Simple and efficient two-way stirring device for production of white carbon black

A two-way stirring, white carbon black technology, applied to mixers with rotating stirring devices, transportation, packaging, dissolution, etc., can solve the problems of low stirring efficiency, easy deposition of bottom materials, uneven stirring, high cost, etc., to achieve reduction The effect of shaking the tank body, improving the stirring efficiency and reducing the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

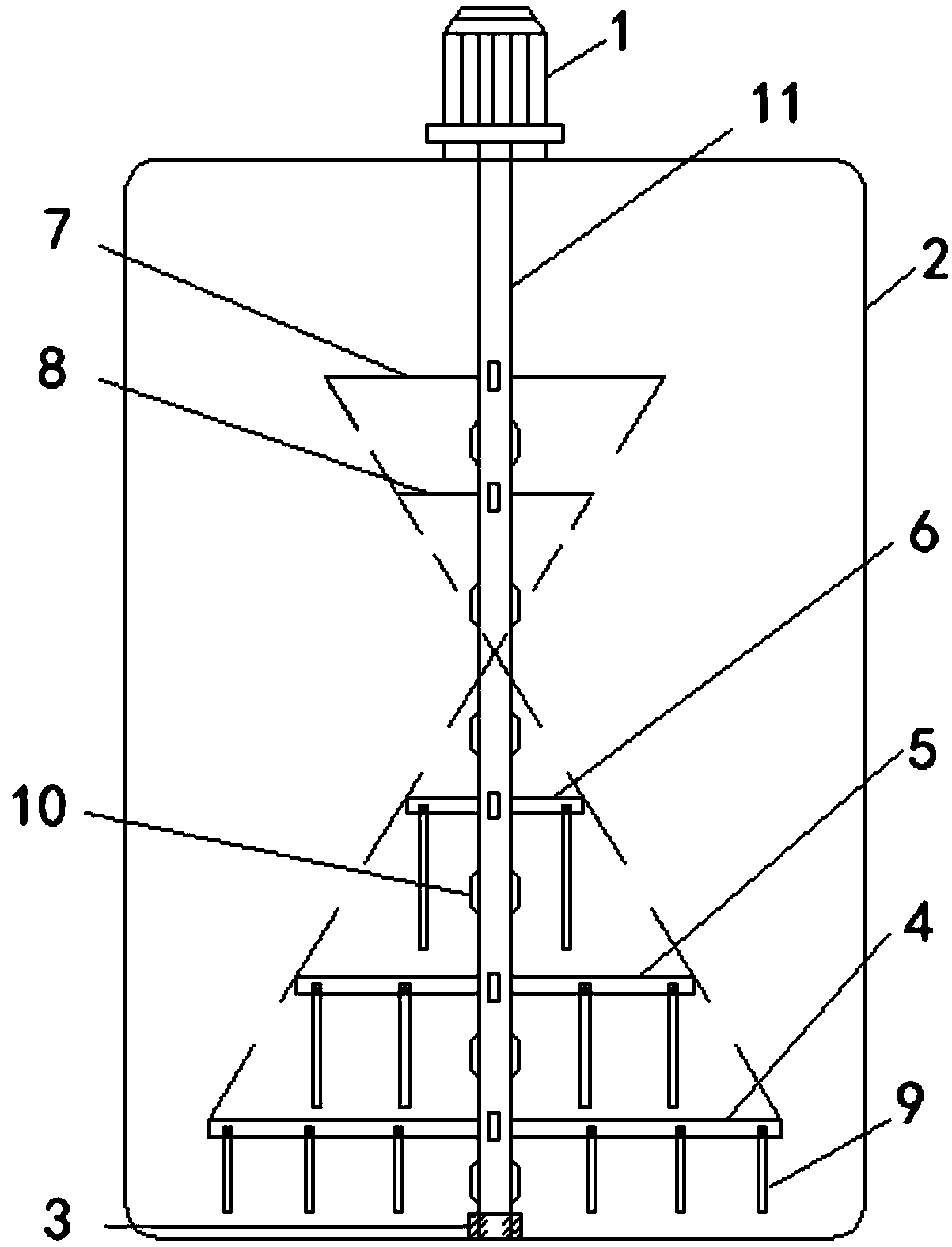

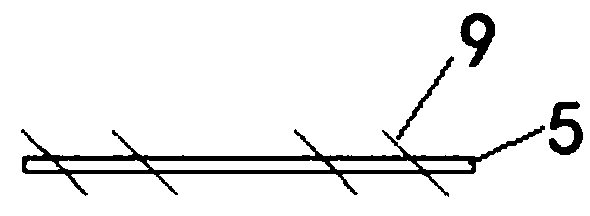

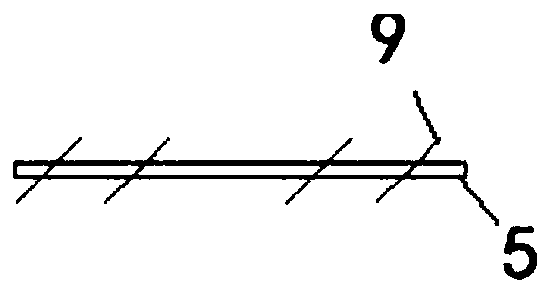

[0020] Such as figure 1 , figure 2 , image 3 As shown, the present invention is achieved in this way, a simple and efficient two-way stirring device applied to the production of white carbon black, the center of the top of the tank body 2 is provided with a variable speed motor 1, and the variable speed motor 1 is connected to one end of the stirring shaft 11, and the stirring shaft 11 The other end goes deep into the tank body 2 and is connected with the positioning hole 3 at the center position of the bottom end of the tank body 2. The bottom position of the stirring shaft 11 is horizontally provided with a first stirring rod 4, and the stirring shaft on the top of the first stirring rod 4 is sequentially A second stirring rod 5 and a third stirring rod 6 are horizontally arranged, and several stirring plates 9 are uniformly connected respectively on the first stirring rod 4, the second stirring rod 5 and the third stirring rod 6, and the stirring shafts The upper part i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap