Resonance cylinder oil densimeter

A density meter and resonance technology, applied in the field of fluid density measurement, can solve the problems of low accuracy, failure to meet the requirements of metering management, and inability to measure the density of oil density distribution, and achieve the effect of facilitating digitization and improving the accuracy of density measurement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

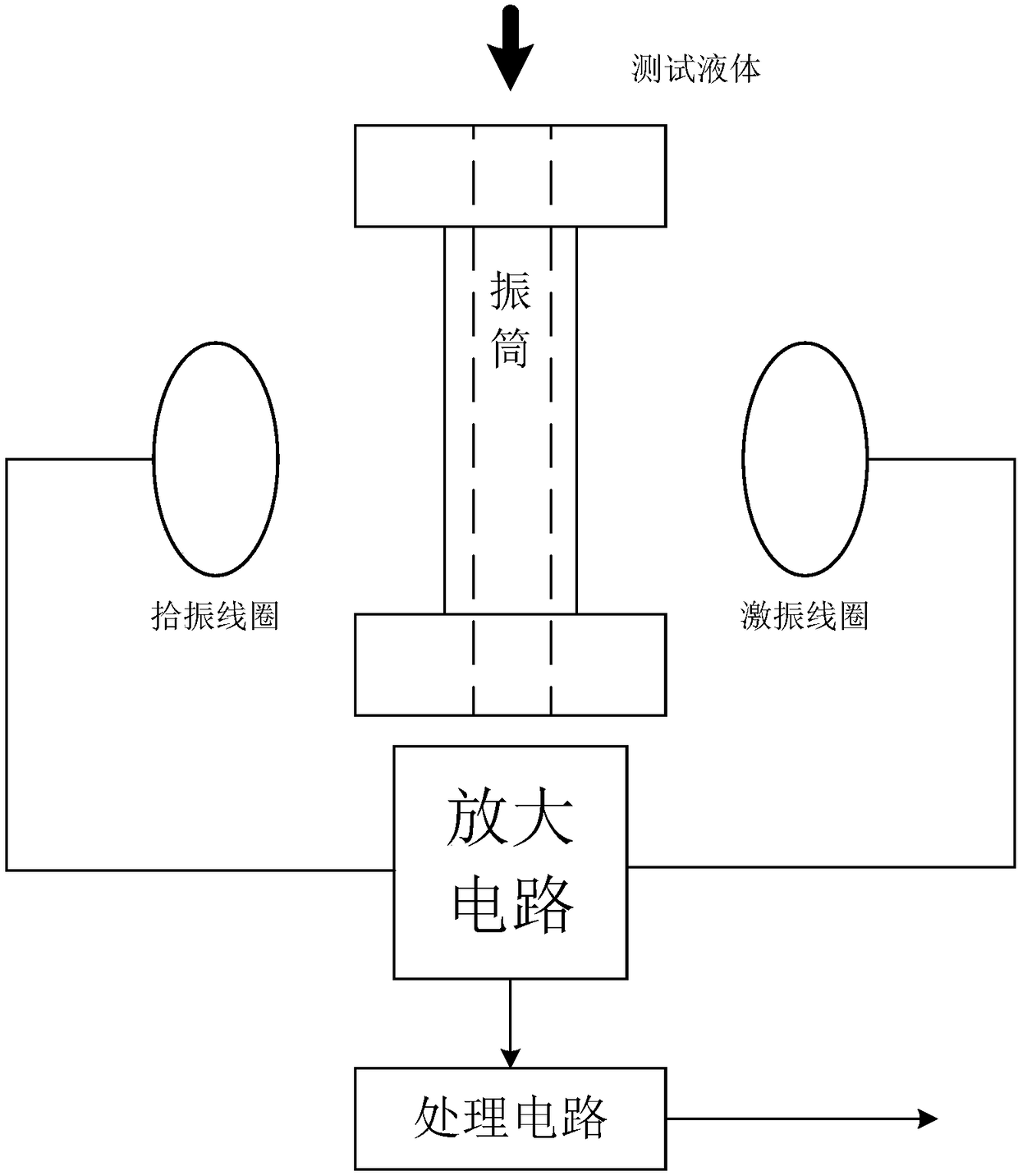

[0015] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0016] A resonant cylinder type oil density meter comprises an amplifier circuit, a processing circuit, an excitation coil and a pickup coil arranged in the amplifier circuit, a resonance cylinder arranged between the excitation coil and the pickup coil, and the excitation coil can be The electromagnetic force is generated to cause a micro-displacement of the wall of the resonant cylinder, and the change of the distance between the cylinder wall and the pickup coil causes the pickup coil to generate an electromotive force, and the processing circuit collects and processes electrical signals and realizes temperature compensation.

[0017] The processing circuit includes an amplification circuit, a conversion circuit, and a temperature measurement circuit, and the processing circuit obtains the density of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com