Enameled wire defect on-line detection method, detection device, computer device and computer-readable storage medium thereof

A defect detection and detection method technology, applied in the direction of measuring devices, material analysis through electromagnetic means, instruments, etc., can solve problems such as outflow, low efficiency of enameled wire defect detection, and excessive abnormal products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

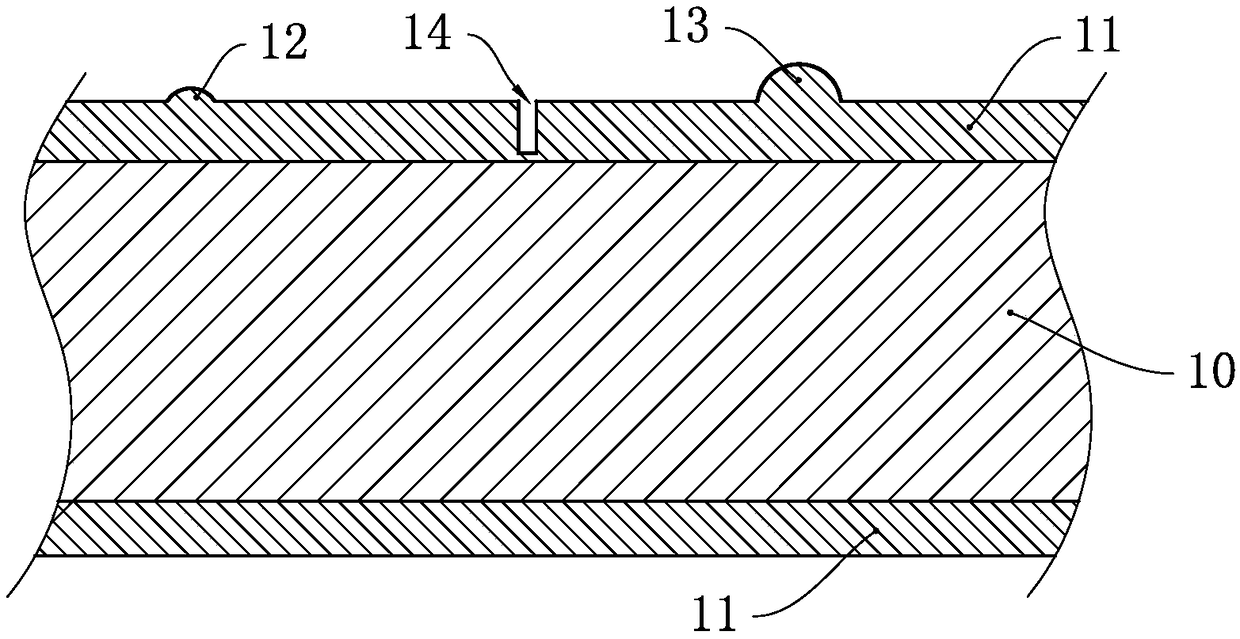

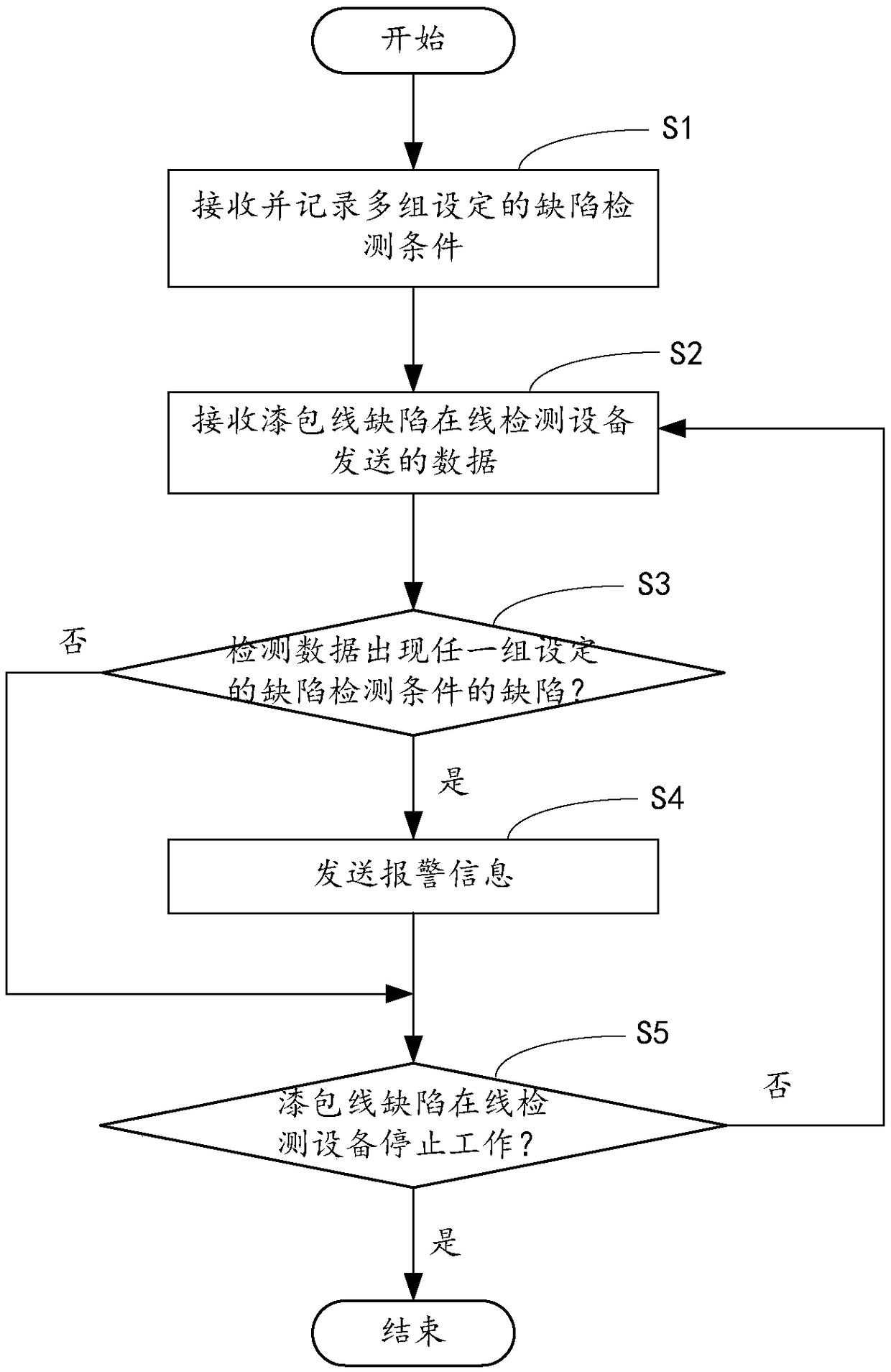

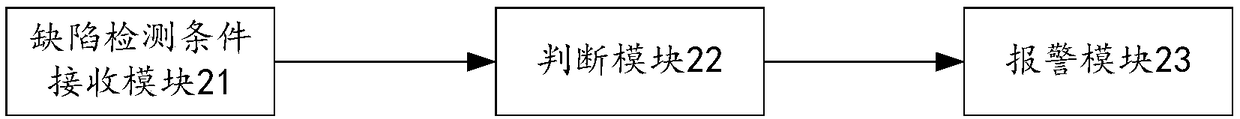

[0024] The online defect detection method for enameled wire of the present invention is used for detecting and analyzing defects on the surface of the enameled wire, for example, detecting the number of large particles, small particles and pinholes on the surface of the enameled wire. The online defect detection device for enameled wire of the present invention can realize the above-mentioned online defect detection method for enameled wire. The computer-readable storage medium of the present invention may be various storage mediums with data storage functions, including but not limited to non-volatile memories such as FLASH and EEPROM.

[0025] Examples of methods for online detection of enameled wire defects:

[0026] The online defect detection method of enameled wire of the present invention can be installed on a computer, for example, a computer used to monitor surface defects of enameled wire.

[0027] Due to the enameled wire production process, the insulating paint coated on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com