A kind of preparation method of fish oil soft capsule

A technology of soft capsules and fish oil, applied in capsule delivery, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc., can solve the problems of low gel performance, non-disintegration, long disintegration time, etc. Achieve the effects of reducing disintegration time, eliminating purchase concerns, and expanding sales range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

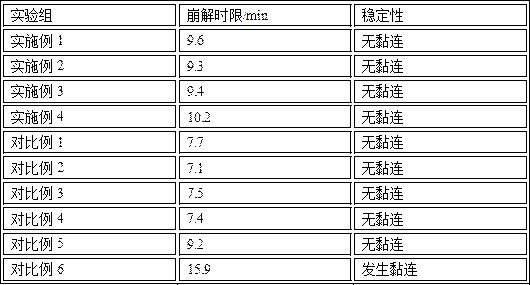

Examples

Embodiment 1

[0032] A preparation method for fish oil soft capsules, comprising the steps of:

[0033] 1) Prepare the contents of the capsules: dry and grind the Herbs officinalis and Digupi into powder, then add them to ethanol with a volume fraction of 50% for 3 hours, and then add fibers to the extracts Composite enzymatic hydrolysis solution with a mass percentage of 0.5% suzyme and 0.01% pectinase; adjust the pH of the extract to 5.5, keep it warm at 40-60°C, oscillate with ultrasonic waves, and enzymatically hydrolyze for 0.5h; After the enzymolysis, take the supernatant, repeat the extraction of the residue three times according to the above extraction and enzymolysis steps, and combine the supernatants extracted each time; evaporate the supernatant to a water content of 5%, add ethyl acetate Extraction is carried out to obtain ethyl acetate extract, and the ethyl acetate extract is evaporated to a paste, that is, to obtain the extract of P. Deep-sea fish oil: vitamin E=85:0.1, and...

Embodiment 2

[0039] A preparation method for fish oil soft capsules, comprising the steps of:

[0040]1) Prepare the contents of the capsules: dry and grind the Herbs officinalis and Digupi into powder, then add them into alcohol with a volume fraction of 60% ethanol for 3 hours of extraction, and then add fibers to the extracts respectively Composite enzymatic hydrolysis solution with 0.7% by mass percentage of suzyme and 0.04% by mass of pectinase; adjust the pH of the extract to 6.0, keep it warm at 40-60°C, oscillate with ultrasonic waves, and enzymatically hydrolyze for 1.0h; After the enzymolysis, take the supernatant, repeat the extraction of the residue 3 times according to the above leaching and enzymolysis steps, combine the supernatants extracted each time; evaporate the supernatant to a water content of 7%, add ethyl acetate Extraction is carried out to obtain ethyl acetate extract, and the ethyl acetate extract is evaporated to a paste, that is, to obtain the extract of P. De...

Embodiment 3

[0046] A preparation method for fish oil soft capsules, comprising the steps of:

[0047] 1) Prepare the contents of the capsules: dry and grind the Herbs officinalis and Digupi into powder, then add them to ethanol with a volume fraction of 70% for 3 hours, and then add fibers to the extracts Composite enzymolysis solution with 0.8% by mass percentage of suzyme and 0.07% by mass of pectinase; adjust the pH of the extract to 6.5, keep it warm at 40-60°C, oscillate with ultrasonic waves, and enzymatically hydrolyze for 1.5 hours; After the enzymolysis, take the supernatant, repeat the extraction of the residue three times according to the above extraction and enzymolysis steps, and combine the supernatants extracted each time; evaporate the supernatant to a water content of 12%, add ethyl acetate Extraction is carried out to obtain ethyl acetate extract, and the ethyl acetate extract is evaporated to a paste, that is, to obtain the extract of P. Deep-sea fish oil: vitamin E=90...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com