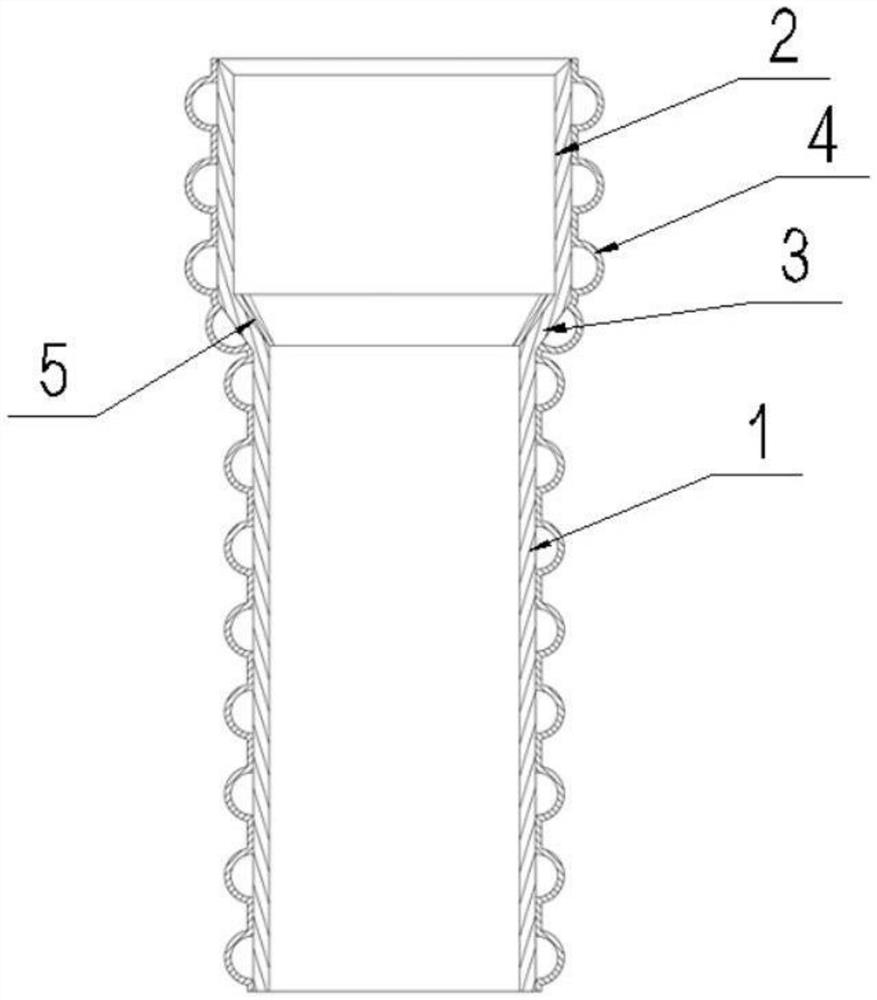

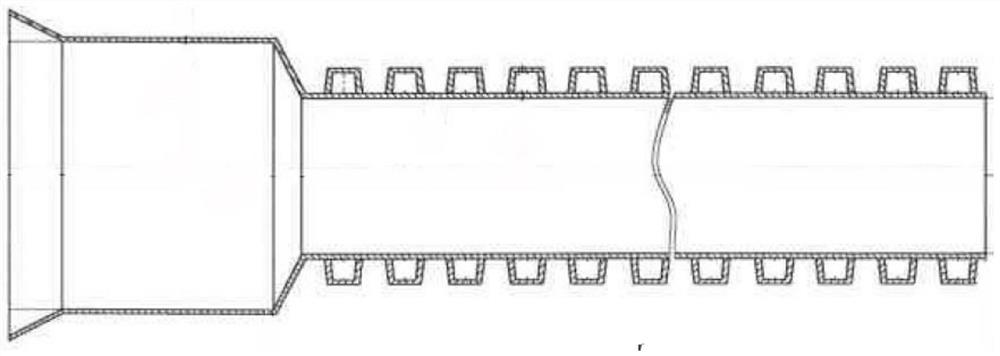

PP-NACC nano-scale active calcium carbonate blended polypropylene flaring reinforced double-wall corrugated pipe

A PP-NACC, 1.PP-NACC technology, applied in the field of double-wall corrugated pipe raw material composition and its preparation, pipe structure, can solve the problems of easy deformation, breakage, deformation at the flaring, etc., to improve the strength and Impact resistance, enhanced strength and impact resistance, less deformation and breakage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

