Soil remediation system for heating based on heat conduction oil and method of soil remediation system

A heat transfer oil heater and soil remediation technology, applied in the field of soil remediation, can solve problems such as secondary pollution and achieve the effect of reducing the generation of dioxins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings.

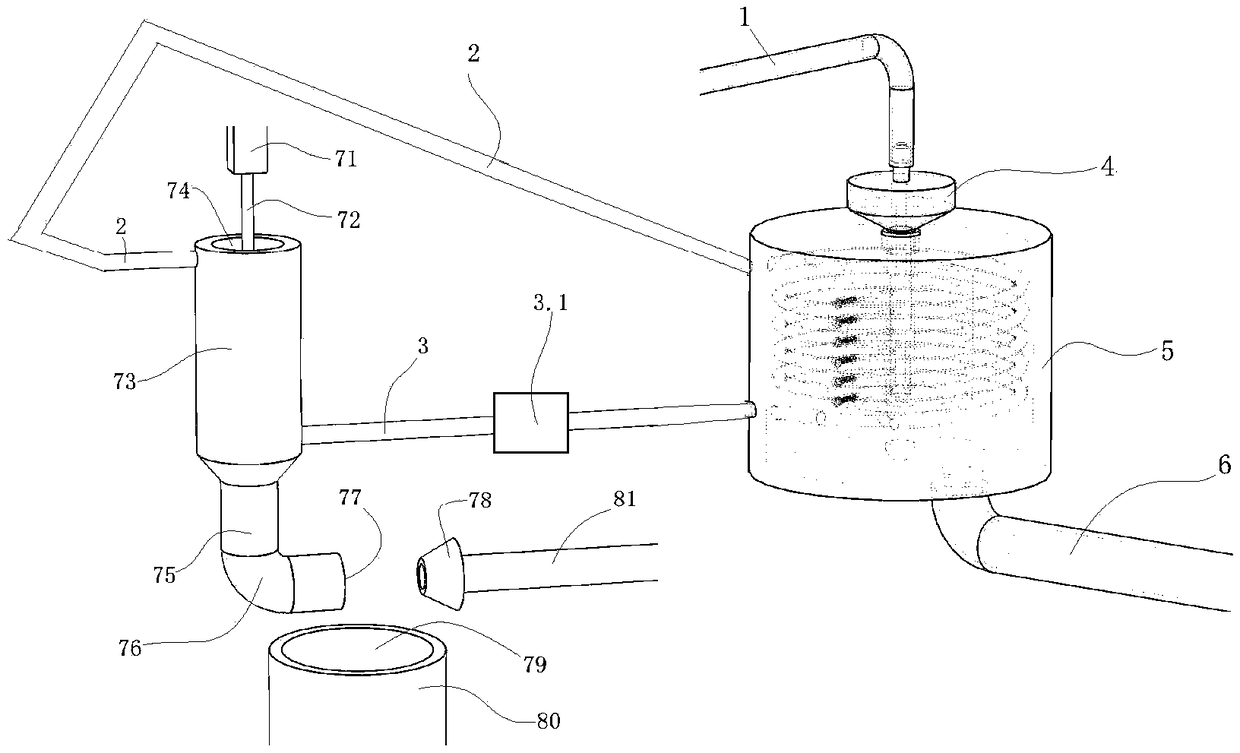

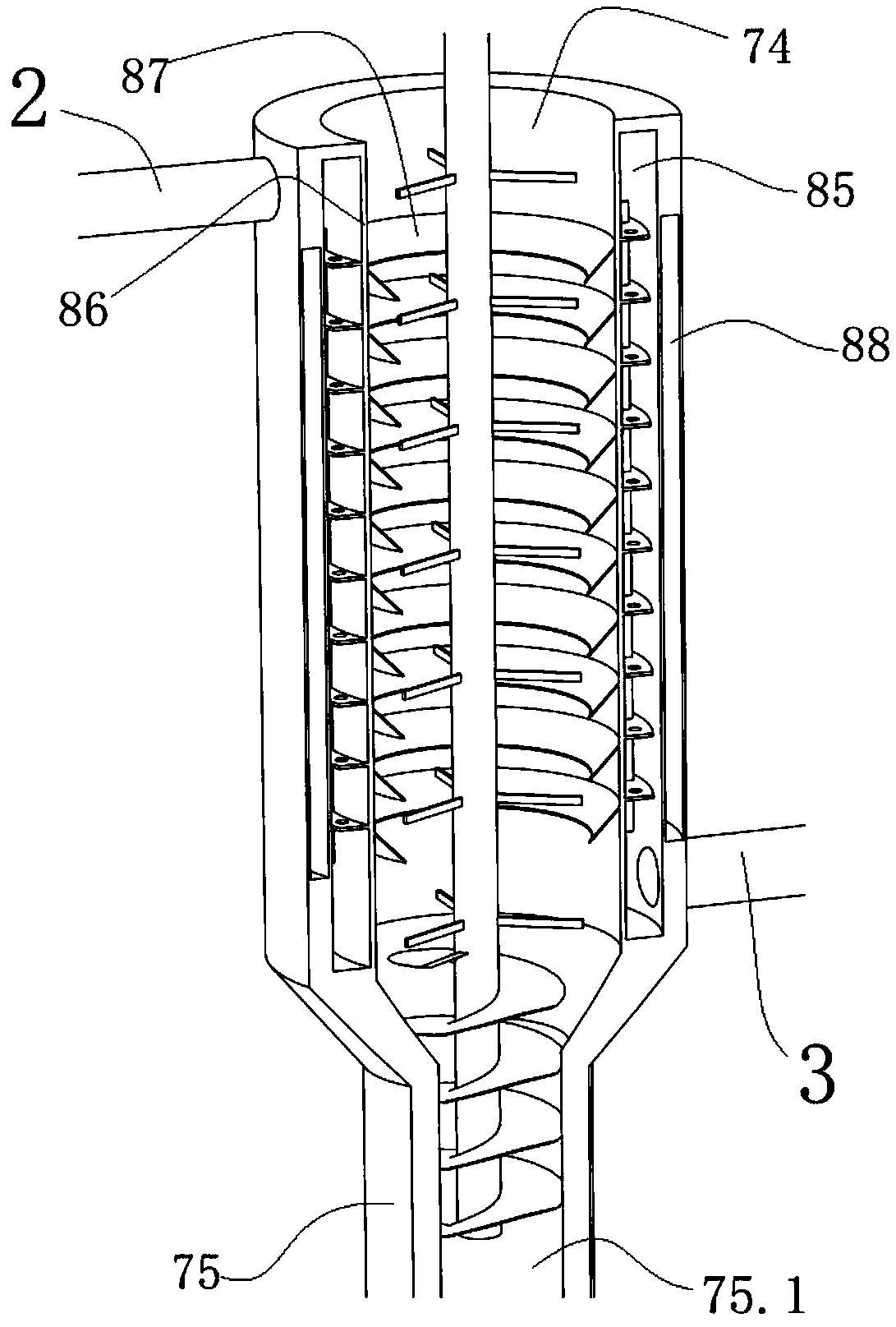

