A micro switch packaging equipment

A micro switch and packaging equipment technology, applied in packaging, packaging protection, transportation and packaging, etc., can solve the problems of low automation and work efficiency, inability to guarantee packaging accuracy, and difficulty in removing spring sheets, so as to improve work efficiency. Efficiency, convenient gripping and transportation, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

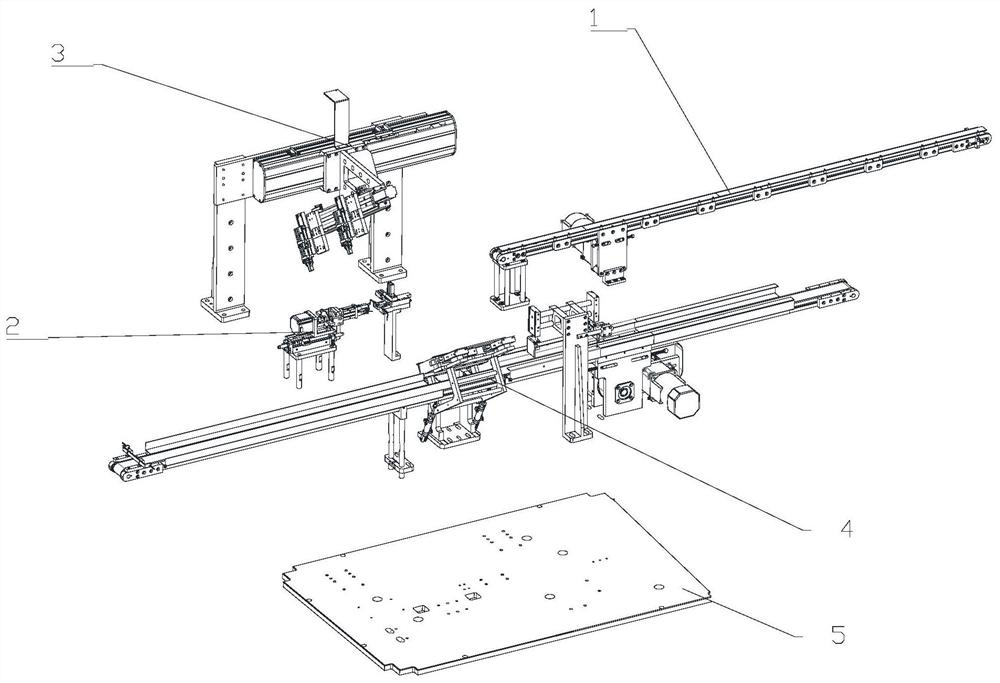

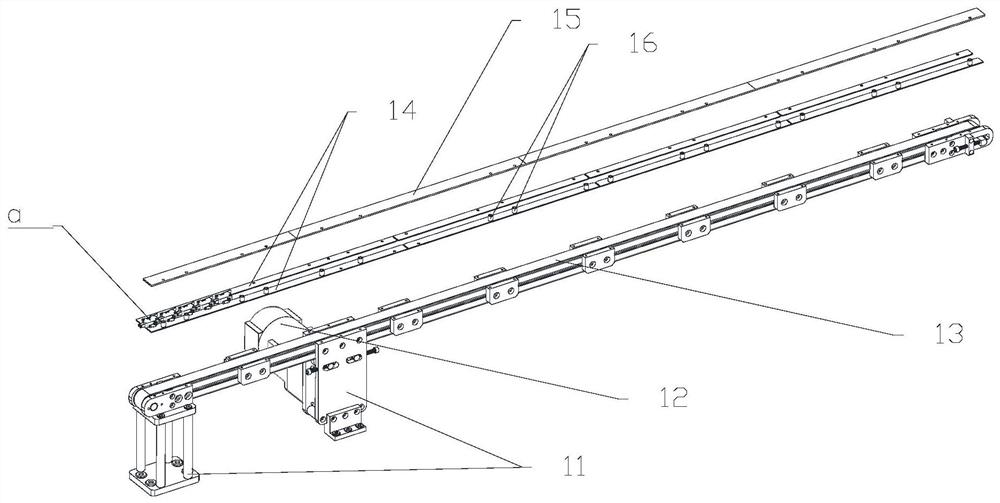

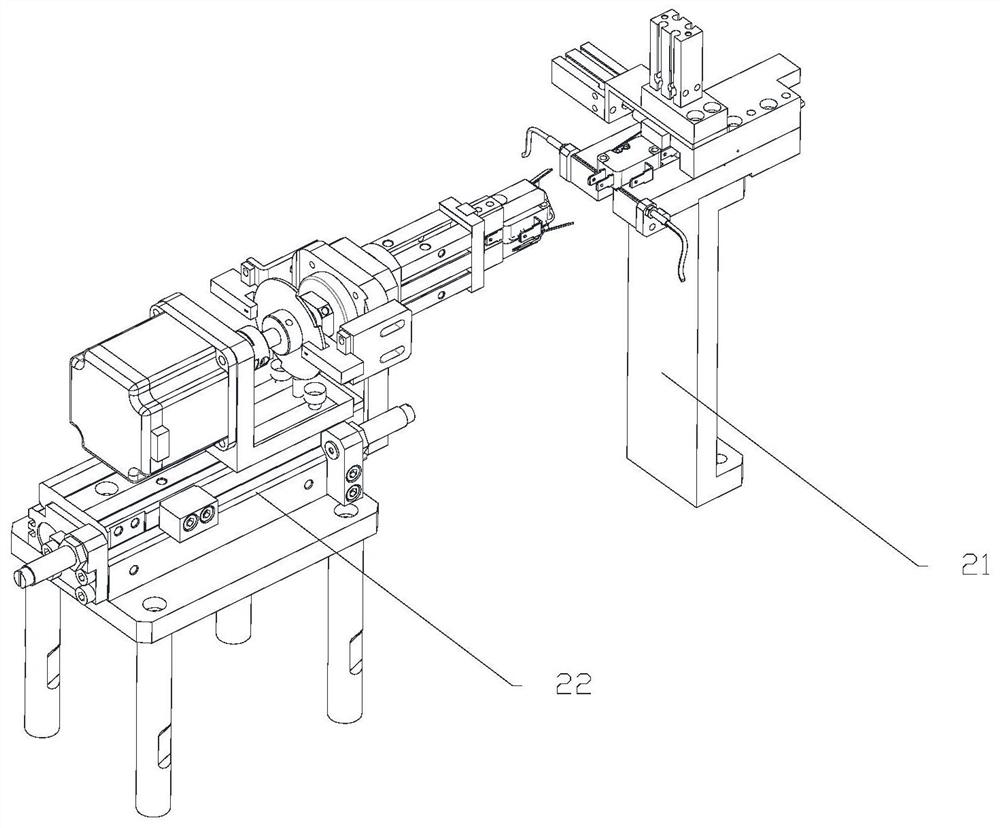

[0025] Such as figure 1 As shown, a micro switch packaging equipment includes a mounting plate 5 and a micro switch feeding device 1 on it, a micro switch distributing device 2 , a micro switch handling device 3 and a packing box loading and unloading device 4 .

[0026] Micro switch feeding device 1 is used for continuous feeding of micro switches. The micro switch distributing device 2 is connected with the outlet of the micro switch feeding device 1, and is used to realize the sorting of a single micro switch. The position of the micro switch handling device 3 corresponds to the micro switch distributing device 2 and the packing box loading and unloading device 4. Transfer of unit 2 to box loading and unloading unit 4. The packaging box loading and unloading device 4 is used to realize the loading of empty magazines, the turning over of magazines ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com