SDT improvement method applied to field of numerical control machine tool monitoring

A technology in the field of numerical control machine tools, applied in general control systems, program control, computer control, etc., can solve the problems of excessive memory consumption and occupying large storage units, and achieve the effect of reducing data compression errors and accurate fitting results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

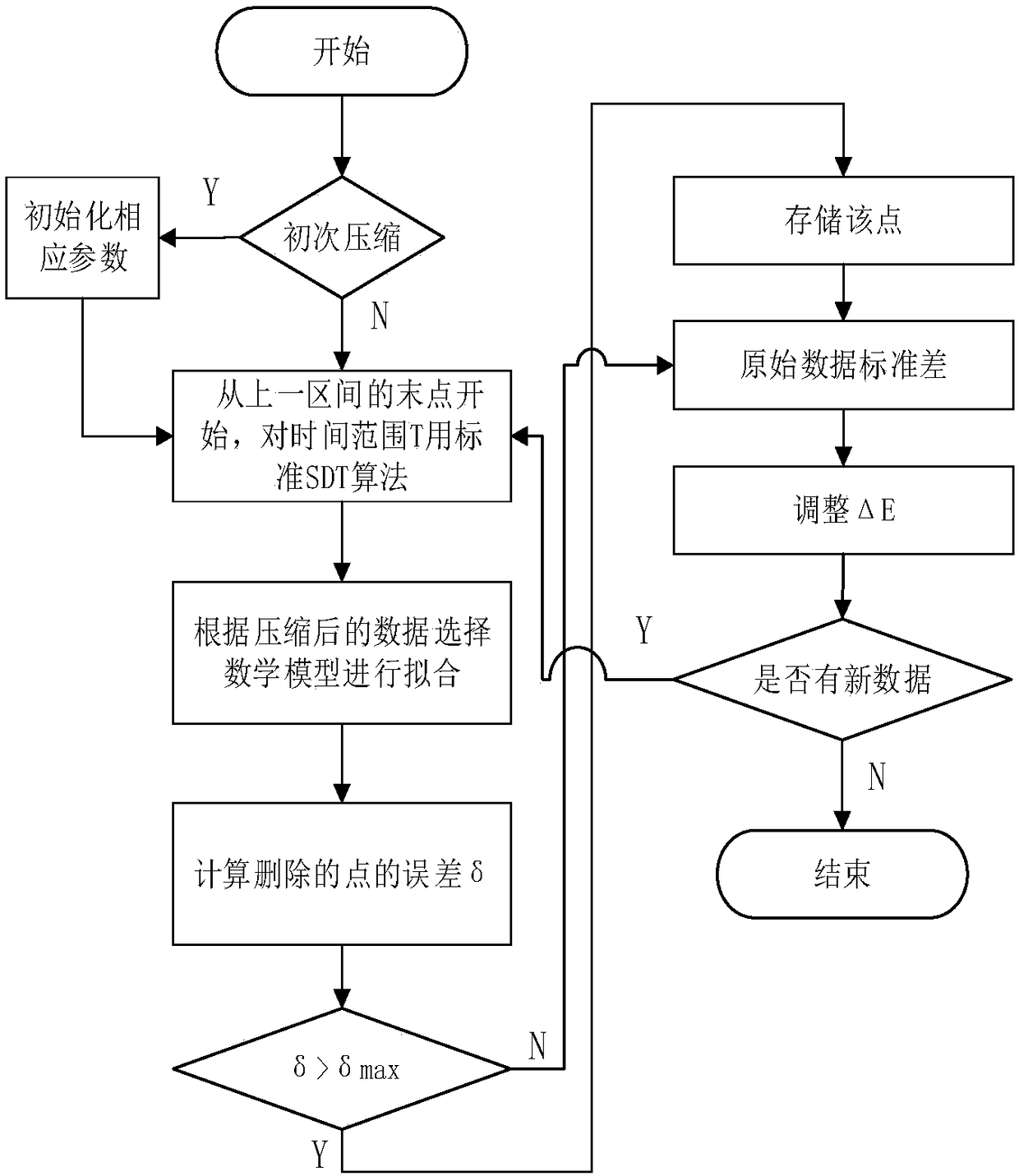

[0037] The method of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0038] In the SDT improved compression algorithm, ΔE represents the tolerance in the SDT algorithm, and the range is ΔE min ≤ΔE≤ΔE max ; T represents the time interval of the compression interval; δ max Indicates the compressed maximum fitting error. Among them, ΔE min is the minimum value of the tolerance, ΔE max is the maximum tolerance.

