Sugarcane cutting and peeling machine

A technology of peeling machine and sugar cane, which is applied in the fields of vegetable or fruit peeling, metal processing, food science, etc., can solve the problems of unclean peeling, low peeling efficiency, and inconvenient sugar cane consumption, so as to improve the efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solution of the present invention will be further described in detail below in conjunction with the drawings and specific embodiments, but the invention is not limited to these embodiments.

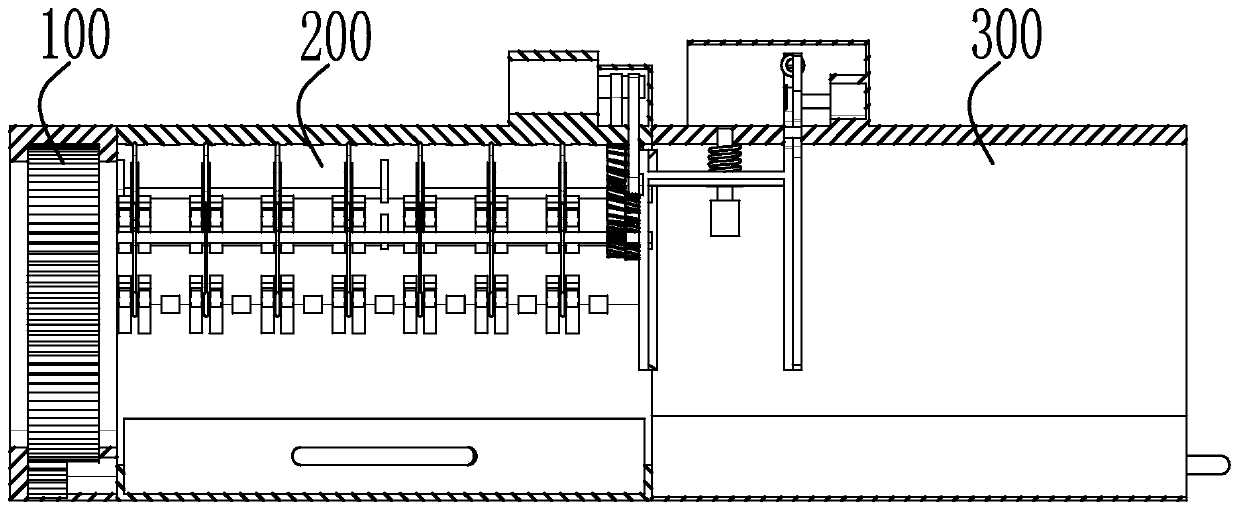

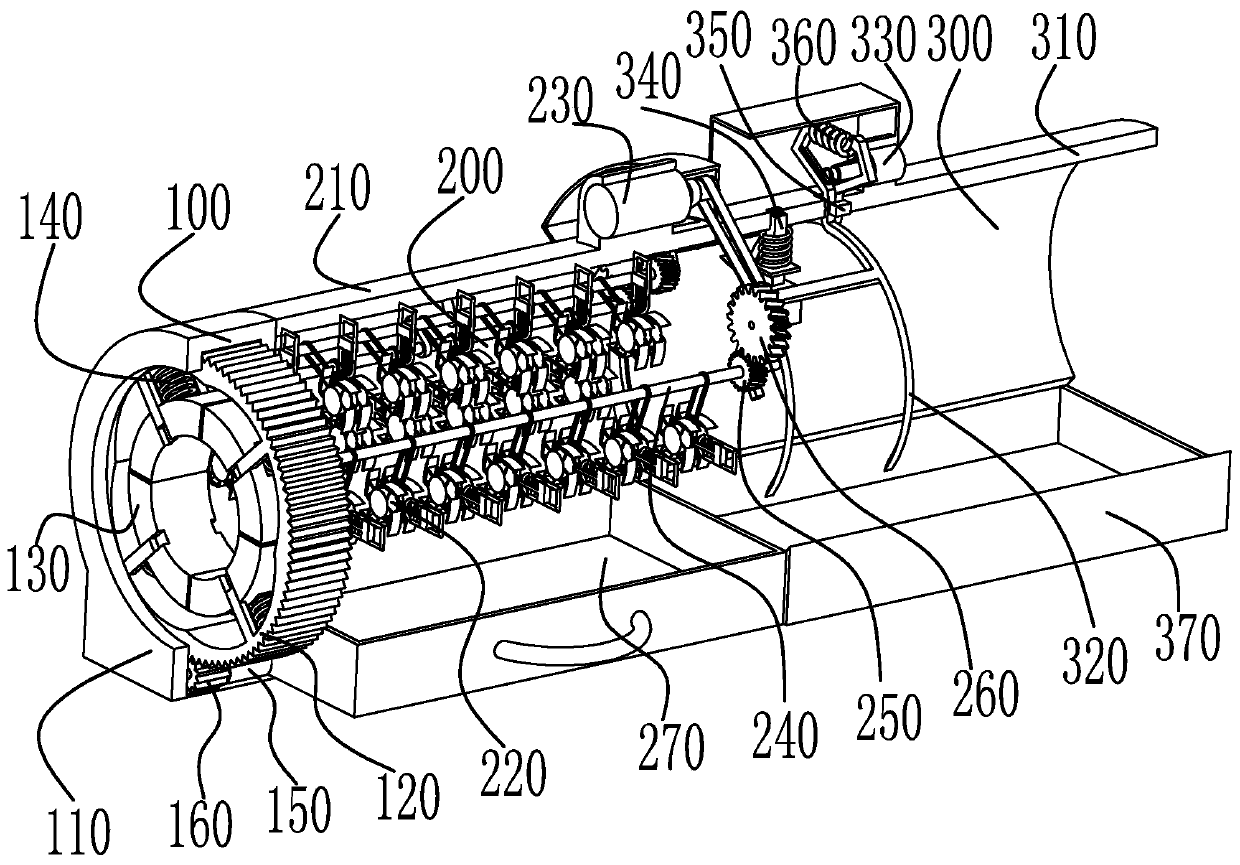