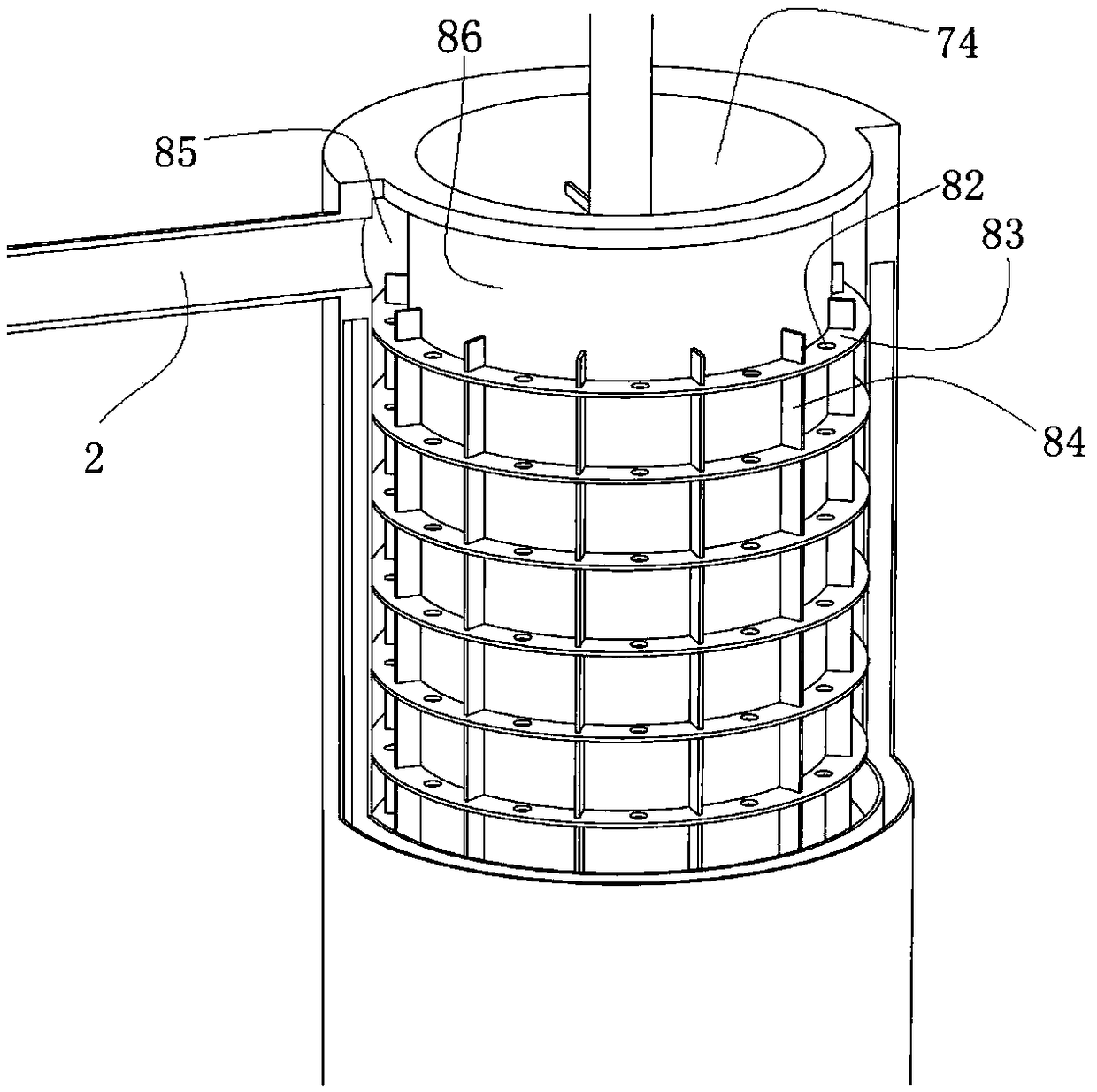

[0038] as attached Figures 1 to 12 The shown soil remediation system based on heat conduction oil heating includes a soil ex-situ thermal desorption tower 73, and a cylindrical soil ex-situ thermal desorption chamber 74 with an open upper end is arranged inside the soil ex-situ thermal desorption tower 73 , the bottom of the soil heterotopic thermal desorption tower 73 is connected to a vertical discharge pipe 75, and the bottom end of the vertical discharge pipe 75 is connected to an elbow 76, and the outlet 77 of the elbow 76 is Orientation level setting;

[0039] Below the discharge port 77 of the curved pipe 76, a material receiving container 80 is arranged, and the soil source discharged from the discharge port 77 of the curved pipe 76 leaks down into the material receiving port 79 of the material receiving container 80; An active air suction pipe 81 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com