Stone impurity roller centrifugal removal device

A centrifugal and drum technology, which is applied in the direction of solid separation, separating solids from solids with airflow, and filtering and sieving, can solve the problems of operating environment pollution, increasing manpower and material investment, and single function, so as to avoid dust. pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

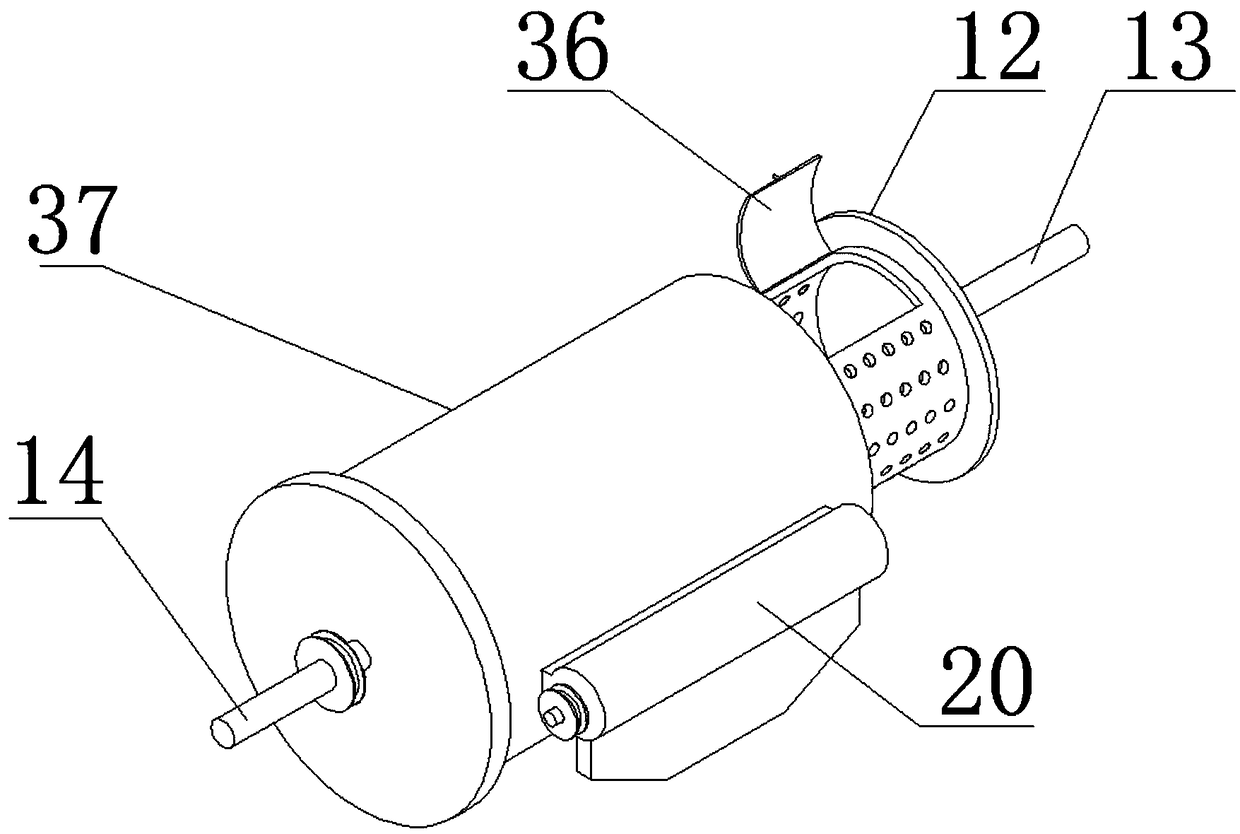

[0033] As a preferred embodiment of the present invention, one side of the centrifugal disc 19 is provided with an annular platform, the annular platform and the centrifugal generating sleeve 37 form a rotary pair, and the inclined blades 42 are arranged inside the annular platform.

