Climbing type material platform with gantry crane

A climbing type, material table technology, applied in the direction of lifting frame, lifting device, etc., can solve the problems of easy site accidents, inconvenient transportation, low work efficiency, etc., to reduce the lack of tower crane transportation, reduce the use of tower cranes, and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

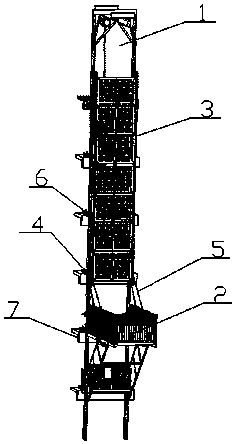

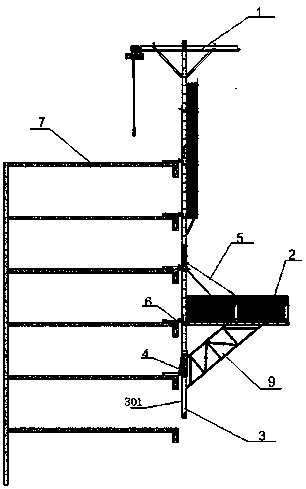

[0037] This embodiment provides a climbing type material platform with a gantry crane, such as figure 1 with 2 As shown, it is mainly composed of a gantry crane 1, a material platform 2, a material platform oblique support 9, two rails 3, a pair of two climbing mechanisms 4, two groups of four long steel cables 5 and four groups of eight floor support shoes 6 , the two tracks 3 are arranged parallel to each other and perpendicular to the ground. The track 3 is located on one side edge of the floor 7 and is perpendicular to the floor 7. The distance between the two tracks 3 is slightly smaller than the width of the material table 2. The gantry crane 1 is fixed on the two tracks 3 The top of the two rails 3 is provided with a number of supporting blocks 301 at equal intervals from top to bottom. They are respectively fixed on both sides of the closed end of the material platform 2, the bottom ends of the other two long steel cables 5 are respectively fixed on the middle sides o...

Embodiment approach 2

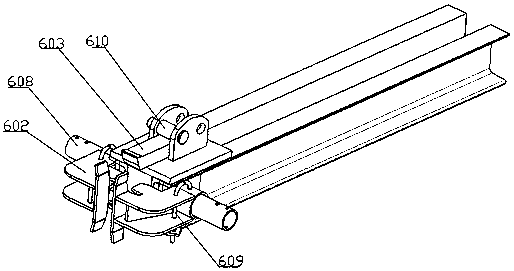

[0042] This embodiment is a further improvement of Embodiment 1. The main improvement is that, in Embodiment 1, if the edge of the floor 7 to be built protrudes a certain distance from the edge of the current floor 7, and the floor support shoe 6 If the position between the base 601 and the third base 801 of the climbing support shoe 8 and the floor 7 is not adjustable, the track 3 will be blocked in the above-mentioned process; and in this embodiment, the base 601 of the floor support shoe 6 and the climbing support The third base 801 of the shoe 8 can move a preset distance to the edge of the floor 7, that is, the track 3 can be moved to a preset distance to the edge of the floor 7, so that it can be applied to working conditions where the upper and lower floors 7 have different widths.

[0043] Specifically, in this embodiment, both the floor support shoe 6 and the climbing support shoe 8 also include an adjustment mechanism (since the structure of the two is the same, only ...

Embodiment approach 3

[0047] This embodiment is a further improvement of Embodiment 2. The main improvement is that, in Embodiment 2, the material table 2 is bulky and inconvenient to transport. However, in this embodiment, the material platform 2 is designed to be foldable, so that it is convenient for transportation.

[0048] Specifically, as Figure 14~16As shown, the material platform 2 is mainly composed of four side panels 203, a rear panel 201, a material platform bottom frame 202, a material platform front flap 208 and four columns 204. The material platform bottom frame 202 is perpendicular to The track 3 is set, the front flap 208 of the material platform is rotatably connected with the front end of the material platform bottom frame 202, the back panel 201 is rotatably connected with the rear end of the material platform bottom frame 202, and the two columns 204 are respectively detachably connected to each other by bolts 205. The edges on both sides of the upper surface of the bottom f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com