Integrally-formed sandwich structure and production technology thereof

A sandwich structure and integrated technology, applied in the direction of synthetic resin layered products, layered products, metal layered products, etc., can solve the problems of easy layering of the surface layer and core material, low production efficiency, and insufficient impact resistance. Achieve good apparent size, good interface bonding, improve strength and impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

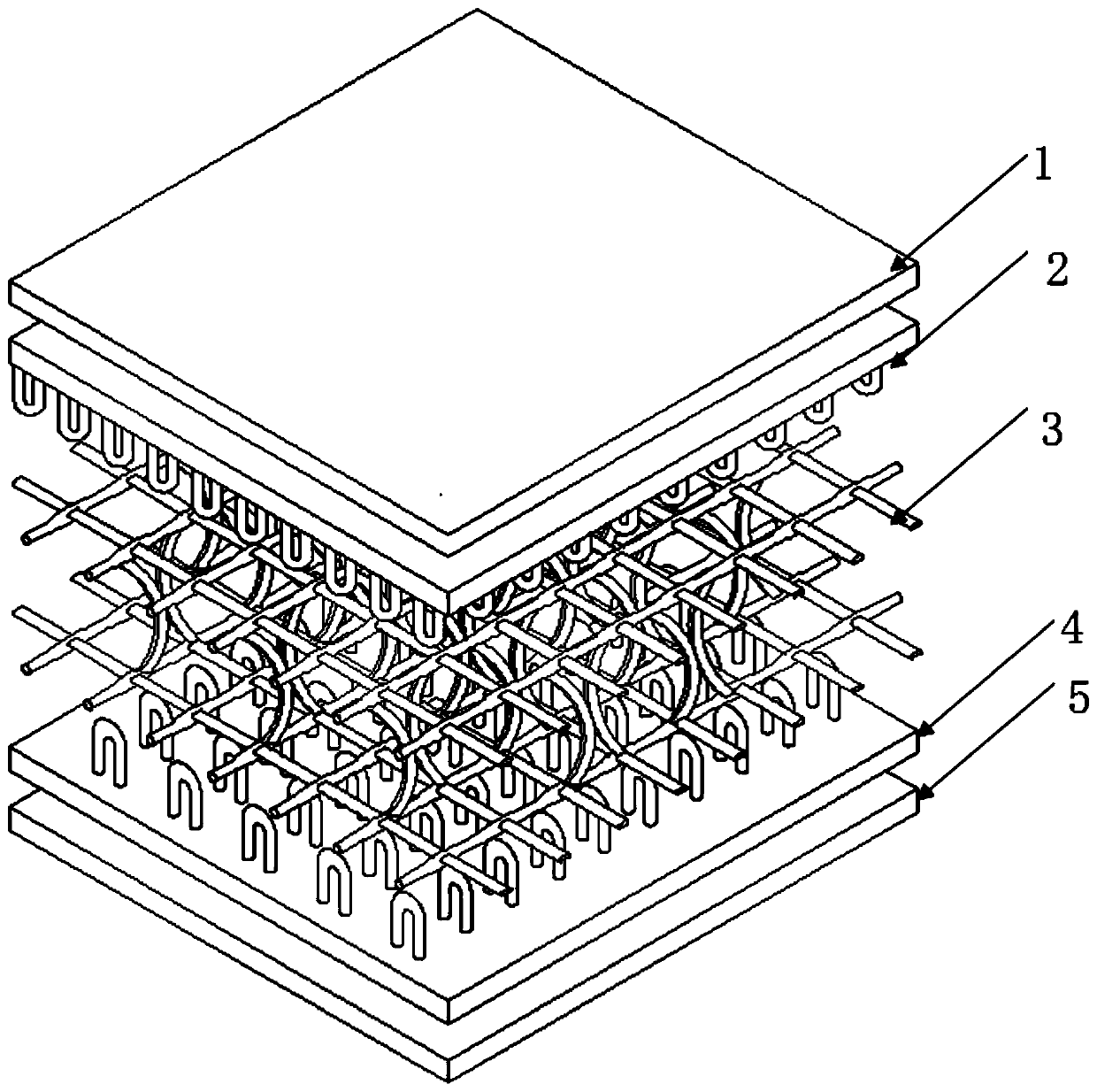

[0030] like figure 1 As shown, an integrally formed sandwich structure includes an upper layer 1, a strength layer, a core layer 3, a strength layer and a lower layer 5 arranged sequentially from top to bottom; the upper layer 1 and the lower layer 5 are surface-treated Aluminum alloy, the reinforcing material of the strength layer is looped fabric, the core layer 3 includes a three-dimensional hollow mesh cloth pre-shaped with a small amount of epoxy resin and a foam material filling the internal voids of the three-dimensional hollow mesh cloth.

[0031] An integrally formed sandwich structure process is prepared according to the following steps:

[0032] Step 1: arrange the aluminum alloy in the mold cavity, and fix it by vacuum adsorption of the mold, where the vacuum degree is 0.093MPa;

[0033] Step 2: Lay the loop fabric, three-dimensional hollow mesh cloth and loop fabric in sequence in the mold;

[0034] Step 3: Import the prepared foamed epoxy resin into the target ...

Embodiment 2

[0038] An integrally formed sandwich structure, including an upper layer 1, a strength layer, a core layer 3, a strength layer and a lower layer 5 arranged sequentially from top to bottom; the upper layer 1 and the lower layer 5 are PVC panels, and the reinforcement material for the strength layer is In the looped fabric, the core layer 3 includes a three-dimensional hollow mesh cloth that has been pre-shaped with a small amount of foamed epoxy resin and a foam material that fills the internal voids of the three-dimensional hollow mesh cloth.

[0039] An integrally formed sandwich structure process is prepared according to the following steps:

[0040] Step 1: arrange PVC panels in the mold cavity, and fix them by vacuum adsorption of the mold, where the vacuum degree is 0.095MPa;

[0041] Step 2: Lay the loop fabric, three-dimensional hollow mesh cloth and loop fabric in sequence in the mold;

[0042] Step 3: Import the prepared foamed epoxy resin into the target mold;

[0...

Embodiment 3

[0045] Embodiment 3: an integrally formed sandwich structure, including an upper layer 1, a strength layer, a core layer 3, a strength layer and a lower layer 5 arranged sequentially from top to bottom; the upper layer 1 and the lower layer 5 are non-woven felts, The reinforcing material of the strength layer is looped fabric, and the core layer 3 includes a three-dimensional hollow mesh cloth pre-shaped with a small amount of foamed epoxy resin and a foam material filling the internal voids of the three-dimensional hollow mesh cloth.

[0046] An integrally formed sandwich structure process is prepared according to the following steps:

[0047] Step 1: arrange the non-woven felt in the mold cavity, and fix it by vacuum adsorption of the mold, where the vacuum degree is 0.097MPa;

[0048] Step 2: Spread loop fabric, three-dimensional hollow mesh cloth, and loop fabric in sequence in the mold;

[0049] Step 3: Import the prepared foamed epoxy resin into the target mold;

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com