Material conveying and positioning device and method thereof and glass processing equipment and method thereof

A technology of material transmission and positioning device, which is applied in the direction of dry goods handling, transportation and packaging, and dry solid materials, etc. It can solve the problems of low accuracy and difficult mechanical alignment of glass substrates, etc., to reduce friction and facilitate alignment operations , to achieve the effect of two-dimensional positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Embodiment 1 of the present invention describes a glass processing equipment, which includes processing areas such as a feeding area, a cleaning area, an air-drying area, and a discharging area. Each processing area is equipped with a conveying roller for conveying glass; The area is equipped with a material transmission positioning device to calibrate and align the glass materials entering the conveyor rollers in the feeding area.

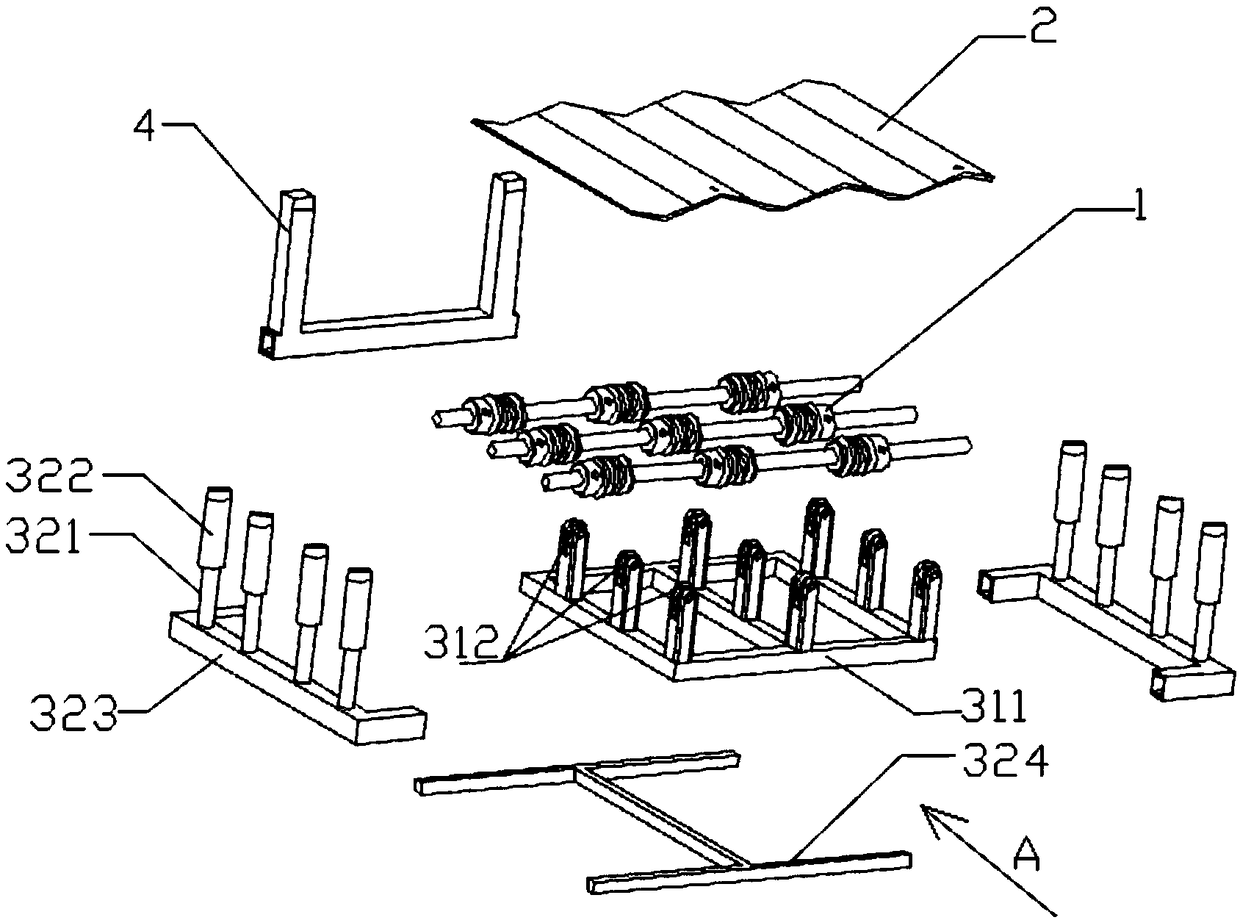

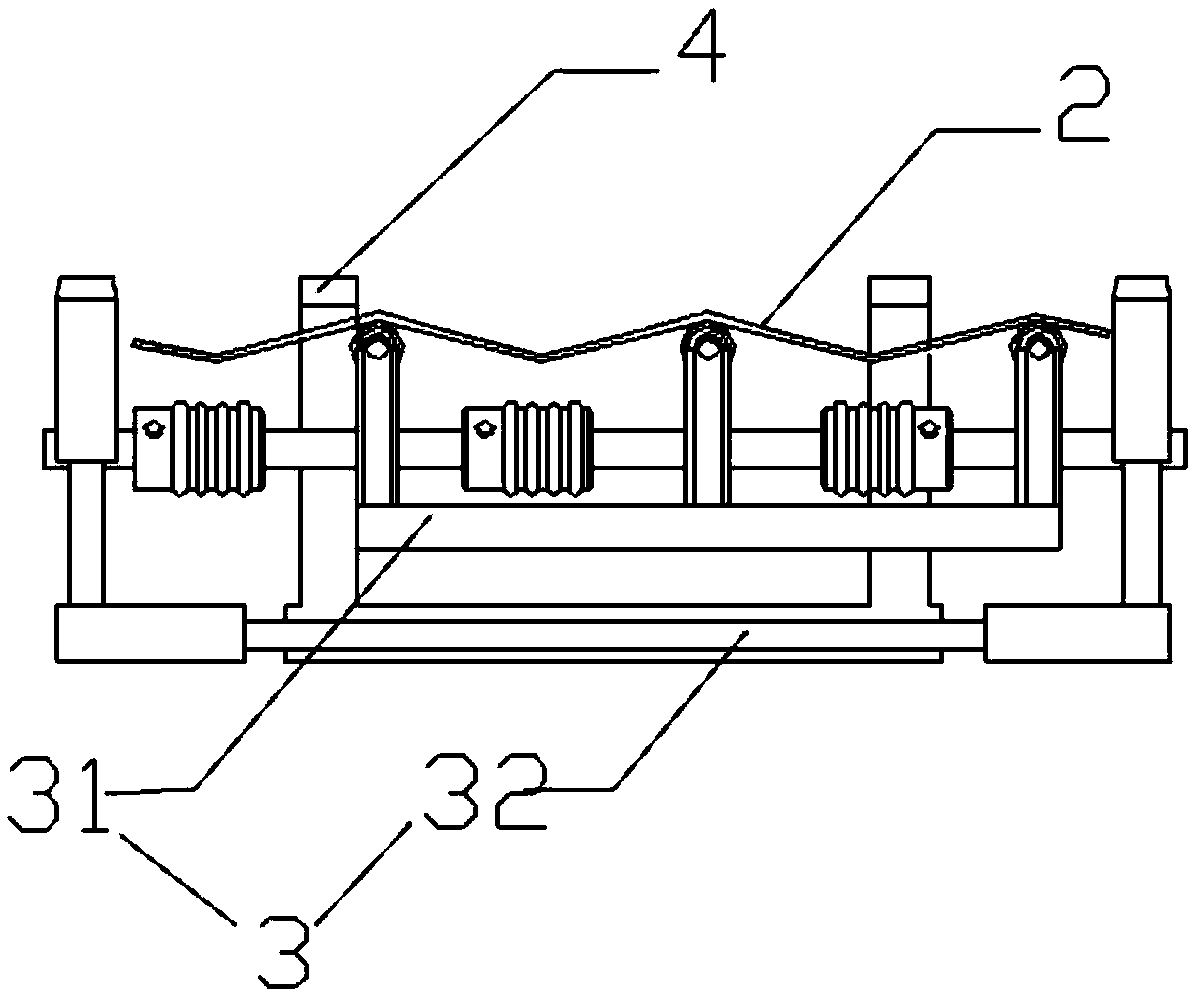

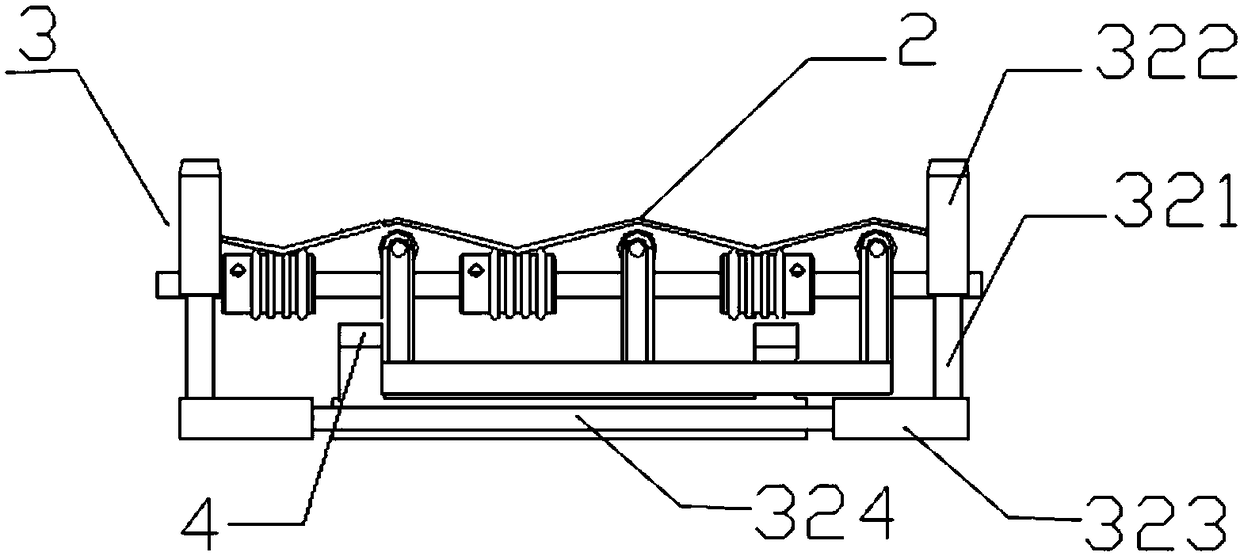

[0063] A material conveying and positioning device in Embodiment 1, such as a glass conveying and positioning device for conveying glass substrates, especially a conveying and positioning device for curved glass, see the attached Figure 1-4 , the curved glass in this embodiment is a wavy curved glass with several crests and troughs. The glass transmission and positioning device includes: several transmission rollers 1 , a deviation correction mechanism 3 and a positioning mechanism 4 . Wherein the conveying roller 1 is set on the base (no...

Embodiment 2

[0077]Embodiment 2 describes a glass processing process, wherein the glass processing process includes a feeding process, a cleaning process, an air-drying process and a material discharging process.

[0078] Among them, in the feeding area of the feeding process, the glass transmission method is as follows:

[0079] 1. Feeding step: put the glass material into the feeding area of the conveying positioning device;

[0080] 2. Alignment correction steps:

[0081] First of all, when the position sensor detects that the glass material is transported to the top of the lifting unit and then sends a signal to the control unit, the control unit controls the operation of the driving part of the lifting unit and drives the lifting unit to lift, and the lifting unit lifts the glass material Lift to the jacking position and stop;

[0082] Then, the control unit drives the alignment unit to perform the alignment operation, and the control unit controls the driving part to drive the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com