Self-adaptive positioning device and system for workpiece hardness detection, and methods

A positioning device and self-adaptive technology, applied in the field of mechanical parts, can solve problems such as low precision and low test efficiency, and achieve the effects of ensuring test accuracy, saving test time, and flexible disassembly and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

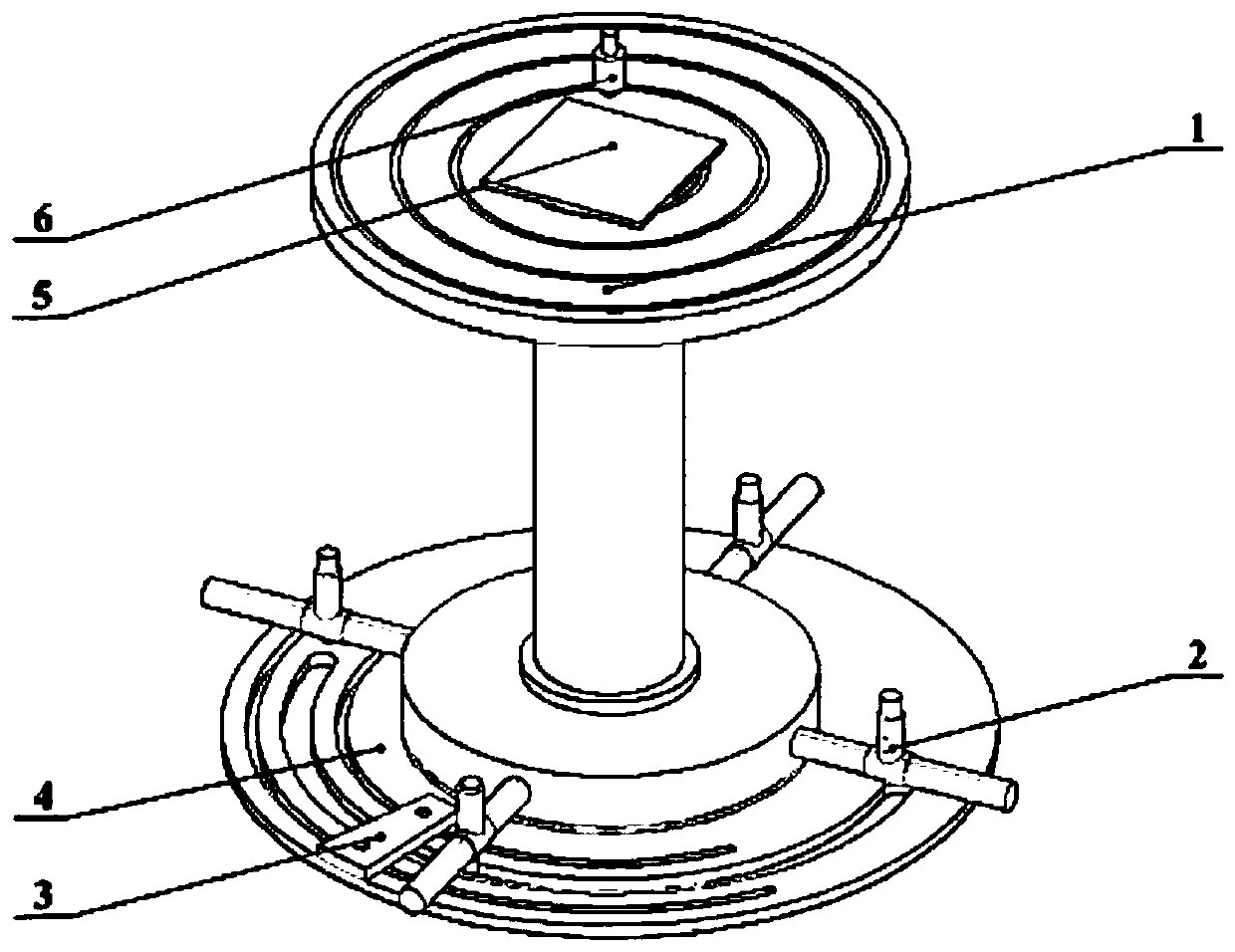

[0032] as attached figure 1 As shown, an adaptive positioning device for hardness testing of workpieces can locate the handwheel position of the starting point of the pressure test of the first workpiece when the hardness testing of a large number of workpieces is performed, and then when the hardness testing of the same batch of workpieces is performed subsequently, Quickly find out the position of the hand wheel to carry out the test work, and solve the problems of low test efficiency and low precision in the existing method of manually adjusting the starting point of the pressure test.

[0033] An adaptive positioning device for workpiece hardness detection, comprising: an adjustment wheel, a limiter and a positioning member; the adjustment wheel is connected to at least one limiter, and the positioning member is fixedly arranged in the direction of movement of the adjustment wheel; The limiting member includes an elastic body with a pre-tightening force, and the elastic bo...