[0035] Such as figure 1 and figure 2 As shown, because the shell is a symmetrical figure, only half of the shell is shown in the figure; the invention provides a sugarcane cutting and peeling machine, including a shell, and the shell is sequentially provided with an adaptive clamping mouth device 100 and a peeling device along the sugarcane feeding direction. 200 and section cutting device 300, the three are fixedly connected. The shell is arranged separately along the feeding direction of the sugarcane, including in turn: the clamping mouth shell 110, the peeling portion shell 210 and the cutting portion shell 310; The back side of the casing 210 is fixedly connected with the section casing 310 .

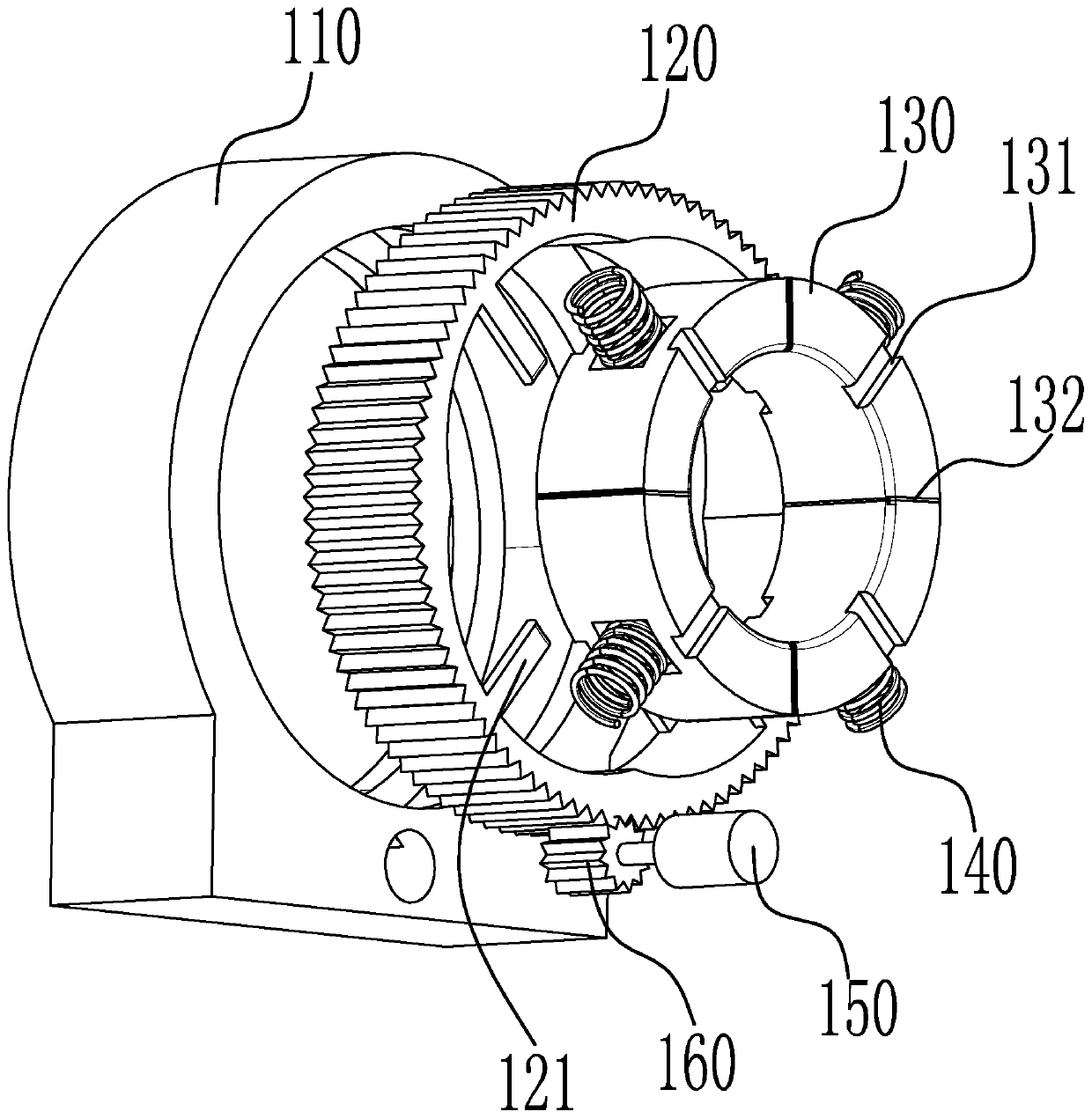

[0036] Preferably, as image 3 , Figure 7 , Figure 8 and F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com