Arc punching equipment for construction

A kind of punching equipment and construction technology, applied in the direction of striking tools, manufacturing tools, light impact tools, etc., can solve the problems of inaccurate punching position, low punching safety guarantee, etc., and achieve the effect of avoiding danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

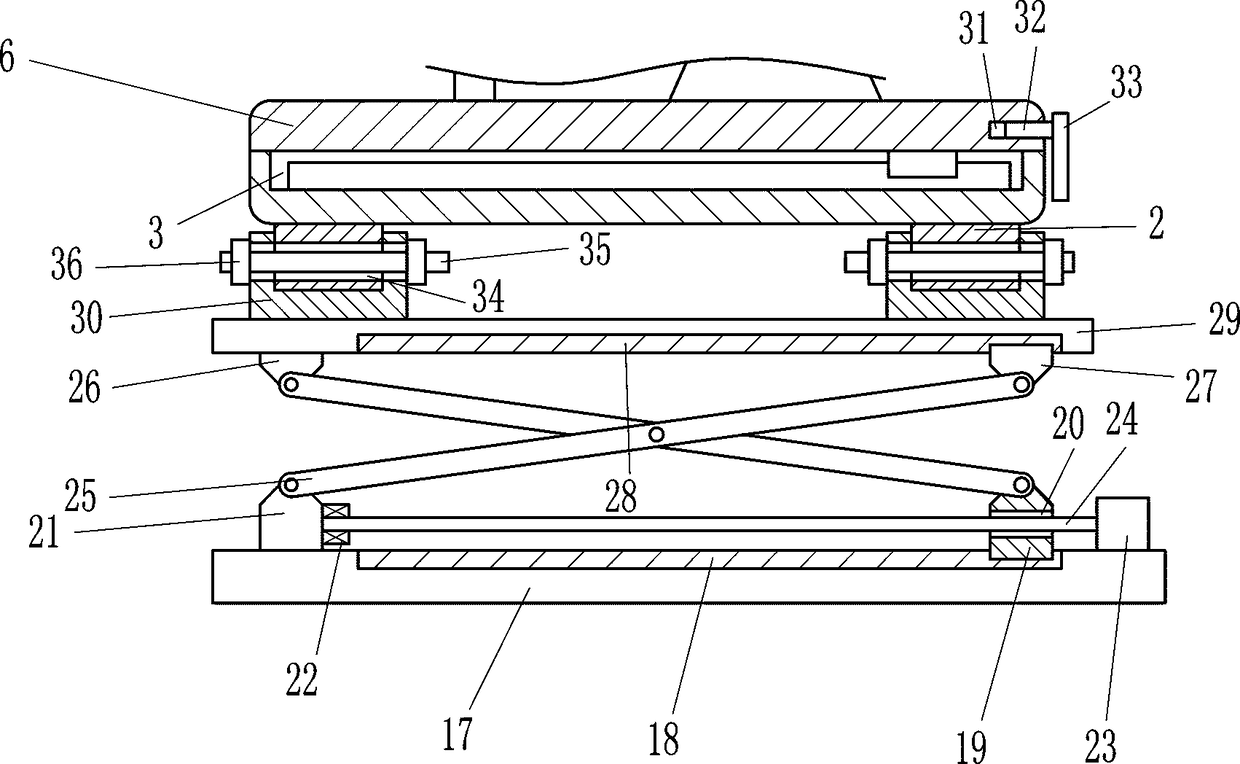

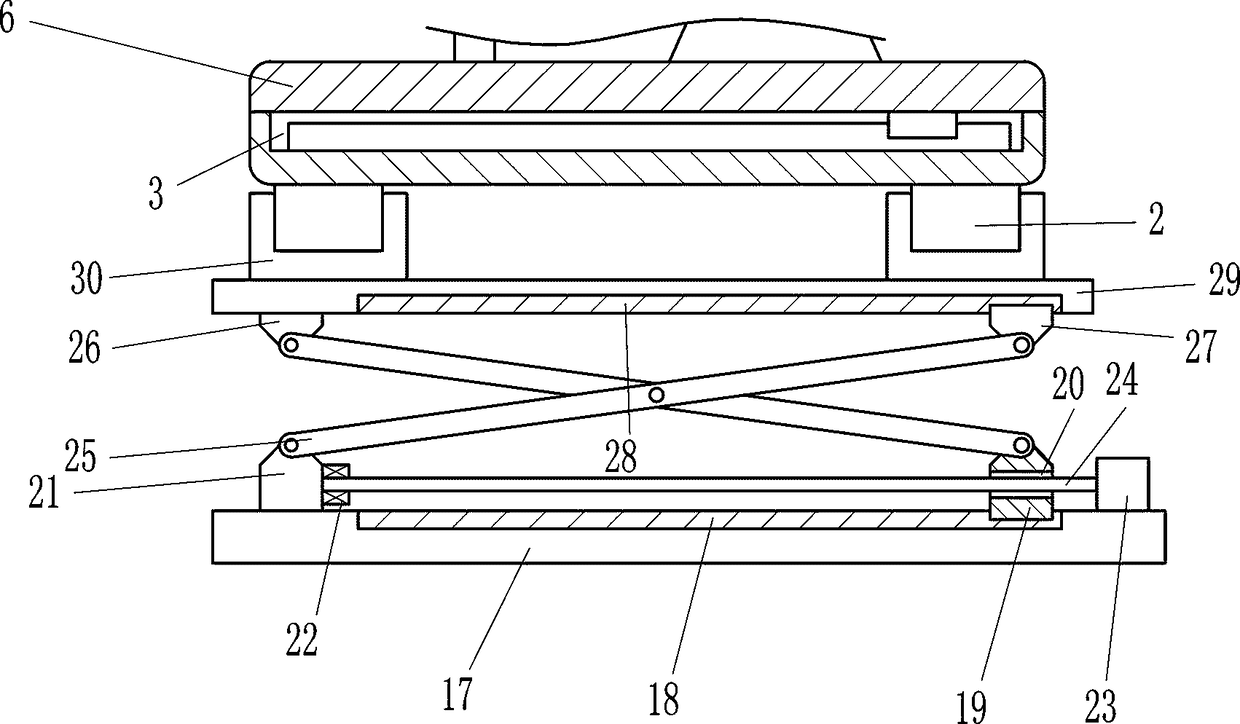

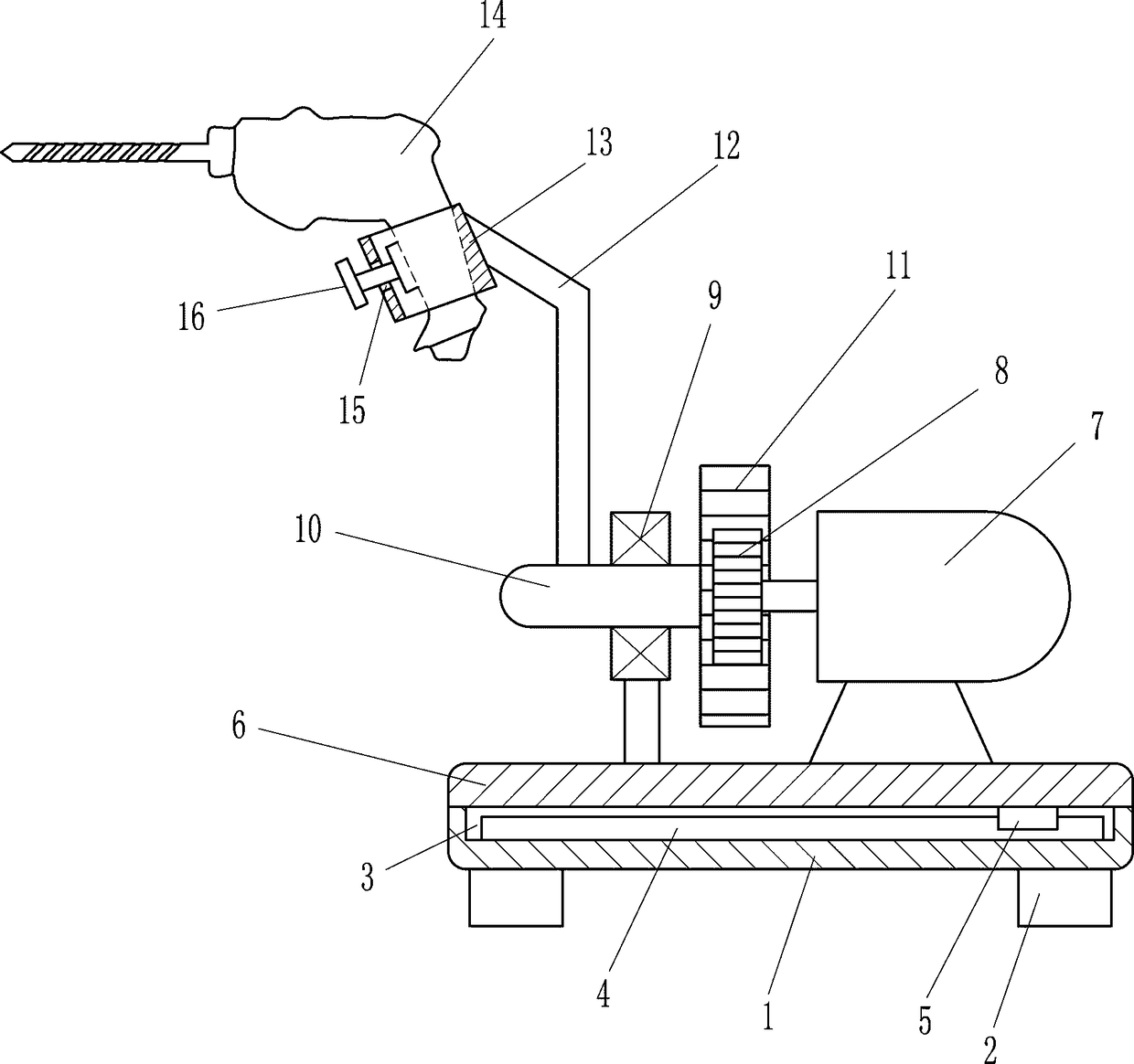

[0021] A kind of arc punching equipment for building construction, such as Figure 1-4 As shown, it includes a bottom plate 1, a cushion block 2, a first slide rail 4, a first slider 5, a moving plate 6, a first motor 7, a pinion 8, a first bearing seat 9, a rotating shaft 10, a large gear 11, Swing rod 12, guide sleeve 13, percussion drill 14 and first bolt 16, spacers 2 are connected to the left and right sides of the bottom of base plate 1, mounting groove 3 is opened in the middle of the top of base plate 1, and the middle part of the lower inner wall of mounting groove 3 is provided with a first Slide rail 4, first slide rail 4 slide type is provided with first slide