Self-aligning roller bearing based on split holder

A technology for spherical roller bearings and cages, which is applied to bearing components, shafts and bearings, mechanical equipment, etc. It can solve the problems of small cross-sectional height of cages, low impact resistance, and low strength, so as to improve random swing Phenomenon, strength and impact resistance are improved, and the effect of increasing bearing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

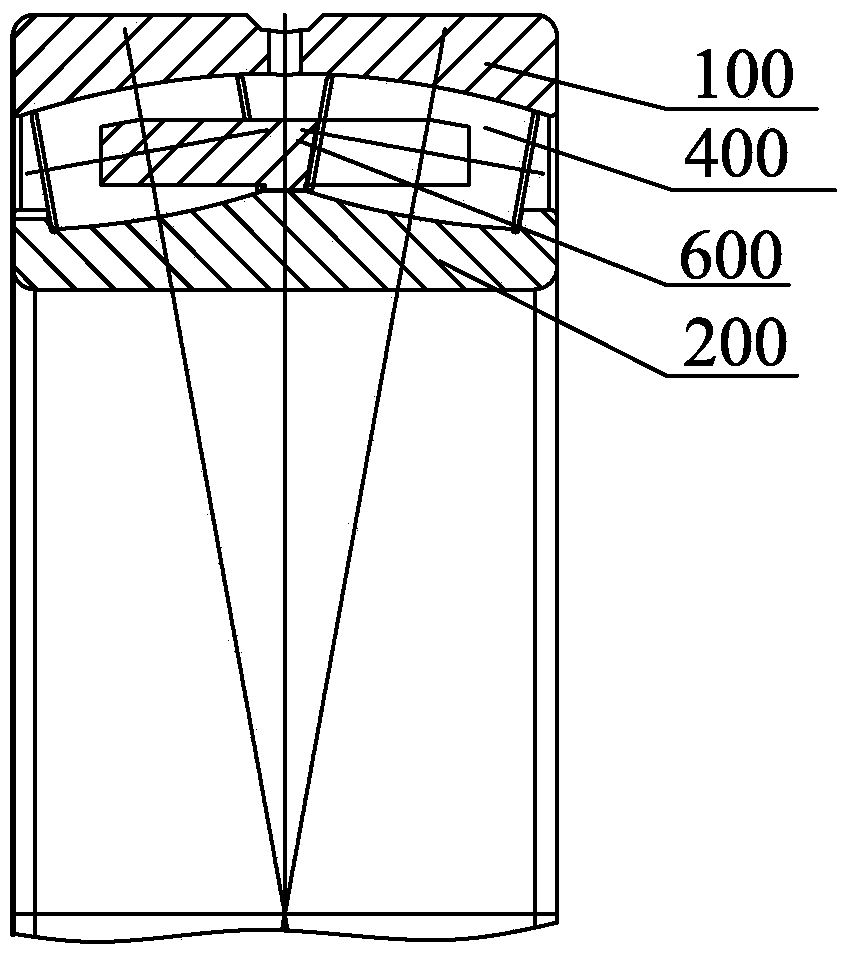

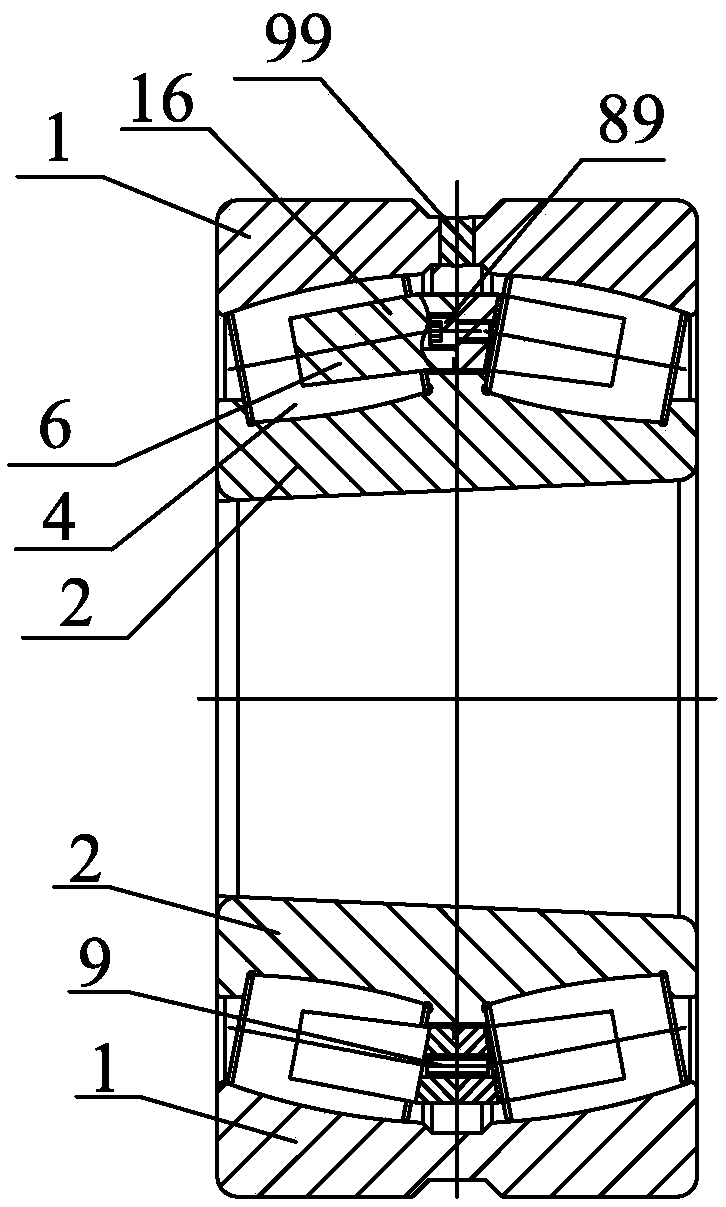

[0023] Such as figure 2 As described above, a spherical roller bearing based on a split cage in the present invention includes a bearing outer ring 1 and a bearing inner ring 2 arranged concentrically, and a bearing outer ring 1 and the bearing inner ring 2 are provided with Split cage.

