Motor shaft manufacturing process

A manufacturing process and motor shaft technology, applied in the field of metal processing, can solve the problems of the central hole of the motor shaft not being located in the central position, high production cost, no pre-positioning of the motor shaft, etc., to achieve the effect of ensuring accuracy and improving machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

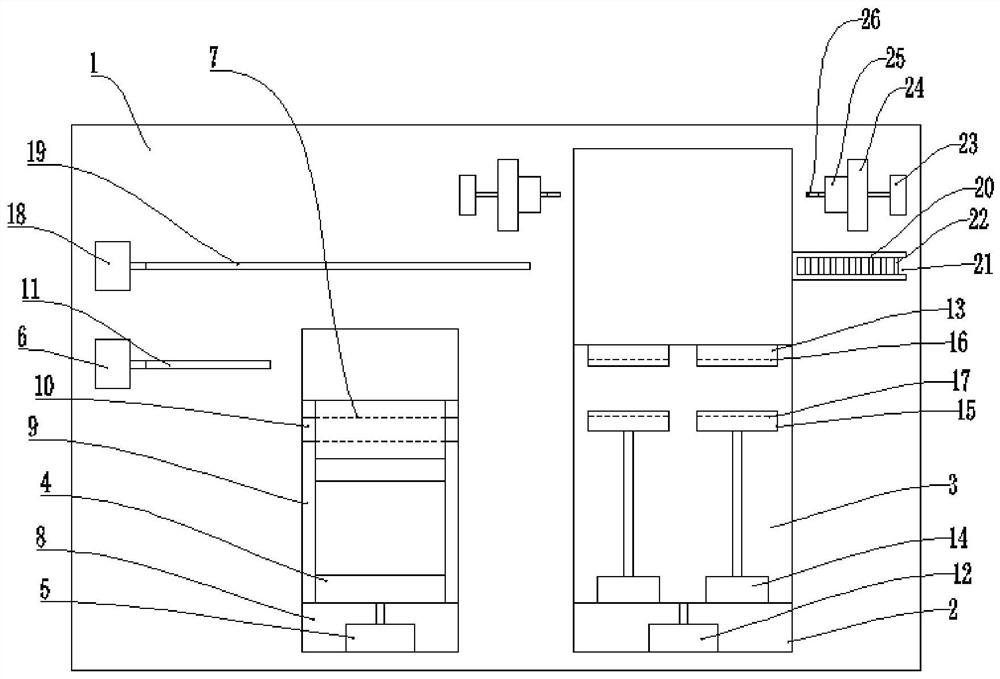

[0036] The manufacturing process of the motor shaft includes the following steps:

[0037] Step 1: Preparation; select a cylindrical iron column with a complete appearance;

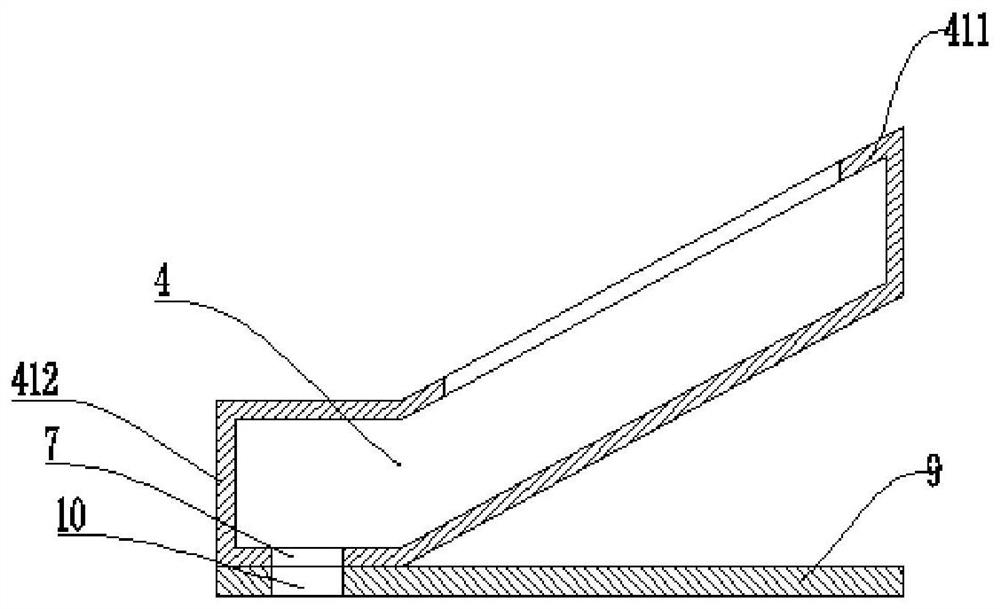

[0038] Step 2: Center hole positioning; center hole positioning device is required, including clamping mechanism and pre-drilling mechanism; the iron column in step 1 is clamped by the clamping mechanism, and the axial direction of the iron column is adjusted by the pre-drilling mechanism. The center position is pre-drilled, so that the axial center position of the iron column has a center slot;

[0039] Step 3: Drilling for the first time; Position the iron column in Step 2, and perform the first drilling process along the path of the central groove;

[0040] Step 4: drilling for the second time; positioning the iron column in step 3, drilling for the second time along the path of the central groove, making the center hole of the iron column, and the center hole runs through the iron column;

[0041] S...

