Double-acting hydraulic climbing die block system

A hydraulic climbing formwork and hydraulic system technology, applied in the field of double-acting hydraulic automatic formwork climbing system, can solve the problems of low repetition rate, modularization and low standardization, and achieve high degree of automation, high degree of mechanization, and high climbing speed. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

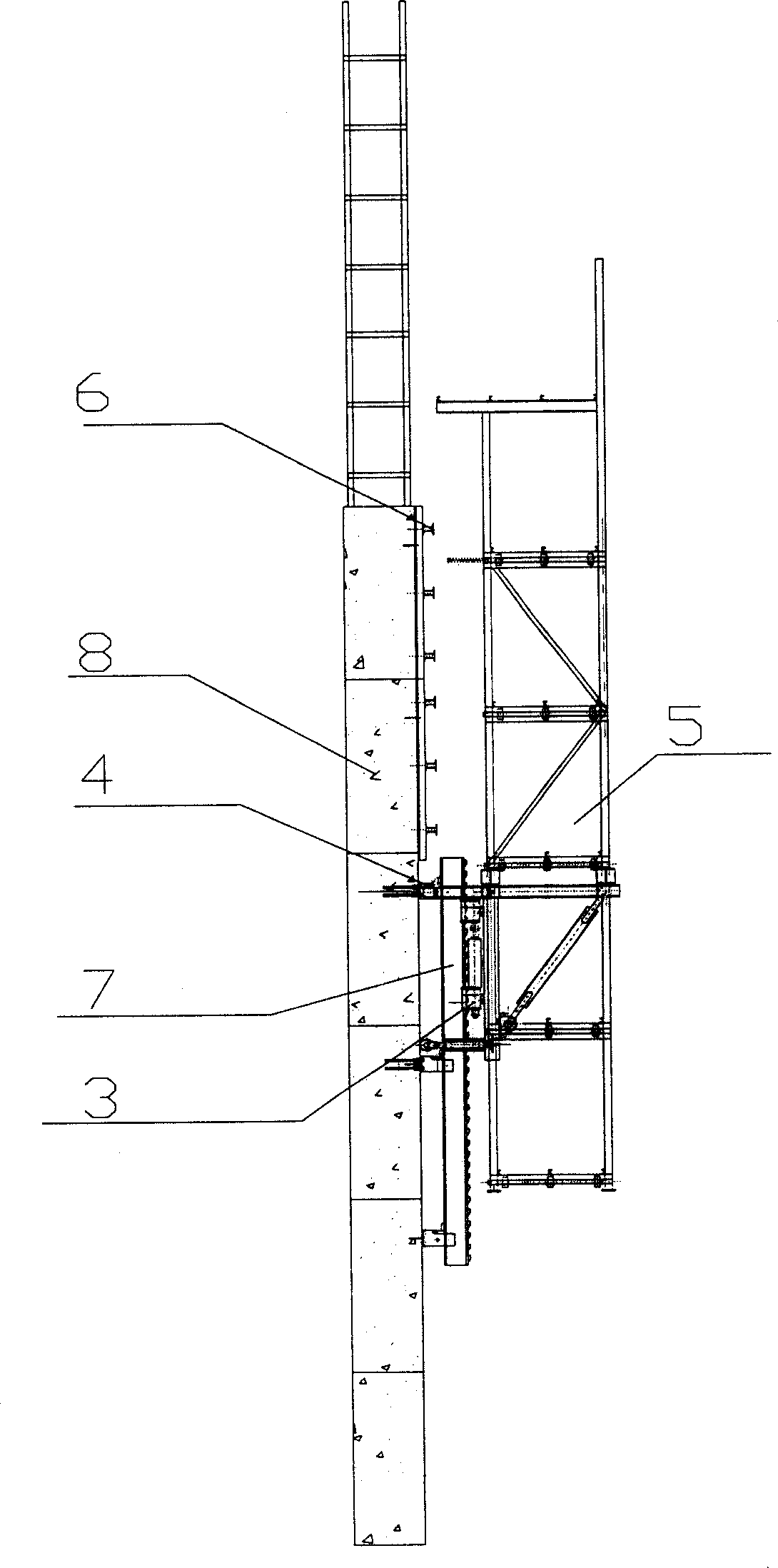

[0007] Such as figure 1 Shown: the double-acting hydraulic formwork climbing system of the present invention includes a hydraulic system (not shown in the figure), a synchronous climbing monitoring system (not shown in the figure), an anti-drop system 3, a climbing frame system 5, a formwork system 6, and a wall-attached system 4. Guide system7. The formwork system 6 is attached to the wall 8, the wall attachment system 4 is fixedly connected to the guide system 7 and the wall 8, and the anti-drop system 3 can move upward in one direction along the guide system 7, so The climbing frame system 5 is fixedly connected with the anti-falling system 3 and can also move upward in one direction along the guiding system 7. The synchronous climbing monitoring system can drive and control the climbing frame system, and collect the working status information of the climbing frame system at the same time , the hydraulic system is connected with the synchronous climbing monitoring system, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com