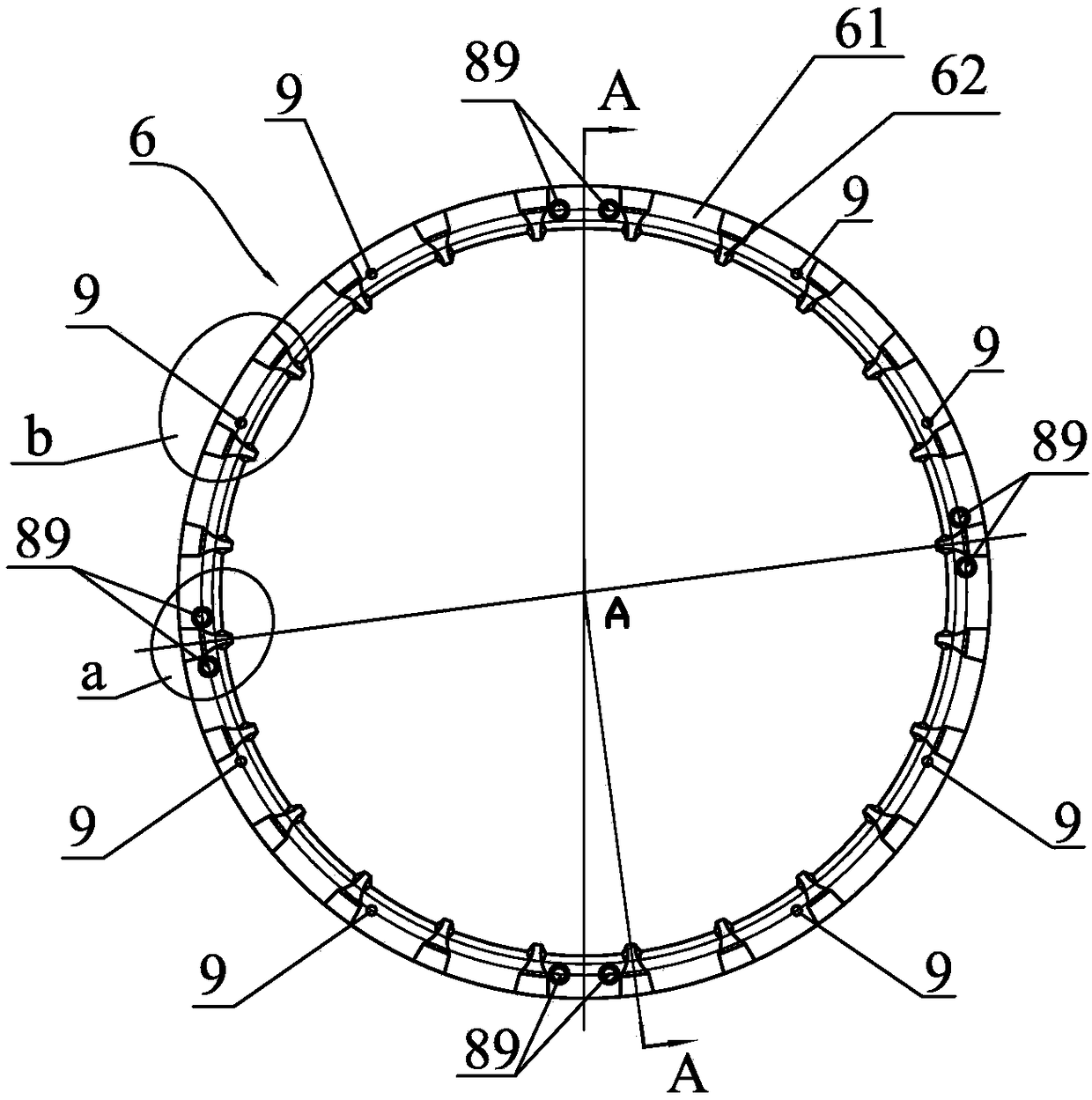

[0024] Such as Figure 2 to Figure 8 As shown, the split cage is composed of the first cage 6 and the second cage 16; the first cage includes a ring-shaped first cage body 61, and the A plurality of first limiting blocks 62 on one side of the first cage body 61, a first pocket 63 is formed between two adjacent first limiting blocks 62, and the first pocket 63 Rolling body 4 is arranged inside.

[0025] Such as Figure 7 , Figure 8 As shown, the second cage includes a ring-shaped second cage body 161 that is the same size as the first cage body 61, and is uniformly arranged on one side of the second cage body 161 in a ring shape. A plurality of second limiting blocks 162 on the top, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com