block 5, and the top of first slide block 5 is connected with moving plate 6, and the right side of the top of moving plate 6 is connected with first motor 7, and the left side of first motor 7 The output shaft on the side is provided with a pinion 8, the left side of the top of the moving plate 6 is connecte...

Embodiment 2

[0023] A kind of arc punching equipment for building construction, such as Figure 1-4 As shown, it includes a bottom plate 1, a cushion block 2, a first slide rail 4, a first slider 5, a moving plate 6, a first motor 7, a pinion 8, a first bearing seat 9, a rotating shaft 10, a large gear 11, Swing rod 12, guide sleeve 13, percussion drill 14 and first bolt 16, spacers 2 are connected to the left and right sides of the bottom of base plate 1, mounting groove 3 is opened in the middle of the top of base plate 1, and the middle part of the lower inner wall of mounting groove 3 is provided with a first Slide rail 4, first slide rail 4 slide type is provided with first slide block 5, and the top of first slide block 5 is connected with moving plate 6, and the right side of the top of moving plate 6 is connected with first motor 7, and the left side of first motor 7 The output shaft on the side is provided with a pinion 8, the left side of the top of the moving plate 6 is connecte...

Embodiment 3

[0026] A kind of arc punching equipment for building construction, such as Figure 1-4 As shown, it includes a bottom plate 1, a cushion block 2, a first slide rail 4, a first slider 5, a moving plate 6, a first motor 7, a pinion 8, a first bearing seat 9, a rotating shaft 10, a large gear 11, Swing rod 12, guide sleeve 13, percussion drill 14 and first bolt 16, spacers 2 are connected to the left and right sides of the bottom of base plate 1, mounting groove 3 is opened in the middle of the top of base plate 1, and the middle part of the lower inner wall of mounting groove 3 is provided with a first Slide rail 4, first slide rail 4 slide type is provided with first slide block 5, and the top of first slide block 5 is connected with moving plate 6, and the right side of the top of moving plate 6 is connected with first motor 7, and the left side of first motor 7 The output shaft on the side is provided with a pinion 8, the left side of the top of the moving plate 6 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com