Coaxial wire feeding double-plasma arc additive manufacturing device

A plasma arc and additive manufacturing technology, applied in the field of additive manufacturing, can solve the problems of complex robot programming, low forming efficiency, difficult forming of complex structures, etc., so as to avoid path planning, maintain consistent weld formation and performance, and improve the feasibility of sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

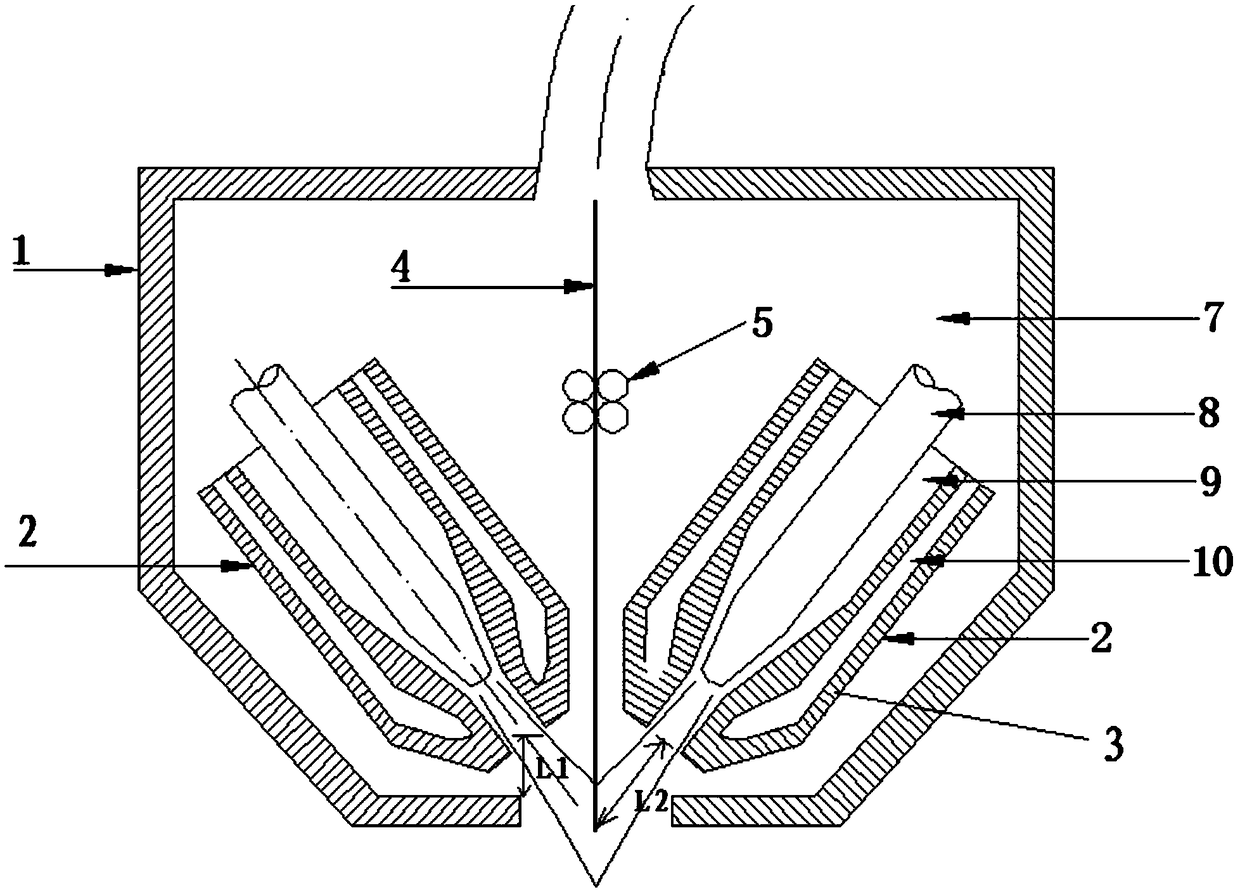

[0021] The invention provides a dual plasma arc additive manufacturing device with coaxial wire feeding, which adopts the design of dual plasma arc welding torches, overcomes the problem of coaxial wire feeding in plasma arc additive, and can effectively avoid path planning caused by side-axis wire feeding , complex structure forming difficulties and other issues; at the same time, the use of coaxial wire feeding can ensure that the weld seam shape and performance remain consistent when welding in any direction during the additive manufacturing process, and the angle of the dual plasma arc torch can be adjusted arbitrarily.

[0022] like figure 1 Shown is a schematic structural diagram of a coaxial wire feeding dual plasma arc additive manufacturing device. It can be seen from the figure that a coaxial wire feeding dual plasma arc additive manuf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Taper | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap