A terminal with a guide structure

A terminal and guide structure technology, which is applied in the field of terminal with guide structure, can solve the problems of no guide structure, insufficient pull-out force, conductor inclination, etc., and achieve the effects of stable contact, improved quality and precise guide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

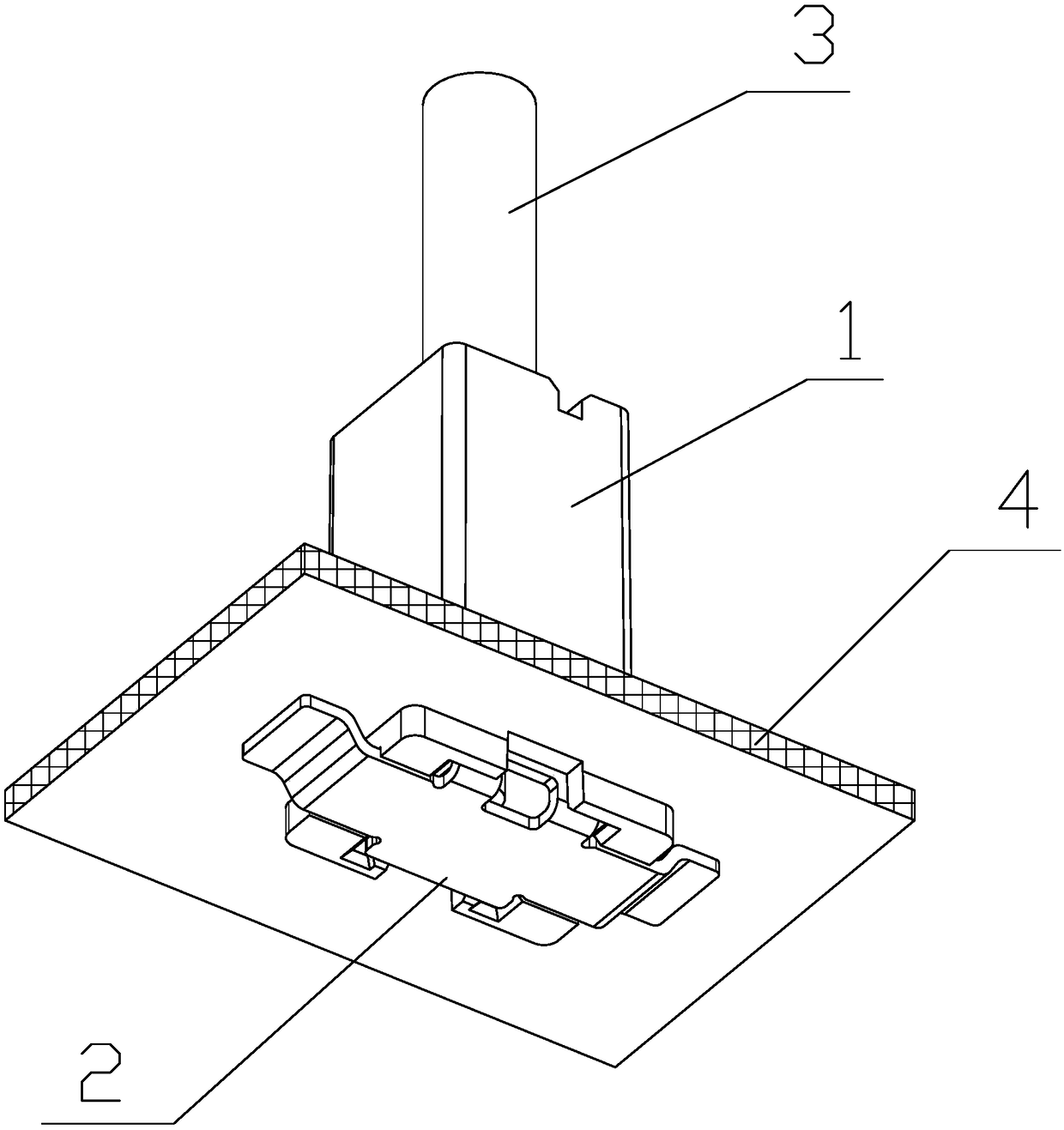

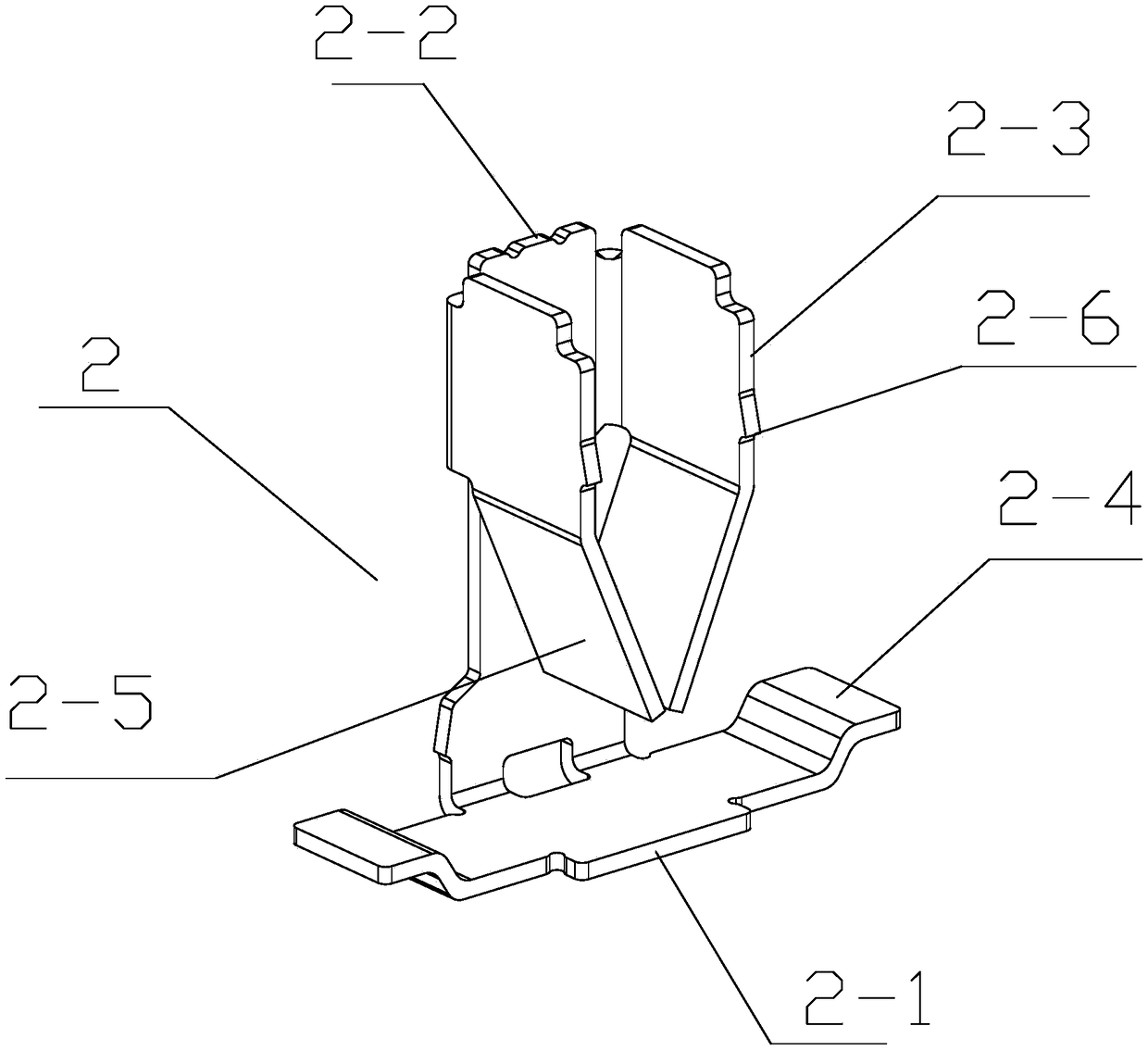

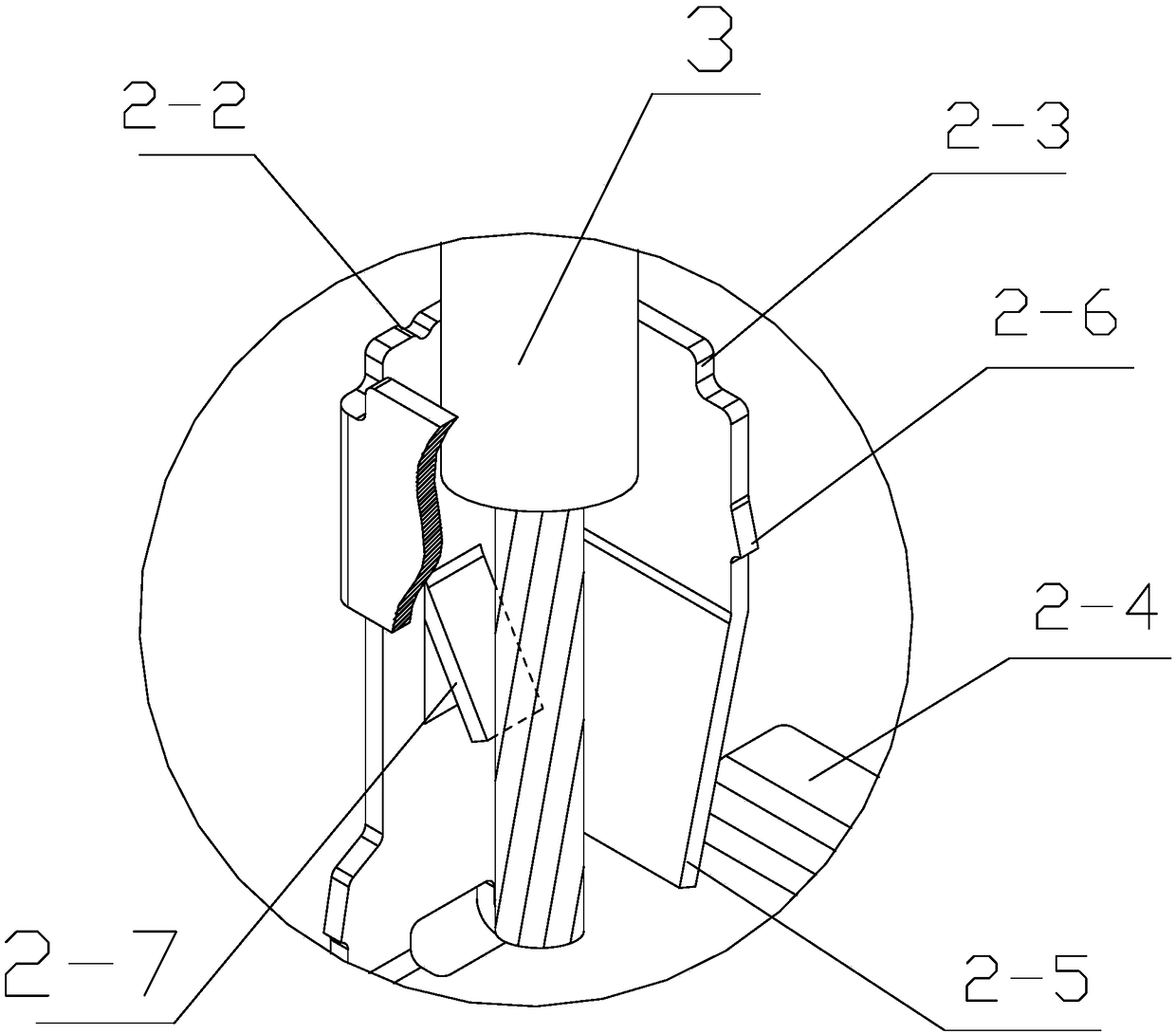

[0014] A connection terminal with a guiding structure, including an insulating housing 1, a conductor 2, a wire 3 and a PCB board 4, the insulating housing 1 runs through up and down, and the PCB board 4 is sleeved outside the insulating housing 1, and the conductor 2 Including the horizontal support part 2-1 and the vertical support part 2-2, both sides of the vertical support part 2-2 are bent to one side of the horizontal support part 2-1 to form a side part 2-3, and the vertical support The part 2-2 and the side part 2-3 are sleeved in the insulating housing 1, and the wire 3 is inserted into the insulating housing 1 from the end away from the horizontal support part 2-1, and the insertion end of the wire 3 is connected to the side part 2. -3 contact, a contact portion 2-4 for contacting with the PCB board 4 is punched out at both ends of the horizontal support portion 2-1. An eccentric groove is arranged on the upper end of the insulating shell, and the eccentric groove i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com