Embodiment approach

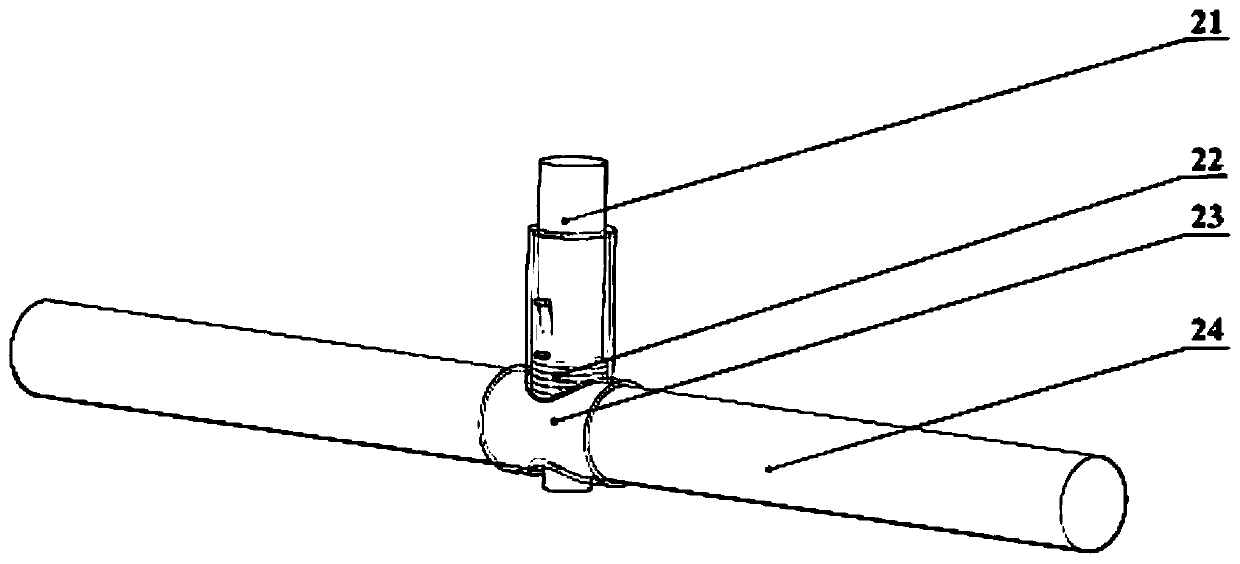

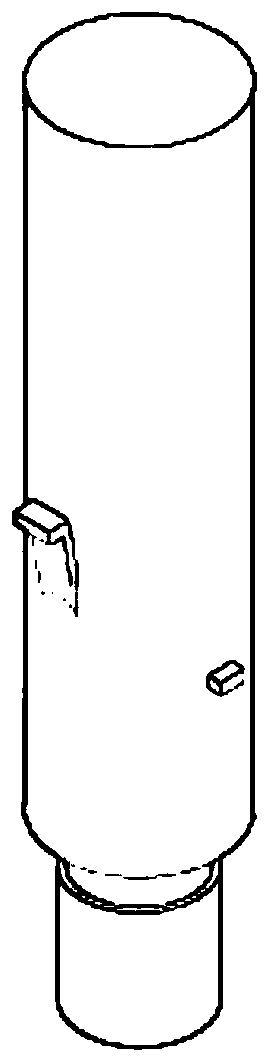

[0037] The adjusting wheel is a hand wheel, and the hand wheel includes a center wheel connected with the transmission mechanism and several rods connected with the center wheel. The several rods are arranged radially in equal parts around the center wheel, and the second hollow tube and The rod of the handwheel is socketed, and the cross-section of the rod is circular, square or polygonal; the cross-section of the second hollow cylinder is the same as that of the rod. The transmission mechanism includes but not limited to a screw transmission mechanism, a rack and pinion mechanism, a slider linkage mechanism and a cam mechanism. As a preferred embodiment, the transmission mechanism is a screw transmission mechanism.

[0038] The locating member includes a chassis and a locating block, the chassis has a locating groove, and the locating groove is a groove structure arranged along the direction of the arc; For installing the positioning block, the positioning block is slidably ...

Embodiment 2

[0042] An adaptive positioning device for hardness testing of workpieces, mainly including push rods, cages, springs, handwheels, positioning blocks and bases. When testing the hardness of large quantities of workpieces, the positioning blocks on the bases can The position of the handwheel, and then when the same batch of workpieces are tested later, the position of the handwheel can be quickly found by fixing the position of the push rod and the positioning block, that is, the pressurized test point of the workpiece, thus saving the time of adjusting the handwheel and greatly Improved testing efficiency.

[0043] A circular sliding groove is provided on the 1 / 4 area of the base, and the circular sliding groove is used to place and limit the positioning block, and the position of the positioning block can be fixed by locking the sliding groove.

[0044] The spring is placed in the middle of the push rod and the hand wheel, and is used for moving and positioning up and down i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com