Rotary type sand sorting and screening equipment

A screening equipment and rotary technology, applied in the fields of sieves, solid separation, chemical instruments and methods, etc., can solve the problems of reduced screening effect and efficiency, time-consuming and laborious shaking and lifting of screen plates, etc., and achieve the effect of simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

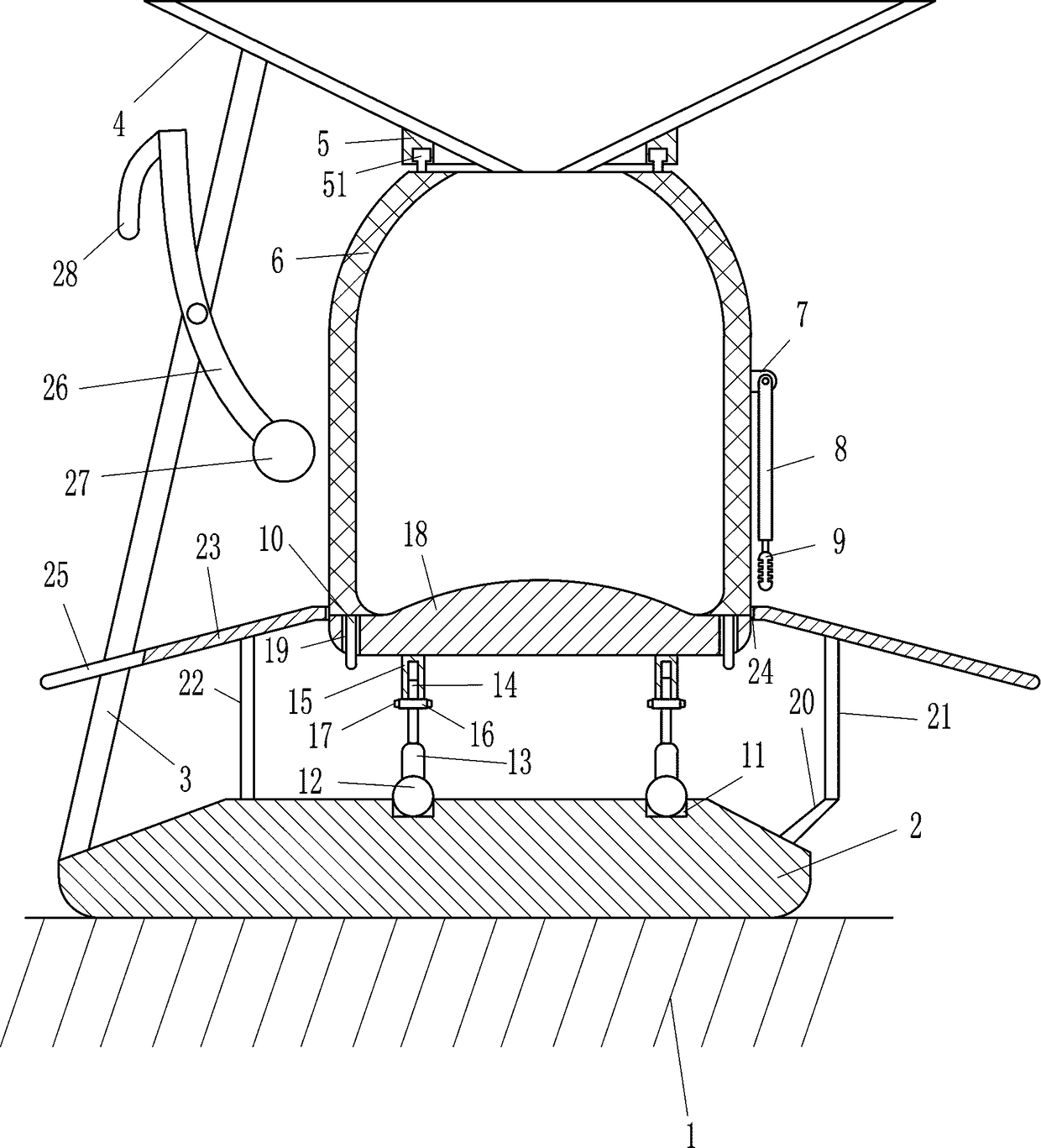

[0015] A kind of sand rotary classification and screening equipment, such as figure 1 As shown, it includes a base 2, a bracket 3, a feed hopper 4, an annular slide rail 5, a slider 51, a screen frame 6, a connecting block 7, a telescopic rod 8, a handle 9, an insertion rod 10, a roller 12, a One connecting rod 13, bolt 14, hollow rod 15, nut 16, handwheel 17 and chassis 18, base 2 is placed on the ground 1, the right side of base 2 top has annular wheel groove 11, is provided with two in annular wheel groove 11 A roller 12, the top of the roller 12 is connected with a first connecting rod 13, the top of the first connecting rod 13 is connected with a bolt 14, the bolt 14 is provided with a nut 16 in a threaded manner, and the outside of the nut 16 is provided with a handwheel 17, and the bolt 14 14 top is covered with hollow rod 15, and hollow rod 15 is positioned at the top of nut 16, and chassis 18 is connected with the top of left and right sides hollow rod 15, and jack 19...

Embodiment 2

[0017] A kind of sand rotary classification and screening equipment, such as figure 1 As shown, it includes a base 2, a bracket 3, a feed hopper 4, an annular slide rail 5, a slider 51, a screen frame 6, a connecting block 7, a telescopic rod 8, a handle 9, an insertion rod 10, a roller 12, a One connecting rod 13, bolt 14, hollow rod 15, nut 16, handwheel 17 and chassis 18, base 2 is placed on the ground 1, the right side of base 2 top has annular wheel groove 11, is provided with two in annular wheel groove 11 A roller 12, the top of the roller 12 is connected with a first connecting rod 13, the top of the first connecting rod 13 is connected with a bolt 14, the bolt 14 is provided with a nut 16 in a threaded manner, and the outside of the nut 16 is provided with a handwheel 17, and the bolt 14 14 top is covered with hollow rod 15, and hollow rod 15 is positioned at the top of nut 16, and chassis 18 is connected with the top of left and right sides hollow rod 15, and jack 19...

Embodiment 3

[0020] A kind of sand rotary classification and screening equipment, such as figure 1 As shown, it includes a base 2, a bracket 3, a feed hopper 4, an annular slide rail 5, a slider 51, a screen frame 6, a connecting block 7, a telescopic rod 8, a handle 9, an insertion rod 10, a roller 12, a One connecting rod 13, bolt 14, hollow rod 15, nut 16, handwheel 17 and chassis 18, base 2 is placed on the ground 1, the right side of base 2 top has annular wheel groove 11, is provided with two in annular wheel groove 11 A roller 12, the top of the roller 12 is connected with a first connecting rod 13, the top of the first connecting rod 13 is connected with a bolt 14, the bolt 14 is provided with a nut 16 in a threaded manner, and the outside of the nut 16 is provided with a handwheel 17, and the bolt 14 14 top is covered with hollow rod 15, and hollow rod 15 is positioned at the top of nut 16, and chassis 18 is connected with the top of left and right sides hollow rod 15, and jack 19...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com