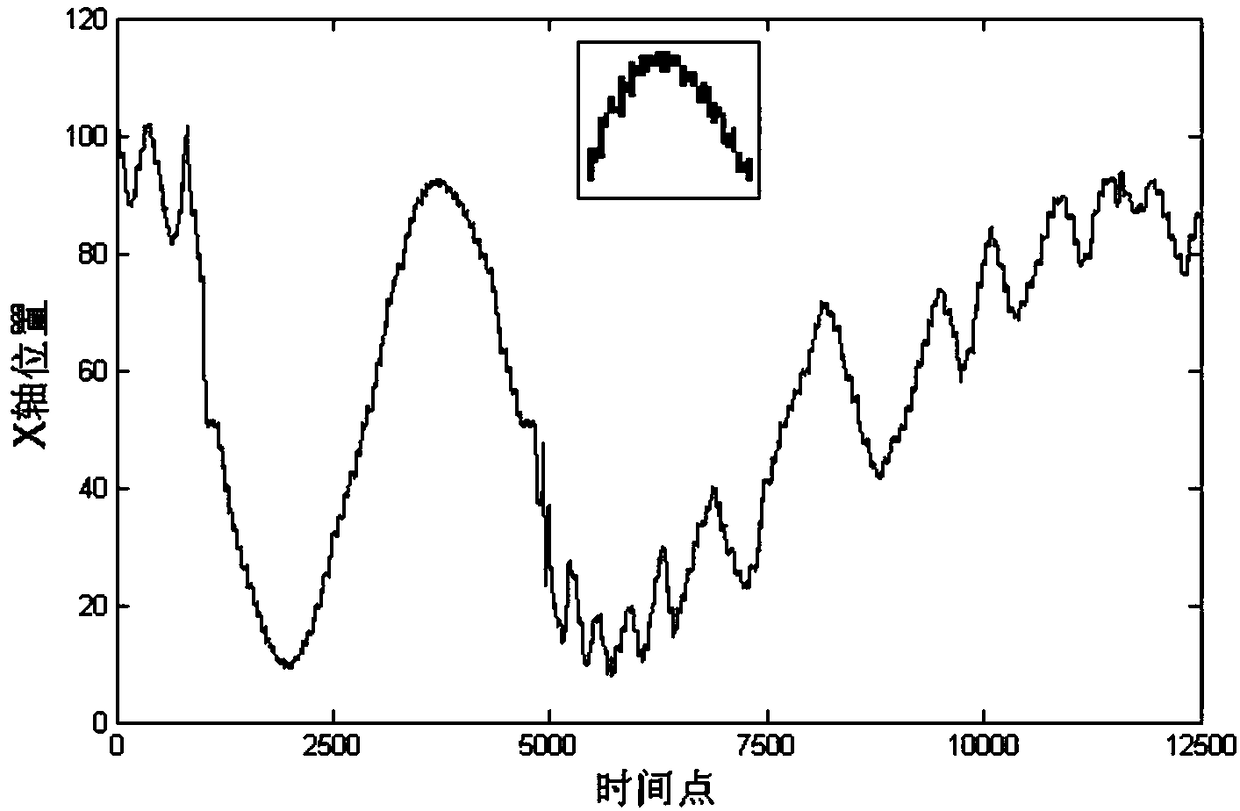

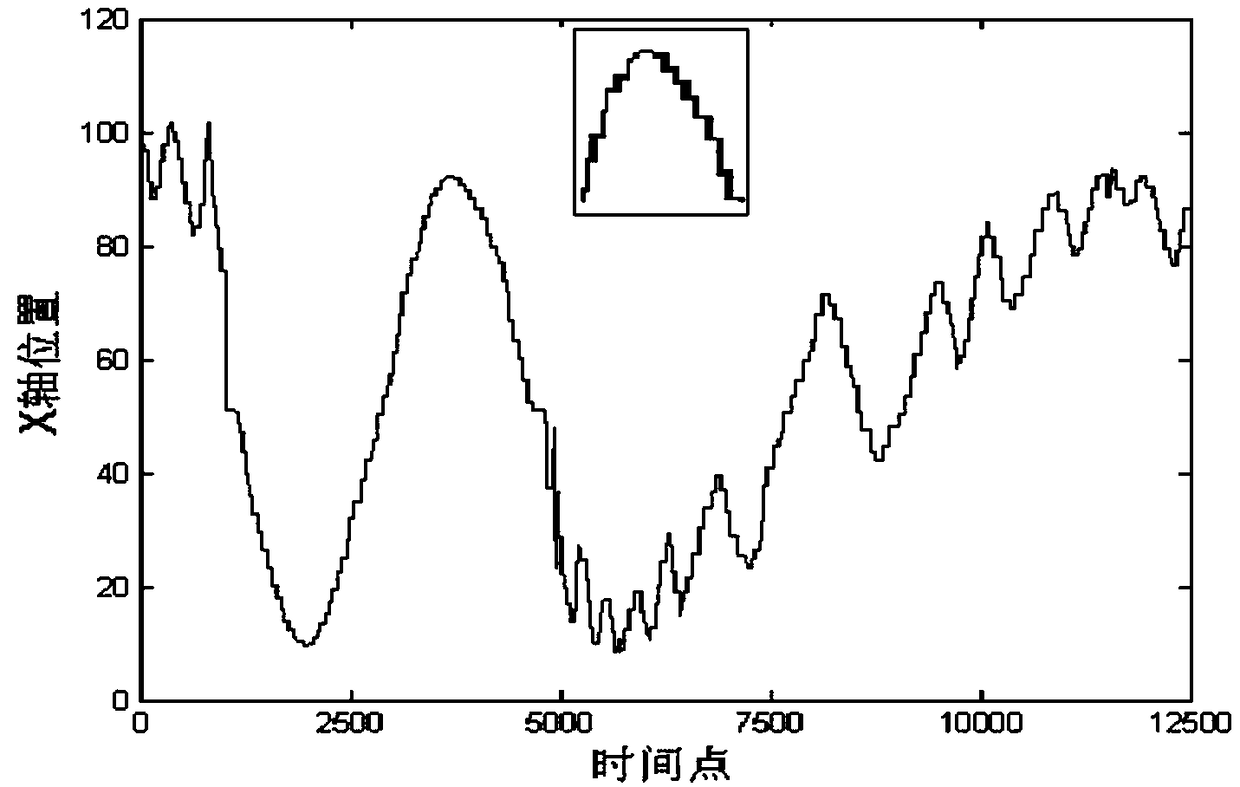

[0039] The indicators to measure the quality of a process data compression algorithm include compression ratio CR (Compression Ratio) and compression error CE (Compression Error). Where n is the number of original data points, m is the number of compressed data points, and satisfies m≤n. the y i is the actual data point value, is the data point value recovered after decompression by compressed data. CE describes how close the data recovered after decompression is to the actual data after compressio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com