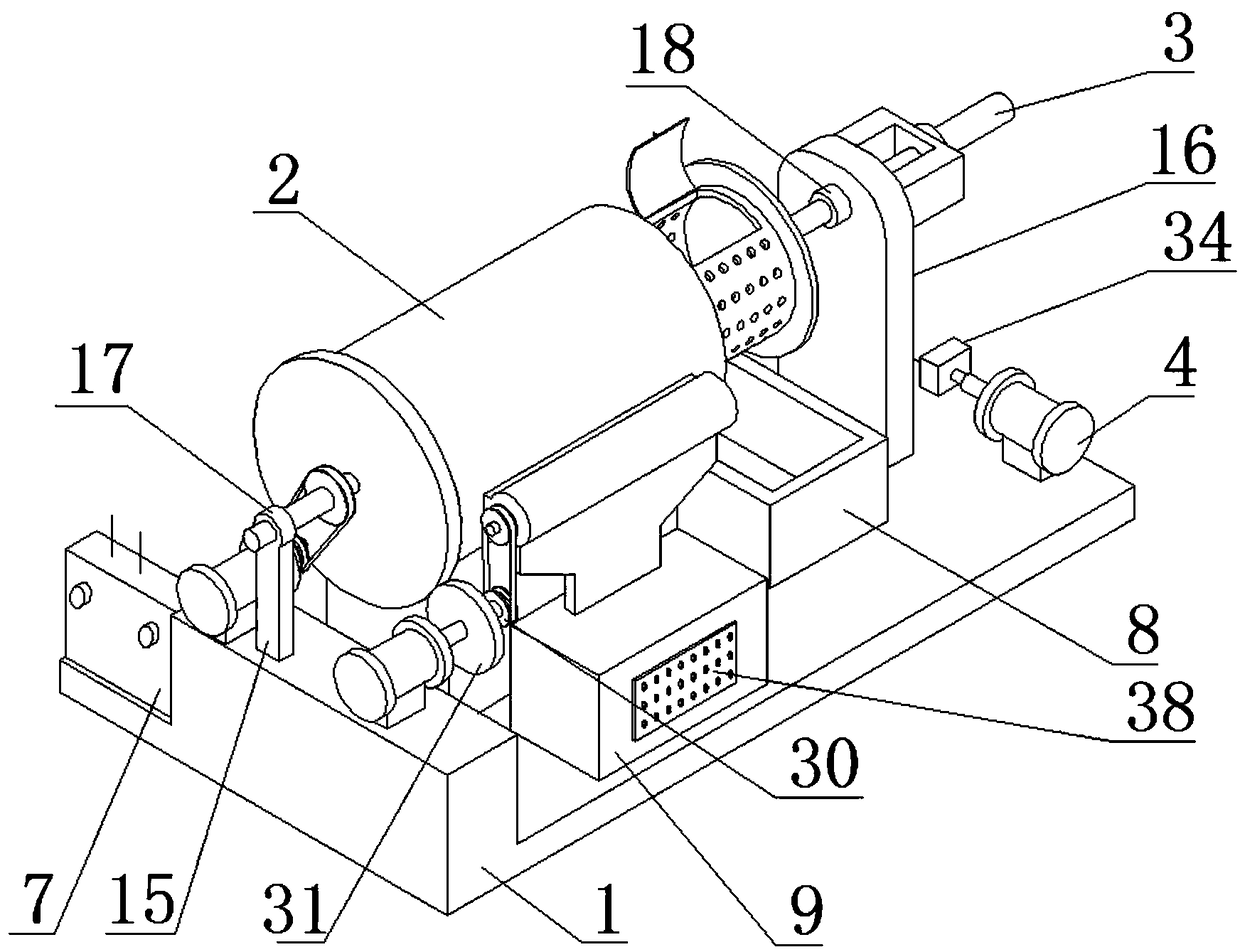

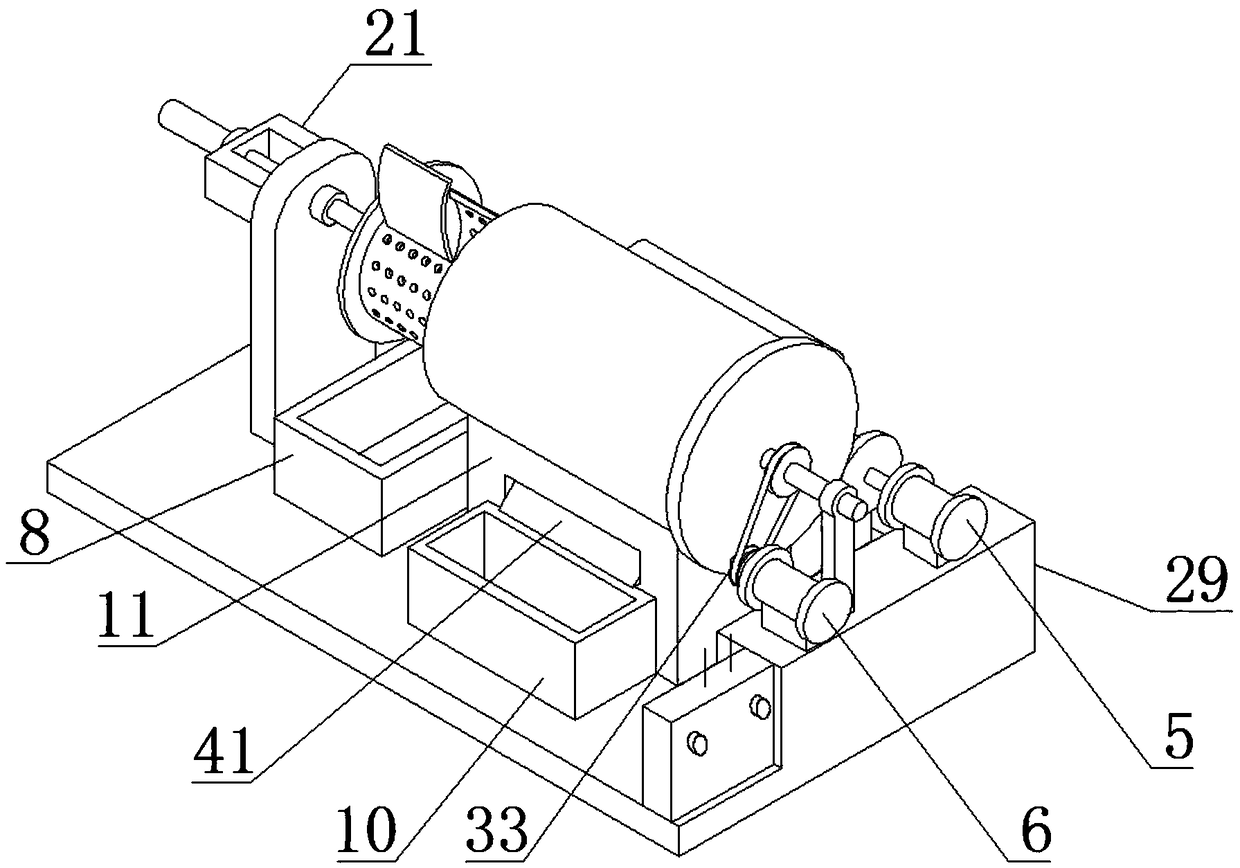

[0034] As a preferred embodiment of the present invention, the passage bracket 11 is provided with a gravel passage 41 , and the dust box 9 is arranged on the horizontal base 1 and corresponds to the gravel passage 41 .

[0035] As a preferred embodiment of the present invention, the bottom of the centrifugal generating sleeve 37 is provided with a filter punching arc plate, and the filter punching arc plate corresponds to the gravel channel 41 .

[0036] As a preferred embodiment of the present invention, the rock trough 8 is arranged on the horizontal base 1 and corresponds to the screen drum 35 .

[0037] As a preferred embodiment of the present invention, an exhaust plate 38 is provided on one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com