All-structure waterproof wall washing lamp

A technology of wall washer and waterproof joint, which is applied in the direction of air-proof/waterproof device, parts of lighting device, lighting device, etc. It can solve the problems of easy falling off of front glass cover and glass glue, failure of waterproofing, long production cycle of lamps, etc. , to achieve the effect of detachable maintainability, reduce material loss cost, and reduce logistics transportation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

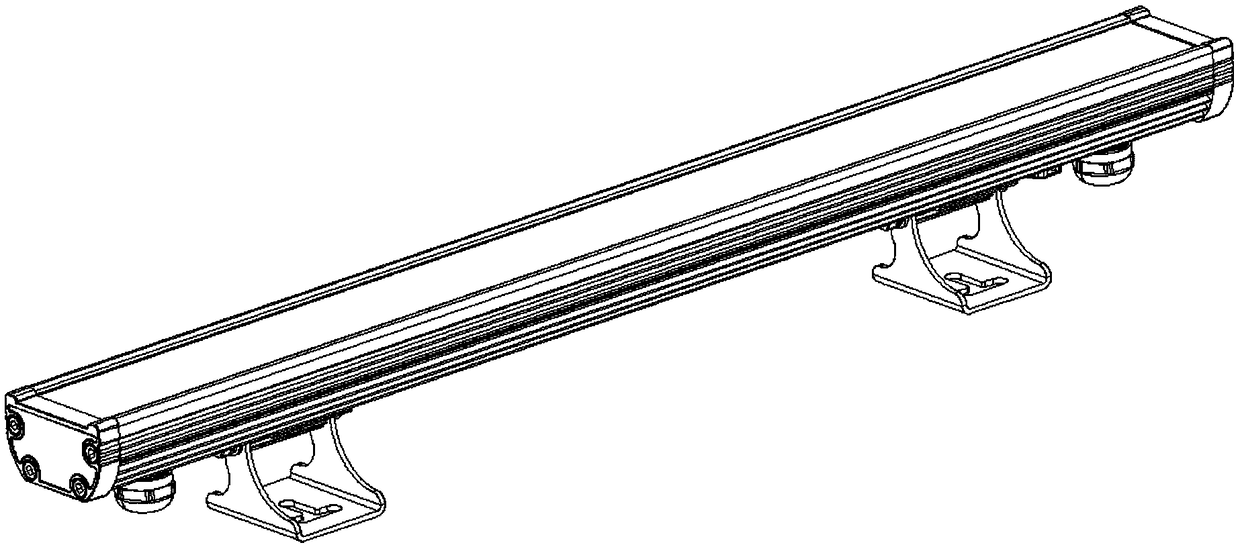

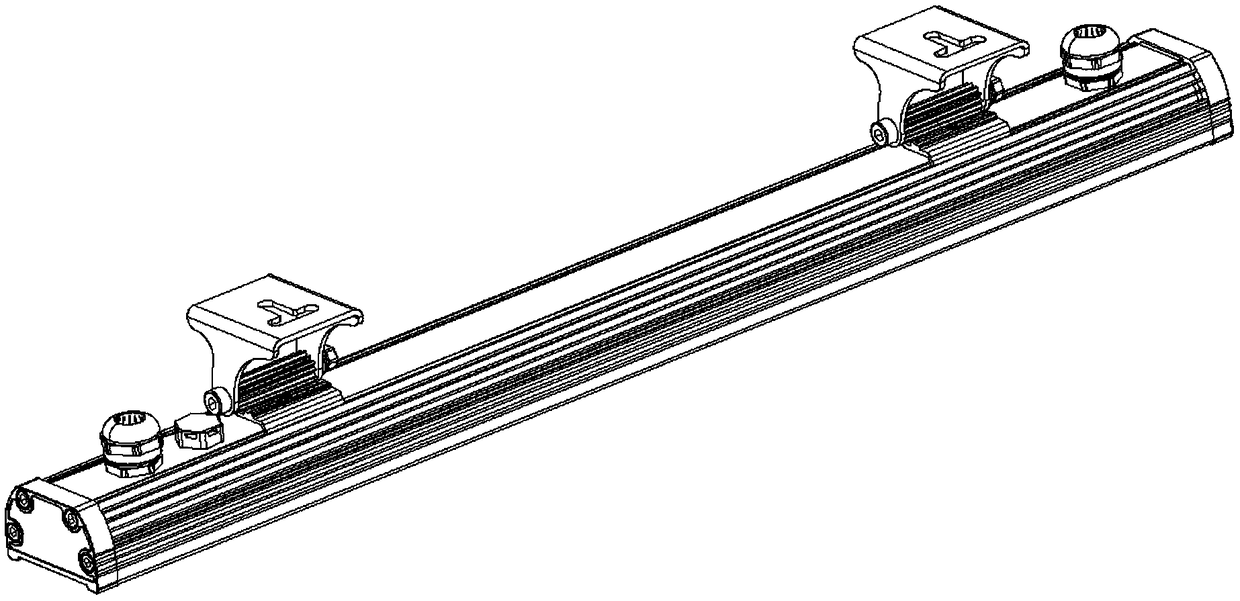

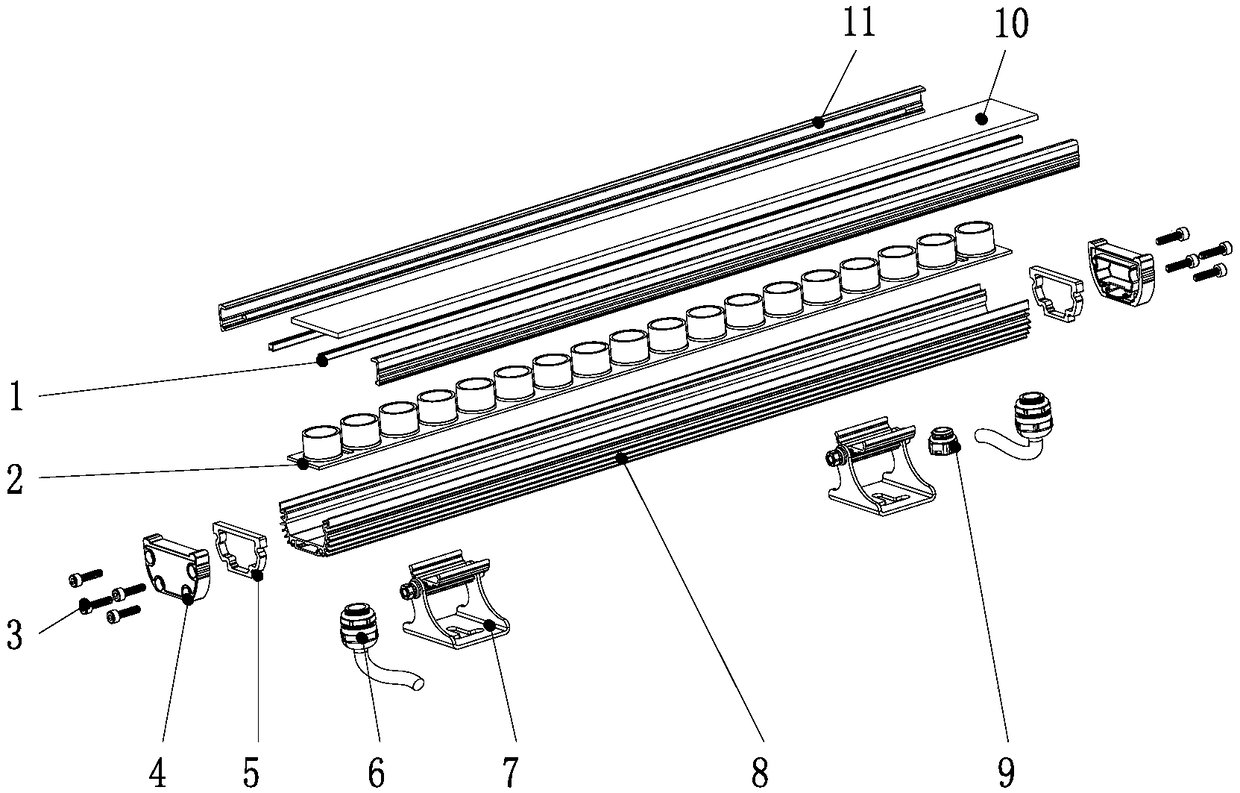

[0021] Such as Figure 1 to Figure 6 As shown, the waterproof of the lamp cavity mainly consists of four parts; the front waterproof (here the front refers to Figure 4 above): the two sides of the main body 8 are installed in the front of the groove along the front of the silicone sealing strip 1, the glass cover 10 is installed on the front of the silicone sealing strip 1, and then the whole is placed in the pressure device 12. The whole here refers to the silicone sealing strip 1, the main body 8 and The whole body composed of glass cover 10 is pressurized from the front side, and after the silicone sealing strip 1 is squeezed and deformed, the pressure strip 11 is loaded into the main body 8 from the side to form the front waterproof of the lamp; the main body 8 has a mounting groove for installing the silicone sealing strip 1 , the main body 8 has a non-removable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com