Equipment and method for protecting large crystalline flake graphite in graphite beneficiation

A technology for protecting equipment and large flakes, applied in flotation, solid separation, grain processing, etc., can solve problems such as affecting the particle size and yield of large flake graphite, great damage to graphite flakes, restricting the application of graphite, etc. The effect of easy popularization, good protection effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

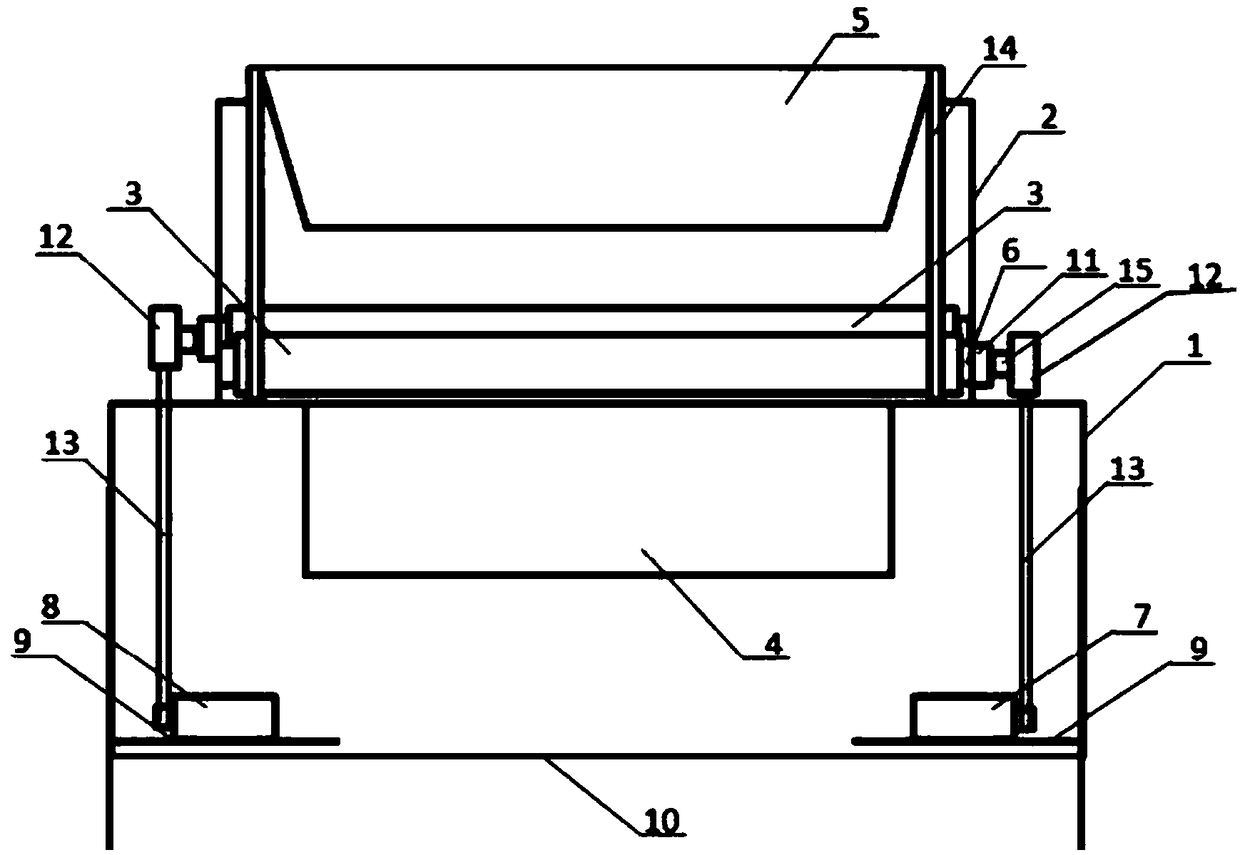

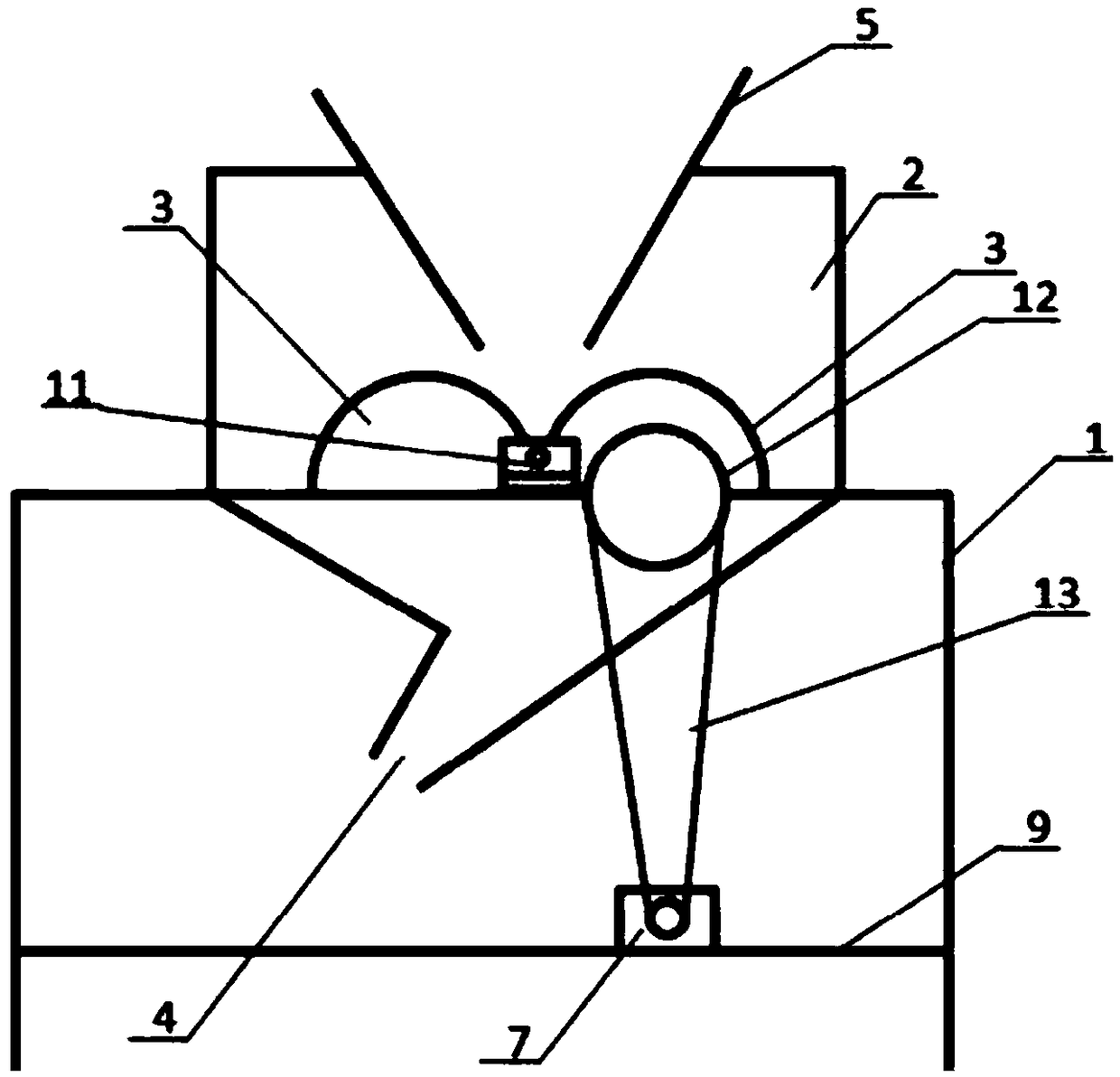

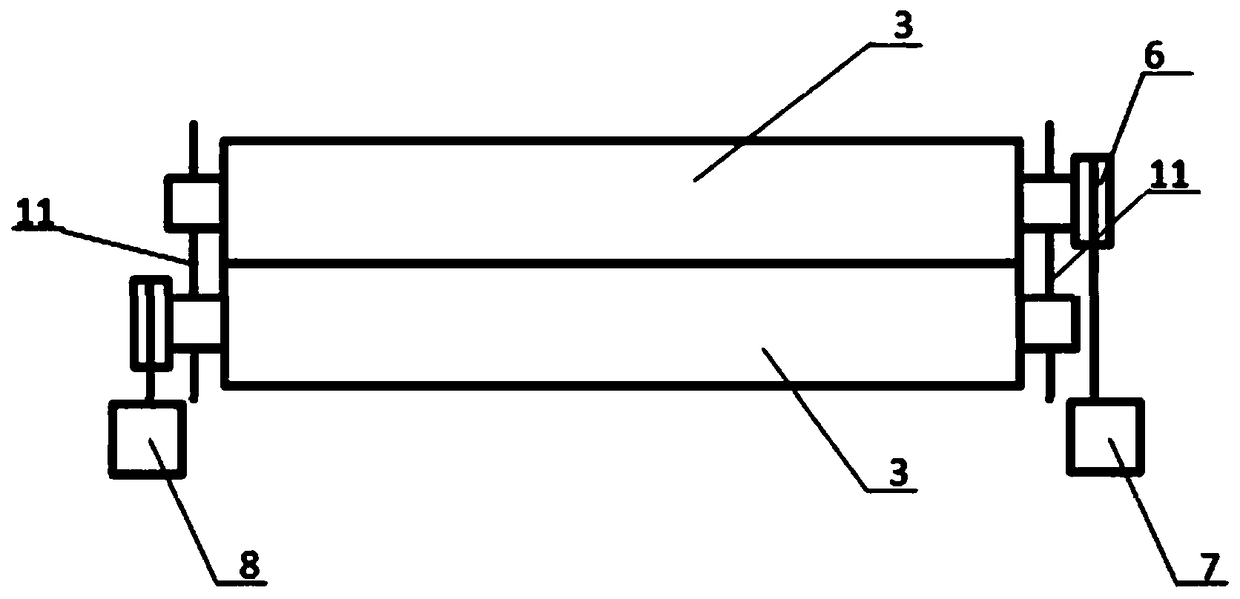

[0020] Such as Figure 1-5 As shown, the large scale protection equipment in graphite beneficiation includes a bracket 1, a tank body 2, a wear-resistant rubber roller 3, a discharge port 4, a hopper 5, a bearing bush 6, a speed regulating motor I7, and a speed regulating motor II8 , motor support plate 9, support tie bar 10, top tightening device 11, belt pulley 12, belt 13, hopper support 14, wear-resistant rubber roller shaft 15.

