Packaging bottle capable of realizing quantitative pouring-out

A technology for packaging bottles and bottles, applied in the field of packaging bottles, can solve the problems of inconvenient use and single function, and achieve the effects of improving efficiency, simple and fast operation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

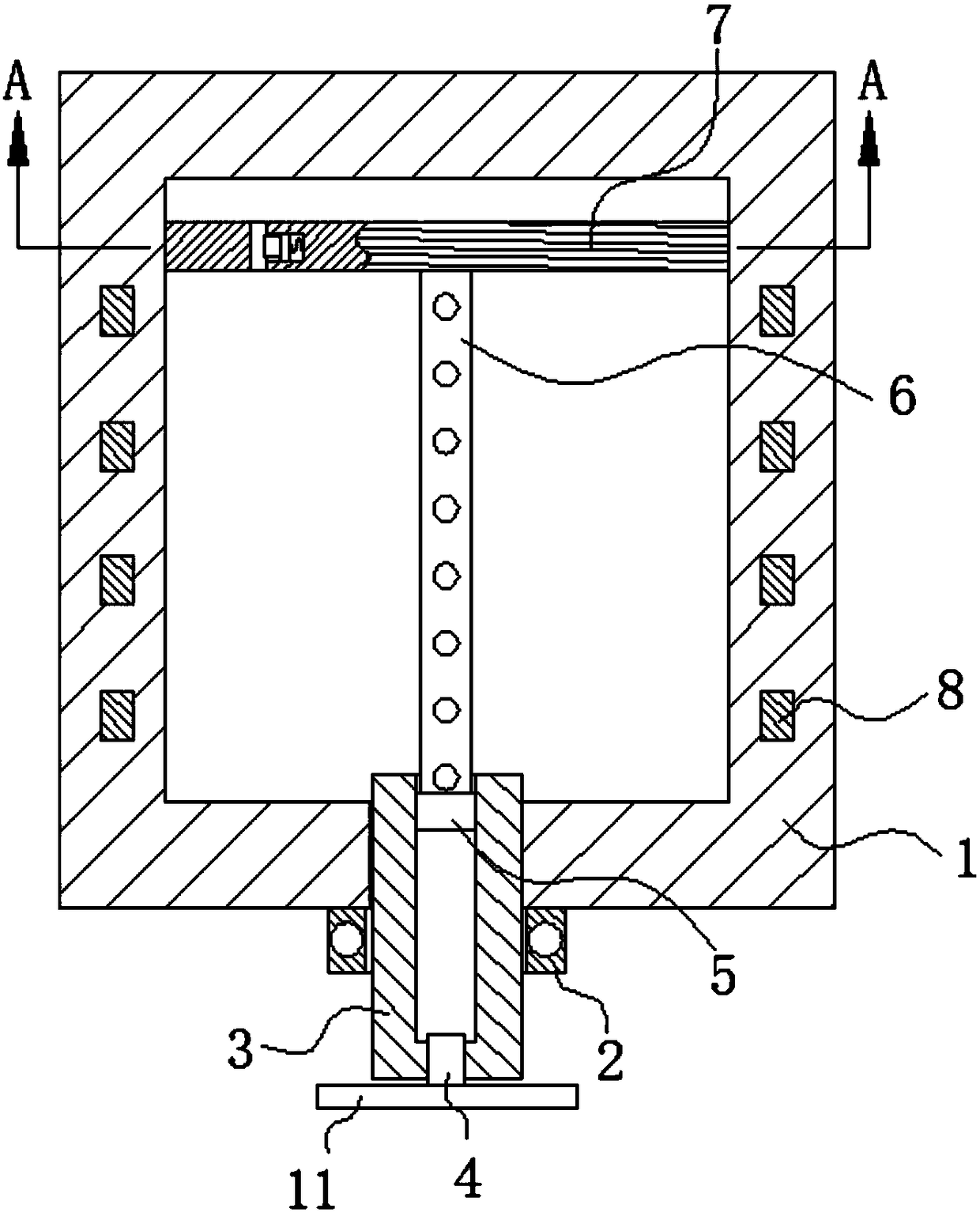

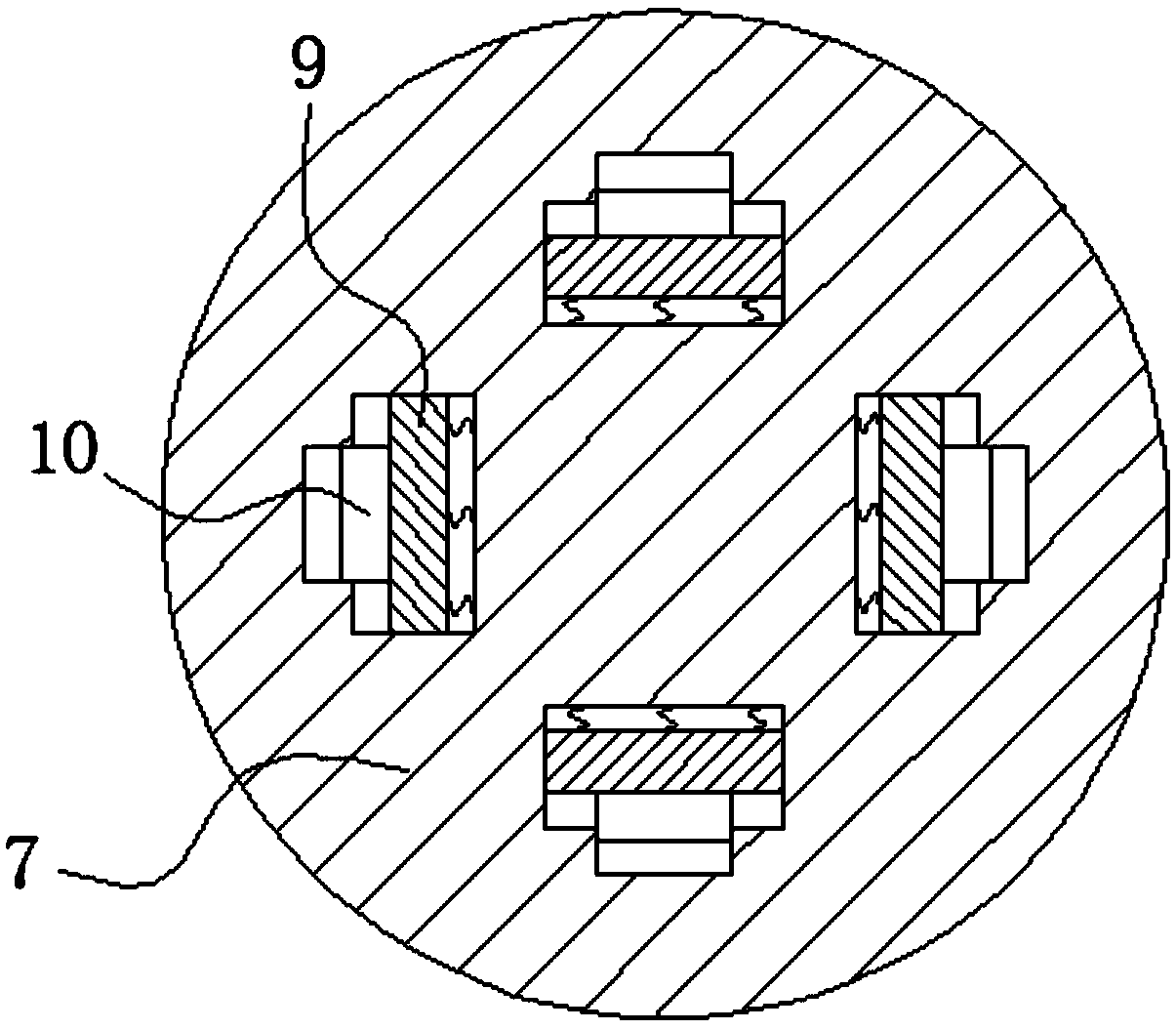

[0014] refer to Figure 1-2 , a quantitatively poured out packaging bottle, comprising a bottle 1, four longitudinally distributed permanent magnet rings 8 are fixedly embedded in the inner wall of the bottle 1, a sealed bearing 2 is connected through the lower end surface of the bottle 1, and the sealed bearing 2 is fixedly plugged with Sleeve 3, the sleeve 3 is inserted through the lower end surface of the bottle 1, the inner cavity of the sleeve 3 is a triangular prism structure, the lower end of the sleeve 3 is movably inserted with a rotating plug 4, and the lower end of the rotating plug 4 is fixedly connected with a rotating plug. The inner wall of the handle ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap