Online plugging device for high-temperature heat transfer oil delivery pipe and construction method thereof

A heat-conducting oil and conveying pipe technology, applied in the polyester field, can solve problems such as hidden safety hazards, large losses, leakage of heat-conducting oil, etc., and achieve the effect of wide application range, elimination of hidden safety hazards and good leakage blocking effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below with regard to specific embodiment:

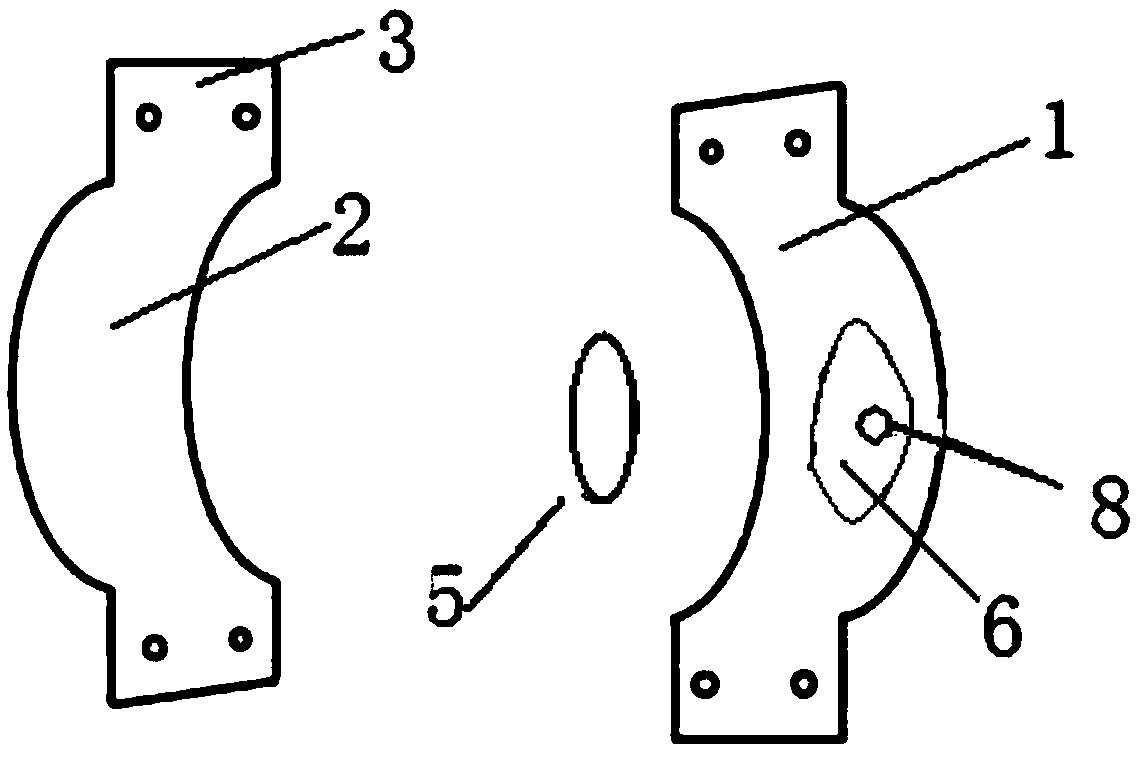

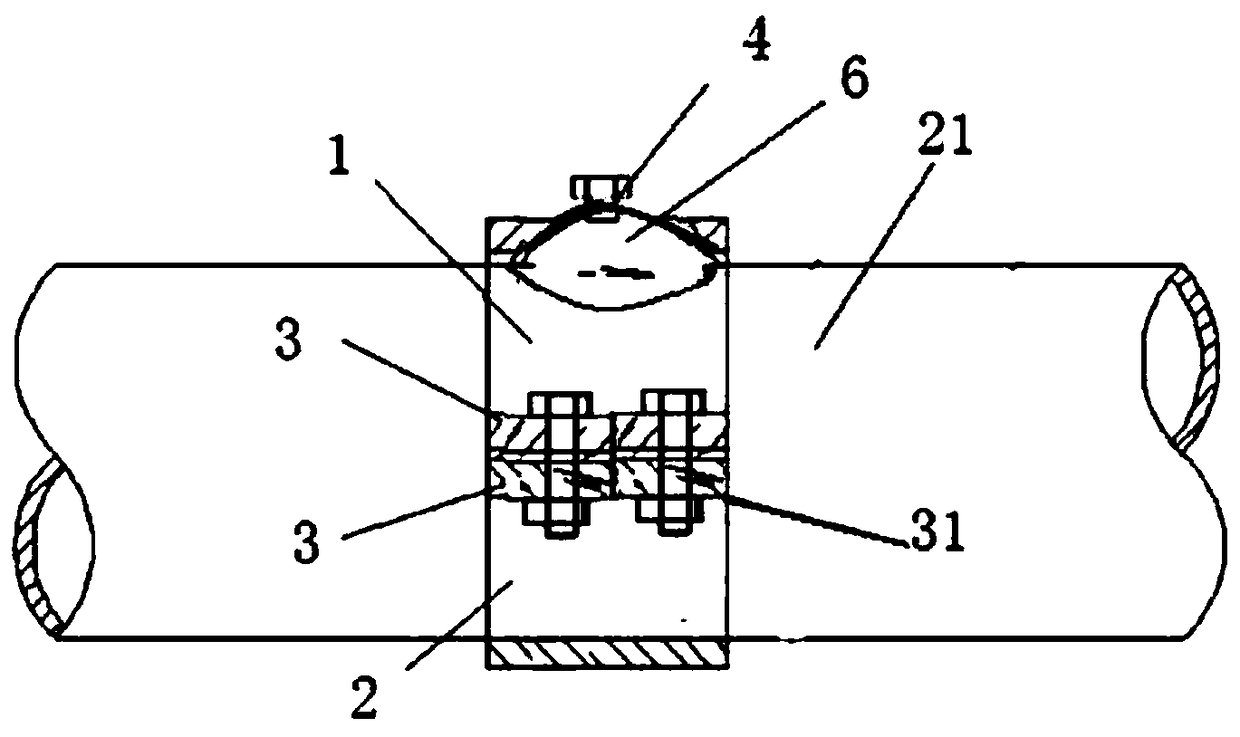

[0019] Such as figure 1 and 2 As shown, an online plugging device for high-temperature heat-conducting oil delivery pipes includes a first hoop 1 and a second hoop 2. The first hoop 1 and the second hoop 2 have a semi-circular fixed body and a The two ends of the fixed body respectively extend the pressing part 3, the pressing part 3 is provided with a corresponding mounting hole, the first hoop and the second hoop are connected by a fastener 31 installed in the mounting hole, and the fastener Bolts can be selected for 31, so that the first hoop and the second hoop are entangled to form a ring and fixed to the high-temperature heat transfer oil delivery pipe 21. Also include plug bolt 4 and high temperature resistant sealing ring 5, high temperature resistant sealing ring 5 can be selected graphite sealing ring, on the fixed body of the first hoop 1, there is an operation part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com