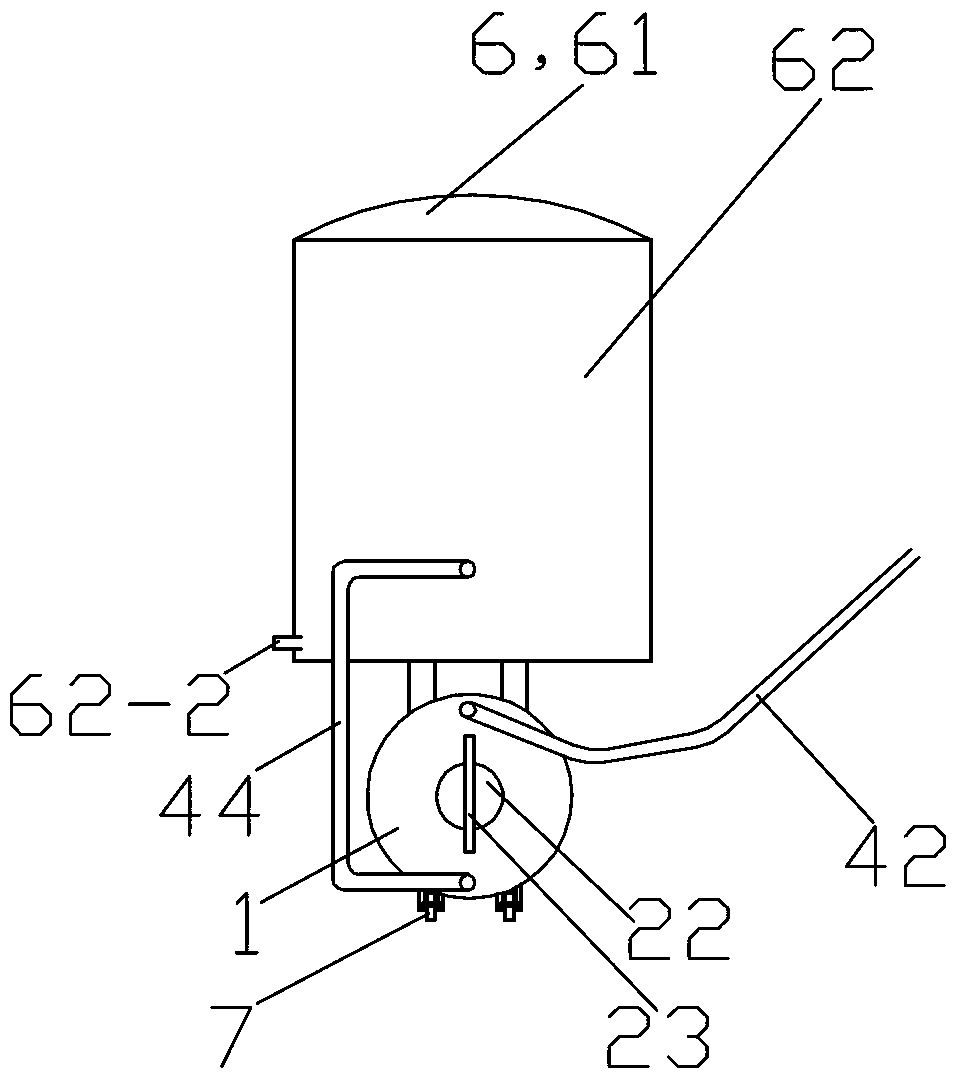

[0030] See Figure 1 to Figure 3 , The brake fluid changer of this embodiment is mainly composed of a piston cylinder 1, a piston assembly 2, a one-way valve assembly 3, a connecting pipe assembly 4, a brake fluid bucket 5, a waste fluid bucket 6 and a roller 7.

[0031] The piston cylinder body 1 is a steel part. The piston cylinder 1 is integrally formed by a circular left side plate, a circular right side plate and a hollow cylinder in the middle. The piston cylinder body 1 is arranged left and right. The upper end and the lower end of the left side plate of the piston cylinder 1 are respectively provided with a left and right through hole as a valve mounting hole, and the two through holes are located on the front and rear central axis of the left side plate of the piston cylinder 1 . The upper end and the lower end of the right side plate of the piston cylinder 1 are also respectively provided with a left and right through hole as a valve installation hole, and the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com