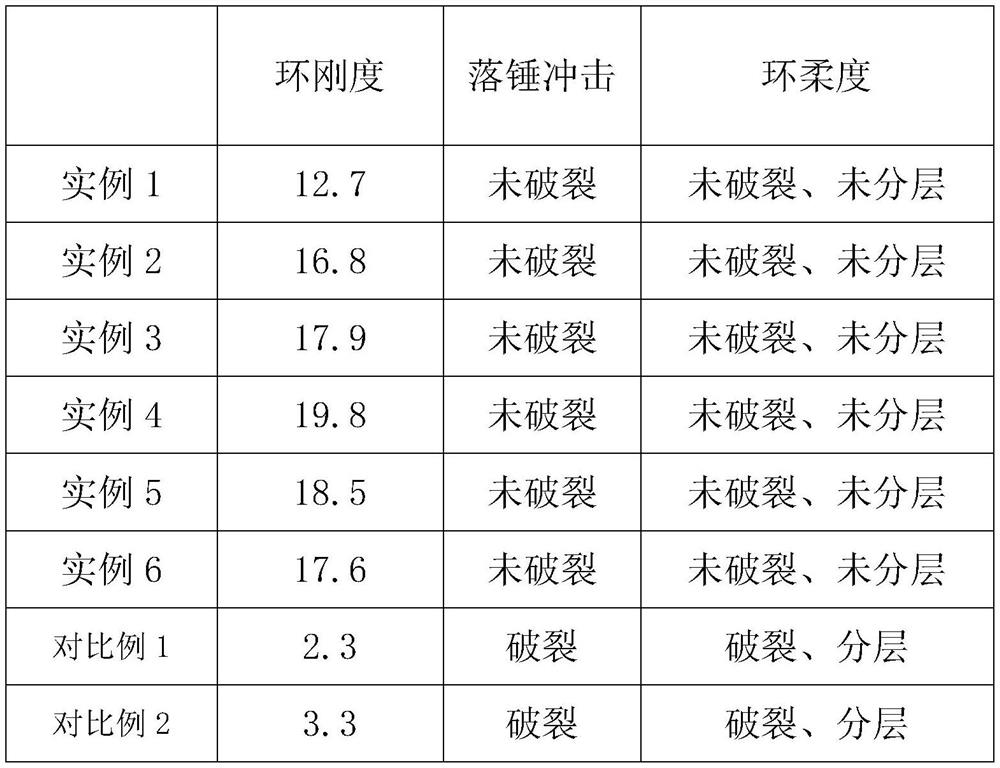

Embodiment 1

[0042] The composition, in parts by weight, includes: 60 parts of polypropylene powder, 28 parts of nano-scale activated calcium carbonate, 12 parts of EPDM rubber, 2 parts of phosphite antioxidant, 2 parts of compatibilizer, and coloring agent 1 part, 2 parts of β-crystal nucleating agent.

[0043] The preparation method of the composition comprises the following preparation steps:

[0044] S1: Weigh the polypropylene powder, nano-scale activated calcium carbonate, and EPDM according to the formula ratio;

[0045] S2: put the mixture obtained in S1 into a high-speed mixer, mix and stir evenly, and then discharge to obtain a mixture A;

[0046] S3: Weigh the phosphite antioxidant, compatibilizer, colorant, and β crystal nucleating agent according to the formula ratio;

[0047] S4: put the mixture obtained in S3 into a high-speed mixer, mix and stir evenly, and then discharge to obtain the mixture B;

[0048] S5: Add the mixture A and the mixture B together into the high-spe...

Embodiment 2

[0058] The difference between this example and Example 1 is that the composition, in parts by weight, includes: 60 parts of polypropylene powder, 29 parts of nano-scale activated calcium carbonate, 10 parts of EPDM rubber, phosphite antioxidant 2 parts, 2 parts of compatibilizer, 1 part of coloring agent, 2 parts of β-crystal nucleating agent.

Embodiment 3

[0060] The difference between this example and Example 1 is that the composition includes, in parts by weight: 60 parts of polypropylene powder, 29 parts of nanoscale activated calcium carbonate, 11 parts of EPDM rubber, and phosphite antioxidant 2 parts, 2 parts of compatibilizer, 1 part of coloring agent, 2 parts of β-crystal nucleating agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com