[0021] Wear-resistant rubber roller 3 is two, promptly two are a group, passes wear-resistant rubber roller shaft 15 in the middle, is placed side by side horizontally, and gap is 0.1mm, is fixed on support 1 upper end. The lower end of the support 1 is provided with four support ribs 10 to make the support 1 more stable. One end of a wear-resistant rubber roller 3 is equipped with a belt pulley 12, and the belt pulley 12 is connected with the speed regulating motor I7 by a belt 13. The other end of another wear-resistant rubber roller 3 is equ...

Embodiment 2

[0029] Such as Figure 1-5 As shown, the large scale protection equipment in graphite beneficiation includes a bracket 1, a tank body 2, a wear-resistant rubber roller 3, a discharge port 4, a hopper 5, a bearing bush 6, a speed regulating motor I7, and a speed regulating motor II8 , motor support plate 9, support tie bar 10, top tightening device 11, belt pulley 12, belt 13, hopper support 14, wear-resistant rubber roller shaft 15.

[0030] There are two wear-resistant rubber rollers 3, which pass through the wear-resistant rubber roller shaft 15 in the middle, are placed side by side horizontally, and the gap is 0mm, and are fixed on the support 1 upper end. The lower end of the support 1 is provided with four support ribs 10 to make the support 1 more stable. One end of a wear-resistant rubber roller 3 is equipped with a belt pulley 12, and the belt pulley 12 is connected with the speed regulating motor I7 by a belt 13. The other end of another wear-resistant rubber rolle...

Embodiment 3

[0048] Such as Figure 1-5 As shown, the large scale protection equipment in graphite beneficiation includes a bracket 1, a tank body 2, a wear-resistant rubber roller 3, a discharge port 4, a hopper 5, a bearing bush 6, a speed regulating motor I7, and a speed regulating motor II8 , motor support plate 9, support tie bar 10, top tightening device 11, belt pulley 12, belt 13, hopper support 14, wear-resistant rubber roller shaft 15.

[0049] Such as Figure 5 As shown, there are four wear-resistant rubber rollers 3, two of which form a group, placed side by side horizontally, two groups placed vertically up and down, wear-resistant rubber rollers 3 pass through the wear-resistant rubber roller shaft 15 in the middle, and the gap is 0mm, fixed on the bracket 1 upper end. A material baffle plate 16 is set between two groups of wear-resistant rubber rollers, and four support ribs 10 are arranged at the lower end of the support 1 to make the support 1 more stable. One end of a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com