Filter element for filtering exhaust gases or process gases, and method for producing such a filter element

A technology for process gas and exhaust gas, which is applied in membrane filters, chemical instruments and methods, separation methods, etc., can solve the problem of not being able to ensure the sealing of the main element of the filter, and achieve enhanced stability, high filter performance, and cheap manufacturing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

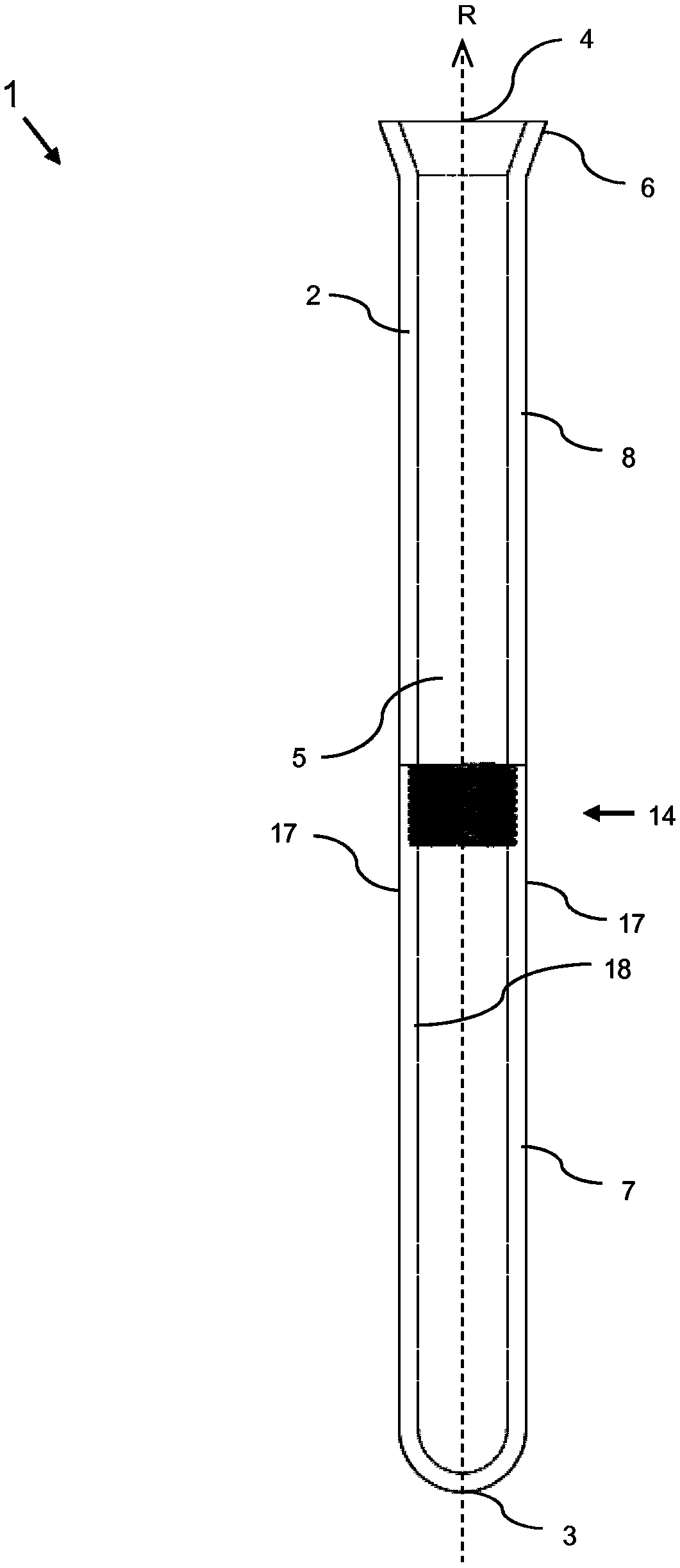

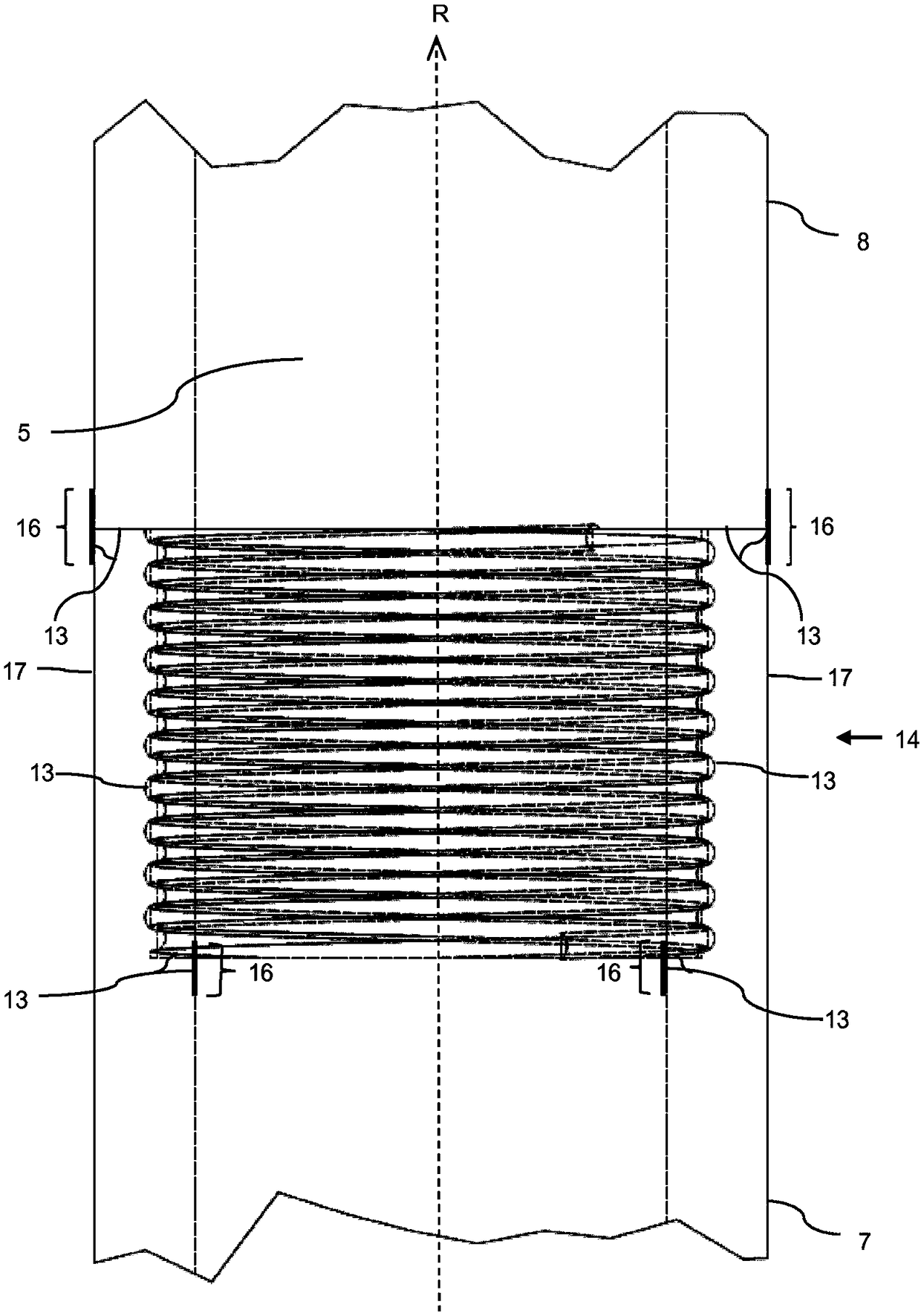

[0031] Figures 1 to 4 A schematic view of a filter element 1 according to the invention designed according to the invention for filtering exhaust gases or process gases is shown. as from figure 1 It can be seen that the filter element 1 is formed in the form of a filter cartridge and has a substantially hollow cylindrical filter body 2 closed hemispherically at one end, namely the lower end 3, and at its opposite end, That is, the upper end 4 is open and defines the inner space 5 of the filter element 1 . At the open end 4 of the filter body 2 a radially protruding conical collar 6 is formed which tapers in the direction of the closed end 3 of the filter body 2 .