Embodiment 2

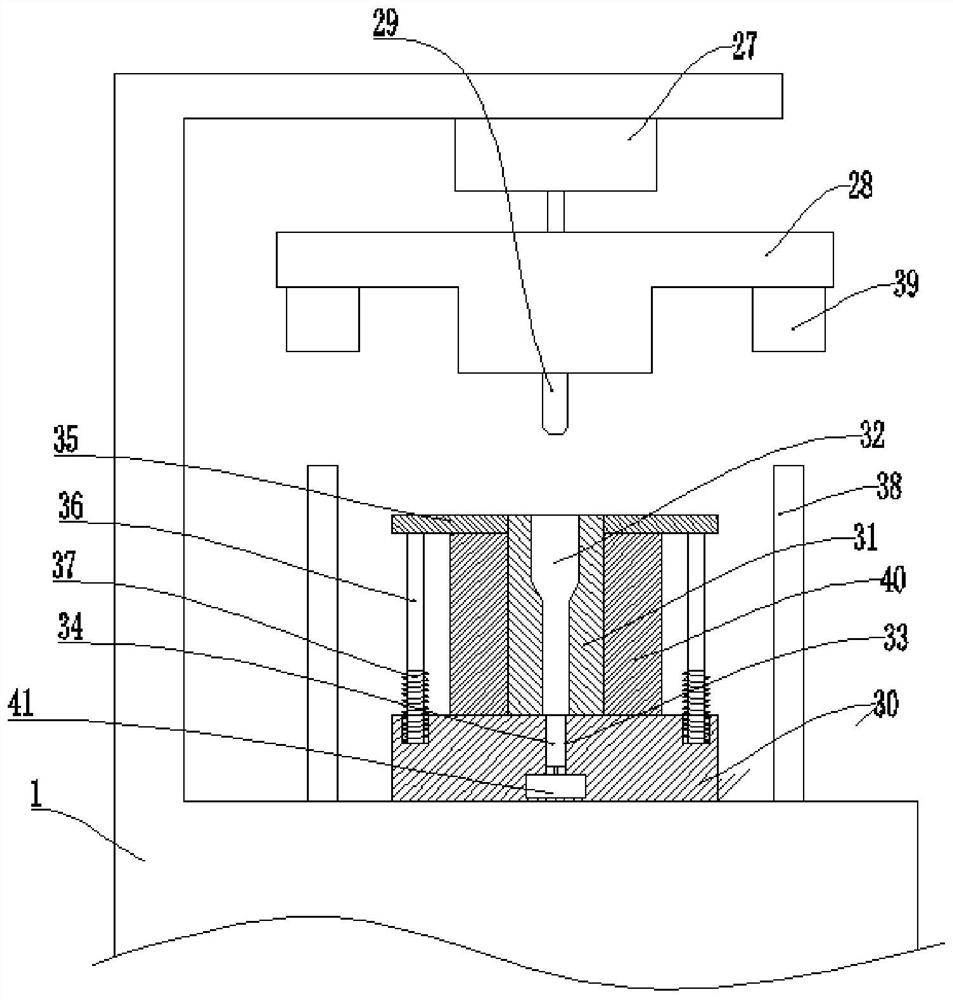

[0064] Basic as attached Figure 4 As shown: the structure and implementation of Embodiment 2 are basically the same as Embodiment 1, the difference is that the diameter reducing device also includes a guide mechanism, and the guide mechanism includes a guide post 42 fixed on the bottom of the stop table 39 and a The guide slot 43 on the top of the positioning post 38 is located on the movement track of the guide post 42 , and the guide post 42 can slide in the guide slot 43 .

[0065] The diameter reducing device also includes a damping mechanism, which includes a damping plate 44 and a spring 45, the damping plate 44 is slidably connected in the guide, and the two ends of the spring 45 are fixedly connected with the damping plate 44 and the guide groove 43 respectively.

[0066] The support column 40 is provided with six vertical grooves 46 in the circumferential direction, and the vertical grooves 46 are arc-shaped;

[0067] The specific implementation process is as follow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com