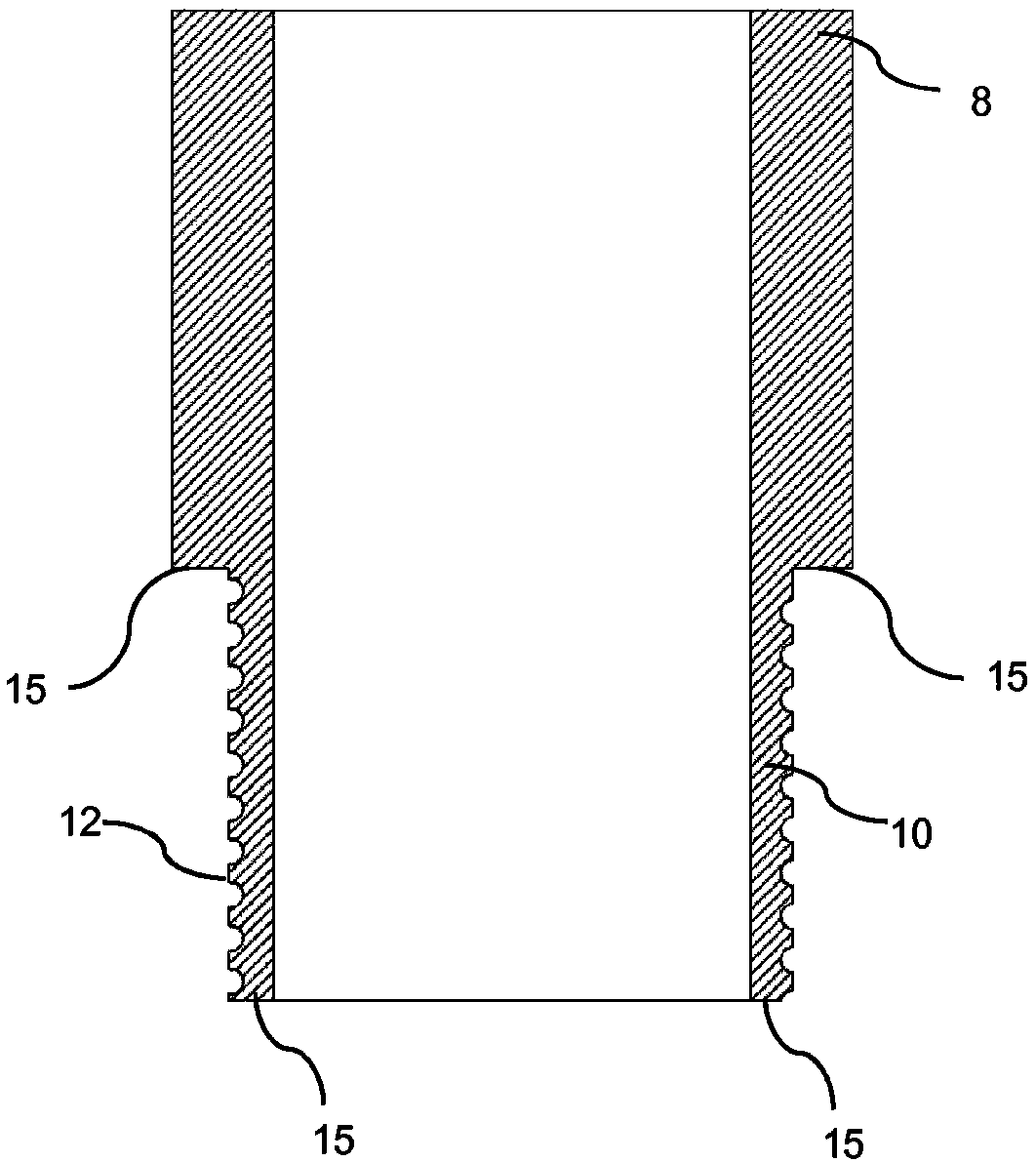

[0032] The filter body 2 defines a longitudinal direction R and is divided along this longitudinal direction R into two substantially cylindrical tubular filter body elements 7, 8 at their ends 9, 8 facing each other. 10 places are connected to each other. To this end, the filter body elements 7 , 8 have at the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com